Method for removing fluorine in wet-method zinc smelting process

A technology of hydrometallurgy and zinc removal, applied in the field of chemical industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

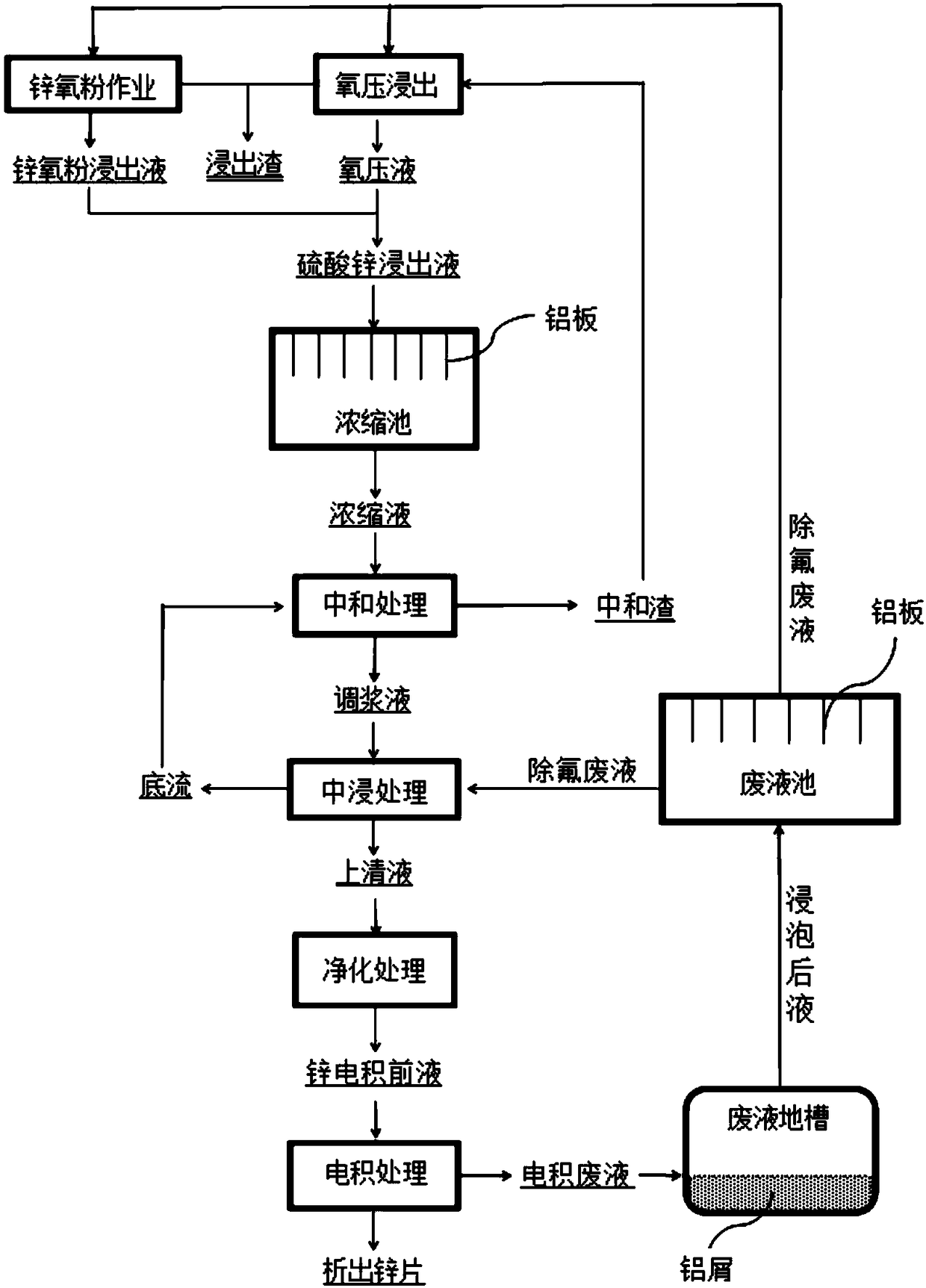

Method used

Image

Examples

Embodiment 1

[0036] Defluoridation Treatment of Acidic Zinc Sulfate Leaching Solution Using Aluminum Plate

[0037] The acidic zinc sulfate leaching solution is passed through the concentration pool for defluoridation treatment, and the acidic zinc sulfate leaching solution is contacted with the aluminum plate during the treatment process to form aluminum fluoride precipitation. Among them, the chloride ion content in the acidic zinc sulfate leaching solution is 1051.5 mg / L, the fluoride ion content is 126.3 mg / L, and the sulfuric acid content is 20 g / L. The ratio of the surface area of the aluminum plate immersed in the acidic zinc sulfate leaching solution to the volume of the zinc sulfate leaching solution is 10cm 2 / L, the contact time between the acidic zinc sulfate leaching solution and the aluminum plate is 17.5h, the reaction temperature is 65°C, the fluoride ion concentration in the concentrated solution is 108mg / L, and the defluorination rate of the acidic zinc sulfate leaching...

Embodiment 2

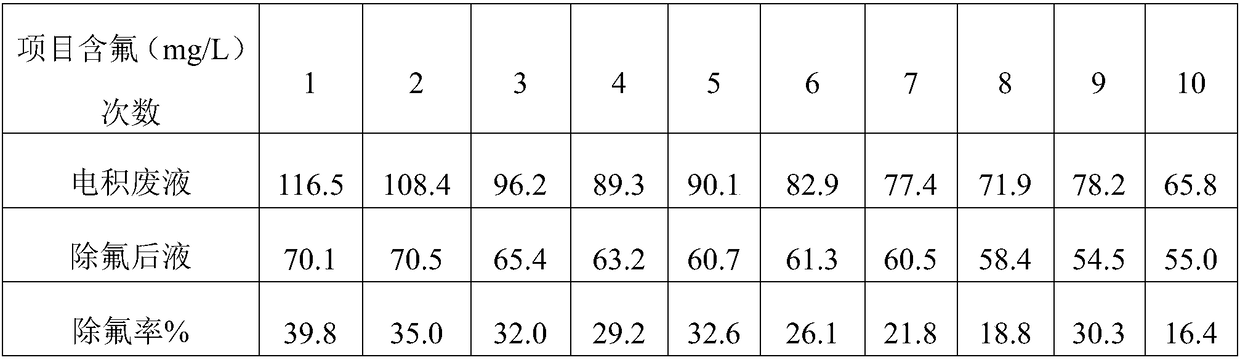

[0039] Aluminum shavings and aluminum plates are used to defluorinate zinc electrowinning waste liquid.

[0040] Pass the zinc electrowinning waste liquid generated during the zinc electrowinning process into the waste liquid storage tank, add aluminum scraps to the zinc electrowinning waste liquid for soaking, and at the same time hang an aluminum plate on the upper part of the waste liquid storage tank and immerse in the zinc electrowinning waste liquid In contact with the waste liquid, it reacts to form aluminum fluoride precipitation, and finally obtains the waste liquid for defluorination; among them, the Cl in the waste liquid - The content is 1200-1600mg / L, the content of sulfuric acid is 150-180g / L, the particle size of aluminum chips is 1cm, the volume ratio of aluminum chips to electrowinning waste liquid is 0.5, the soaking time is 5h, and the soaking temperature is 35°C; The ratio of the surface area of the aluminum plate immersed in the soaking liquid to the vol...

Embodiment 3

[0045] The aluminum plate is used to defluoride the acidic zinc sulfate solution.

[0046] Take acidic zinc sulfate leaching solution containing 224.1mg / L of fluorine, 926.45mg / L of chlorine and 70.58g / L of zinc for defluorination treatment. Take 5L of zinc sulfate leaching solution and raise the temperature to 40°C, put a certain amount of waste aluminum plate into the solution, the volume ratio of the surface area of waste aluminum plate to zinc sulfate leaching solution is 50cm 2 / L, put it statically for 24 hours, so that the fluoride ions can fully react with the aluminum plate in the presence of chloride ions to form a precipitate; filter through a vacuum filter, the volume of the filtrate is 4.995L, and the fluorine content is 80.67mg / L. Zinc 70.49g / L, fluorine removal rate 64.04%, zinc loss rate 0.23%.

[0047] The experimental results show that the defluoridation treatment of zinc sulfate leaching solution by using waste aluminum plate not only does not need to add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com