Rare-earth electrolysis fume cleaning system and method

A flue gas purification system and rare earth technology, applied in the direction of electrolysis components, electrolysis process, etc., can solve the problems of high energy consumption, large pollution of rare earth electrolysis flue gas, etc., and achieve high heat utilization rate, good fluoride removal effect, and high automation level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

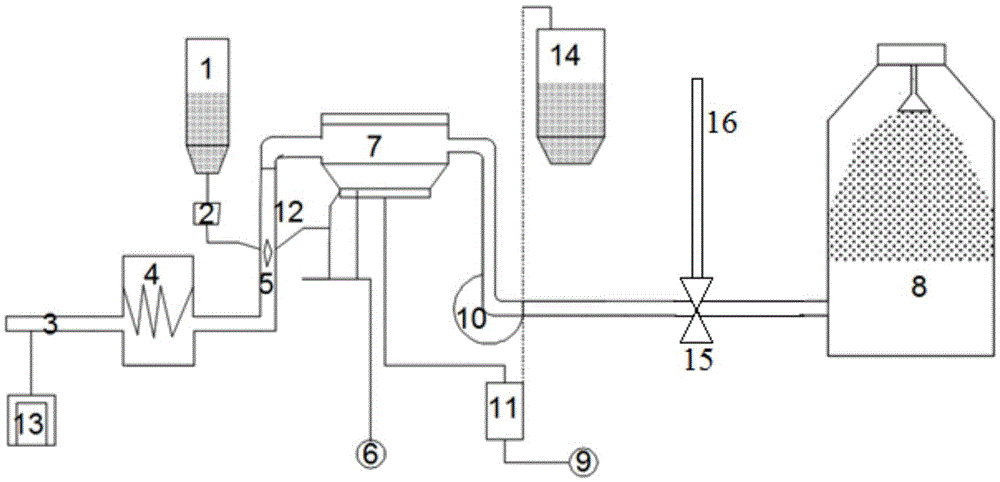

[0042] The flue gas from the rare earth electrolyzer is collected into the exhaust pipe and then enters the partition cooler to reduce the temperature of the flue gas from 100°C to 40°C. The cooled flue gas enters the Venturi reactor and undergoes an adsorption reaction with the fresh praseodymia from the adsorbent silo and the fluorine-loaded praseodymia from the bag filter. The adsorbed fluorine-loaded praseodymium oxide enters the bag filter together with dust and other solids and flue gas for gas-solid separation. The fluorine-loaded adsorbent is collected by the bag filter, and part of it is sent to the Venturi reactor for circulation through the pneumatic chute. Adsorption, a part is sent to the air lifter through the air chute to be lifted to the fluorine-loaded adsorbent silo, and the fluorine-loaded praseodymium oxide in the fluorine-loaded adsorbent silo is directly returned to the rare earth electrolytic cell for production. The dedusted flue gas is sent to the bott...

Embodiment 2

[0044] The flue gas from the rare earth electrolyzer is collected in the exhaust pipe and enters the heat exchanger to reduce the temperature of the flue gas from 200°C to 30°C. The flue gas after cooling enters the fixed-bed reactor, and the alumina in the alumina silo is added to the reactor to absorb the flue gas through a quantitative feeding device and a pneumatic chute, and a certain amount of fluorine-loaded alumina is added as required. After the reaction, the fluorine-loaded alumina enters the electrostatic precipitator together with dust and other solids and flue gas for gas-solid separation. The fluorine-loaded alumina is collected by the electrostatic precipitator, part of it is used as a circulating adsorbent, and part of it overflows from the fluidized bed at the lower part of the dust collector to the pneumatic chute, and is sent to the air elevator through the pneumatic chute to be lifted to the fluorine-loaded alumina silo , the fluorine-containing alumina is ...

Embodiment 3

[0046] The flue gas from the rare earth electrolytic cell is collected into the smoke exhaust pipe, and the length of the smoke exhaust pipe is set to be longer, so that the temperature of the flue gas is reduced from 170°C to 90°C. The cooled flue gas enters the fluidized bed, and the terbium oxide in the terbium oxide silo is added to the reactor to absorb the flue gas through a quantitative feeding device and a pneumatic chute, and a certain amount of fluorine-carrying terbium oxide is added as required. After the reaction, the fluorine-loaded terbium oxide enters the electrostatic precipitator together with dust and other solids and flue gas for gas-solid separation. Fluorine-carrying terbium oxide is collected by the cyclone dust collector, part of which is used as a circulating adsorbent, and part overflows from the lower part of the dust collector to the pneumatic chute, and is sent to the air elevator through the pneumatic chute to be lifted to the fluorine-carrying ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com