Diuranate product fluorine reduction technique

A technology of diuranate and products, applied in the fields of uranium compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of excessive fluorine content, increased treatment cost, impact of purification treatment, etc. Good effect, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

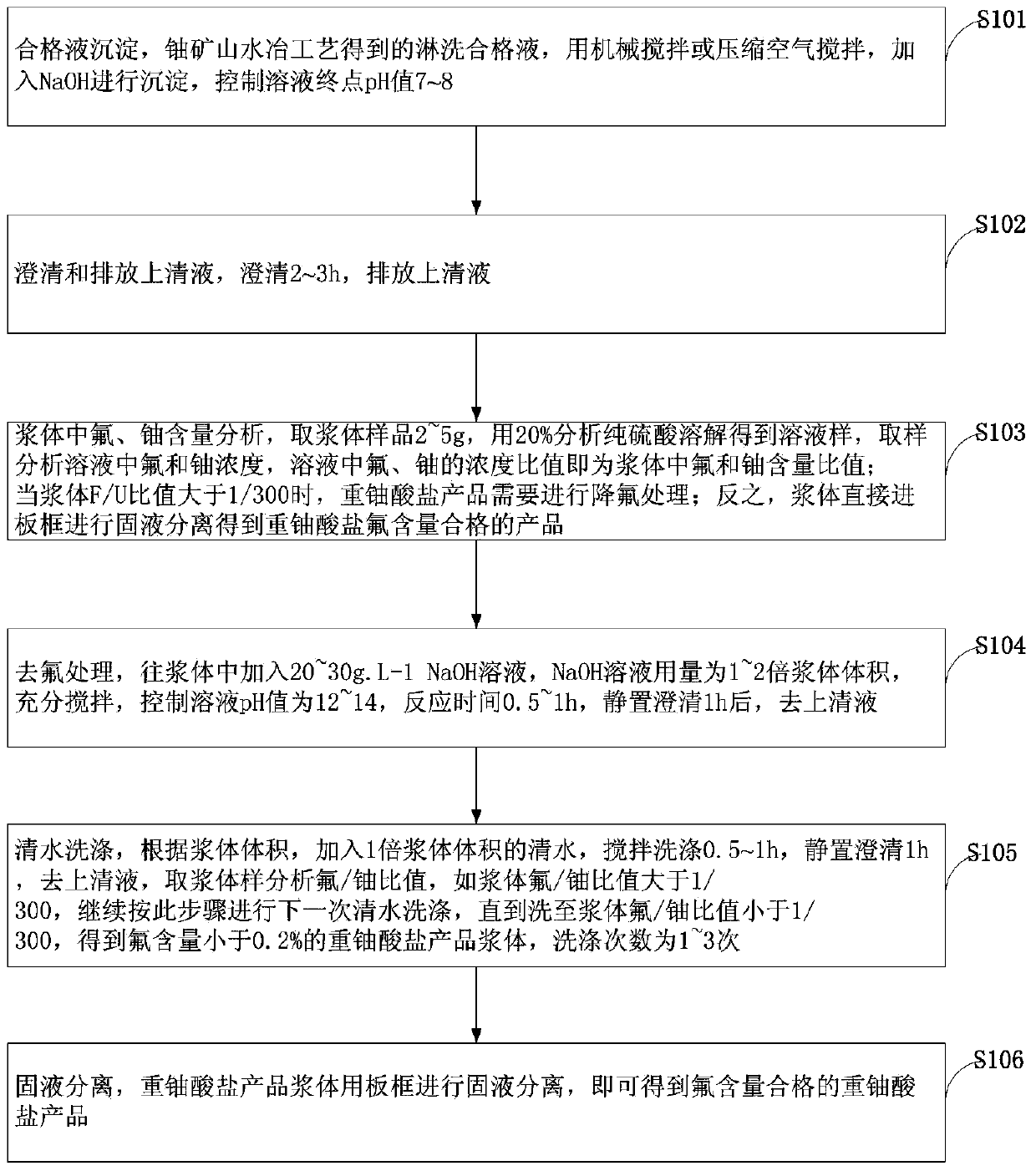

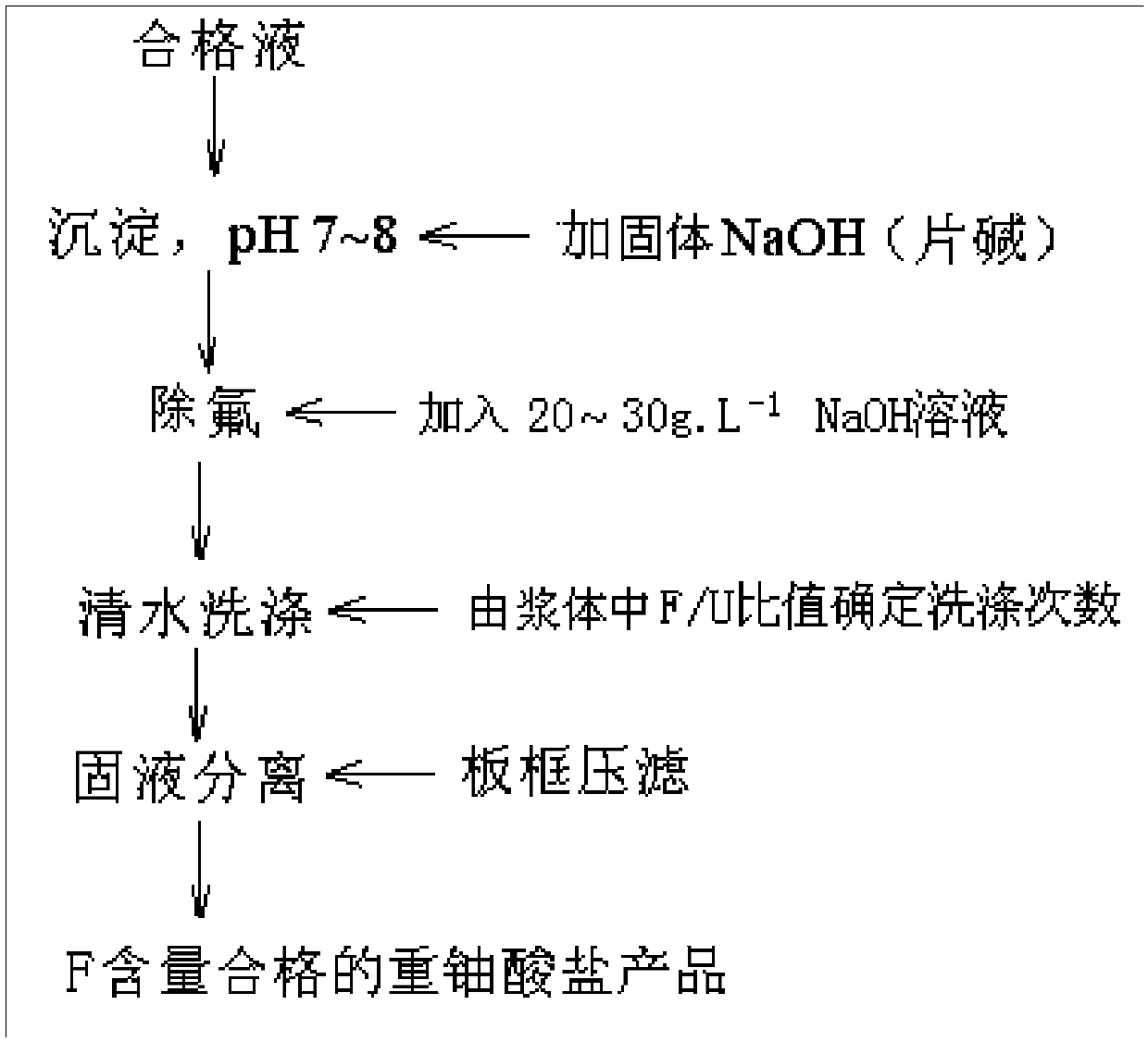

[0031] (1) Precipitation of qualified liquid, leaching qualified liquid obtained by uranium mine water smelting process, stirred by mechanical or compressed air, adding caustic soda (NaOH) for precipitation, and controlling the final pH value of the solution to 7-8 (generally about 7.5) ;

[0032] (2) Clarify and drain the supernatant. Clarify for about 2 to 3 hours, and discharge the supernatant;

[0033] (3) Analysis of F and U content in the slurry. Take 2-5g of the slurry sample, dissolve it with 20% analytically pure sulfuric acid to obtain a solution sample, take a sample and analyze the concentration of F and U in the solution, and the concentration ratio of F and U in the solution is the fluorine (F) and uranium (U) in the slurry Content ratio, according to the requirements of national first-class diuranate products, the percentage content of fluorine (F) is less than 0.2%, and the percentage content of uranium (U) is greater than 60%. When the F / U ratio of the slurr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com