Zirconium loaded biological composite adsorbent used for removing fluorine in water, and regeneration method and applications thereof

A composite adsorption and biological technology, applied in water pollutants, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of hindering adsorption mass transfer efficiency, lack of nano-size effect, low working adsorption capacity, etc. Work efficiency and application space, realize the effect of purification and safety control, and easy control of production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

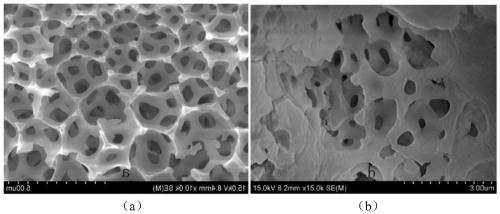

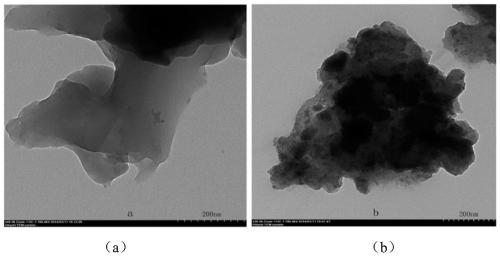

[0031] Example 1: Preparation of zirconium-loaded biocomposite adsorbent 1

[0032] 4g zirconium oxychloride (ZrOCl 2 ) was dissolved in 100 mL of water, and after being stirred by a stirrer, 20% sodium hydroxide was added, and the pH was adjusted to 6.5 with dilute hydrochloric acid. Heated in a water bath at 70°C, suction-filtered the white precipitate, washed the precipitate with distilled water until neutral, dried at 110°C for 1 hour, cooled and pulverized. Weigh 4 g of Artemia egg shells, wash them with deionized water until neutral, and dry them. The activated zirconia and Artemia egg shells after the above treatment were placed in 100 mL of absolute ethanol solution, and ultrasonicated at room temperature for 4 hours at a frequency of 60 Hz. Afterwards, magnetic stirring was performed for 4 hours to carry out the in-situ precipitation reaction, and zirconium hydroxide was generated in the pores of Artemia eggshells, and all the eggshells sank to the bottom of the con...

Embodiment 2

[0033] Embodiment 2: Preparation 2 of loaded zirconium biocomposite adsorbent

[0034] 15g zirconium oxychloride (ZrOCl 2 ) was dissolved in 150 mL of water, and after being stirred by a stirrer, 20% sodium hydroxide was added, and the pH was adjusted to 7.0 with dilute hydrochloric acid. Then heat in a water bath at 50°C, suction filter the white precipitate, wash the precipitate with distilled water until neutral, then dry at 100°C for 2 hours, cool and pulverize. Weigh 5 g of Artemia egg shells, wash them with deionized water until neutral, and dry them. The activated zirconia and Artemia egg shells after the above treatment were placed in 150 mL of absolute ethanol solution, and ultrasonicated at room temperature for 6 hours at a frequency of 100 Hz. Afterwards, magnetic stirring was performed for 5 hours to carry out in-situ precipitation reaction, and zirconium hydroxide was generated in the pores of Artemia eggshells, and all the eggshells sank to the bottom of the co...

Embodiment 3

[0035] Example 3: Removal of fluoride ions in water and regeneration 1 by using zirconium-loaded biocomposite adsorbent

[0036] Put 6g of the above-mentioned zirconium-loaded biocomposite adsorbent in a glass adsorption column (ф12×220mm), and fluoride-contaminated water (F - =1.5mg / L and SO 4 2- =100mg / L, Cl - =100mg / L, NO 3 - =100mg / L, pH=6) flow through the adsorption column equipped with biocomposite material from top to bottom, the temperature is controlled at 15°C, the flow rate is 10BV / h, and the concentration of fluorine ion in the effluent after adsorbent treatment is 1.0mg / L Below, the processing capacity is as high as 1000BV. When there is obvious leakage of adsorption (F - >1.0mg / L), stop the adsorption. Regenerate with 50mL NaOH and NaCl mixed solution (NaOH mass concentration is 3%; NaCl mass concentration is 2%), control regeneration flow rate to 1BV / h, temperature 25°C, complete regeneration after 4BV desorption reaction (desorption rate is as high as 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com