Method for removing fluorine from zinc sulfate solution with active alumina

A technology of zinc sulfate solution and activated alumina, applied in chemical instruments and methods, other chemical processes, improvement of process efficiency, etc., can solve problems such as lack of solutions, excessive fluoride ions, etc., and achieve easy technical operation, high recovery rate and The effect of high quality and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

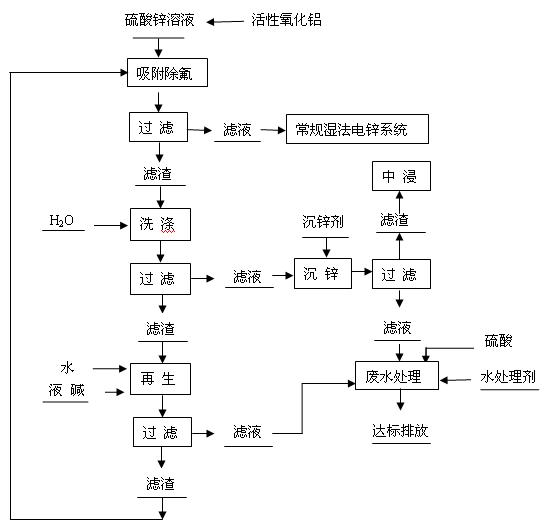

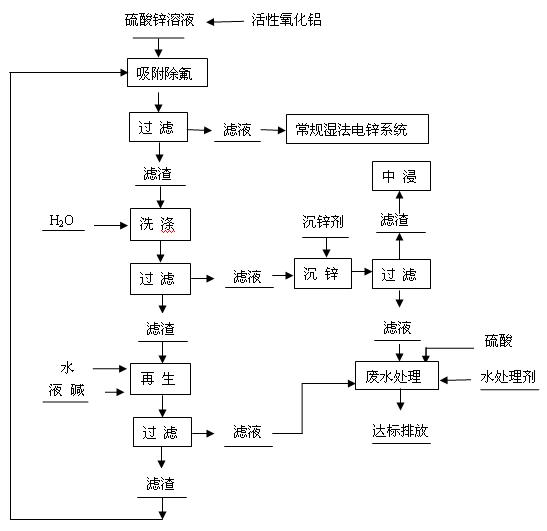

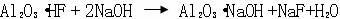

[0029] A method for removing fluorine in zinc sulfate solution with activated alumina, comprising the following sequential steps, A. Adsorption and chlorine removal: 60m 3 High-fluorine zinc sulfate solution, the temperature of the zinc sulfate solution is 50°C, the pH value is 5.2, and the fluorine content is 0.432g / L. Add a dry weight of 7780kg of activated alumina to the zinc sulfate solution. Alumina, the mass ratio of activated alumina to fluorine in the zinc sulfate solution is 300:1, absorb for 120 minutes, and remove most of the fluorine in the zinc sulfate solution through the adsorption of activated alumina, so that the fluorine content in the solution is 0.093g / L, filtration, the filtrate with low fluorine content enters the conventional wet zinc smelting system, and the filter residue enters the washing tank; B. Washing process: the filter residue of step A enters the washing tank, and about 40m 3 water, so that the liquid-solid mass ratio is 5:1, wash, and at a t...

Embodiment 2

[0032] A method for removing fluorine in zinc sulfate solution with activated alumina, comprising the following sequential steps, A. Adsorption and chlorine removal: 60m 3High-fluorine zinc sulfate solution, the temperature of the zinc sulfate solution is 45°C, the pH value is 5.4, and the fluorine content is 0.432g / L. Add a dry weight of 10400kg of activated alumina to the zinc sulfate solution. Alumina, the mass ratio of activated alumina to fluorine in the zinc sulfate solution is 400:1, absorb for 105 minutes, and remove most of the fluorine in the zinc sulfate solution through the adsorption of activated alumina, so that the fluorine content in the solution is 0.075g / L, filtration, the filtrate with low fluorine content enters the conventional wet zinc smelting system, and the filter residue enters the washing tank; B. Washing process: the filter residue of step A enters the washing tank, and about 40m 3 water, so that the liquid-solid mass ratio is 4:1, wash, and at a t...

Embodiment 3

[0035] A method for removing fluorine in zinc sulfate solution with activated alumina, comprising the following sequential steps, A. Adsorption and chlorine removal: 60m 3 High-fluorine zinc sulfate solution, the temperature of the zinc sulfate solution is 55°C, the pH value is 5.0, and the fluorine content is 0.432g / L. Add 13000kg dry weight activated alumina to the zinc sulfate solution. Alumina, the mass ratio of activated alumina to fluorine in the zinc sulfate solution is 500:1, absorb for 90 minutes, and remove most of the fluorine in the zinc sulfate solution through the adsorption of activated alumina, so that the fluorine content in the solution is 0.052g / L, filtration, the filtrate with low fluorine content enters the conventional wet zinc smelting system, and the filter residue enters the washing tank; B. Washing process: the filter residue of step A enters the washing tank, and about 40m 3 water, so that the liquid-solid mass ratio is 3:1, wash, and at a temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com