Chitosan/natural zeolite material for removing fluorine in water

A technology of natural zeolite and chitosan, applied in water/sewage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc. Metal residue and other problems, to achieve the effect of large defluorination capacity, stable defluorination effect and good defluorination performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0029] Chitosan / natural zeolite material for removing fluorine in water of the present invention, its preferred embodiment is:

[0030] The material is particles coated with chitosan on the surface of natural zeolite, wherein the chitosan accounts for 0.1-16.7% of the total mass of the particles, and the average particle diameter of the particles is 1-2mm.

[0031] The chitosan accounts for 0.5-6.55% of the total amount.

[0032] Described chitosan accounts for 6% of total amount.

[0033] The material was prepared by the following steps:

[0034] a. Calcining the screened natural zeolite in a muffle furnace at a temperature of 450-550°C for 1-2 hours, taking it out for later use;

[0035] b. Add glacial acetic acid to the container, add deionized water, and prepare a 0.5-10% glacial acetic acid solution;

[0036] c. At room temperature, add chitosan to the glacial acetic acid solution while stirring, and stir for 5 to 30 minutes to obtain a viscous chitosan solution with a...

Embodiment 1

[0058] In a 50mL glass beaker, add 14mL of glacial acetic acid solution with a concentration of 2.0%, accurately weigh 0.7g of chitosan into the beaker, stir with a glass rod until completely dissolved, then weigh 10g of calcined natural zeolite into the beaker , stirred at room temperature for 15 minutes, transferred to an evaporating dish, dried at 40-105° C., crushed and sieved to obtain chitosan / natural zeolite granular materials with a particle size of 1-2 mm.

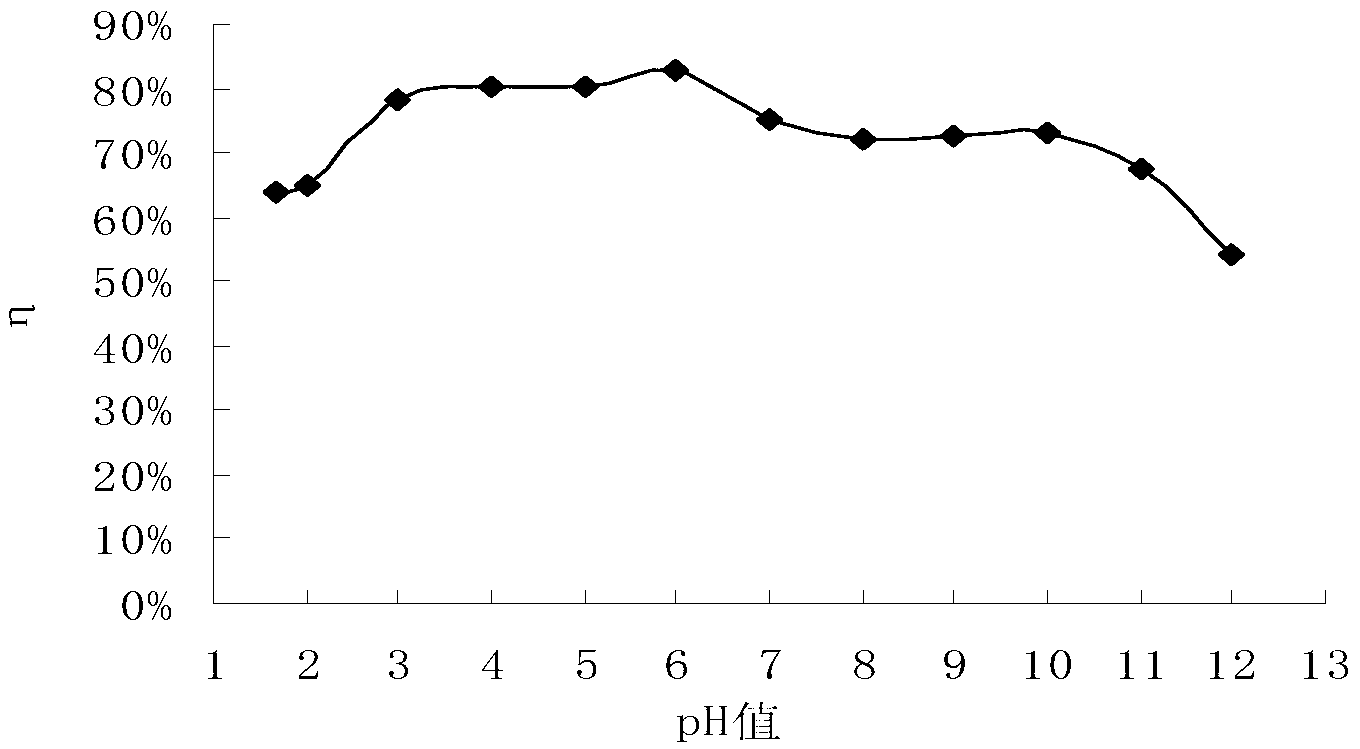

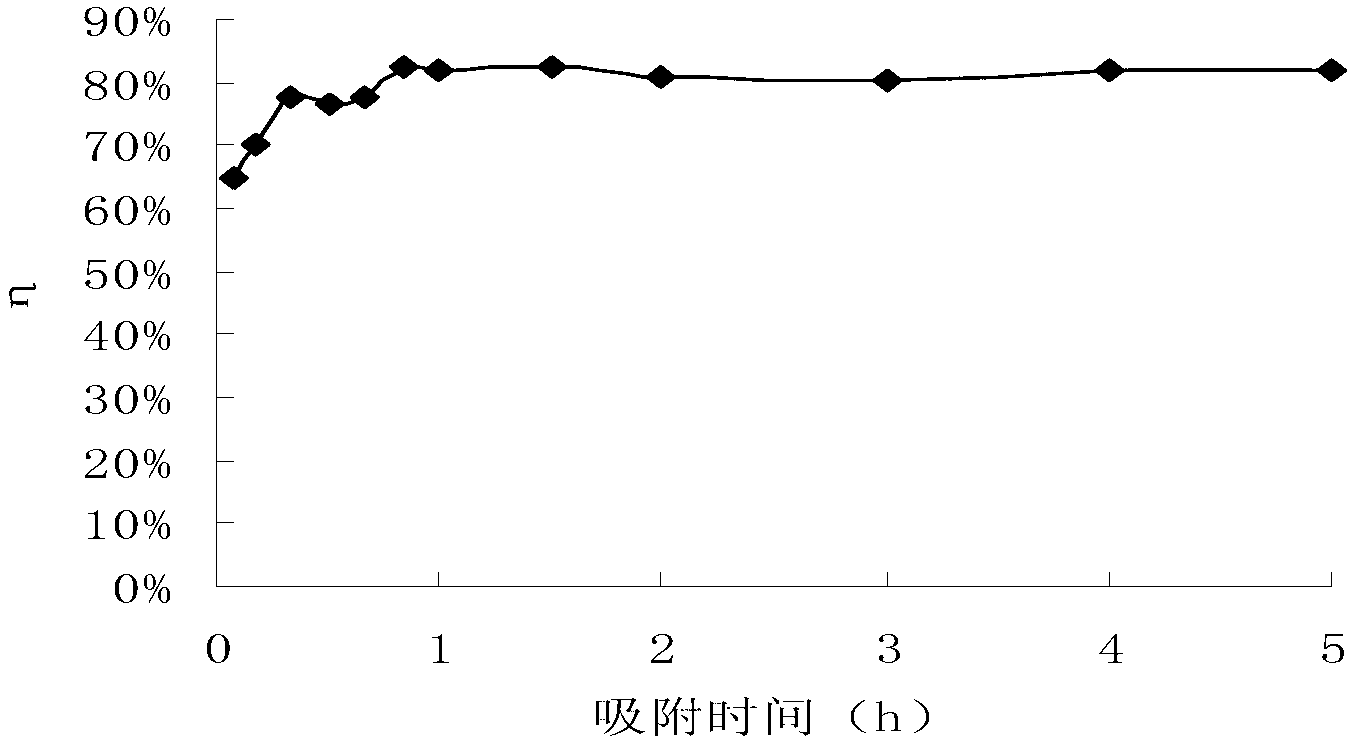

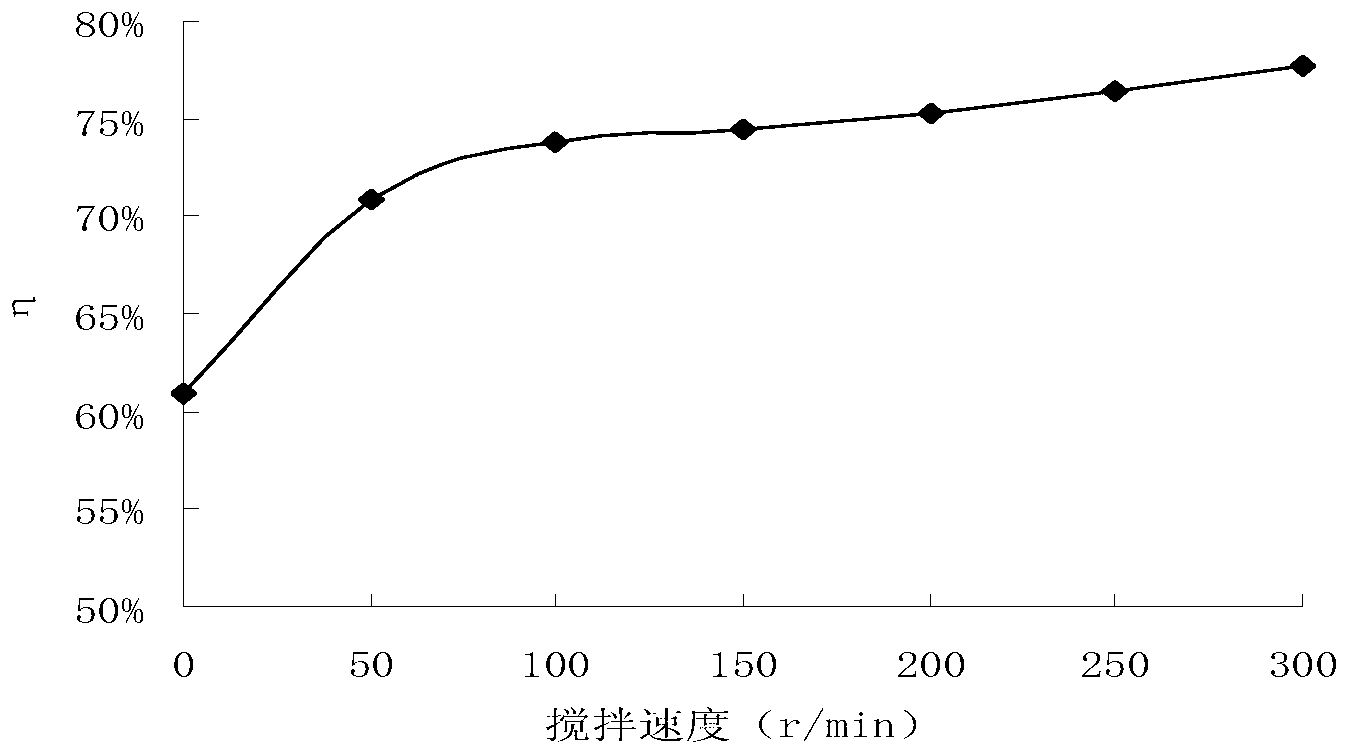

[0059] Using this material to treat fluorine-containing water, when the initial fluorine concentration is 2mg / L, the pH value is 6.0 ( figure 1 ), stirring at a speed of 100r / min at room temperature ( image 3 ) adsorption for 50min ( figure 2 ) reaches saturation. When using 0.1g / 250mL adsorbent ( Figure 4 ), the fluorine ion removal rate can reach 61%, and the fluorine concentration in the effluent is 0.78mg / L, which meets the sanitary standard of drinking water. Fluoride removal agent for F - The adsorpt...

Embodiment 2

[0061] First, it is prepared with analytically pure NaF with a purity of 98%. Weigh 2.210g of reference NaF (pre-dried at 105-110°C for 2h, or at 500-650°C for about 40min, and cool in a desiccator), transfer it to a 1000mL volumetric flask, dilute to the marked line, and shake well. Stored in polyethylene bottles, this solution contains fluorine (F - ) 1000 μg. Pipette 2mL, 5mL, and 10mL of the stock solution into 1000mL volumetric flasks respectively, and shake to a constant volume to obtain F with a concentration of 2mg / L, 5mg / L, and 10mg / L. - solution.

[0062] Second, add appropriate amount of sodium chloride and sodium bicarbonate to fluorinated water to prepare Cl - , HCO 3 - Water samples with concentrations of 100, 200, 400, 600, 800 and 1000 mg / L were adjusted to pH 6.0.

[0063] Finally, take 250mL of the above-mentioned anion-containing solution in a 500mL plastic cup, add 0.5g of adsorbent, place it on a six-way mixer, stir at a speed of 100r / min for 50min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com