Spherical hydroxyapatite fluoride-removing material regenerated powder and application thereof

A technology of hydroxyapatite and fluorine materials, applied in the field of water treatment, can solve the problem of high regeneration cost, and achieve the effects of low treatment cost, cost reduction and water quality safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The regenerated powder of spherical hydroxyapatite defluoridation material includes kaolin and aluminum sulfate with a mass ratio of 20:80; wherein, the particle size of kaolin is between 0.01-1 μm.

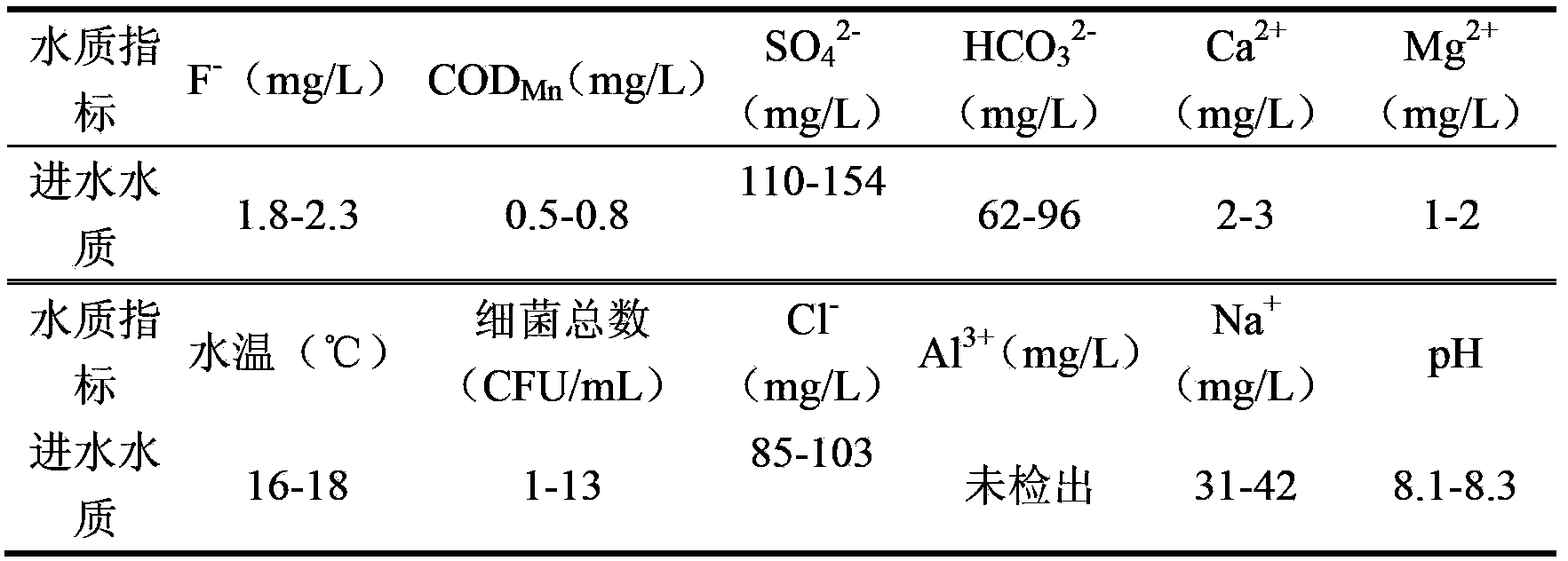

[0034] Utilize above-mentioned recycled powder to defluoride groundwater, comprise the following steps:

[0035] (1) Put the regenerated powder into the water inlet pipe of the groundwater defluorination device. The amount of regenerated powder added per liter of groundwater is 120mg. Mix evenly in the fluorine device;

[0036] (2) The groundwater mixed with regenerated powder flows into the spherical hydroxyapatite filter layer of the groundwater defluoridation device. The thickness of the spherical hydroxyapatite filter layer is 2.0m, and the thickness of the spherical hydroxyapatite filter layer increases The defluoridation effect is better, and the spherical hydroxyapatite particle size used in the spherical hydroxyapatite filter layer is between 0.5-1.0mm; the upward...

Embodiment 2

[0041] The regenerated powder of spherical hydroxyapatite defluoridation material includes clay and polyaluminum chloride with a mass ratio of 10:90; wherein, the particle size of kaolin is between 0.01-1 μm.

[0042] Utilize above-mentioned recycled powder to defluoride groundwater, comprise the following steps:

[0043] (1) Put the regenerated powder into the water inlet pipe of the groundwater defluorination device. The amount of regenerated powder added per liter of groundwater is 60mg. Mix evenly in the fluorine device;

[0044] (2) The groundwater mixed with regenerated powder flows into the spherical hydroxyapatite filter layer of the groundwater defluorination device. The thickness of the spherical hydroxyapatite filter layer is 3.0m. The spherical hydroxyapatite filter layer used in the spherical hydroxyapatite filter layer The particle size of hydroxyapatite is between 0.5-1.0mm; adopting the upward flow filtration method, the flow rate of groundwater in the spheric...

Embodiment 3

[0049] Spherical hydroxyapatite defluoridation material regenerated powder, including natural particles and inorganic aluminum salts at a mass ratio of 30:70, wherein the natural particles are a mixture of kaolin and clay at a mass ratio of 1:1, and the inorganic aluminum salts are at a mass ratio of It is a 1:1 mixture of aluminum sulfate and polyaluminum chloride; wherein, the particle size of natural particles is between 0.01-1 μm.

[0050] Utilize above-mentioned recycled powder to defluoride groundwater, comprise the following steps:

[0051] (1) Put the regenerated powder into the water inlet pipe of the groundwater defluorination device. The amount of regenerated powder added per liter of groundwater is 200mg. Mix evenly in the fluorine device;

[0052] (2) The groundwater mixed with regenerated powder flows into the spherical hydroxyapatite filter layer of the groundwater defluoridation device. The thickness of the spherical hydroxyapatite filter layer is 4.0m. The sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com