A kind of defluoridation material based on bacteria residue and its regeneration method

A technology of fluorine material and fungus residue, which is applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., to achieve the effect of reducing the cost of defluorination, fast defluorination, and increasing defluorination capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

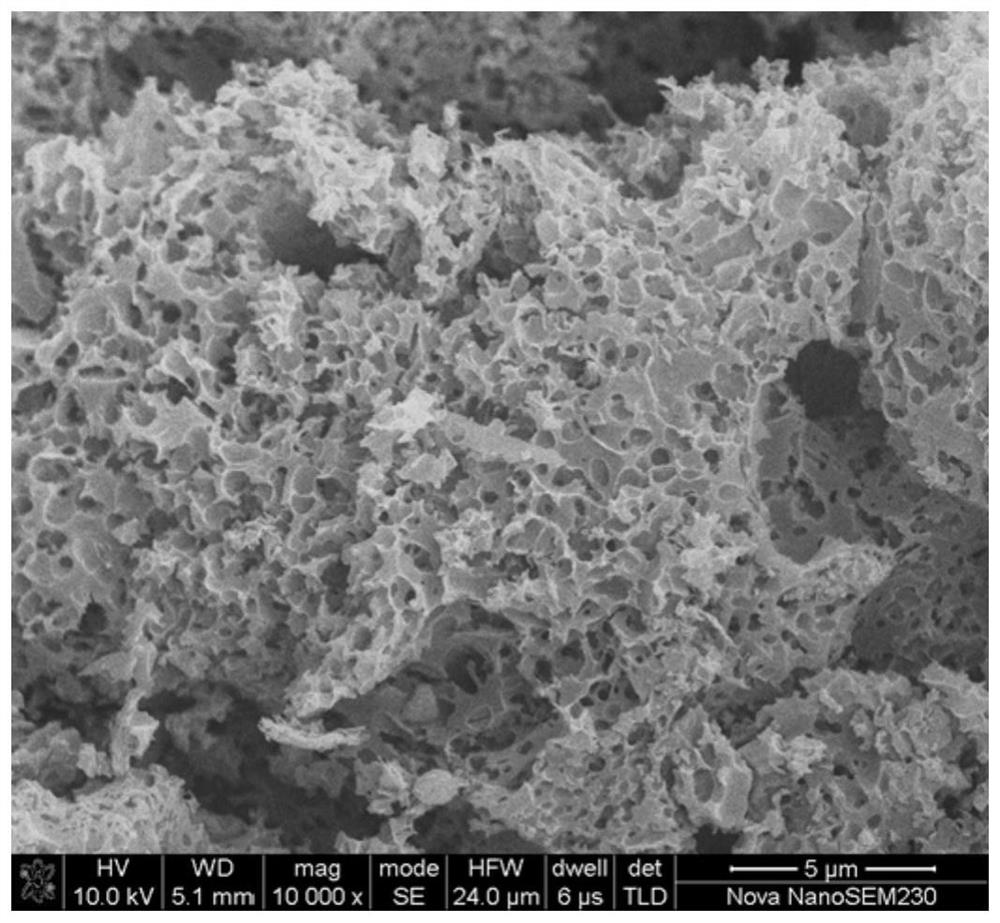

Image

Examples

Embodiment 1

[0048] 1. A defluoridation material based on oxytetracycline slag and lanthanum nitrate and its regeneration

[0049] (1) The preparation steps of the defluoridation material based on oxytetracycline slag are as follows

[0050] The first step: dry and grind oxytetracycline

[0051] Bake the oxytetracycline residue in an oven at 100°C for 12 hours to obtain dry residue, and then place the dried residue in a ball mill for ball milling for 6 hours to obtain powder with an average particle size of 10 μm;

[0052]The second step: preparation of slurry containing finely ground oxytetracycline slag powder and soluble rare earth salt

[0053] Take respectively ground oxytetracycline slag powder and lanthanum nitrate by mass ratio 1:0.1, mix the two together to obtain mixed powder;

[0054] Add the mixed powder into deionized water according to the solid-to-liquid ratio of 1:5, and then stir at 50°C for 2 hours to obtain a slurry;

[0055] Step 3: Add NaOH and evaporate to dryness ...

Embodiment 2

[0068] A kind of defluoridation material based on mixed bacteria residue / lanthanum nitrate / cerium chloride and its regeneration

[0069] (1) Preparation of defluoridation material based on mixed bacteria residue / lanthanum nitrate / cerium chloride, comprising the following steps:

[0070] The first step: dry and grind the mixed bacteria residue

[0071] Put the oxytetracycline residues, penicillin residues and cephalosporin residues taken from antibiotic production enterprises with no fixed ratio in an oven at 80°C for 36 hours to obtain dry mixed residues, and then put the dried residues in a ball mill Medium ball milling for 12 hours to obtain fungal residue powder with an average particle size of about 20um;

[0072] Step 2: Prepare a slurry containing finely ground mixed bacterial slag powder and soluble rare earth salt

[0073] First, weigh lanthanum nitrate and cerium chloride according to the mass ratio of 1:2 to obtain mixed rare earth; At 5:1; followed by stirring at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com