Method for removing fluorine from zinc sulfate solution after roasting of zinc smelting silicon residues

A technology of zinc sulfate solution and silicon slag, which is applied to the improvement of process efficiency, photographic technology, instruments and other directions, can solve the problem that the fluorine removal rate can only reach 30-60%, and achieves good fluorine removal effect, easy operation, and high efficiency. economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

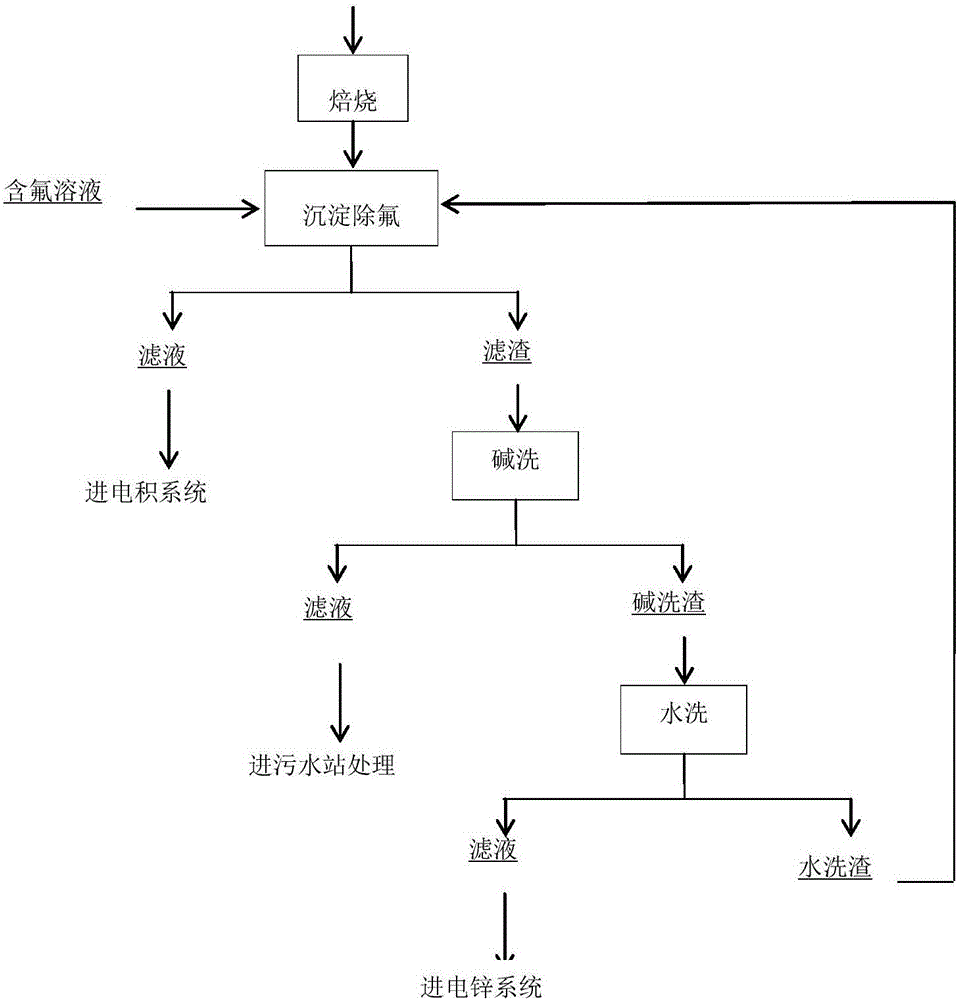

[0031] The method for removing fluorine in the zinc sulfate solution after the zinc smelting silicon slag is roasted comprises the following sequential steps:

[0032] A. Silicon slag preparation: Zinc smelting silicon slag is roasted at 400°C;

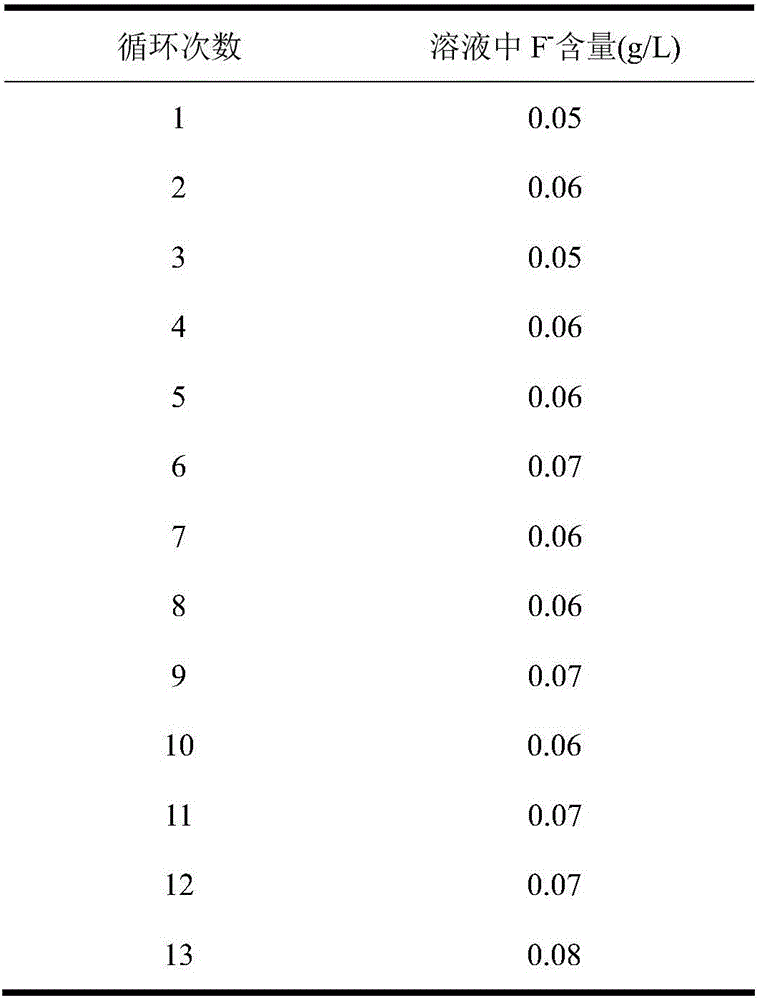

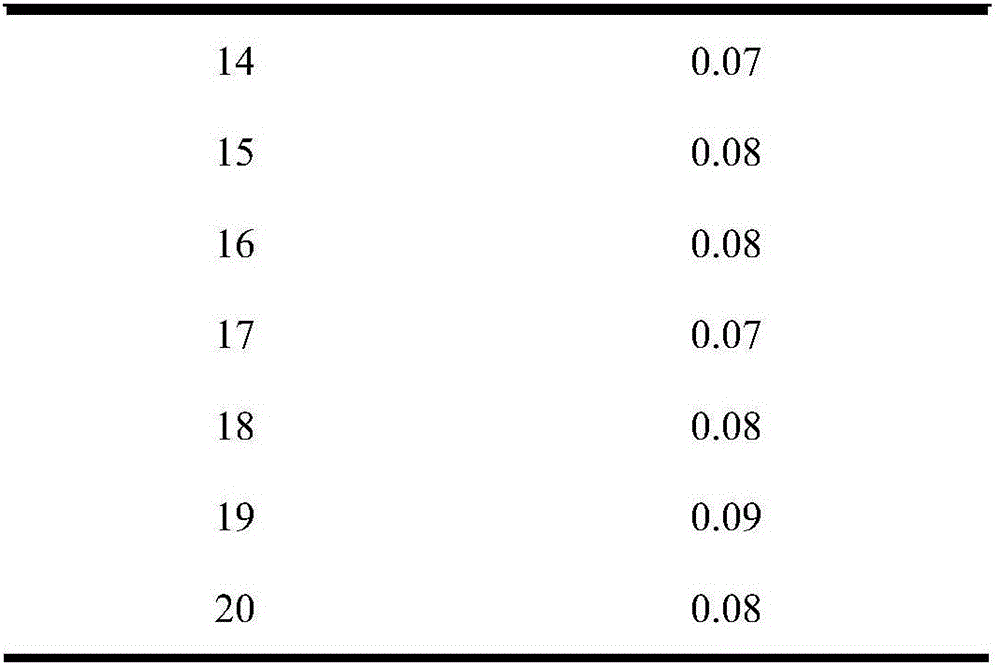

[0033] B. Defluorination by precipitation: Add 1.40t of the roasted silicon slag obtained in step A into a zinc sulfate solution with a pH of 5.0, and the volume of the zinc sulfate solution is 45m 3 , the fluorine content is 0.29g / L, the liquid-solid ratio is 32:1, the reaction temperature is normal temperature, the reaction is stirred, and pressure filtration is carried out after 2 hours.

[0034] C. Alkaline washing of precipitated slag: The slag obtained in step B is alkaline washed with a liquid-solid ratio of 5:1 and a pH of 10. Under the condition of a reaction temperature of 80°C, the reaction is carried out for 1 hour, the liquid enters the sewage system, and the slag reaches Next step;

[0035] D. Washing of alkali-washed ...

Embodiment 2

[0042] The method for removing fluorine in the zinc sulfate solution after the zinc smelting silicon slag is roasted comprises the following sequential steps:

[0043] A. Silicon slag preparation: Zinc smelting silicon slag is roasted at 500°C;

[0044] B. Defluorination by precipitation: Add 1.26t of the roasted silicon slag obtained in step A into the zinc sulfate solution with a pH of 2.5 to 3.0, and the volume of the zinc sulfate solution is 48m 3 , the fluorine content is 0.3g L, the liquid-solid ratio is 38:1, the reaction temperature is normal temperature, the reaction is stirred, and pressure filtration is carried out after 2 hours.

[0045] C. Alkaline washing of precipitated slag: The slag obtained in step B is alkaline washed with a liquid-solid ratio of 5:1 and a pH of 10. Under the condition of a reaction temperature of 80°C, the reaction is carried out for 1 hour, the liquid enters the sewage system, and the slag reaches Next step;

[0046] D. Washing of alkali...

Embodiment 3

[0053] The method for removing fluorine in the zinc sulfate solution after the zinc smelting silicon slag is roasted comprises the following sequential steps:

[0054] A. Silicon slag preparation: Zinc smelting silicon slag is roasted at 500°C;

[0055] B. Defluorination by precipitation: Add 1.53t of the roasted silicon slag obtained in step A to the waste electrolyte of zinc electrowinning with a pH of 3.5, and the volume of the waste electrolyte is 46m 3 , the fluorine content is 0.29g / L, the liquid-solid ratio is 30:1, the reaction temperature is normal temperature, the reaction is stirred, and pressure filtration is carried out after 2 hours.

[0056] C. Alkaline washing of precipitated slag: the slag obtained in step B is alkali-washed with an alkali solution with a liquid-solid ratio of 5:1 and a pH of 10. Under the condition of a reaction temperature of 80°C, the reaction is carried out for 1 hour, and the liquid enters the sewage system, and the slag reaches Next ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com