System and method for simultaneously removing carbon tetrafluoride (CF4) and concomitant nitrogen oxide (NOx) gases

A gas removal technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of unstable treatment effect, inability to remove, catalyst capacity limitation, etc. of the gas to be treated, so as to improve the utilization efficiency and avoid Active effect, guaranteed active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

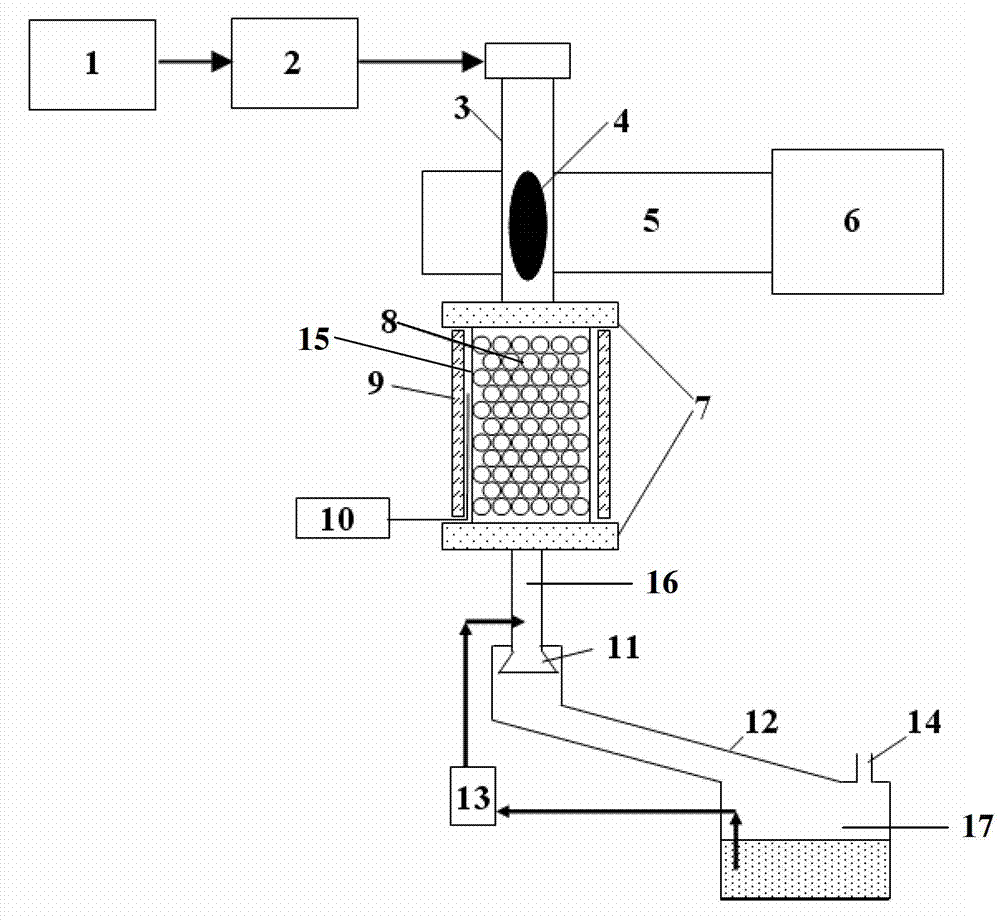

[0032] A flow controller 2 is arranged at the input port 1 of the gas to be treated, and the flow controller is connected to the quartz tube reactor 3 through a pipeline, and the plasma 4 is generated by microwaves inside the quartz tube reactor, and the plasma is generated by microwaves The device 6 provides energy through the waveguide 5, and the waveguide and the quartz tube reactor are connected by a central point direct coupling mode; the quartz tube reactor and the quartz tube 15 of the catalytic reaction device are connected by a flange or a screw 7, so that the filled catalyst The inner diameter and length of the quartz tube are adjustable. After being treated by plasma, the gas to be treated passes through the catalyst bed for reaction, and the outside of the quartz tube reactor wall filled with the catalyst is covered with an insulating layer 9 . The treated gas enters the tail gas treatment device through the flange or screw, and the exhaust gas inlet 11 is provided...

Embodiment 2

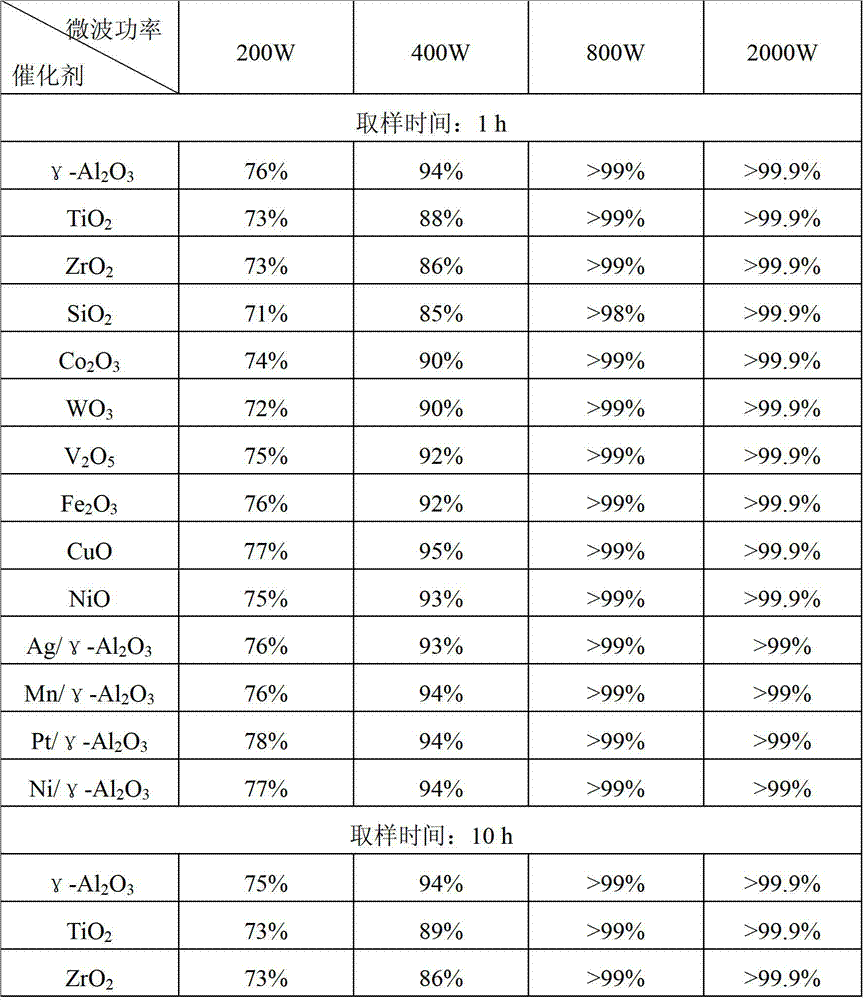

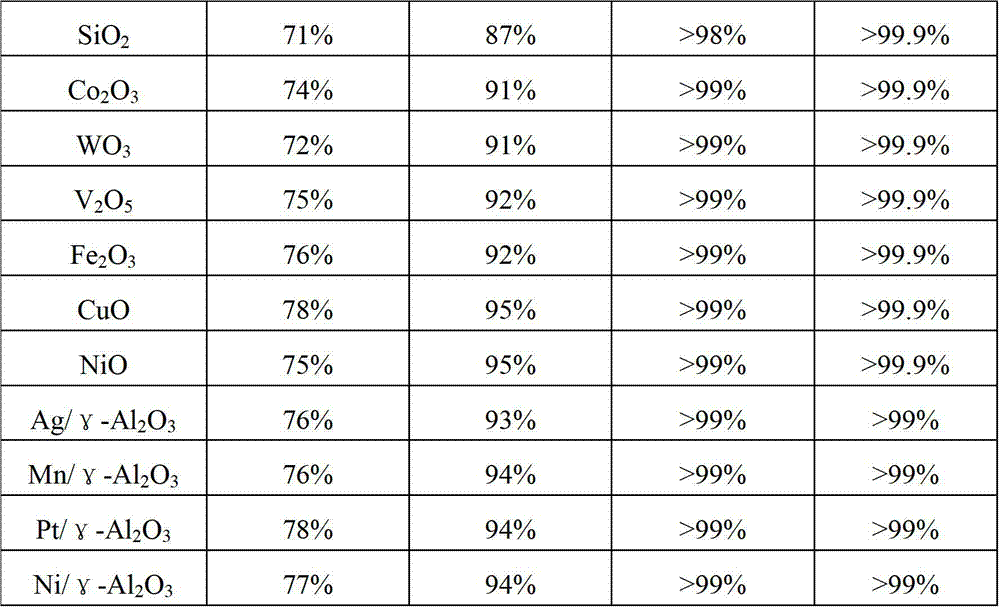

[0034] Adopt the device described in embodiment 1 to process containing CF 4 and NO x Gas waste gas method that will be treated containing CF 4 The gas 1 passes through the flow controller 2 into the reaction tube 3, the inner diameter of the reaction tube 3 is about 15mm, and the length is about 500mm; the microwave power is 200W-2000W, the gas flow rate is 2L / min, CF 4 The concentration is 2000mL / m 3 , using microwave ignition in the reaction tube to generate microwave plasma to continuously process the mixed gas; the treated gas is further processed through the catalyst bed 8 . The volume of the catalyst bed is about 30mL, and the temperature of the bed is 600-900K. The treated gas adopts wet method (wet absorption method uses saturated Ca(OH) 2 solution as absorbent) or dry absorption method (dry absorption method uses aluminum oxide powder as absorbent) and discharge after absorption treatment. Total CF 4 The removal efficiency is shown in Table 1.

[0035] Table I...

Embodiment 3

[0040] CF 4 The gas 1 is passed into the reaction tube 3 through the flow controller (or valve) 2, the inner diameter of the reaction tube 3 is about 15mm, and the length is about 500mm; the microwave power is 200W-2000W, the gas flow rate is 2L / min, CF 4 The concentration is 2000mL / m 3 , using microwave ignition in the reaction tube to generate microwave plasma to continuously process the mixed gas; the treated gas is further processed through the catalyst bed 8 . The volume of the catalyst bed is about 100mL, and the temperature of the bed is 600-900K. The treated gas is absorbed and treated by wet or dry absorption method and discharged, and the wet absorption liquid adopts saturated Ca(OH) 2 The solution and the dry absorbent use aluminum oxide powder, and the temperature is below 40 degrees at room temperature. When the catalyst is Ag / γ-Al 2 O3, the by-product NO x After the system runs for 40 minutes, the concentration does not change significantly, and the concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com