Activating method for high-nickel catalyst

An activation method and catalyst technology, which can be used in catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., and can solve the problems of low diene hydrogenation rate, usage, incomplete diene hydrogenation, etc. , to achieve the effect of prolonged time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

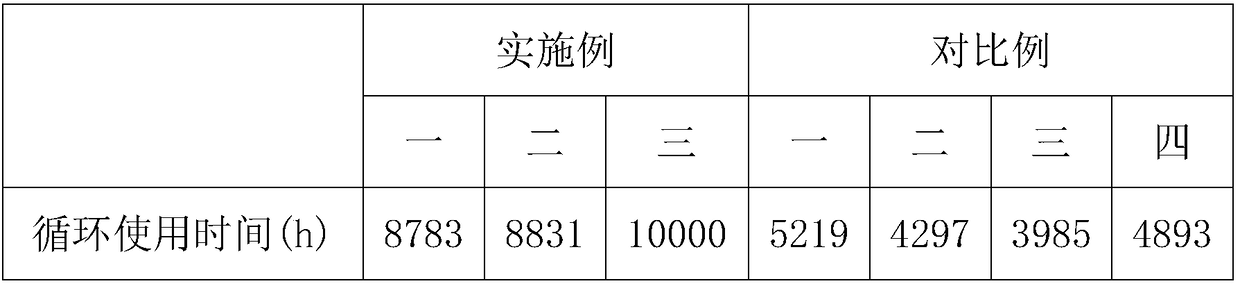

Examples

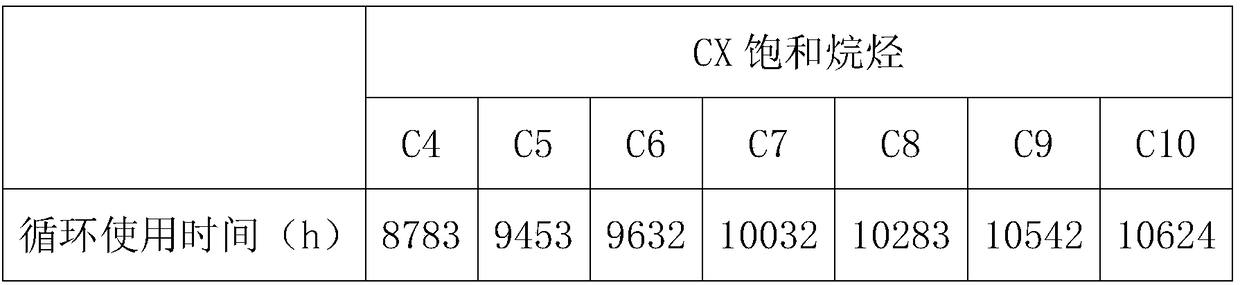

Embodiment 1

[0026] A kind of high-nickel catalyst activation method that the present invention proposes comprises the following steps:

[0027] S1. Regeneration of high-nickel catalyst: Add the high-nickel catalyst that has entered the final stage into the reactor, and control the temperature of the reactor to 220 ° C, the pressure to 2.5 MPa, and feed C4 saturated alkane for 72 hours. Activation of the high-nickel catalyst, after the activation is completed, the activator and the high-nickel catalyst are separated to obtain the activated high-nickel catalyst and the used activator, and the activated high-nickel catalyst can be reused after vacuum drying;

[0028] S2. Regeneration of the activator: the used activator separated in step S1 is regenerated by rectification, and the regenerated activator is used for regeneration of the high-nickel catalyst.

Embodiment 2

[0030] A kind of high-nickel catalyst activation method that the present invention proposes comprises the following steps:

[0031] S1. Regeneration of high-nickel catalyst: Add the high-nickel catalyst that has entered the final stage into the reactor, and control the temperature of the reactor to 220 ° C, the pressure to 2.5 MPa, and feed C8 saturated alkane for 36 hours. Activation of the high-nickel catalyst, after the activation is completed, the activator and the high-nickel catalyst are separated to obtain the activated high-nickel catalyst and the used activator, and the activated high-nickel catalyst can be reused after vacuum drying;

[0032] S2. Regeneration of the activator: the used activator separated in step S1 is regenerated by rectification, and the regenerated activator is used for regeneration of the high-nickel catalyst.

Embodiment 3

[0034] A kind of high-nickel catalyst activation method that the present invention proposes comprises the following steps:

[0035] S1. Regeneration of high-nickel catalyst: Add the high-nickel catalyst that has entered the final stage into the reactor, and control the temperature of the reactor to 180°C, the pressure to 2.5MPa, and feed hydrogen with a purity of more than 99% for a time of After 48 hours, activate the high-nickel catalyst. After the activation is completed, separate the activator from the high-nickel catalyst to obtain the activated high-nickel catalyst and the used activator. The activated high-nickel catalyst can be vacuum-dried use again;

[0036] S2. Regeneration of the activator: the used activator separated in step S1 is regenerated by rectification, and the regenerated activator is used for regeneration of the high-nickel catalyst.

[0037] In the present invention, it is equipped with a filter buffer tank and a supporting hydrogen torch system. If th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com