Water treatment defluorination agent and preparation method thereof

A technology of water treatment and pharmaceuticals, which is applied in the directions of water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the problem of harsh process conditions, unfavorable large-scale quantitative production, and complicated preparation process To achieve the effect of enhancing the complexation effect, obvious effect of fluorine removal, and changing the floc structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

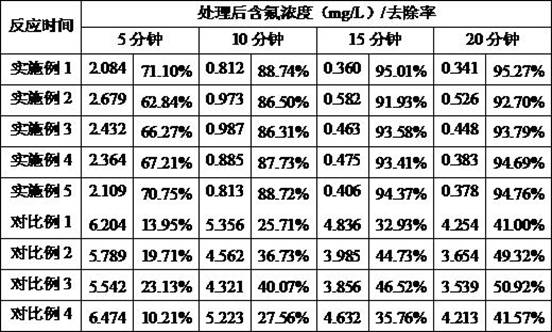

Examples

Embodiment 1

[0033] According to the following experimental procedures, the fluoride removal agent CF-1 was prepared. Specific steps are as follows:

[0034] Step 1: Weigh a fixed amount of sodium silicate and dissolve it in quantitative water to obtain a sodium silicate solution with a mass concentration of 3-5%. Put the sodium silicate solution in a constant temperature water bath, set the constant temperature at 50°C, and quickly Stir for 20 minutes to obtain a colorless and transparent solution, add dilute hydrochloric acid solution with a mass concentration of 15% for activation until pH = 4.5, stir and react for 30 minutes, and let stand for 20 minutes after the reaction to obtain solution A.

[0035] Step 2: Weigh a fixed amount of aluminum chloride hexahydrate solid, and slowly add it to solution A under constant stirring. The mass ratio of aluminum chloride hexahydrate solid mass to solution A is 3:10. The solution gradually changed from turbid to clear, and the stirring time was...

Embodiment 2

[0039] Prepare the fluorine removal agent CF-2 according to the following experimental procedures. Specific steps are as follows:

[0040] Step 1: Weigh a fixed amount of sodium silicate and dissolve it in quantitative water to obtain a sodium silicate solution with a mass concentration of 3-5%. Put the sodium silicate solution in a constant temperature water bath, set the constant temperature at 50°C, and quickly Stir for 20 minutes to obtain a colorless and transparent solution, add dilute hydrochloric acid solution with a mass concentration of 15% for activation until pH = 4.0, stir and react for 30 minutes, and let stand for 20 minutes after the reaction to obtain solution A.

[0041] Step 2: Weigh a fixed amount of aluminum chloride hexahydrate solid, and slowly add it to solution A under constant stirring, the mass ratio of aluminum chloride hexahydrate solid mass to solution A is 2:10. The solution gradually changed from turbid to clear, and the stirring time was 20 mi...

Embodiment 3

[0045] Prepare the fluorine removal agent CF-3 according to the following experimental procedures. Specific steps are as follows:

[0046] Step 1: Weigh a fixed amount of sodium silicate and dissolve it in quantitative water to obtain a sodium silicate solution with a mass concentration of 3-5%. Put the sodium silicate solution in a constant temperature water bath, set the constant temperature at 50°C, and quickly Stir for 20 minutes to obtain a colorless transparent solution, add dilute hydrochloric acid solution with a mass concentration of 15% for activation, until pH = 4.3, stir for 30 minutes, and stand for 20 minutes after the reaction to obtain solution A.

[0047] Step 2: Weigh a fixed amount of aluminum chloride hexahydrate solid, and slowly add it to solution A under constant stirring. The mass ratio of aluminum chloride hexahydrate solid mass to solution A is 4:10. The solution gradually changed from turbid to clear, and the stirring time was 20 minutes. Continue t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com