Weight hanging structure of prefabricated inner partition wall board and construction technology thereof

A construction process and technology for inner partition walls, which are applied in manufacturing tools, building structures, stone processing tools, etc., can solve the problems of stability and safety discounts, inconvenient hanging heavy objects, and narrow wall thickness. Improve the structural stability and bearing strength, strengthen the overall stability, and save the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

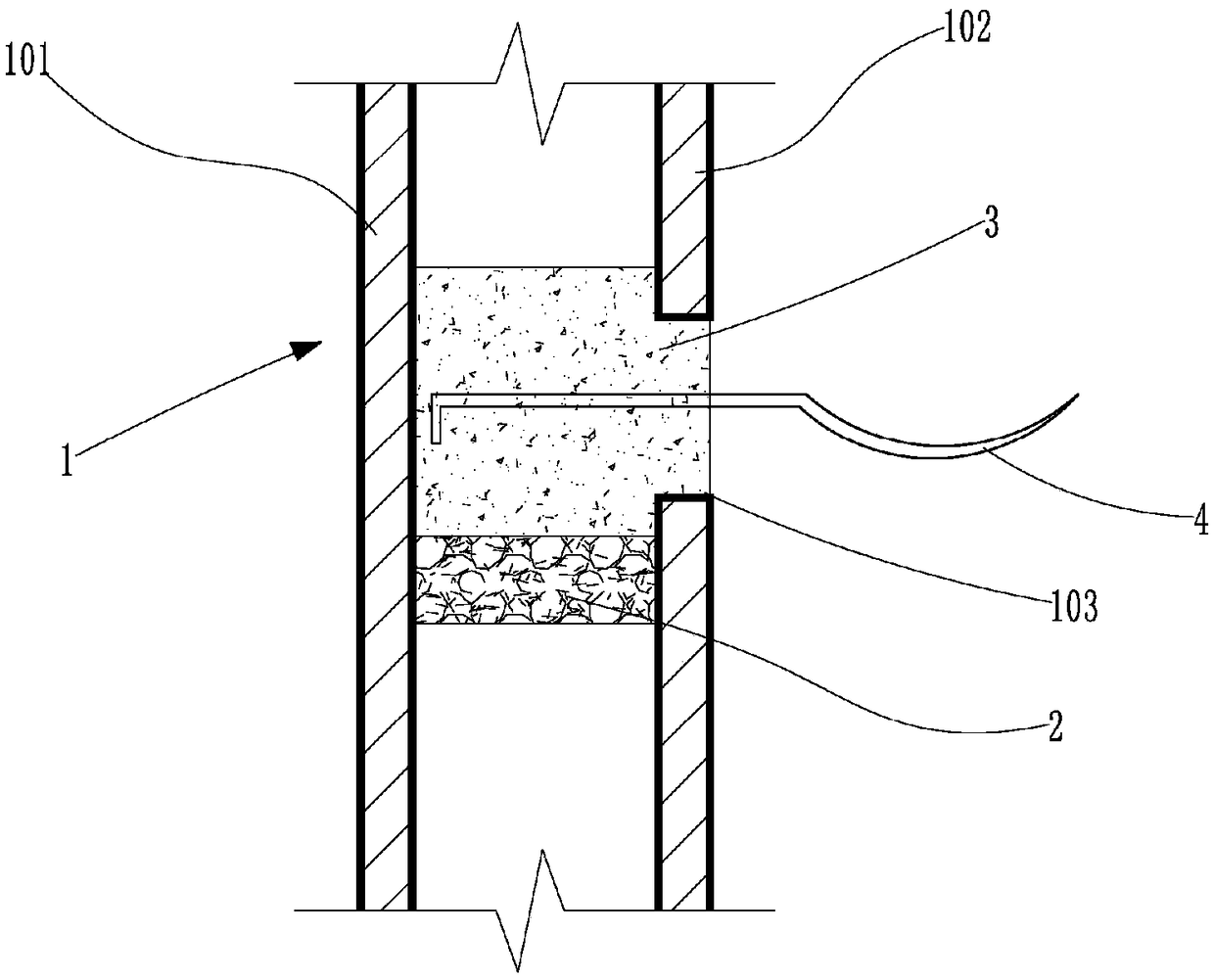

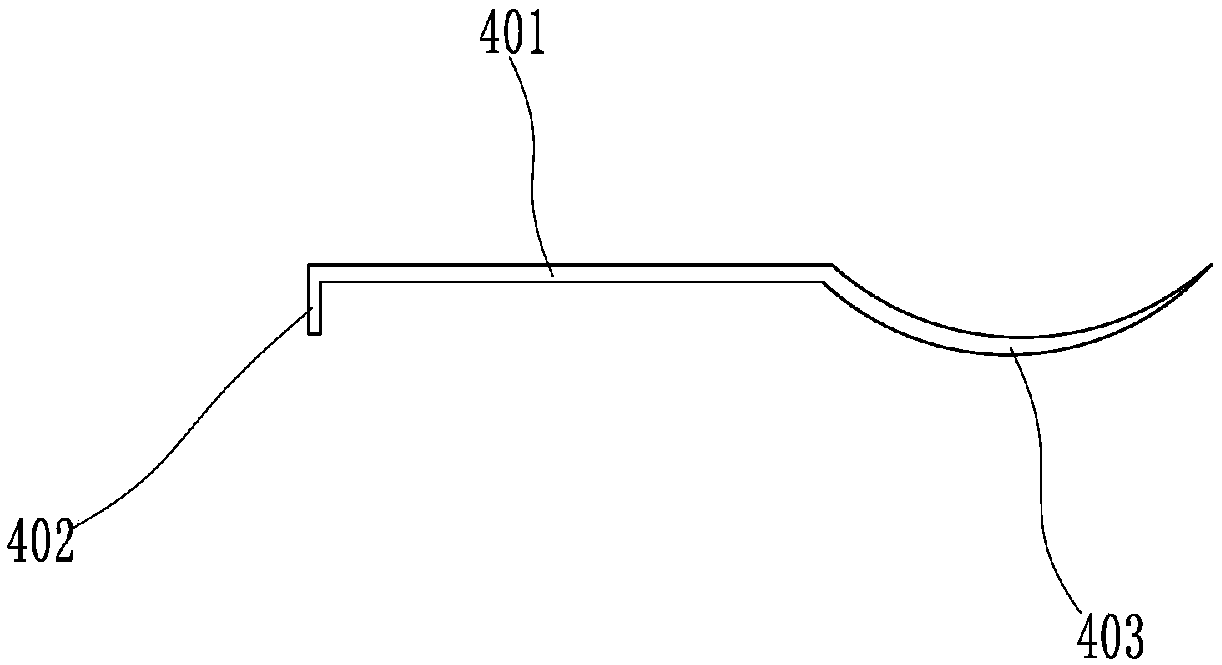

[0027] The construction process of a prefabricated inner partition wall panel heavy object hanging structure according to the present invention comprises the following steps:

[0028] a. Positioning: Carry out positioning and marking on the inner wall panel 102 of the prefabricated inner partition wall panel 1 and determine the center point. The specific position of the center point is determined according to the position of the hanging hole on the heavy object to be hung. When making a line, use a nail with a sharp thorn to mark the line on the interior wall panel 102 in the hanging hole, so as to determine the position of the line.

[0029] b. Hole opening: Drill a through hole 103 on the inner wall panel 102 with the center point as the center of the circle through a special machine. The drill bit in the wall hole saw first drills the center hole on the interior wall panel 102 with the center point determined by the marking line as the center, and then allows the wall hole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com