Vertical film lifting mechanism

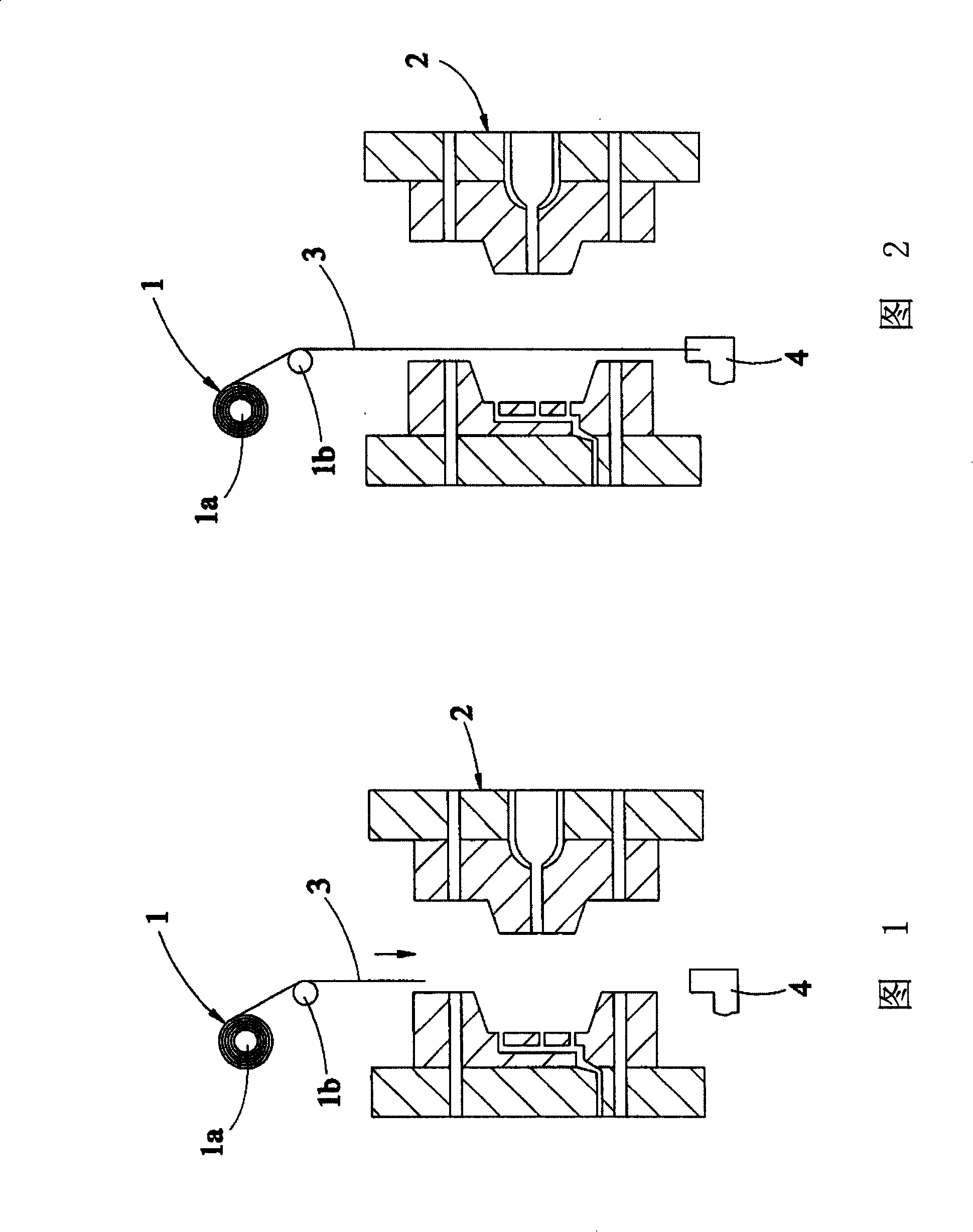

A vertical, film-rolling technology, applied in the direction of winding strips, sending objects, thin material processing, etc., can solve the problems of uneven surface of film 3, inconvenient film replacement operation, and increased defective rate of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

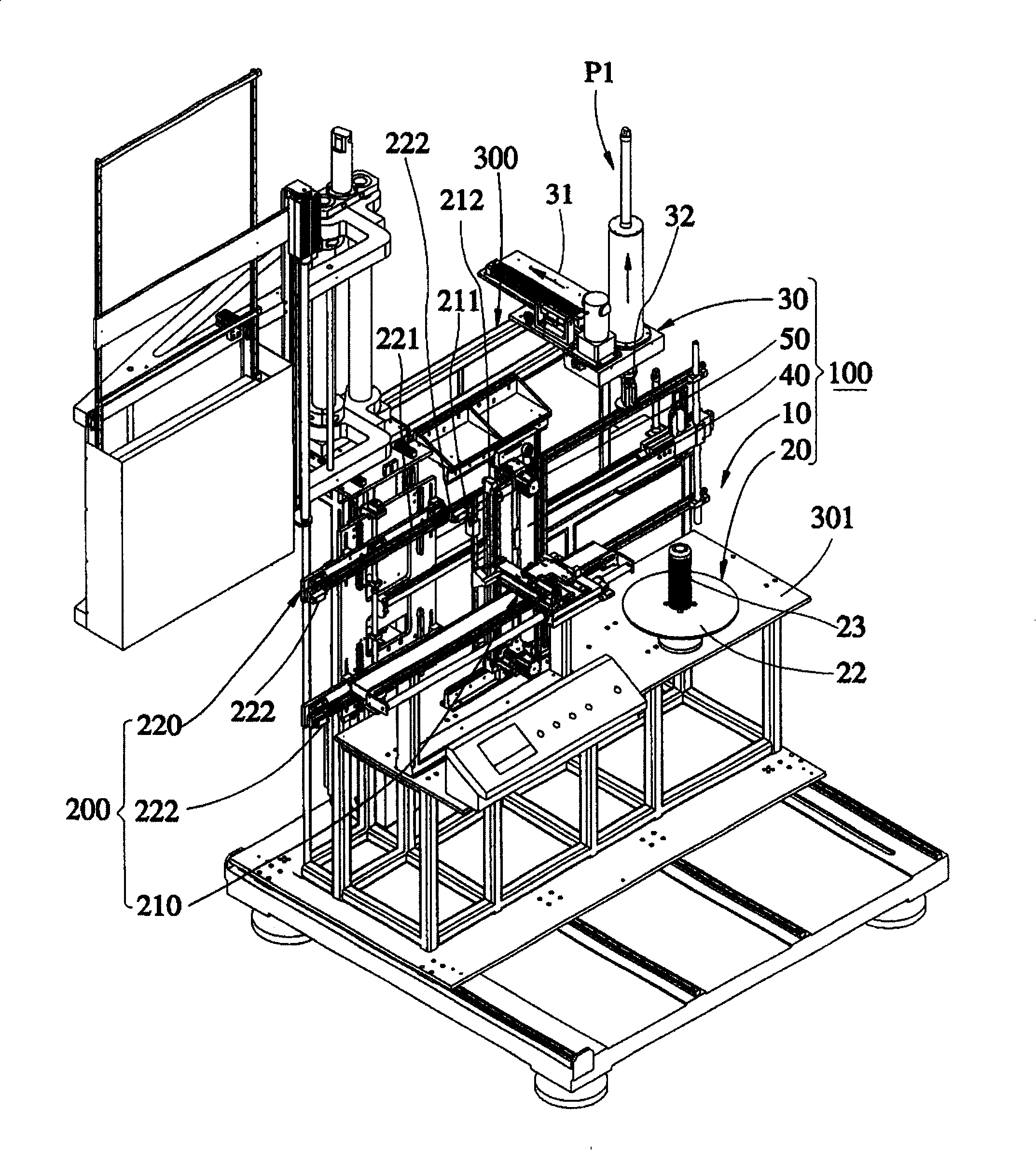

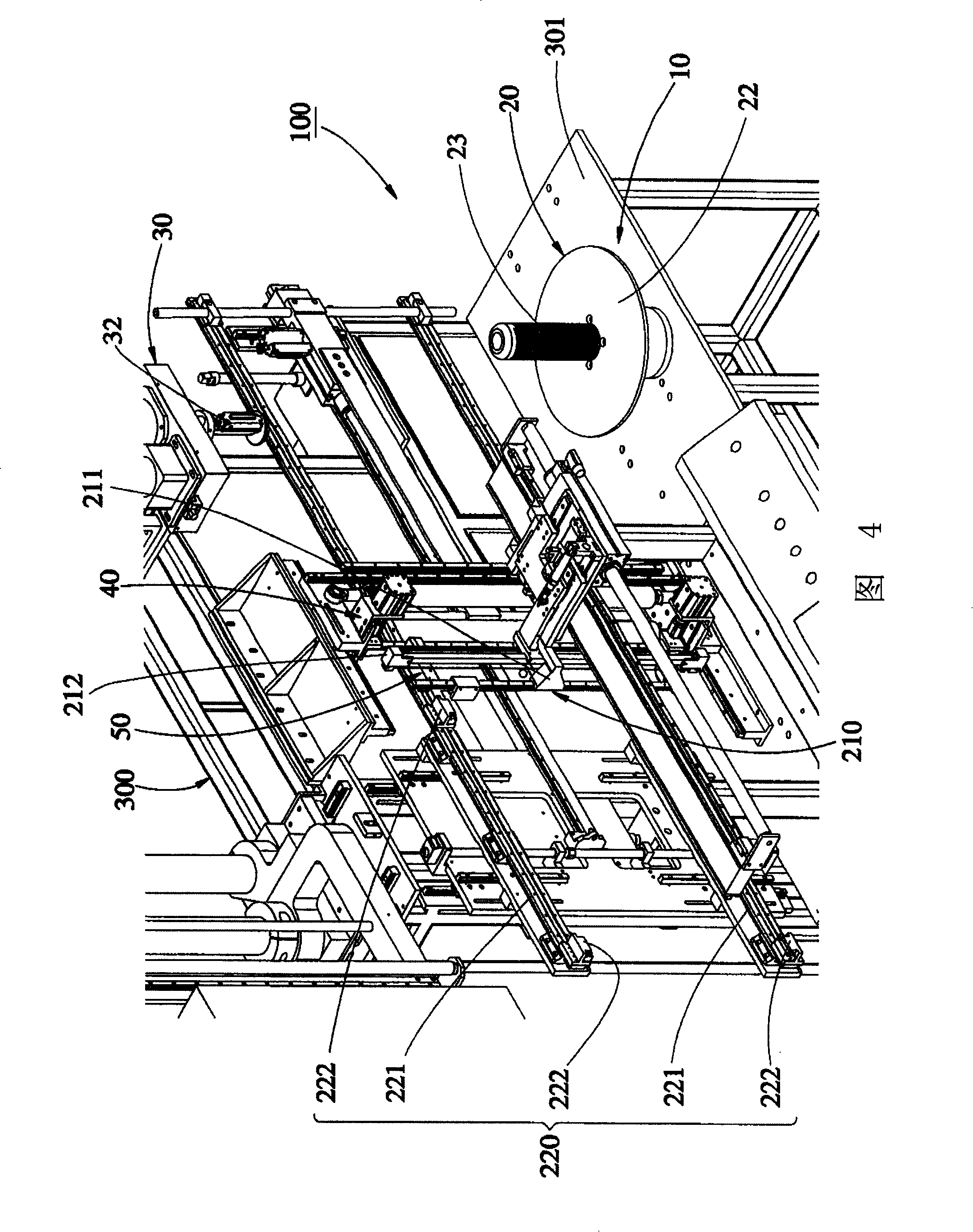

[0032] In order to illustrate the structure and the achieved effects of the present invention in detail, the following preferred embodiments are given below together with the accompanying drawings.

[0033] Such as image 3 ~Shown in Fig. 15, it is a vertical film-on-film mechanism 100 of a preferred embodiment of the present invention. A platform 301, before illustrating the vertical film-on-film mechanism 100 of the present invention, the film-drawing mechanism 200 and roll film 99 that cooperate with this mechanism are introduced as follows:

[0034] Such as image 3 As shown in FIG. 4 , the film pulling mechanism 200 has a film pulling device 210 and a film feeding device 220 that can move relative to the frame 300 . The film pulling device 210 is connected with a film pulling part 211 and a cutting part 212 . The film feeding device 220 has two cantilever arms 221, and the cantilever arm 221 is provided with four grippers 222 (because the film pulling mechanism 200 is not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com