Backlight module

A technology of backlight module and light guide plate, which is applied in the direction of light guide, optics, optical components, etc., and can solve the problems of deflection and deformation of reflective sheet, affecting the display quality of flat-panel display, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The following will clearly illustrate the spirit of the present invention with drawings and detailed descriptions. Anyone with ordinary knowledge in the technical field can change and modify the technology taught by the present invention after understanding the preferred embodiments of the present invention. without departing from the spirit and scope of the present invention.

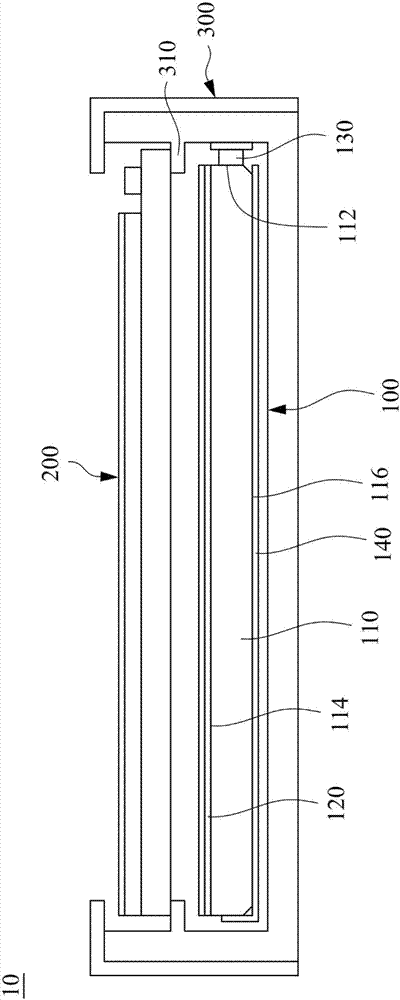

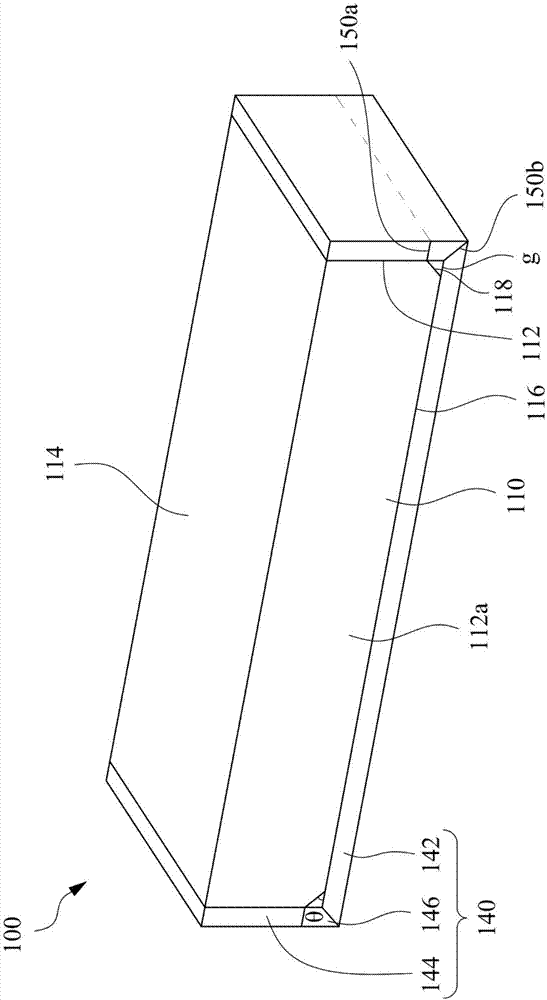

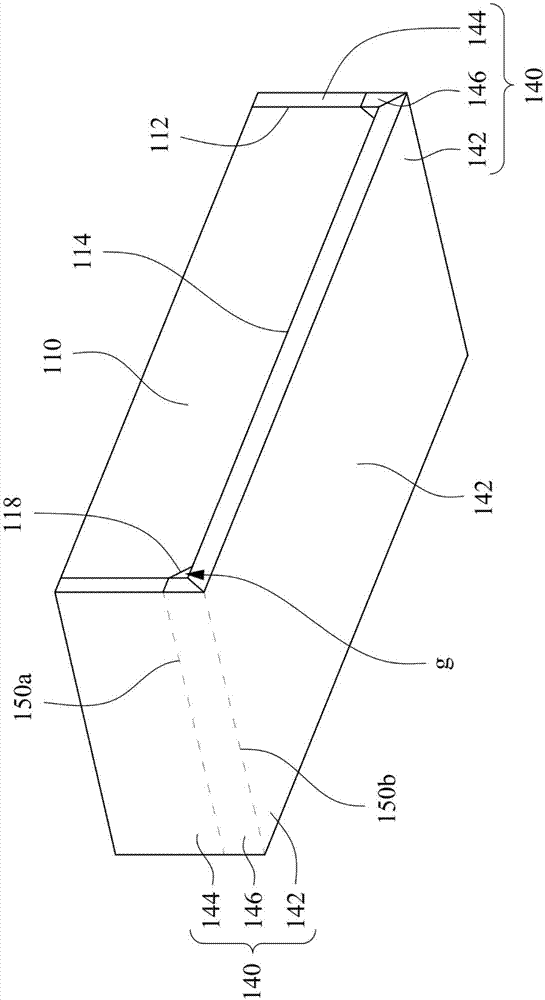

[0050] refer to figure 1 , which is a schematic cross-sectional view of an embodiment of a flat panel display using the backlight module of the present invention. The flat panel display 10 includes a backlight module 100 , a display panel 200 and a frame 300 , wherein the display panel 200 is located above the backlight module 100 , and the backlight module 100 and the display panel 200 are fixed in the frame 300 .

[0051] In one embodiment, the material of the frame body 300 includes plastic (such as thermosetting material, thermoplastic material, or a combination thereof), metal (such as alu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com