Manufacturing technology of integrated forged steel piston

A manufacturing process and integrated technology, applied in the direction of pistons, engine components, machines/engines, etc., can solve the problems of the danger of engine cylinder pulling, the welding seam cannot be cleaned, energy waste and other problems, meet the requirements of welding equipment is not high, reduce equipment cost The effect of inputting and improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

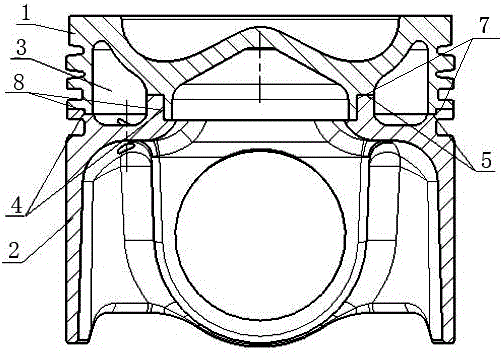

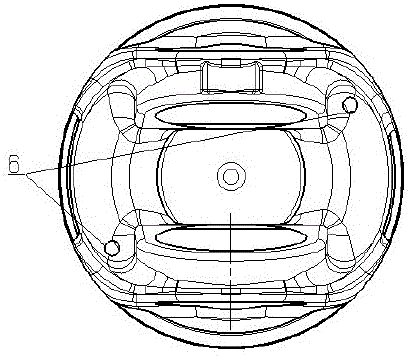

[0053] In order to clearly illustrate the technical characteristics of this solution, the following will describe this solution through specific implementation modes and in conjunction with the accompanying drawings.

[0054] A manufacturing process for a one-piece forged steel piston, rough machining the forged piston head 1 and piston skirt 2, and then brazing the piston head 1 and piston skirt 2, specifically, the forged rough machining of the piston head 1 and piston skirt 2, apply borax flux on the welding area of the piston head 1, assemble the piston head 1 and piston skirt 2 together and heat them, after the heating is completed, take out the workpiece and make it Allow to cool naturally.

[0055] The manufacturing process of this monolithic forged steel piston comprises the following steps successively:

[0056] (1) Rough machining of forged piston head 1 and piston skirt 2;

[0057] (2) The cylindrical surface 4 and the plane 5 of the piston head 1 are plated wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com