Forging process for Cr12MoV steel

A technology of processing technology and process, which is applied in the field of forging processing technology of Cr12MoV steel, can solve the problems of increasing production cost, improper temperature control, difficult forging, etc., and achieve the effect of reducing material waste, reducing local fracture, and reducing forging difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail below.

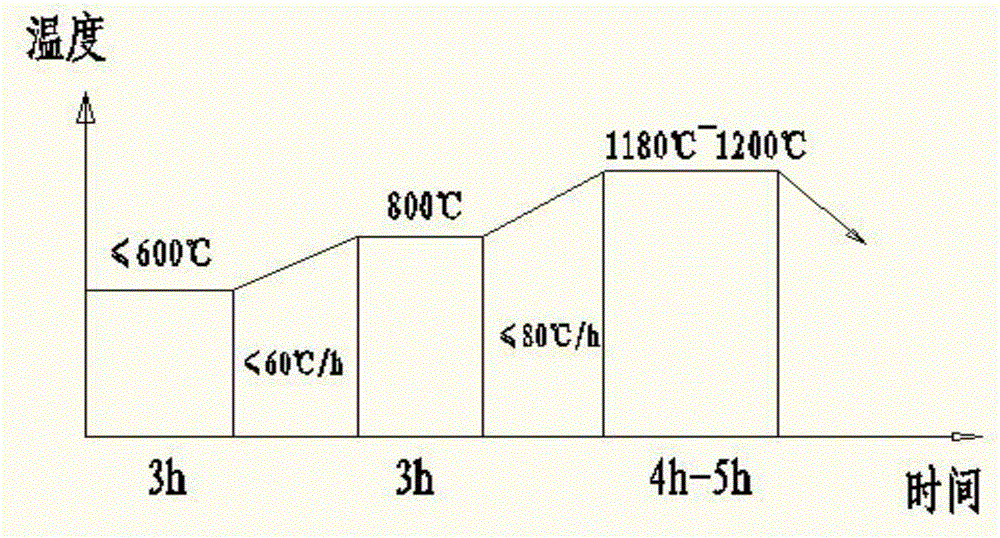

[0022] Please refer to figure 1 , a forging process of Cr12MoV steel, its specific forging process is:

[0023] (1) Preheating stage: Before the forgings are put into the furnace, the interior of the furnace body is firstly preheated, and the dead corners in the furnace are heated by jet gas, so that the temperature in the furnace reaches 270°C uniformly, and the furnace body is preheated in advance , can avoid local overcooling of the furnace body, affecting the uniformity of forging heating.

[0024] (2) Heating stage: Put the forgings into the preheated furnace for heating, and continuously turn over the forgings during heating:

[0025] When heating, put the forging into the furnace at low temperature, and when the temperature reaches 600°C, keep it warm for 3 hours;

[0026] Then heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com