Iron-based magnetic alloy powder containing rare earth element, method for producing same, resin composition for bonded magnet obtained from same, bonded magnet, and compacted magnet

A manufacturing method and technology of alloy powder, applied in the field of dense magnets, can solve the problems of insufficient affinity of binder resin, low mechanical strength, breakage, etc., and achieve excellent corrosion resistance, high mechanical strength and high industrial value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

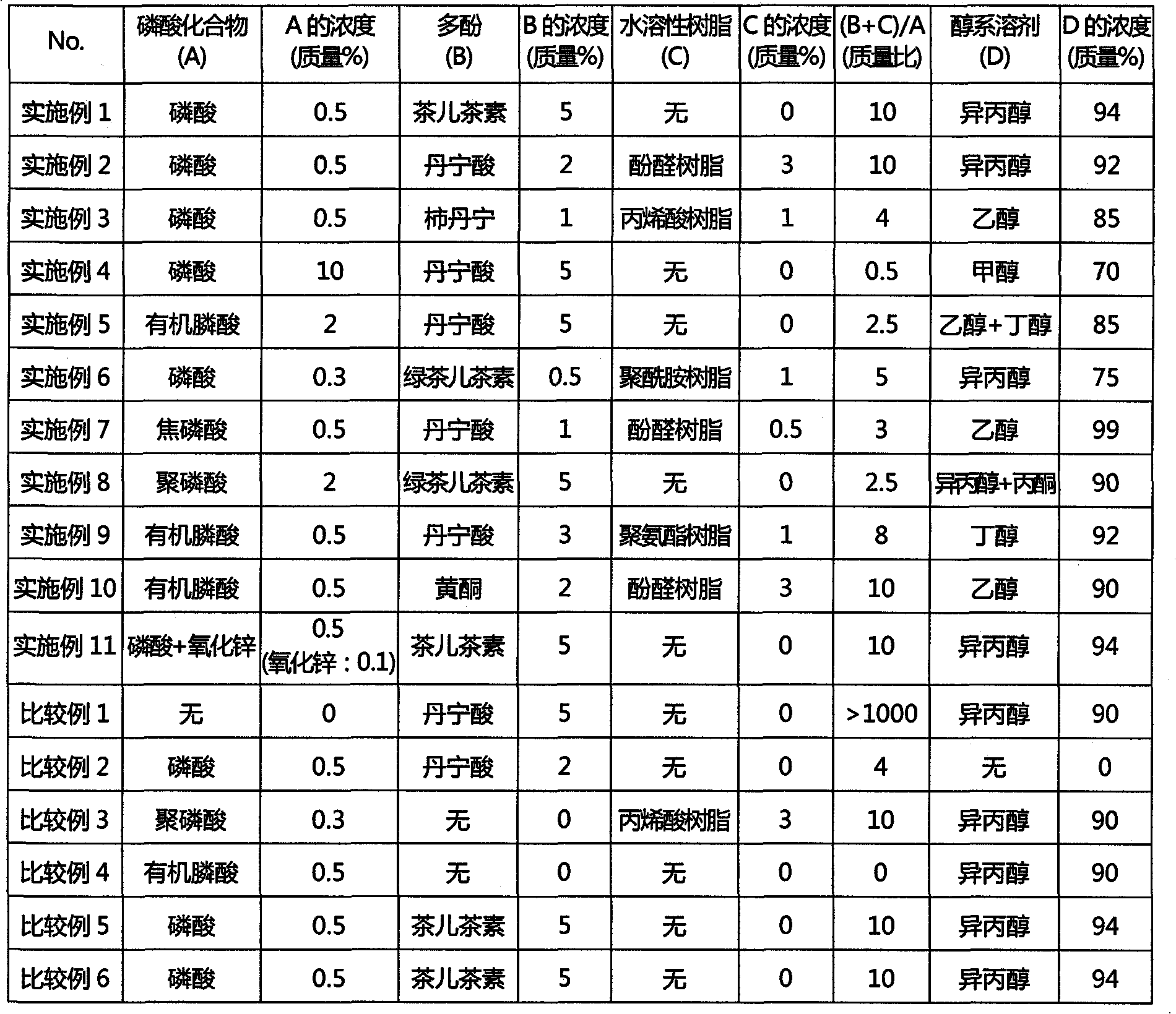

Embodiment 1~11

[0192] Magnet powder A was used directly without crushing. Magnet powder B was crushed to an average particle size of 50 μm with an organic solvent as a crushing solvent by a media stirring roller. Magnet powder C was similarly crushed to an average particle size of 70 μm. They were used as Magnet alloy powder for processing.

[0193] Next, add the coating treatment liquid containing phosphoric acid compound, polyphenol, alcohol solvent and water described in Table 1 to the above-mentioned alloy powder at a ratio of 15 g per 1 kg of magnet alloy powder, and stir with a mixer for 5 g. ~60 minutes to make a slurry. As the alcohol-based solvent, methanol, ethanol, isopropanol, butanol, and acetone are used alone or in combination. The residual solvent other than the alcoholic solvent is water.

[0194] Here, in Examples 2, 3, 6, 7, 9, and 10, a water-soluble resin was also added, and in Example 11, 2% by mass of zinc oxide was mixed with phosphoric acid instead of the water-sol...

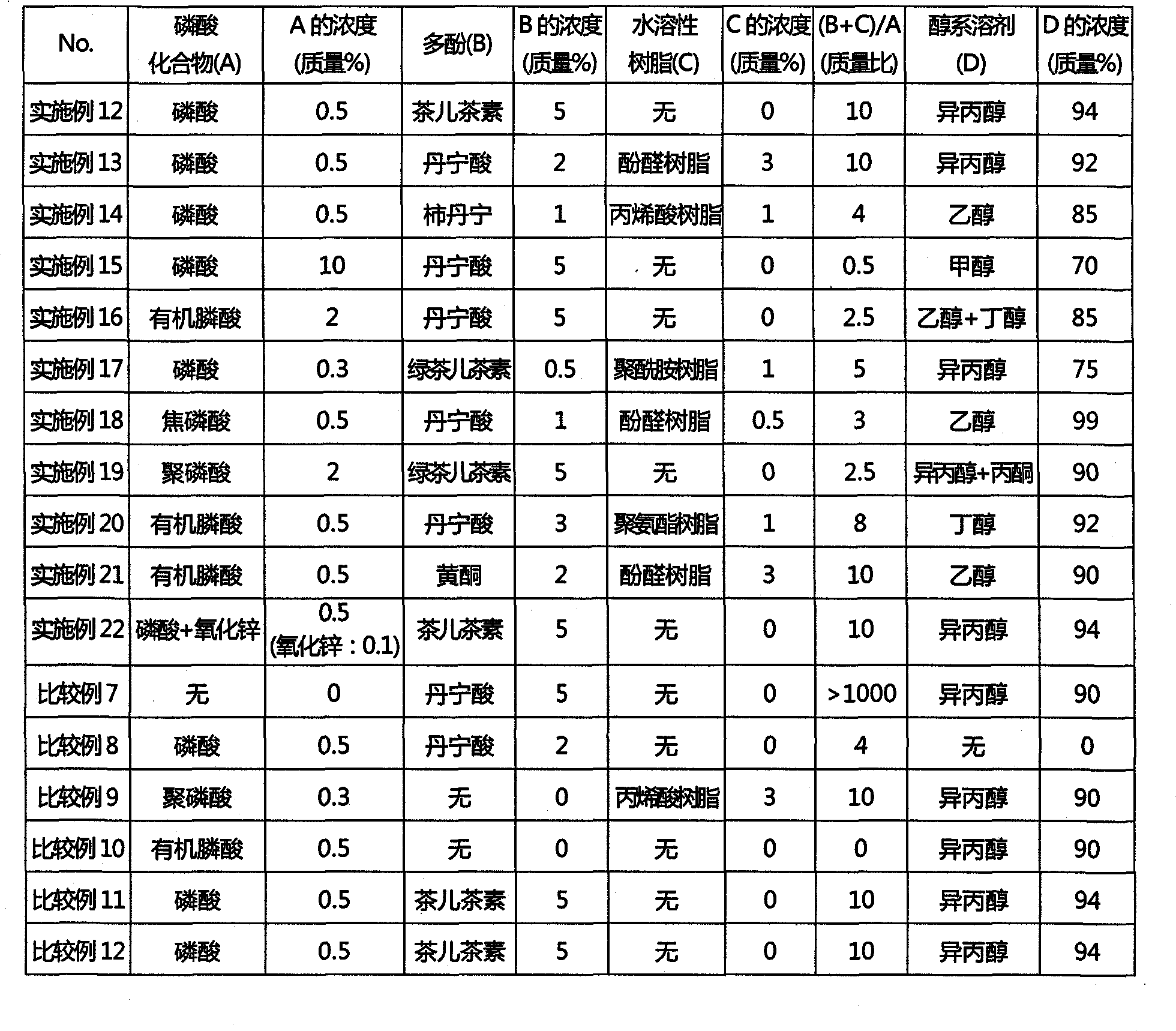

Embodiment 12~22

[0201] The magnet powder D was mixed with an organic solvent, put into a media agitation mill whose inside of the container was replaced with nitrogen, and pulverized to an average particle size of 3 μm to produce a magnet alloy powder.

[0202] Next, add the coating treatment solution containing phosphoric acid compound, polyphenol, alcohol solvent, and water described in Table 2 to the alloy powder at a ratio of 50 g per 1 kg of magnet alloy powder, and stir for 5 to 60 minutes. , to make it slurry. As the alcohol-based solvent, methanol, ethanol, isopropanol, butanol, and acetone are used alone or in combination. The residual solvent other than the alcoholic solvent is water.

[0203] Here, in Examples 13, 14, 17, 18, 20, and 21, a water-soluble resin was also added, and in Example 22, 2% by mass of zinc oxide was mixed with phosphoric acid instead of the water-soluble resin, and slurry was performed. . Then, the slurry was filtered, and the filtrate was put into a Hensc...

Embodiment 23~27

[0219] Magnet powders A to E shown in Table 5 were used alone or in combination, and injection-molded bonded magnets were prepared according to the method described in Evaluation of Salt Water Resistance. The molded body was coated to evaluate salt water resistance. In addition, the magnet powder D was pulverized by the same method as in Comparative Example 7, and used as a magnet alloy powder.

[0220] [table 5]

[0221]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com