Manufacturing method of stainless aluminum handle, product and module thereof

A production method and stainless aluminum technology, applied in the field of machinery, can solve the problems of easy corrosion cost, low mechanical strength, easy damage, etc., and achieve the effects of good corrosion resistance, long service life and fewer pinholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

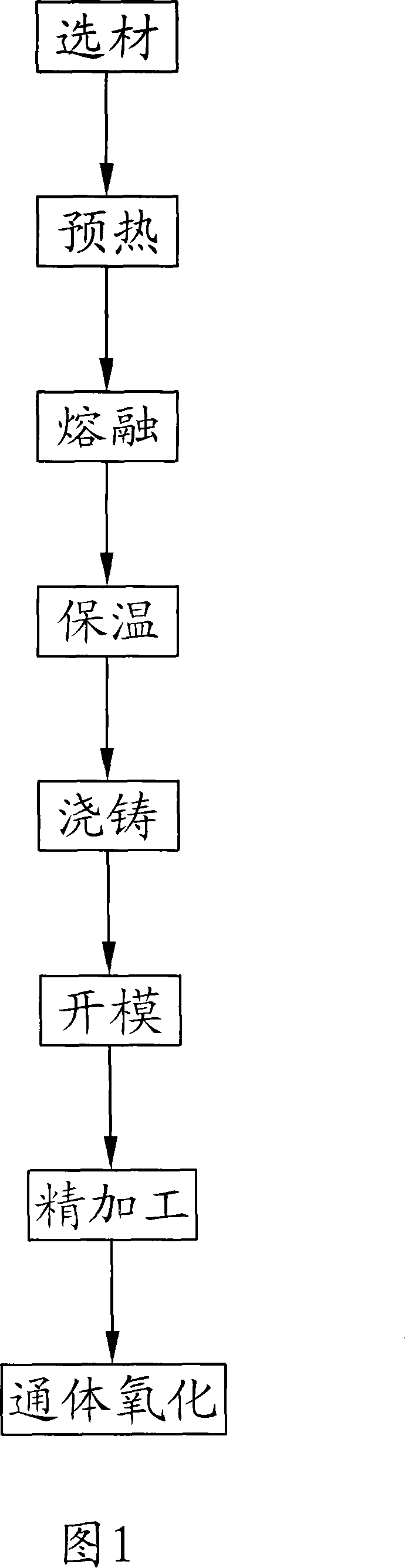

[0039] A. Material selection and melting: Select the stainless aluminum with the weight percentage composition of Example 1 in Table 1 as the raw material. First, preheat at a temperature of 300°C for 5 hours. The purpose of preheating is to remove moisture and oil stains in the stainless aluminum ;Before the raw materials are added to the electric furnace, the electric furnace is heated to 600°C to remove the moisture and other chemical substances adsorbed in the electric furnace, and then the raw materials are added to the electric furnace to melt, and after melting, they are kept at 500°C for 2 hours;

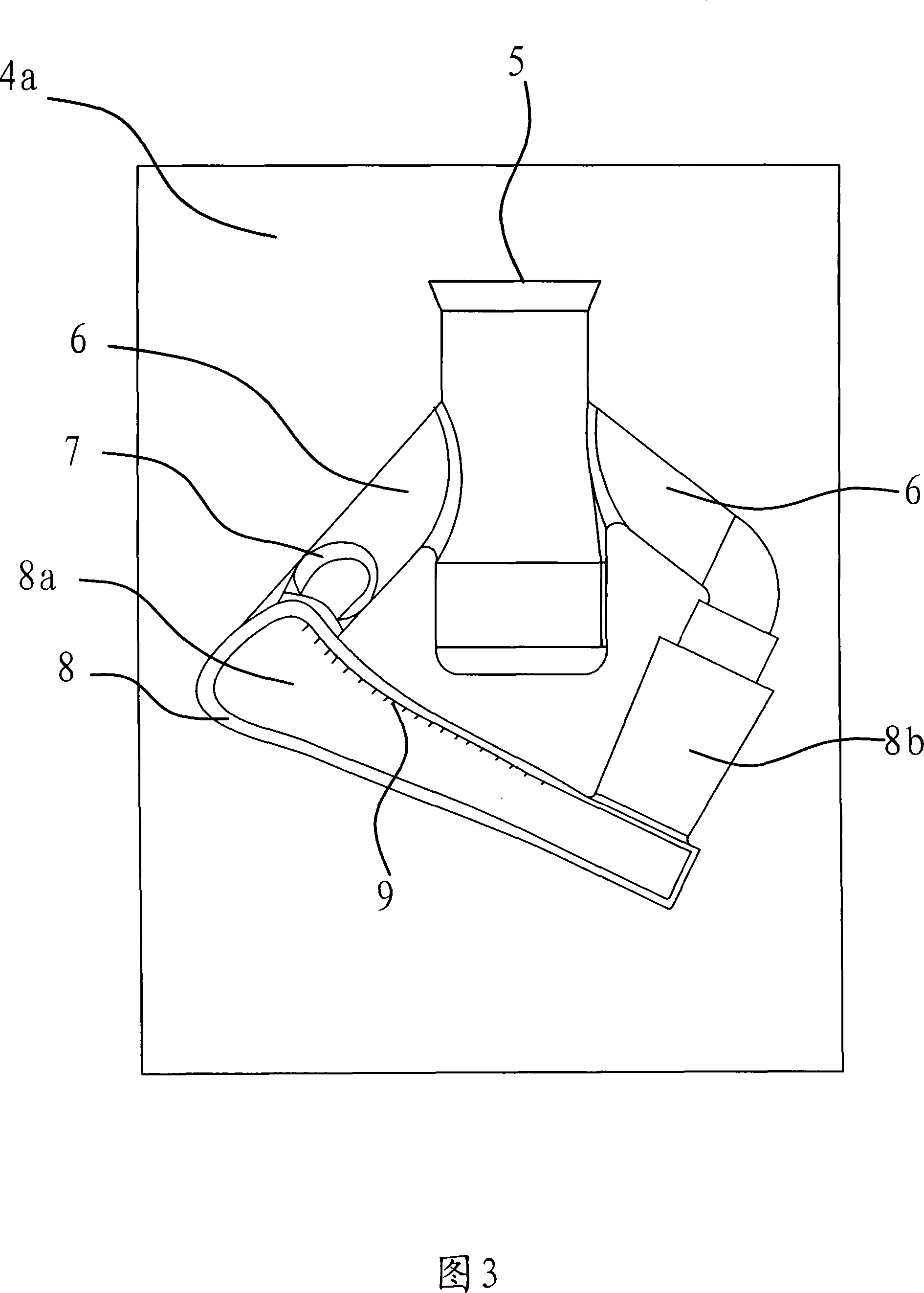

[0040] B. Casting: Cast the above-mentioned molten stainless aluminum material into the mold shown in Figure 3 and Figure 4, and remove hydrogen and other oxidized inclusions in the molten stainless aluminum material by nitrogen degassing, The degassing time is 8 minutes, after degassing and cooling at room temperature for 10 minutes, the mold is opened to make a stainless al...

Embodiment 2

[0043]A. Material selection and melting: Select the stainless aluminum with the composition of Example 2 weight percent in Table 1 as the raw material. First, preheat for 4 hours at a temperature of 400 ° C. The purpose of preheating is to remove moisture and oil stains in the stainless aluminum ;Before the raw materials are added to the electric furnace, the electric furnace is heated at a temperature of 750°C to remove the moisture and other chemical substances adsorbed in the electric furnace, and then the raw materials are added to the electric furnace to melt, and after melting, they are kept at 550°C for 1 hour;

[0044] B. Casting: Cast the above-mentioned molten stainless aluminum material into the mold shown in Figure 3 and Figure 4, and remove hydrogen and other oxidized inclusions in the molten stainless aluminum material by means of compound degassing, The compound used for degassing is 1Kg sodium chloride, which is directly poured into the molten stainless aluminum...

Embodiment 3

[0047] A. Material selection and melting: Select the stainless aluminum with the composition of Example 3 weight percent in Table 1 as the raw material, first preheat at a temperature of 450°C for 3 hours, the purpose of preheating is to remove moisture and oil stains in the stainless aluminum ;Before the raw materials are added to the electric furnace, the electric furnace is heated at a temperature of 850°C to remove the moisture and other chemical substances adsorbed in the electric furnace, and then the raw materials are added to the electric furnace to melt, and after melting, they are kept at 600°C for 0.5 hours;

[0048] B. Casting: Cast the above-mentioned molten stainless aluminum material into the mold shown in Figure 3 and Figure 4, and remove hydrogen and other oxidized inclusions in the molten stainless aluminum material by nitrogen degassing, The degassing time is 8 minutes, after degassing and cooling at room temperature for 30 minutes, the mold is opened to make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com