Riveted rolled plate type long large hose

A technology for riveting coils and flexible pipes, which is applied in the directions of hoses, pipes, pipes/pipe joints/fittings, etc., and can solve the problems of difficult construction, easy leakage and pollution, and high cost.

Inactive Publication Date: 2006-06-14

罗晓晖

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to overcome the shortcomings of the existing fluid transport facilities, which are easy to leak and pollute, difficult to construct, high cost, difficult to maintain and occupy a lot of land, the present invention provides a riveted roll-type flexible hose

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

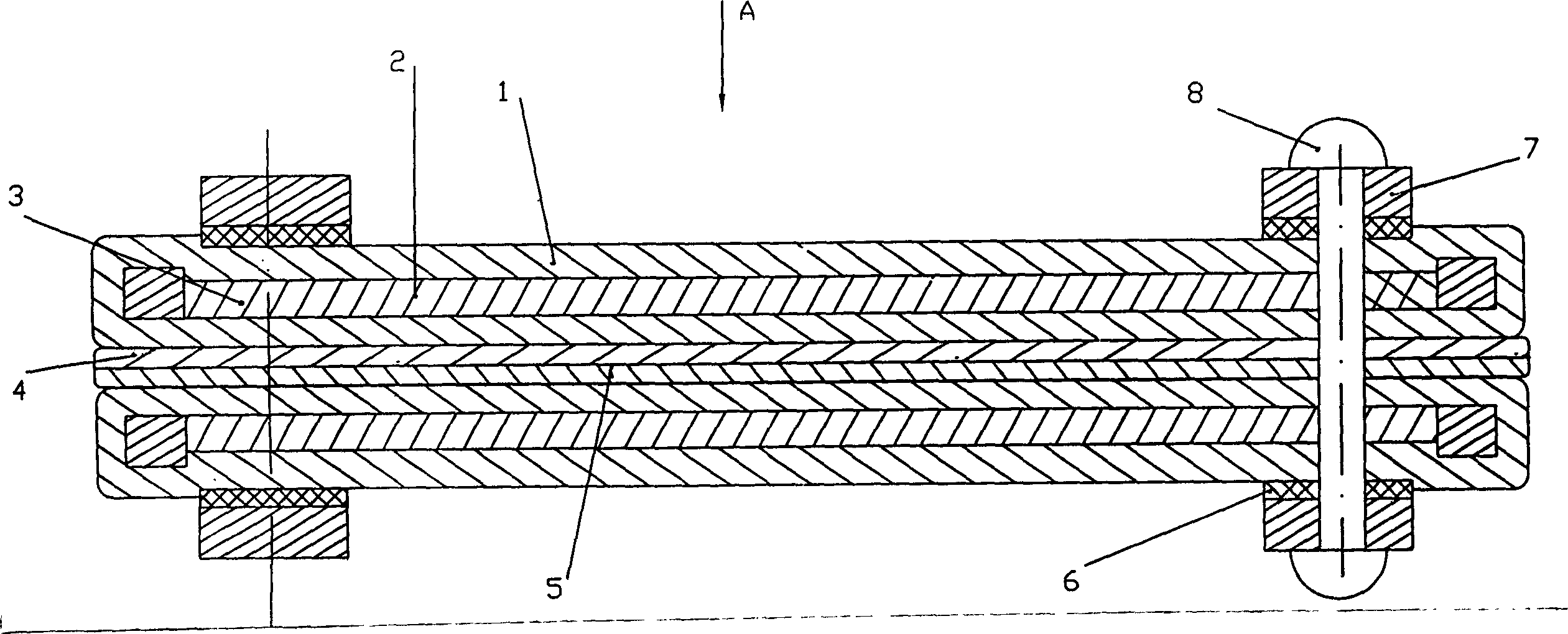

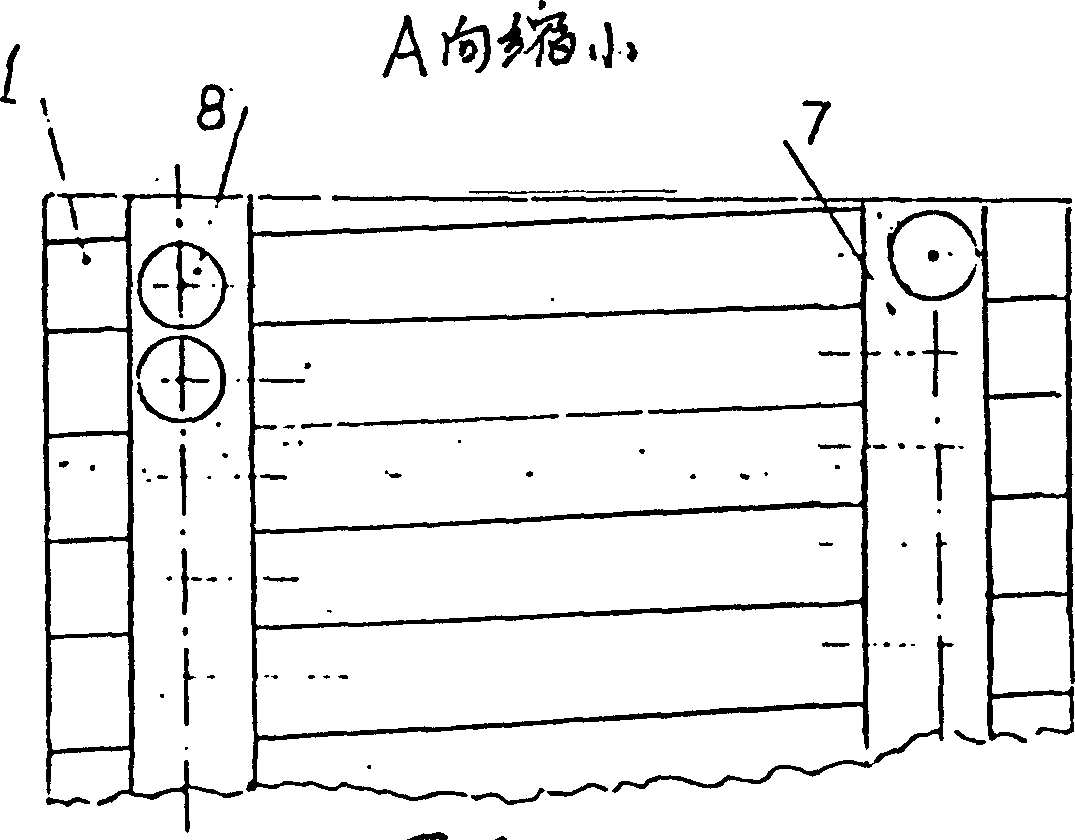

A riveted rolling-piece type long flexible pipe is adapted for flow guiding. It is made of cheap plastic and cloth and riveted to a long flexible pipe according to the need. It is also riveted to a large circumferential tank for storing oil-gas. The invention can be floating anchored on the water surface so that ití»s easy to find the fault.

Description

Technical field The invention is a new type of easy-to-use long flexible pipeline manufacturing method for fluid transmission, which is suitable for South-to-North water diversion, West-to-East gas transmission or sewage treatment. Background technique At present, hard pipes such as steel are mostly used for conveying fluid, and the diameter of the pipe is difficult to exceed 2 meters, and the length is difficult to exceed 20 meters. To be spliced into a person with sufficient length and large flow, there are a lot of interfaces. This hard interface is extremely difficult to align. Construction is difficult and expensive. It is also inevitable that it will be leaked, or even leaked into a disaster. Laying hard pipes requires a lot of earthwork, and they are often pierced by construction, threatening lives. In addition, the material of the hard tube is more expensive, and it is necessary to thicken the consumables in order to resist compression, bending and cracking. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16L11/00F16L11/02

Inventor 罗晓晖罗凤禧

Owner 罗晓晖

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com