Cable reinforcement core and production method thereof

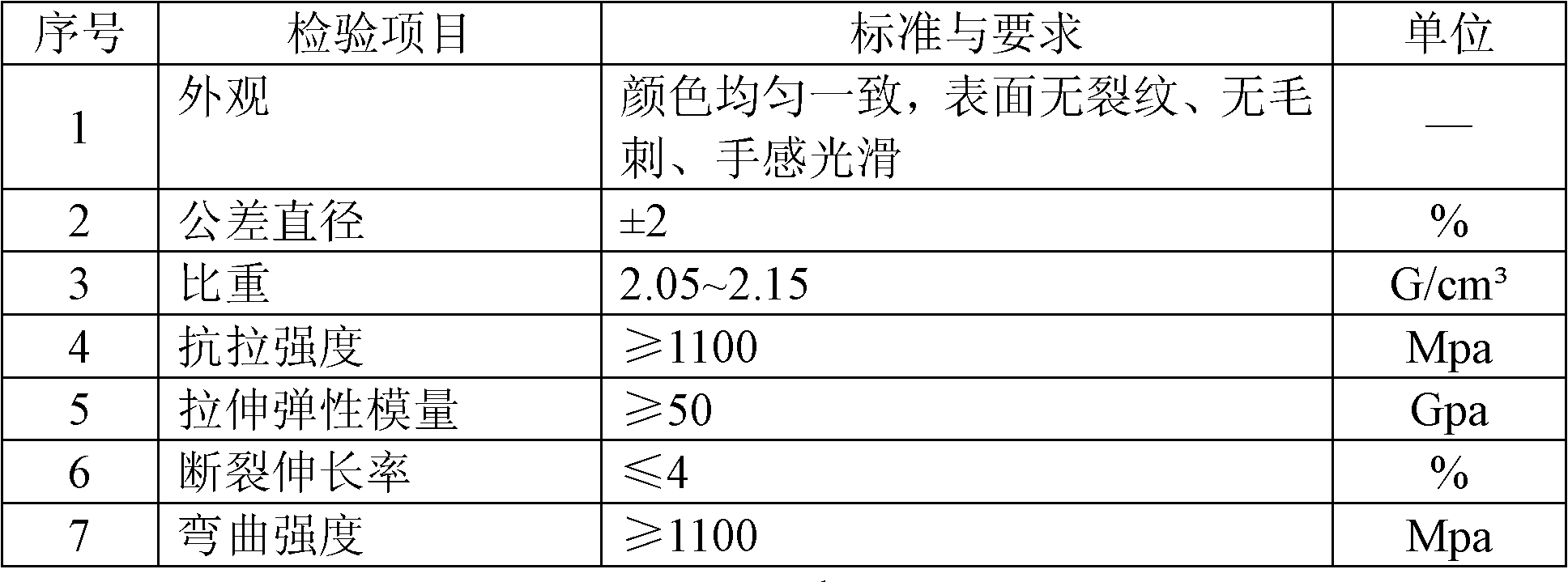

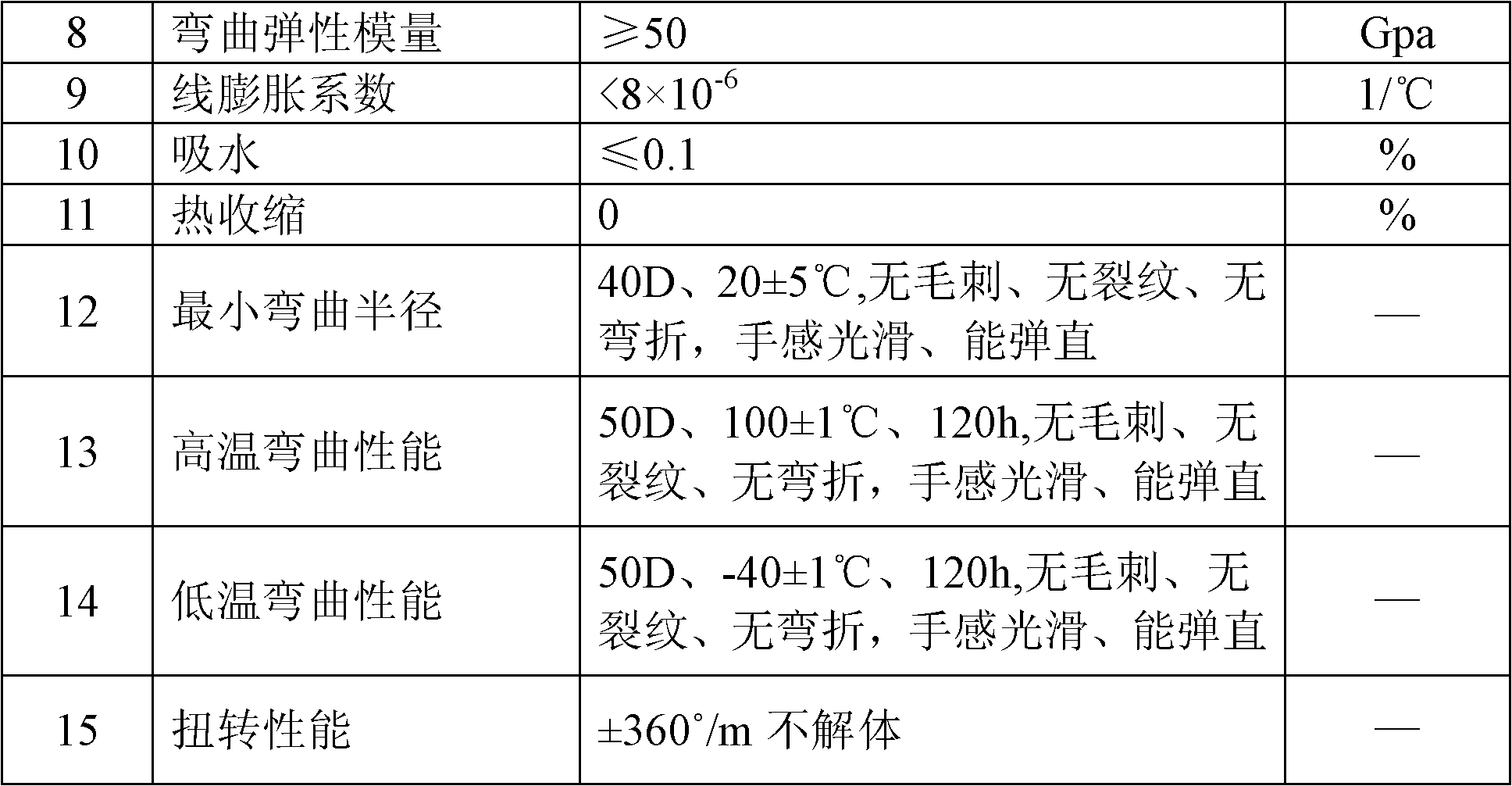

A technology of optical cable strengthening core and production method, applied in the direction of fiber mechanical structure, etc., can solve the problems of poor corrosion resistance of steel wire, hydrogen loss, affecting the performance of optical cable, etc., and achieve the effect of long service life and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] An optical cable strengthening core, the formula is as follows in parts by weight: 61 parts of glass fiber, 30 parts of epoxy vinyl ester resin, 6 parts of curing agent BPO, 2 parts of curing agent TBPB, 1 part of release agent PUL24 and 10 parts of filler .

[0017] The filler is light calcium carbonate. The glass fibers are alkali-free glass fibers with a density of 2.5 to 2.7 g / cm 3 .

[0018] A production method of an optical cable strengthening core, the steps are as follows in parts by weight:

[0019] (1) Preparation of resin mixture: put 30 parts of epoxy vinyl ester resin, 6 parts of curing agent BPO, 2 parts of curing agent TBPB, 1 part of release agent PUL24 and 10 parts of filler into the liquid tank, and stir Evenly, to obtain the resin mixture;

[0020] (2) Glass fiber plying: heat the mold to be used to 90°C, and take 61 parts of glass fiber plying into the required wire diameter;

[0021] (3) Preparation of fiber optic cable reinforcement core: take...

Embodiment 2

[0023] An optical cable strengthening core, the formula is as follows in parts by weight: 70 parts of glass fiber, 40 parts of epoxy vinyl ester resin, 5 parts of curing agent BPO, 3 parts of curing agent TBPB, 2 parts of release agent PUL24 and 8 parts of filler .

[0024] The filler is light calcium carbonate. The glass fibers are alkali-free glass fibers with a density of 2.5 to 2.7 g / cm 3 .

[0025] A production method of an optical cable strengthening core, the steps are as follows in parts by weight:

[0026] (1) Preparation of resin mixture: put 40 parts of epoxy vinyl ester resin, 5 parts of curing agent BPO, 3 parts of curing agent TBPB, 2 parts of release agent PUL24 and 8 parts of filler into the liquid tank, and stir Evenly, to obtain the resin mixture;

[0027] (2) Glass fiber plying: heat the mold to be used to 100°C, and take 70 parts of glass fiber plying into the required wire diameter;

[0028] (3) Preparation of fiber optic cable reinforcement core: tak...

Embodiment 3

[0030] An optical cable strengthening core, the formula is as follows in parts by weight: 80 parts of glass fiber, 20 parts of epoxy vinyl ester resin, 4 parts of curing agent BPO, 1 part of curing agent TBPB, 3 parts of release agent PUL24 and 12 parts of filler .

[0031] The filler is light calcium carbonate. The glass fibers are alkali-free glass fibers with a density of 2.5 to 2.7 g / cm 3 .

[0032] A production method of an optical cable strengthening core, the steps are as follows in parts by weight:

[0033] (1) Preparation of resin mixture: put 80 parts of epoxy vinyl ester resin, 4 parts of curing agent BPO, 1 part of curing agent TBPB, 3 parts of release agent PUL24 and 12 parts of filler into the liquid tank, and stir Evenly, to obtain the resin mixture;

[0034] (2) Glass fiber plying: heat the mold to be used to 100°C, and take 80 parts of glass fiber plying into the required wire diameter;

[0035] (3) Preparation of fiber optic cable reinforcement core: tak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com