Spiral nozzle used in controlled rolling and controlled cooling technology and spiral type water feeding method

A spiral nozzle, controlled rolling and controlled cooling technology, applied in the field of metal rolling, can solve the problems of easy corrosion and oxidation of the nozzle, unsatisfactory heat exchange effect between the cooling medium and the rolled piece, etc., to achieve potential mining, strong corrosion resistance and performance improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

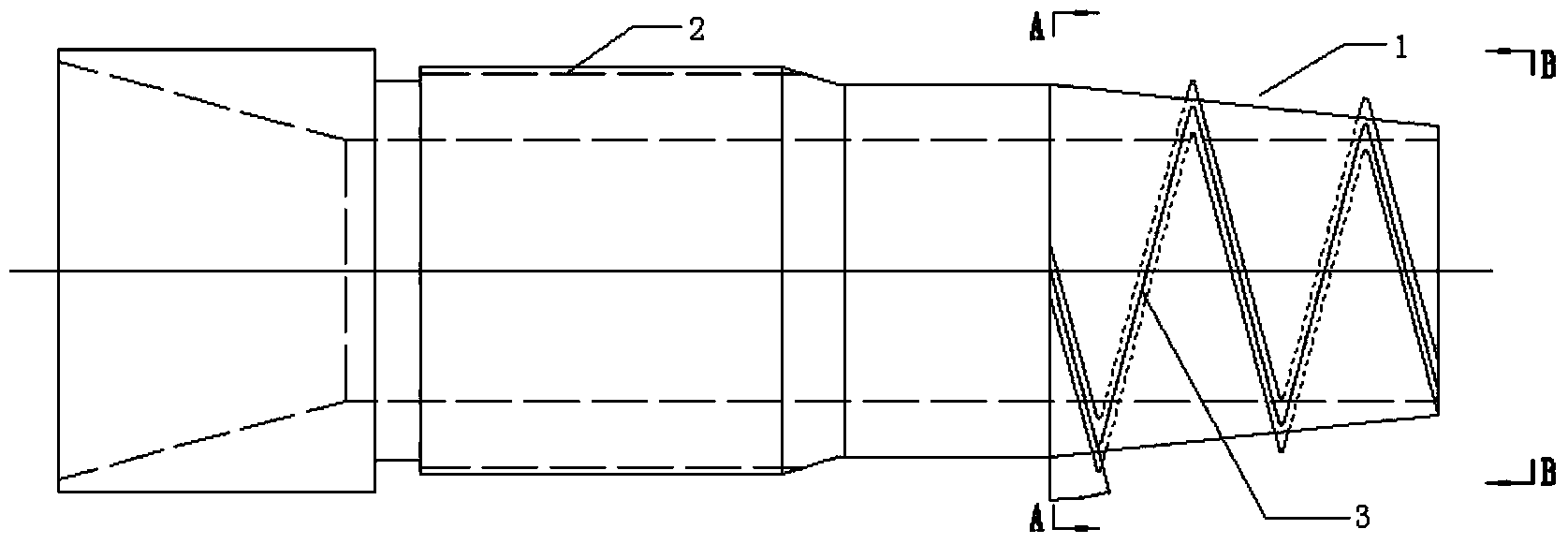

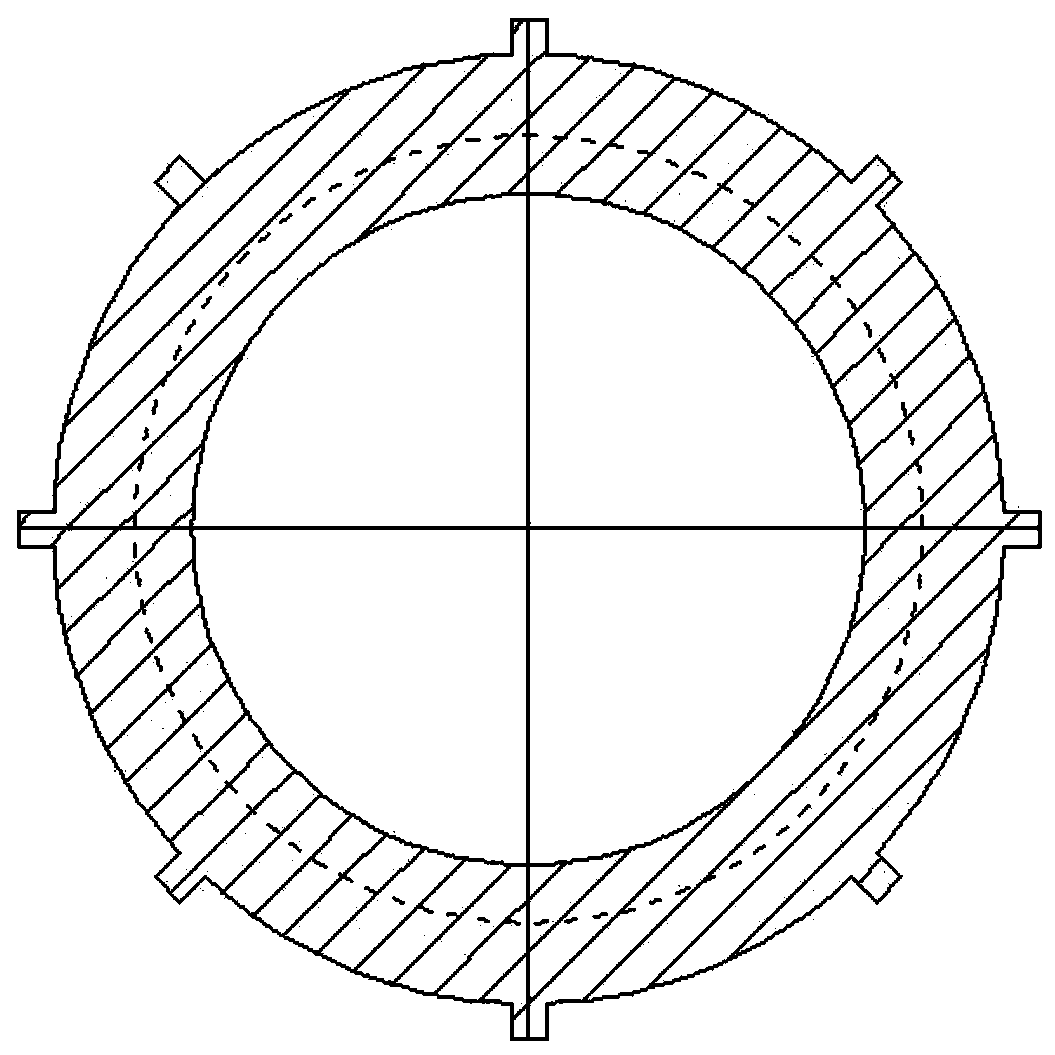

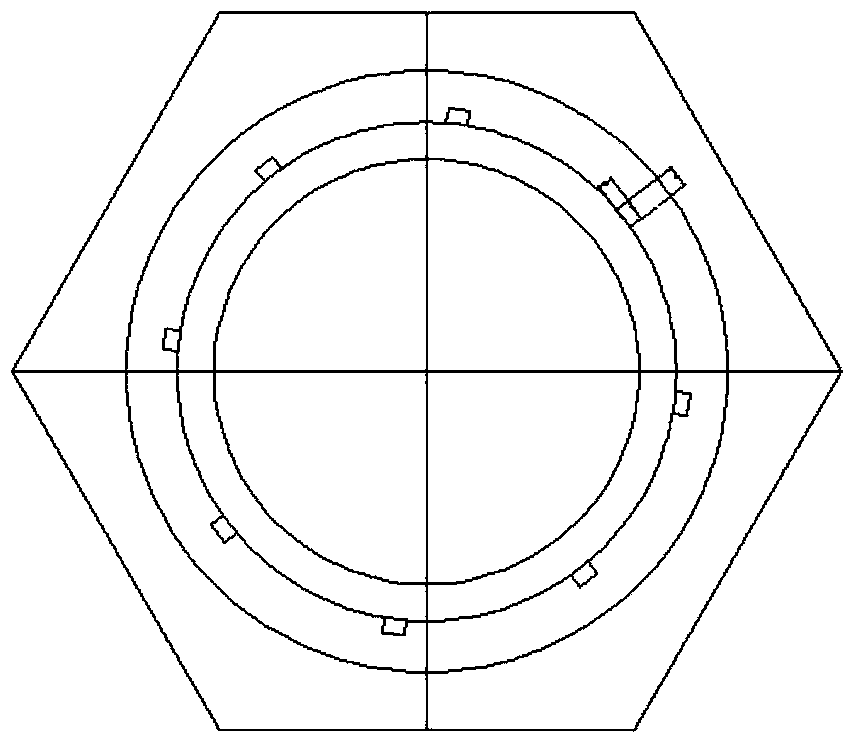

[0024] Such as figure 1 As shown, this embodiment provides a spiral nozzle 1 used in the controlled rolling and controlled cooling process, including a nozzle body 2 and an adjustable spiral annular seam 3 arranged along its circumference on the outer wall of the nozzle body. figure 2 and image 3 That is, the structure of the adjustable helical annular seam is illustrated.

[0025] Such as Figure 4 As shown, in practical applications, the spiral nozzle 1 is used in conjunction with the water supply chamber 4 and the turbulence pipe 5, the turbulence pipe 5 is placed on the connecting fixture 6, and the water supply chamber 4 is in communication with the inner cavity formed by the nozzle body , and the water su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com