Composite pulverized coal destructive distillation device and method

A technology of pulverized coal and dry distillation, applied in the field of coal chemical industry, can solve the problem of unsatisfactory mixing of heat carrier and pulverized coal, and achieve the effects of easy temperature control, strong adaptability, and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

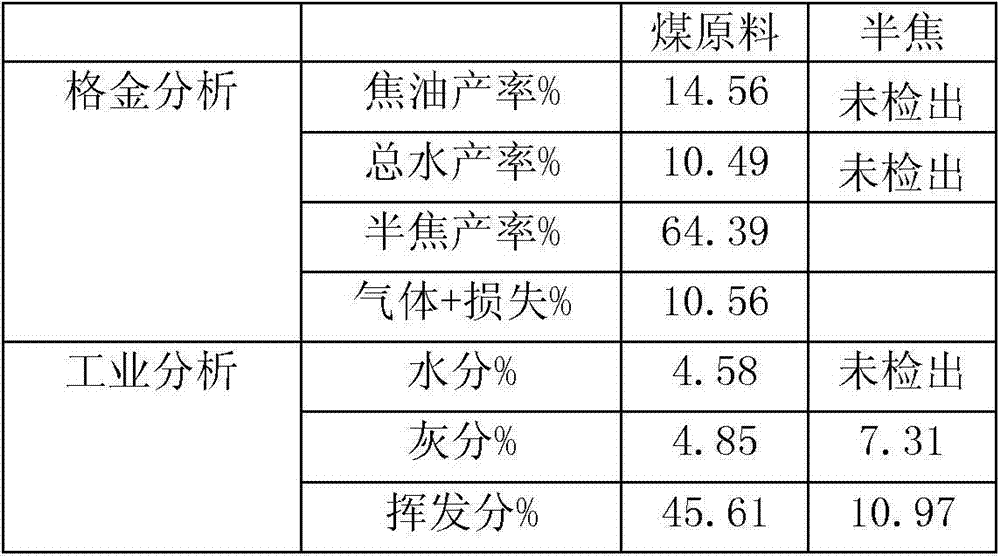

Examples

specific Embodiment approach 1

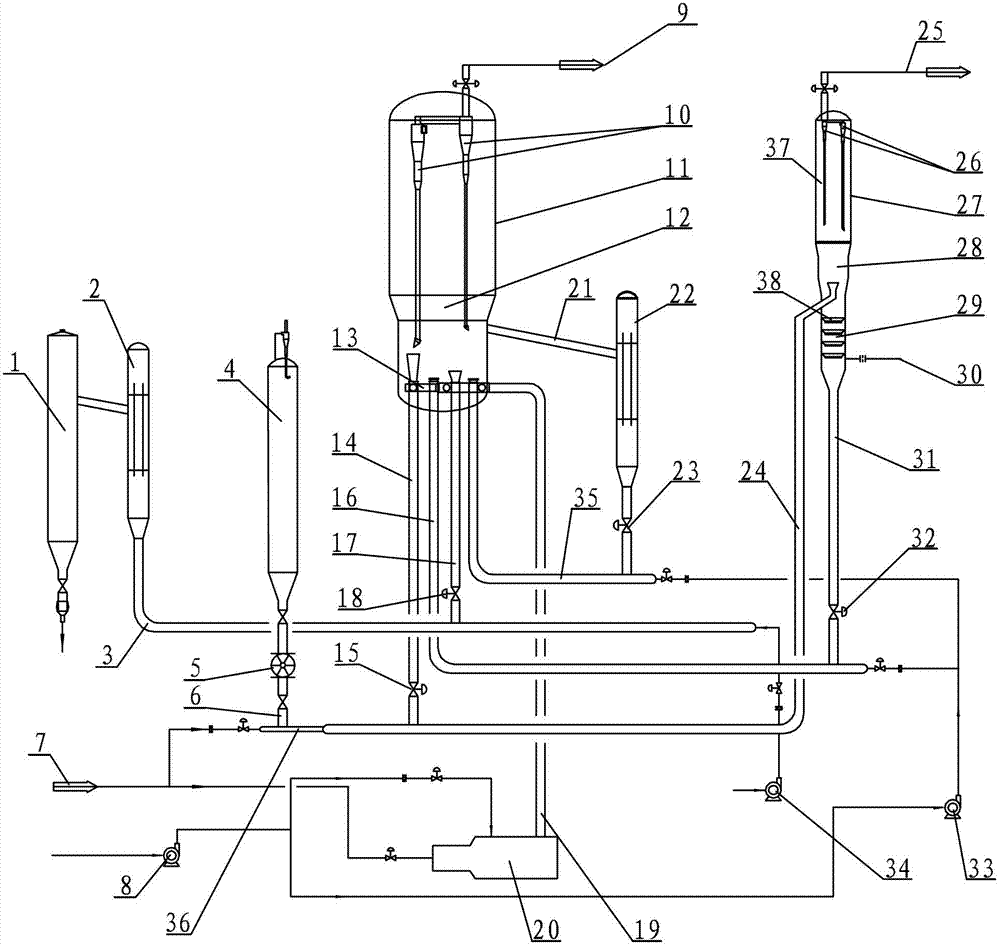

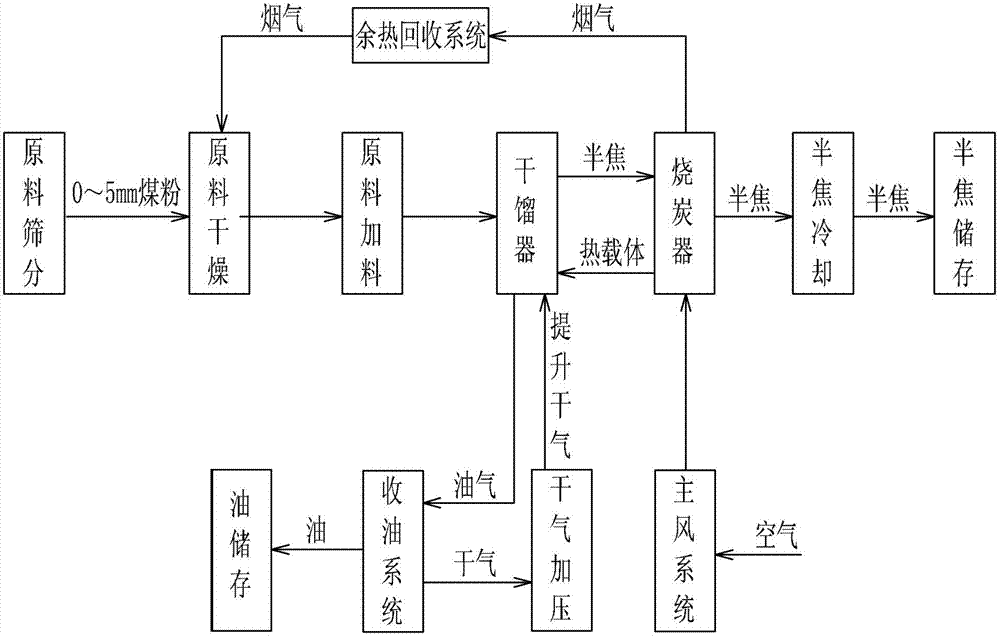

[0021] Specific implementation mode one: combine figure 1 with figure 2Describe this embodiment, which includes a semi-coke storage tank 1, a semi-coke cooler 2, a discharge pipe 3, a raw material tank 4, a feeder 5, a raw material pipe 6, a main fan 8, and a first multistage cyclone 10. Charcoal burner 11, dense phase bed of charcoal burner 12, main air distributor 13, heat carrier standpipe 14, semi-coke conveying pipe 16, discharge standpipe 17, main air pipe 19, auxiliary burner 20, semi-coke Inclined coke tube 21, heat extractor 22, riser reactor 24, second multistage cyclone 26, dry distillation reactor 27, semi-coke descending riser 31, supercharger 33, flue gas machine 34, heat extractor Pipe 35, dry gas inlet pipe 36 and stripping steamer 38, the first multi-stage cyclone 10 is arranged on the upper part in the charcoal burner 11, and the dense phase bed 12 of the charcoal burner is arranged in the middle part in the charcoal burner 11, The charcoal burner 11 uses ...

specific Embodiment approach 2

[0022] Specific implementation mode two: combination figure 1 This embodiment is described. The difference between this embodiment and the first embodiment is that it also adds a heat carrier slide valve 15 installed on the heat carrier standpipe 14 . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0023] Specific implementation mode three: combination figure 1 This embodiment is described. The difference between this embodiment and the first embodiment is that it also has a discharge slide valve 18 installed on the discharge standpipe 17 . Other compositions and connections are the same as those in Embodiment 1 or 2.

[0024] Specific implementation mode four: combination figure 1 This embodiment is described. The difference between this embodiment and the first embodiment is that it also adds a heat extraction slide valve 23 , and the heat extraction slide valve 23 is installed on the heat extractor 22 . Other components and connections are the same as those in the third embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com