Double-pipe heat exchanger

A heat exchanger, casing type technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problems of lack of production and application, achieve light weight, increased overall life, durable Corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

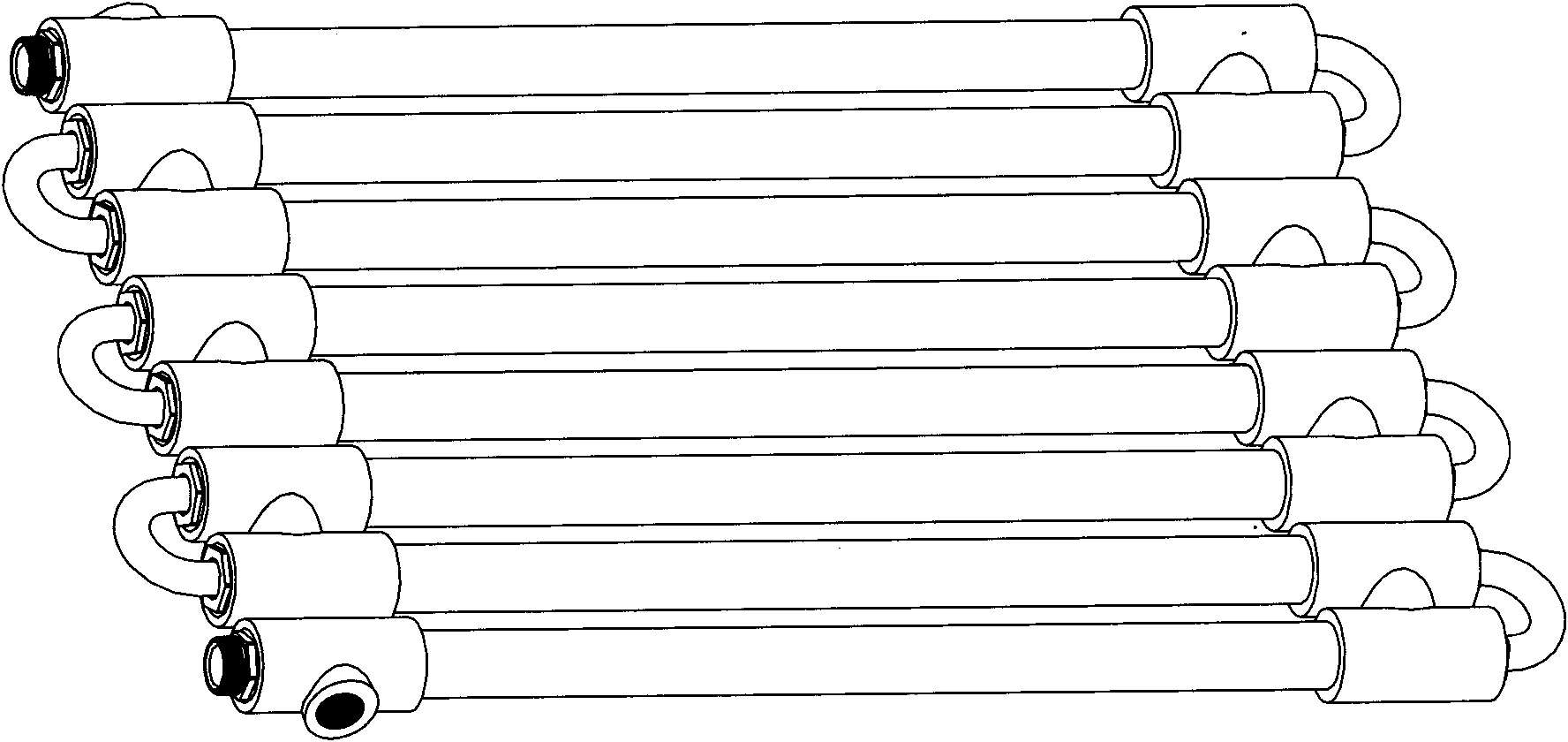

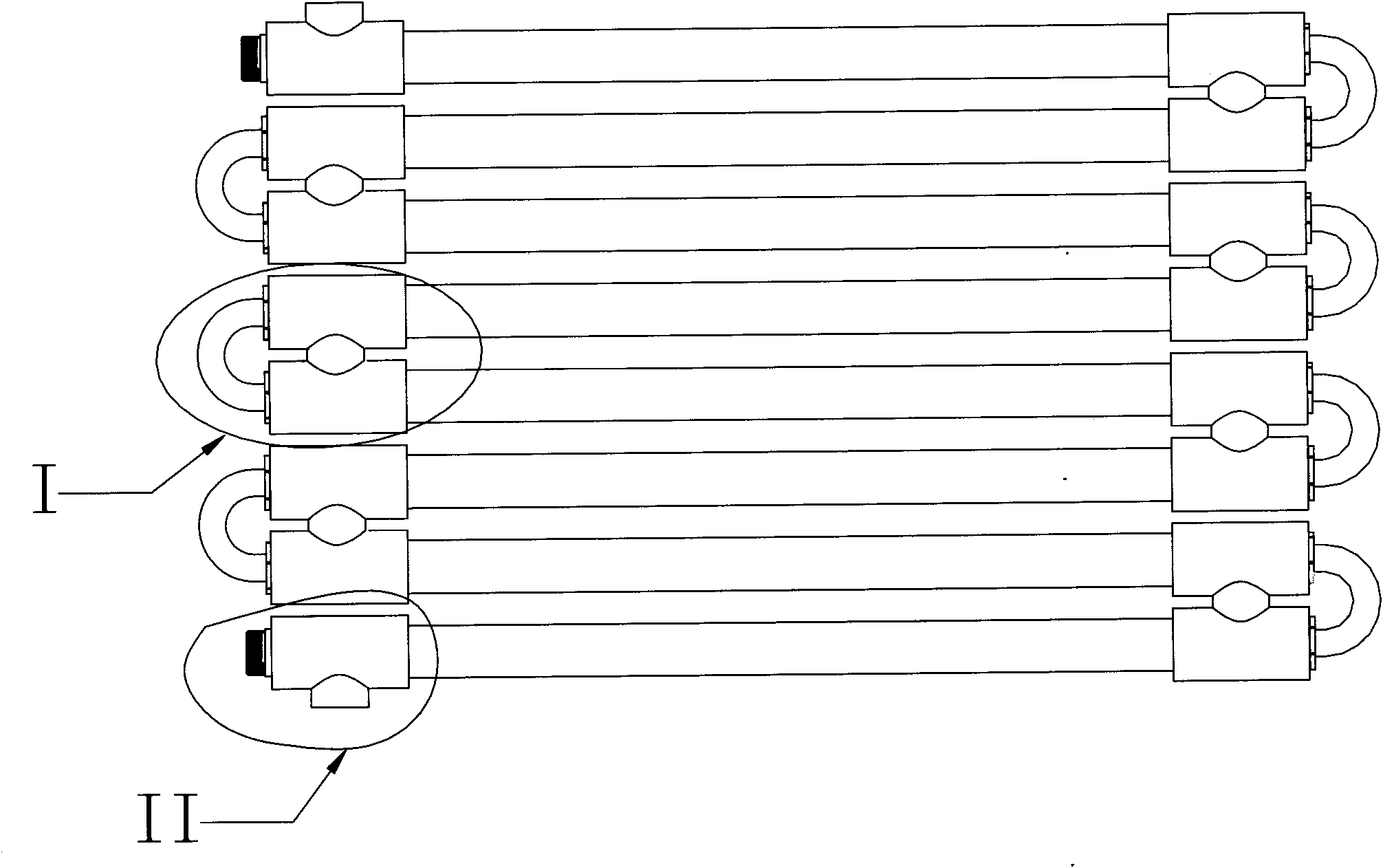

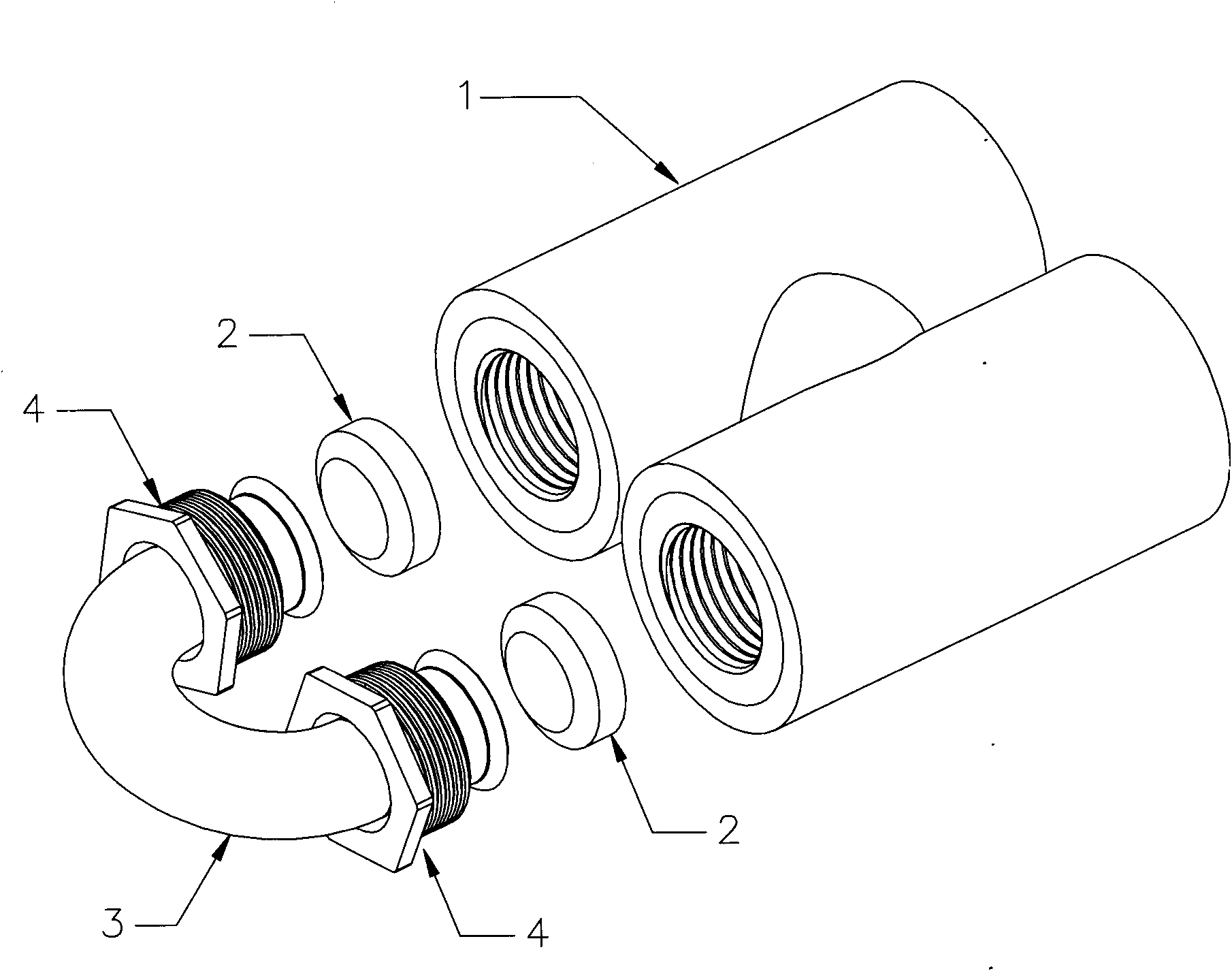

[0043] figure 1 It is a three-dimensional schematic diagram of a single-layer assembly example of the present invention, figure 2 It is a schematic plan top view of a single-layer assembly example, both of which can vividly illustrate the general structure of the present invention. image 3 , Figure 4 The three-dimensional schematic diagrams of the matching parts of the H-shaped cross and the T-shaped tee are respectively shown, and the principle and process of the assembly of the matching parts of the H-shaped cross and the T-shaped tee can be easily understood.

[0044] In this example, the metal inserts of the H-shaped cross and the T-shaped tee adopt the same internal thread insert, the side passage of the T-shaped tee also adopts the same internal thread metal insert, and the rubber sealing ring also adopts the same internal thread. Specifications, which can effectively reduce the types of materials, reduce manufacturing and management costs. In this example, the H-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com