Anti-retrogradation rice powder and preparation method thereof

A rice flour, anti-regeneration technology, applied in the field of food processing, can solve the problems of stiff food taste, enterprise loss, indigestion and divergence, etc., to achieve soft and delicate taste, maintain taste and smell, and maintain the effect of taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] The formula of the anti-retrogradation rice flour of the present embodiment is as follows:

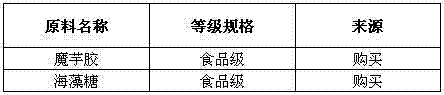

[0070] 100 kg of modified rice flour, 1 kg of konjac gum, and 0.8 kg of trehalose, wherein 1 kg equals 1 part by weight in this embodiment.

[0071] Above-mentioned modified rice flour is modified through the following steps:

[0072] (1) Cleaning: Clean the rice to remove impurities such as floating dust, bran and sand on the surface of the rice;

[0073] (2) Soaking: Soak the rice washed in (1) in 0.5% lactic acid solution, the mass-to-liquid ratio of rice to lactic acid solution is 1:2, the soaking temperature is room temperature, and the soaking time is 3 hours;

[0074] (3) Refining: use a refiner to refine the rice and lactic acid solution soaked in (2) into rice milk;

[0075] (4) Micronization: use a colloid mill to micronize the rice pulp after (3) refining, the processing time is 4 minutes, and the particle size of the rice pulp after the micronization treatment is 1...

Embodiment 2

[0083] The formula of the anti-retrogradation rice flour of the present embodiment is as follows:

[0084] Modified rice flour 100kg, konjac gum 2.5kg, trehalose 0.5kg.

[0085] Above-mentioned modified rice flour is modified through the following steps:

[0086] (1) Cleaning: Clean the rice to remove impurities such as floating dust, bran and sand on the surface of the rice;

[0087] (2) Soaking: Soak the rice cleaned by (1) in 0.3% lactic acid solution, the mass-to-liquid ratio of rice to lactic acid solution is 1:2, the soaking temperature is room temperature, and the soaking time is 5 hours;

[0088] (3) Refining: use a refiner to refine the rice and lactic acid solution after soaking in (2) into rice milk;

[0089] (4) Micronization: use a colloid mill to micronize the rice pulp after (3) refining, the processing time is 6 minutes, and the particle size of the rice pulp after the micronization treatment is 10-30 μm;

[0090] (5) Neutralization: Add solid sodium bicarbo...

Embodiment 3

[0097] The formula of the anti-retrogradation rice flour of the present embodiment is as follows:

[0098] Modified rice flour 100kg, konjac gum 1.5kg, trehalose 1kg.

[0099] Above-mentioned modified rice flour is modified through the following steps:

[0100] (1) Cleaning: Clean the rice to remove impurities such as floating dust, bran and sand on the surface of the rice;

[0101] (2) Soaking: Soak the rice washed in (1) in 0.4% lactic acid solution, the mass-to-liquid ratio of rice to lactic acid solution is 1:2, the soaking temperature is 20±0.5°C, and the soaking time is 4h;

[0102] (3) Refining: use a refiner to refine the rice and lactic acid solution after soaking in (2) into rice milk;

[0103] (4) Micronization: use a colloid mill to micronize the rice pulp after (3) refining, the processing time is 5 minutes, and the particle size of the rice pulp after the micronization treatment is 10-30 μm;

[0104] (5) Neutralization: Add solid sodium bicarbonate to the ric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com