Low alkane-to-olefin catalyst by dehydrogenation and preparation method

A catalyst and a technology for producing olefins, which are applied in the field of catalyst and catalyst preparation to achieve good environmental protection advantages, increase electron cloud density, and reduce surface acidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

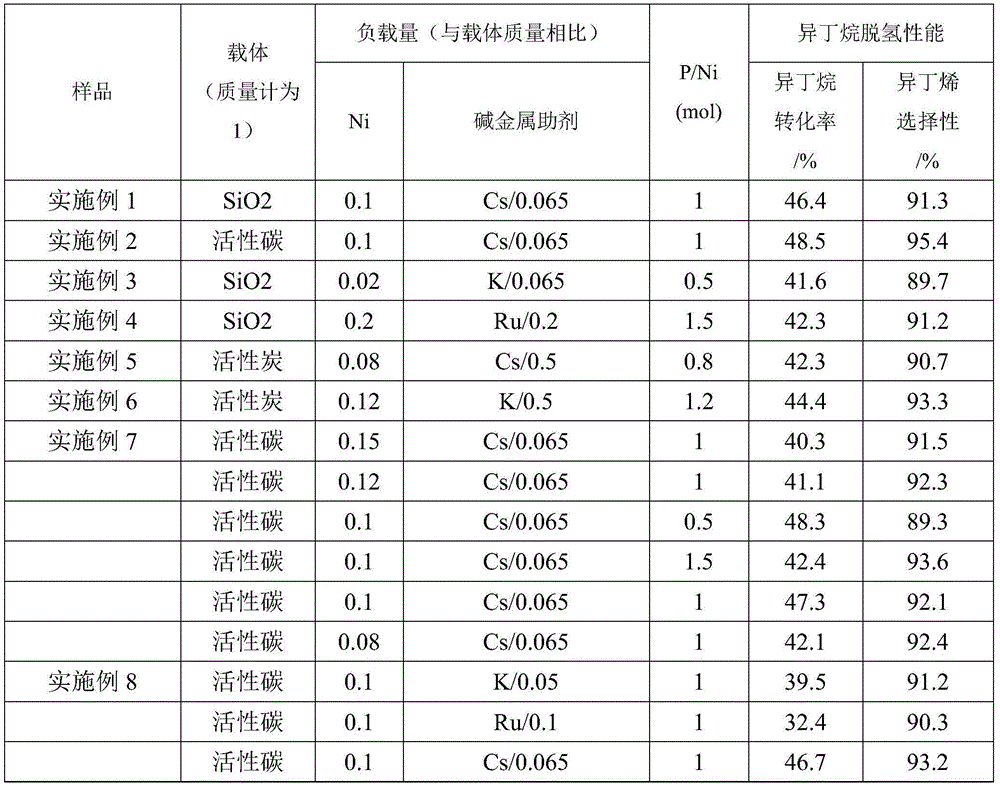

Embodiment 1

[0032] A preparation method of a low-carbon alkane dehydrogenation olefin catalyst, comprising the steps of:

[0033] (1) Take 10gSiO2 2 Pellets, dried at 200°C for 12 hours; 10g SiO 2 The saturated water absorption of the pellet is 10ml; SiO 2 The specific surface area of the ball is 500m 2 / g, particle size is 2mm;

[0034] (2) 4.955gNi(NO 3 )·6H 2 O, 1.96gNH 4 h 2 PO 4 with 0.95gCsNO 3 Add 10ml of water to obtain a mixed solution, SiO 2 The pellets are immersed in the mixed solution;

[0035] (3) shaking for 4 hours, standing for 4 hours, drying at 120°C for 12 hours, and calcining for 4 hours at 500°C under a nitrogen atmosphere to obtain a catalyst precursor;

[0036] (4) Take 0.5g of the catalyst precursor, put it into a stainless steel fixed-bed reactor with an inner diameter of 8mm, and then raise the temperature to 700°C at a heating rate of 2°C / min under a hydrogen flow of 50mL / min, and then raise the temperature to 700°C. After constant temperature red...

Embodiment 2

[0039] A preparation method of a low-carbon alkane dehydrogenation olefin catalyst, comprising the steps of:

[0040] (1) Take 10g of activated carbon pellets and dry them at 200°C for 12 hours; the saturated water absorption of 10g of activated carbon pellets is 8ml; the specific surface area of activated carbon pellets is 1200g / m 2 , the particle size is 2mm;

[0041] (2) 4.955gNi(NO 3 )·6H 2 O, 1.96gNH 4 h 2 PO 4 with 0.95gCsNO 3 Add 8ml of water to obtain a mixed solution, and soak the activated carbon pellets in the mixed solution;

[0042] (3) shaking for 4 hours, standing for 4 hours, drying at 120°C for 12 hours, and calcining for 4 hours at 500°C under a nitrogen atmosphere to obtain a catalyst precursor;

[0043] (4) Take 0.5g of the catalyst precursor, put it into a stainless steel fixed-bed reactor with an inner diameter of 8mm, and then raise the temperature to 700°C at a heating rate of 2°C / min under a hydrogen flow of 50mL / min, and then raise the temper...

Embodiment 3

[0046] A preparation method of a low-carbon alkane dehydrogenation olefin catalyst, comprising the steps of:

[0047] (1) 10gSiO 2 Dry the pellets at 150°C for 16 hours; 10g SiO 2 The saturated water absorption of the ball is 8ml; SiO 2 The specific surface area of the pellet is 300g / m 2 , the particle size is 1mm;

[0048] (2) Add nickel nitrate, ammonium dihydrogen phosphate and potassium nitrate to SiO 2 The ball is saturated in water with water absorption, and a mixed solution is obtained, and the SiO 2 The pellets are immersed in the mixed solution, the SiO 2 The mass ratio of pellets, Ni and potassium is 1:0.02:0.01, and the P / Ni molar ratio is 0.5;

[0049] (3) shaking for 1 hour, standing for 2 hours, drying at 80°C for 48 hours, and calcining for 2 hours at 400°C under a nitrogen atmosphere to obtain a catalyst precursor;

[0050] (4) The catalyst precursor was heated to 500°C at a heating rate of 1°C / min under a hydrogen flow of 20mL / min, and was reduced at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com