High-efficiency hydrate inhibitor containing corrosion inhibitor

A hydrate inhibitor and corrosion inhibitor technology, used in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc. Coalescence and other problems, to achieve the effect of overcoming corrosion, protecting pipelines, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

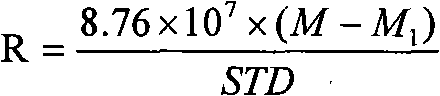

Method used

Image

Examples

Embodiment 1

[0052] Experimental steps and conditions such as comparative example, add 150mL crude oil sample in reactor, in crude oil sample, add inhibitor of the present invention, wherein the weight ratio of span20 and water in crude oil sample is 0.5%, the weight ratio of sodium chloride and water It is 12%, and the weight ratio of cinnamaldehyde and water is 20ppm. The initial temperature of the reaction was set at 3°C, and gas (CH 4 91.05%, C 2 h 6 6.05%, C 3 h 8 2.90%), make the pressure reach 6MPa, open the magnetic stirrer and start the reaction. By magnetic stirring, it was found that hydrates were formed, and the pressure reached 4.7 MPa. After the reaction, it was measured that the hydrates started to form in 170 minutes, and the hydrates were completely formed in 400 minutes. Comparing the test results with Comparative Examples 2 and 4, the results show that the combined use of 0.5% Span20 (sorbitan monolaurate) and 12% sodium chloride significantly prolongs the formation...

Embodiment 2

[0054] In reactor, add 150mL crude oil sample, in crude oil sample, add inhibitor of the present invention, wherein the weight ratio of water in Span20 (sorbitan monolaurate) and crude oil sample is 1%, the weight ratio of magnesium chloride and water is 8%, the weight ratio of cinnamaldehyde to water is 15ppm; the experimental steps and conditions are as in Example 1, it can be found that hydrate is formed by magnetic stirring, the pressure reaches 4.6MPa, the hydrate formation time is 160min, and the hydrate complete formation time is 410min. The results show that the inhibitor of the present invention has obvious inhibitory and anti-polymerization effects.

Embodiment 3

[0056] Add 150mL crude oil sample in reactor, in crude oil sample, add inhibitor of the present invention, wherein the weight ratio of span20 (sorbitan monolaurate) and water in crude oil sample is 0.05%, calcium chloride and crude oil sample The weight ratio of water is 25%, and the weight ratio of cinnamaldehyde and water in the crude oil sample is 15ppm; Experimental procedure and condition are as embodiment 1, and reaction initial temperature is set as 3 ℃, feeds gas (CH 4 91.05%, C 2 h 6 6.05%, C 3 h 8 2.90%), make the pressure reach 6MPa, open the magnetic stirrer and start the reaction. It can be found that hydrate is formed by magnetic stirring, the pressure reaches 4.8MPa, the hydrate formation time is 190min, and the hydrate complete formation time is 350min. The results show that the inhibitor of the present invention has obvious inhibitory and anti-polymerization effects.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion rate | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com