Carbon-free high-purity aluminum magnesium machine pressing brick for refining steel ladles as well as preparation method thereof

A high-purity, ladle technology, applied in the field of refractory materials for steelmaking, can solve the problems of inconvenient production management, low bulk density, and large fluctuations affected by environmental factors, and achieve excellent medium and high temperature strength and thermal shock stable phase, high The effect of green body strength, excellent resistance to slag erosion and penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

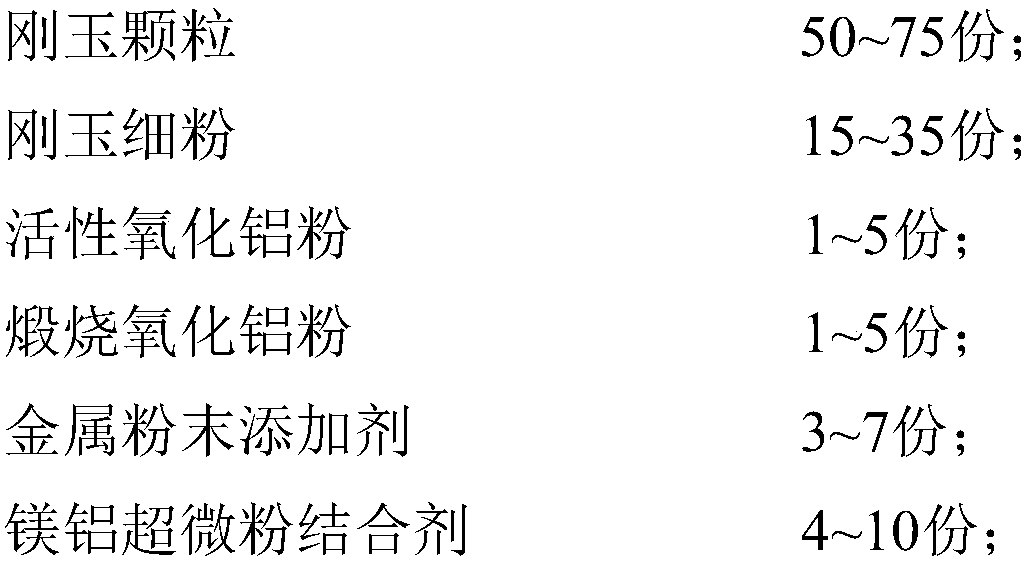

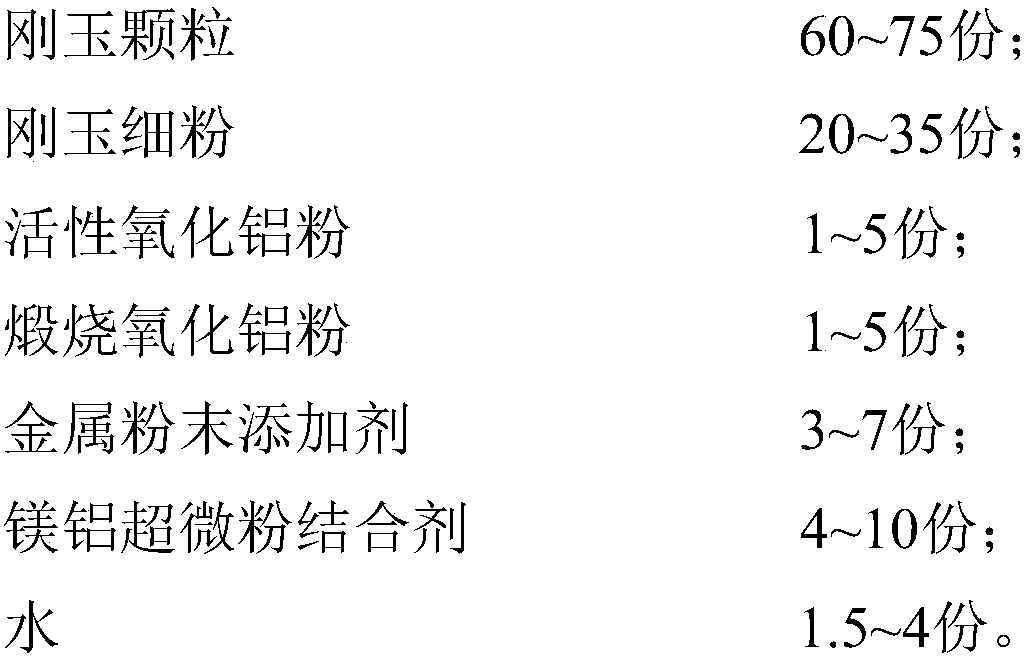

Method used

Image

Examples

Embodiment 1~5

[0051] The preparation methods of carbon-free high-purity aluminum-magnesium press bricks in each embodiment are as follows:

[0052] 1) Burn MgO and ρ-Al 2 O 3 Co-milling in a high-energy ball mill to lightly burn MgO and ρ-Al 2 O 3 The weight ratio is 2:1, the rotating speed of the ball mill is 250r / min, and the ball milling time is 3h to obtain the magnesium-aluminum superfine powder binder. The particle size is <0.5μm.

[0053] The chemical composition and mass percentage of light burned MgO are MgO≥90.00wt%, SiO 2 ≤3.00%, Fe 2 O 3 ≤0.60%, CaO≤2.00%, IL (loss on ignition)≤5.00%.

[0054] ρ-Al 2 O 3 The chemical composition and mass percentage are Al 2 O 3 ≥90.00wt%, Na 2 O≤0.50%, IL≤7.00%.

[0055] 2) The raw materials of the carbon-free high-purity aluminum-magnesium press bricks, such as aggregates, fine powder, binder and water, are mixed uniformly and pressed into a green body, and then the green body is baked at 200 ℃ for 10 hours. Get carbon-free high-purity aluminum-magnesi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com