Ceramic-base high-strength lightweight buoyancy material

A buoyancy material, ceramic-based technology, applied in the field of preparation of new ceramic-based high-strength light-weight buoyancy materials, can solve the problems of ceramic ball damage, cracking and bursting since the 1980s, and achieve strong seawater corrosion resistance, The effect of uniform distribution of pores and small volumetric water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

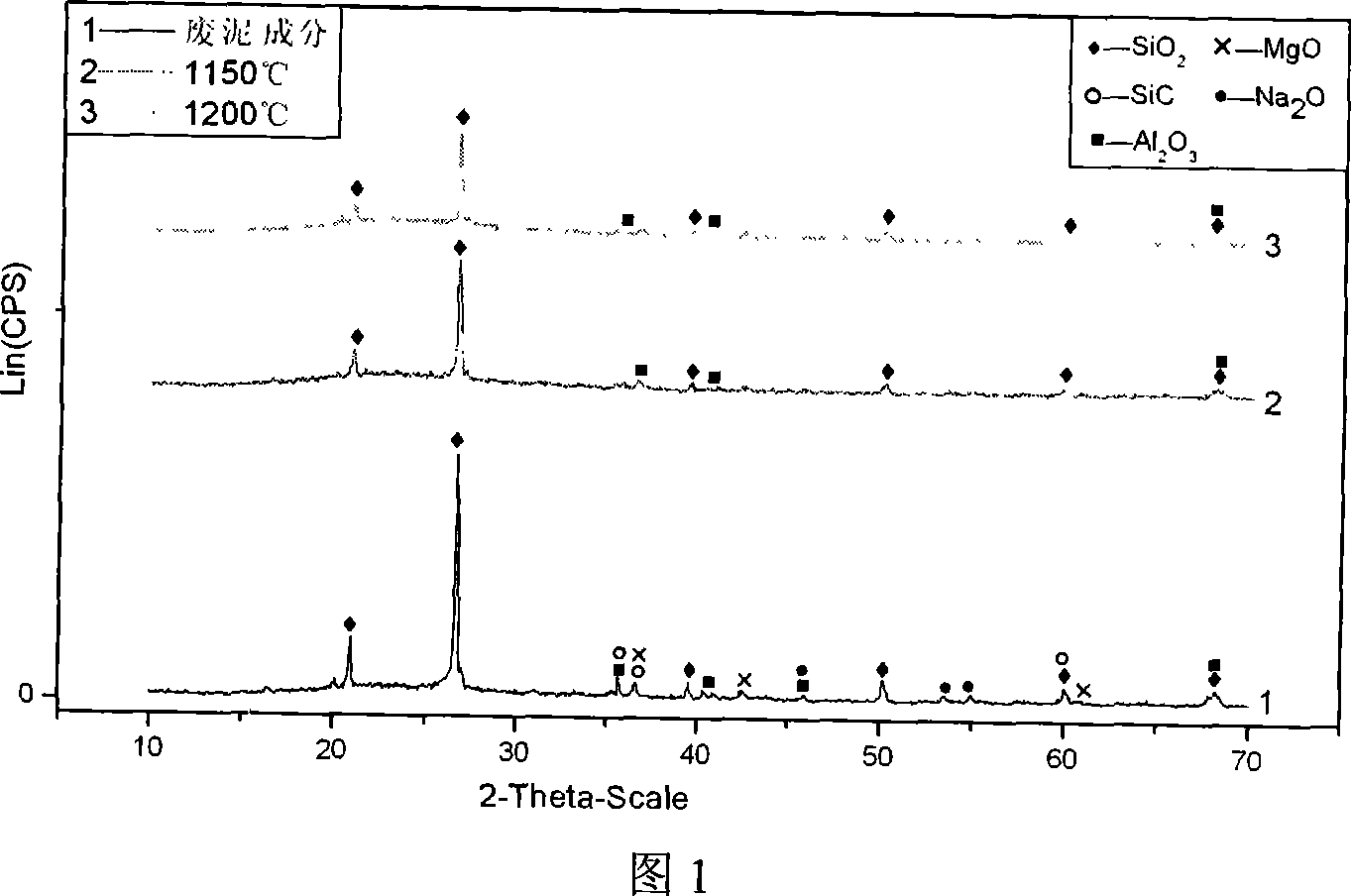

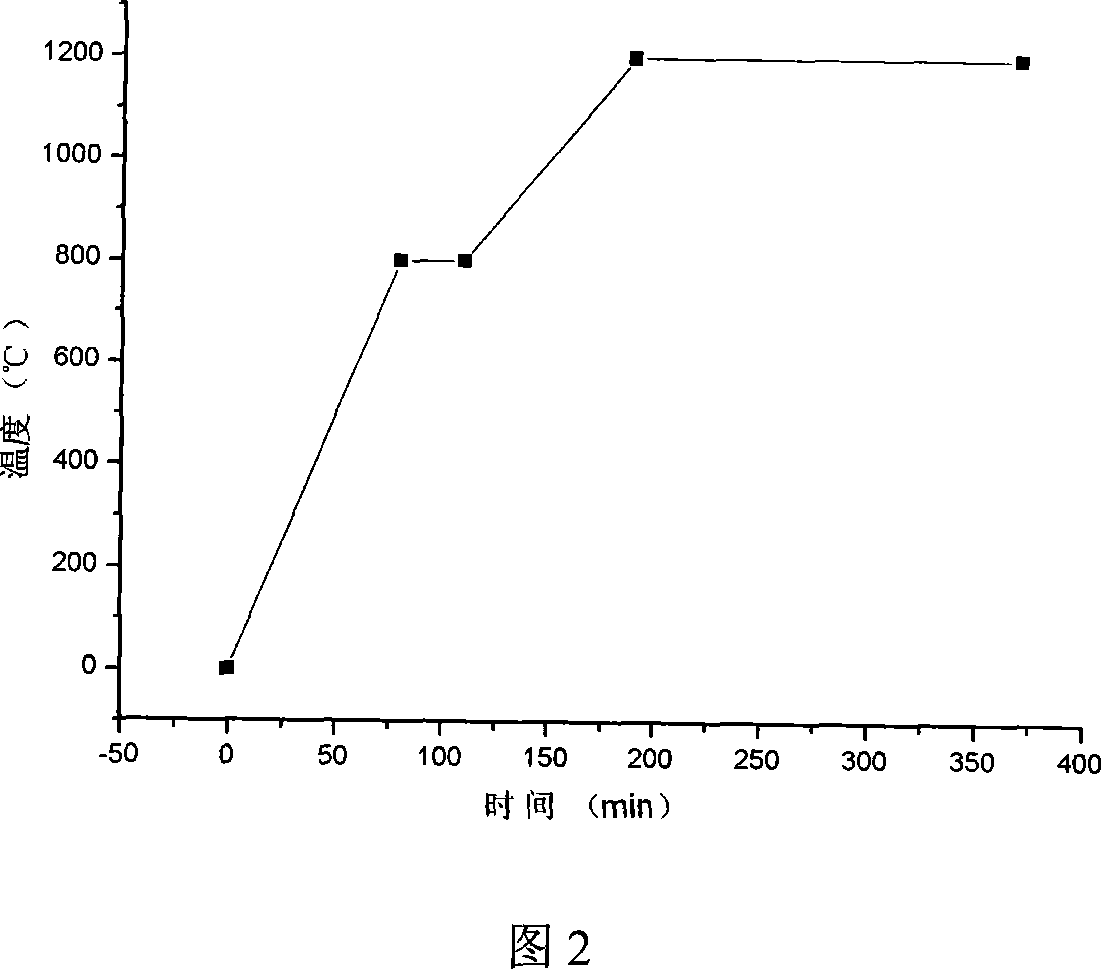

[0031] After granulating 35g of polishing waste mud powder, dry-press under 17MPa single-stroke pressure to form a green body; after granulating 75g of polishing waste mud, dry-press to form a green body under 17MPa and 14.5MPa two-stroke pressure, and sinter to prepare a porous ceramic matrix , its sintering temperature curve is shown in Figure 2, and its density is 0.35g / cm 3 , the compressive strength is 7.3MPa; the density of the buoyant material is 0.52g / cm after the sintered porous ceramics are modified with epoxy resin 3 , The compressive strength is 21MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com