High-strength organic silicon heat-conducting sealant and preparation method

A sealant and silicone technology, applied in chemical instruments and methods, adhesives, heat exchange materials, etc., can solve problems such as poor adhesion and poor strength, reduce residues, improve adhesion performance, and be convenient and quick to use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

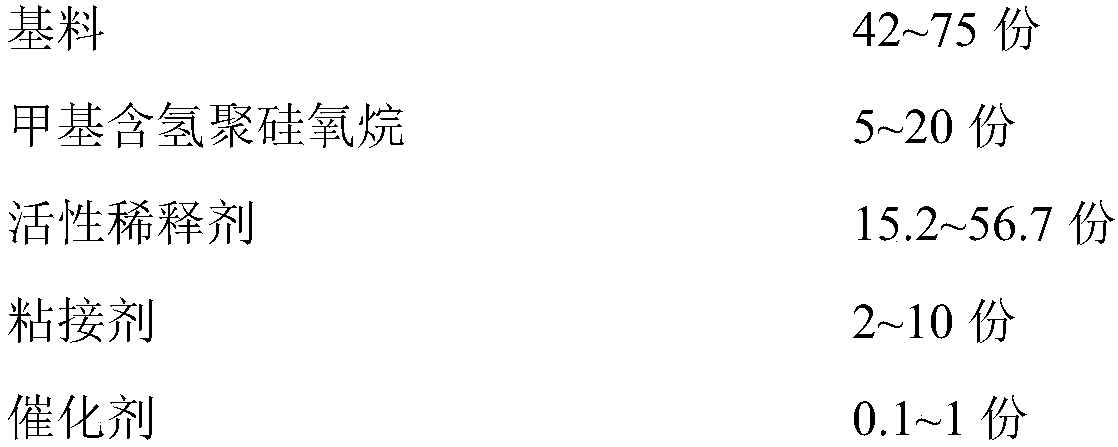

Method used

Image

Examples

Embodiment 1

[0036] (1) Base material preparation: at room temperature, 35 parts of vinyl-terminated silicone oil with a viscosity of 100000mPa.s, 15 parts of vinyl-terminated silicone oil with a viscosity of 60000mPa.s, 6 parts of fumed silica R974, and a structural control agent Add 1 part of dimethyldichlorosilane to the kneader one by one at a speed of 50-200rpm, mix at 150°C for 1-4 hours, and vacuumize to obtain the base material;

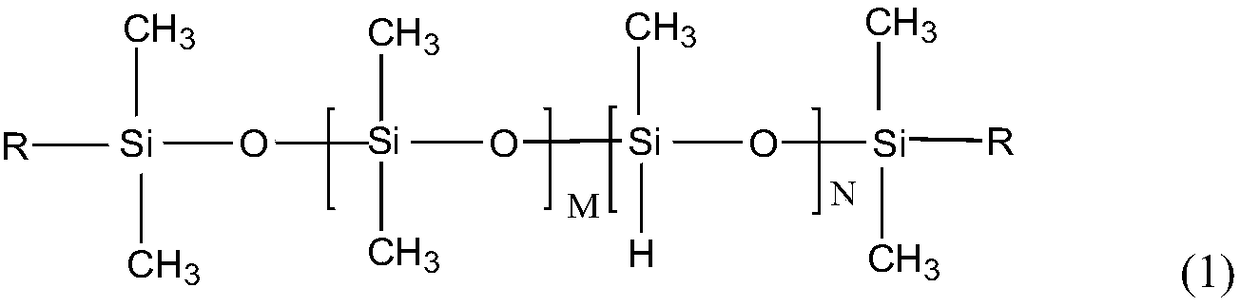

[0037] (2) Preparation of heat-conducting sealant: at room temperature, add 60 parts of base material to a double planetary mixer, and the structure of methyl hydrogen-containing polysiloxane is as in formula (1), wherein R=-CH 3 , M=3, N=4, 15 parts, 0.2 parts of inhibitor 2-methyl-3-butyn-2-ol, after mixing evenly, add vinyl-terminated silicone oil with reactive diluent viscosity of 100000mPa.s, 40.6 Parts, adhesive such as structural formula (2), wherein m=2, n=2, 6 parts, toughening agent such as structural formula (3), wherein x=800, y=2, 12 parts, c...

Embodiment 2

[0039] (1) Base material preparation: at room temperature, 30 parts of vinyl-terminated silicone oil with a viscosity of 100000mPa.s, 30 parts of vinyl-terminated silicone oil with a viscosity of 60000mPa.s, 12 parts of fumed silica R974, and a structural control agent Add 4.6 parts of hexamethyldisilazane into the kneader one by one at a speed of 50-200 rpm, mix at 150°C for 1-4 hours, and vacuumize to obtain the base material;

[0040] (2) Preparation of heat-conducting sealant: at room temperature, add 55 parts of base material to a double planetary mixer, and the structure of methyl hydrogen-containing polysiloxane is as in formula (1), wherein R=-H, M=3, N=4 , 12 parts, 0.2 parts of inhibitor 2-methyl-3-butyn-2-ol, 0.05 parts of acetylene cyclohexanol, after mixing evenly, add 38 parts of vinyl-terminated silicone oil with a reactive diluent viscosity of 60000mPa.s, Adhesive such as structural formula (2), wherein m=3, n=1, 8 parts, toughening agent such as structural for...

Embodiment 3

[0042] (1) Preparation of base material: at room temperature, 40 parts of vinyl-terminated silicone oil with a viscosity of 100000mPa.s, 20 parts of vinyl-terminated silicone oil with a viscosity of 20000mPa.s, 15 parts of fumed silica DM-20s, the structure Add 3 parts of hexamethyldisilazane, a chemical control agent, into the kneader in turn at a speed of 50-200rpm, mix at 150°C for 1-4 hours, and vacuumize to obtain the base material. (2) Preparation of heat-conducting sealant: At room temperature, add 68 parts of the base material to the double planetary mixer, the structure of methylhydrogen polysiloxane is as in formula (1), where R=-CH 3, M=3, N=8, 10 parts, inhibitor 3-methyl-1-pentyn-3-ol 0.35 parts, after mixing evenly, add 49 parts of vinyl-terminated silicone oil with reactive diluent viscosity of 20000mPa.s , adhesive such as structural formula (2), wherein m=3, n=2, 6 parts, toughening agent such as structural formula (3), wherein x=1000, y=2, 10 parts, catalyst ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com