High-entropy carbide nano-powder material with high sphericity degree and high activity as well as preparation method and application of high-entropy carbide nano-powder material

A nano-powder, high-sphericity technology, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problem of deteriorating high-entropy carbide ceramic powder activity and other properties, high-entropy carbonization To solve the problems of limited chemical activity of materials, unfavorable environmental protection and wide application, etc., to achieve stable product quality, easy control and lower production temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

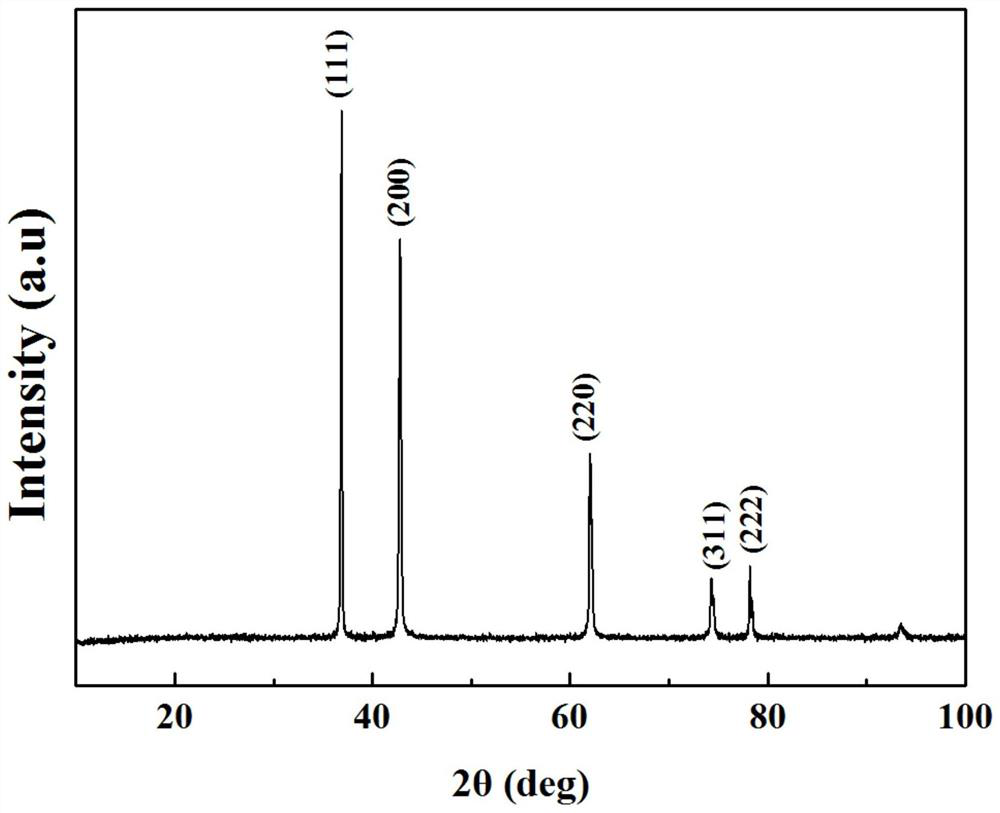

[0036] (Zr 0.25 Ti 0.25 Mo 0.25 V 0.25 ) Preparation of C high-entropy carbide nanopowders

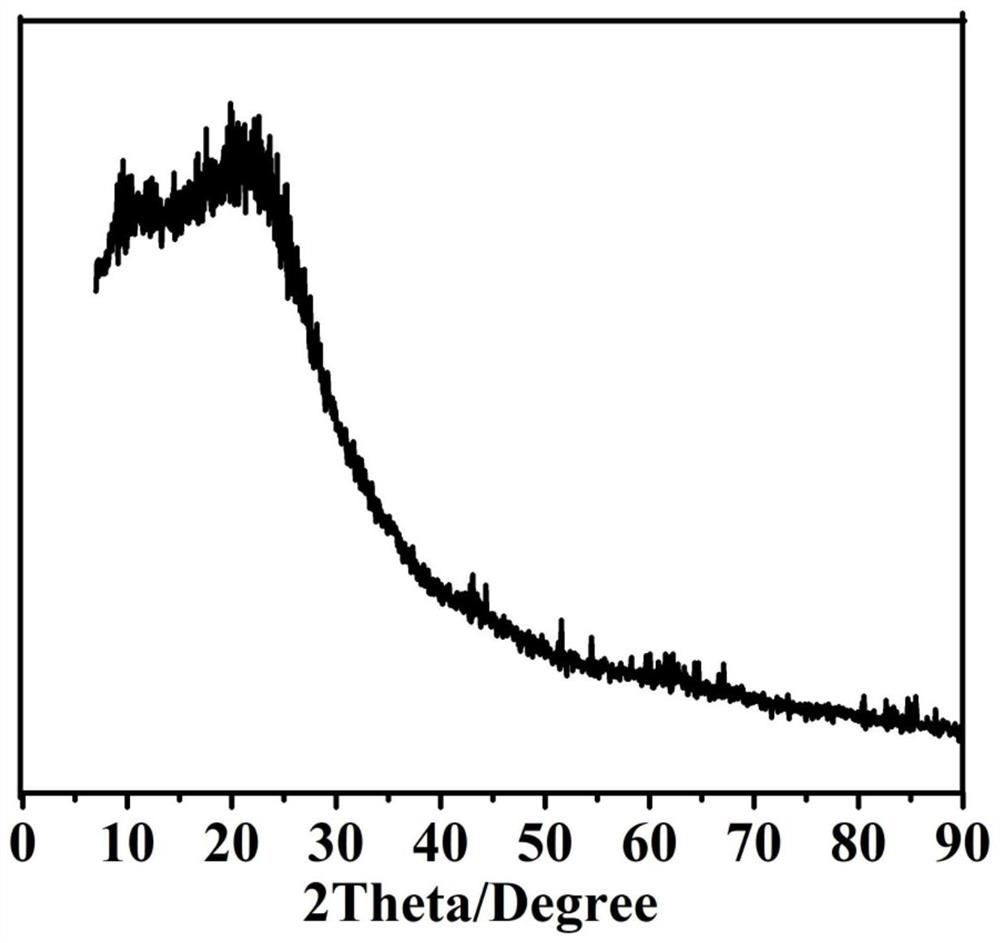

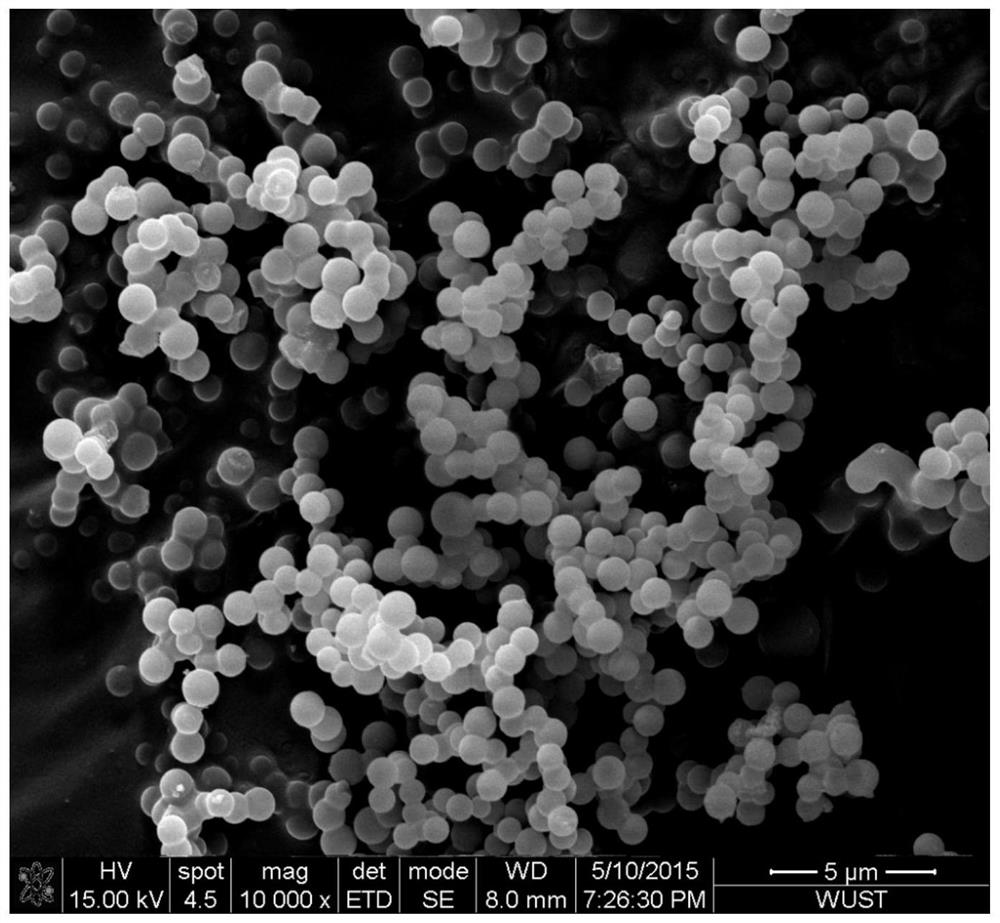

[0037] First prepare carbon microspheres: weigh 9.008g glucose (C 6 h 12 o 6 ) was dissolved in 100mL of a mixed solution of water and ethanol with a volume ratio of 9:1, adding sodium polyacrylate and sodium hexametaphosphate with a mass of 0.109g, and after mixing evenly, carried out hydrothermal carbonization reaction at 120°C for 6h, and suction filtered and heat treatment at 450°C for 2h after drying, prepared as figure 1 and 2 Amorphous, spherical carbon microspheres with an average particle size of 1.1 μm are shown.

[0038] Then prepare the high-entropy carbide precursor: weigh equimolar metal salt solutions and dissolve them in 15mL distilled water, specifically 1.6113g ZrOCl 2 .8H 2 O, 1.2001g Ti(SO 4 ) 2 , 0.1401g (NH 4 ) 6Mo 7 o 24 4H 2 O and 0.5849gNH 4 VO 3 . After mixing the above metal salt solution evenly, add 0.2400g carbon microspheres (1mL), and ...

Embodiment 2

[0041] (Zr 0.2 Ti 0.2 Mo 0.2 V 0.2 Nb 0.2 ) Preparation of C high-entropy carbide nanopowders

[0042] First prepare carbon microspheres: weigh 0.7500g starch (C 5 h 10 o 5 ) was dissolved in 167mL of a mixed solution of water and ethanol with a volume ratio of 4:1, adding sodium polyacrylate and sodium hexametaphosphate with a mass of 0.0839g, mixing evenly, performing hydrothermal carbonization reaction at 150°C for 6h, and suction filtration After drying and heat treatment at 550°C for 1 h, amorphous spherical carbon microspheres with an average particle size of 1.0 μm were prepared.

[0043] Then prepare the high-entropy carbide precursor: weigh equimolar metal salt solutions and dissolve them in 20mL distilled water, specifically 1.6113g ZrOCl 2 ·8H 2 O, 1.2001g Ti(SO 4 ) 2 , 0.1401g (NH 4 ) 6 Mo 7 o 24 4H 2 O, 0.5849gNH 4 VO 3 and 0.1358g NbCl 5 , mix the above metal salt solution evenly, add 0.2400g carbon microspheres (5mL), and use a rotary evaporat...

Embodiment 3

[0046] (Zr 0.2 Ti 0.2 W 0.2 V 0.2 Nb 0.2 ) Preparation of C high-entropy carbide nanopowders

[0047] First prepare carbon microspheres: weigh 1.7125g sucrose (C 12 h 22 o 11 ) was dissolved in 125mL of a mixed solution of water and ethanol with a volume ratio of 4:1, adding 0.1267g of sodium polyacrylate and 0.0634g of sodium hexametaphosphate, and after mixing evenly, carried out hydrothermal carbonization reaction at 150°C for 7h. After suction filtration and drying, heat treatment at 550°C for 1 h prepared amorphous spherical carbon microspheres with an average particle size of 1.3 μm.

[0048] Then prepare the high-entropy carbide precursor: weigh equimolar metal salt solutions and dissolve them in 10mL distilled water, specifically 1.6113g ZrOCl 2 .8H 2 O, 1.2001g Ti(SO 4 ) 2 , 1.2752g (NH 4 ) 10 h 2 (W 2 o 7 ) 6 , 0.5849gNH 4 VO 3 and 0.1358g NbCl 5 , mix the above metal salt solution evenly, add 0.2400g carbon microspheres (1mL), and use a rotary ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com