Method for preparing lightweight aggregate through low-temperature self-heating sintering of multiple types of coal gangues

A technology of coal gangue and self-heating, applied in the production of ceramic products, clay products, ceramic materials, etc., can solve problems such as inability to consume energy, endanger the environment, and reduce landfill and accumulation of coal gangue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

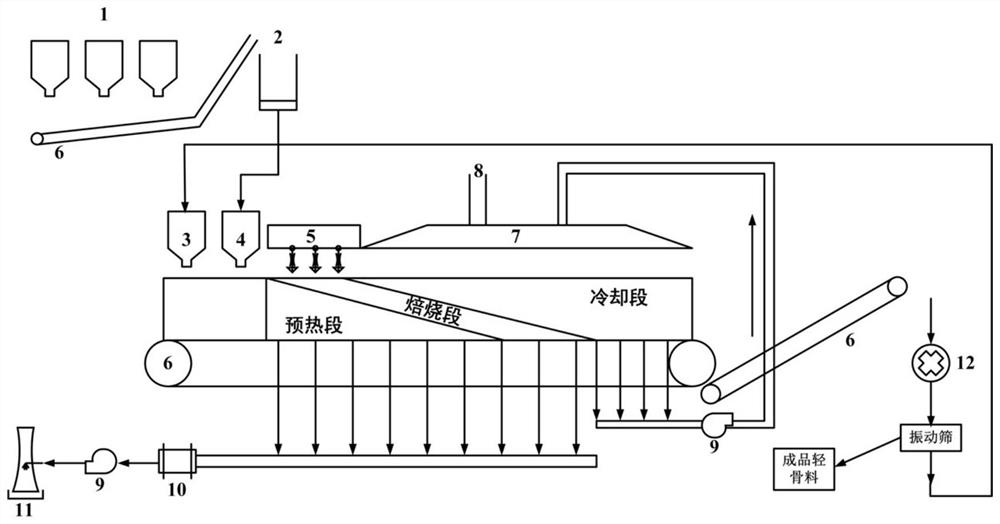

Method used

Image

Examples

Embodiment 1

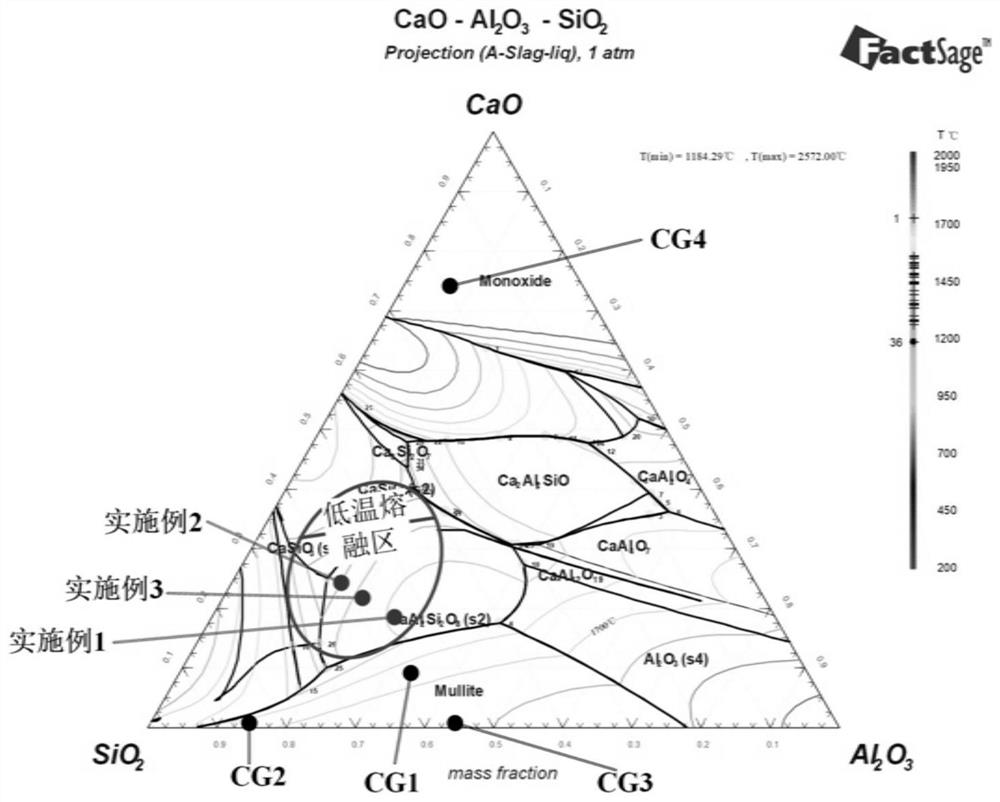

[0060] (1) Take different types of coal gangue after crushing, mix CG1, CG2, CG3, and CG4 according to the mass ratio of 2:2:4:2, and the content of the mixed material after mixing is: SiO 2 +Al 2 o 3 = 69.1%; Fe 2 o 3 +CaO+MgO=18.22%; CaO-SiO 2 -Al 2 o 3 The relative content of each component in the system is: 17.2%: 55.0%: 27.8%; the carbon content is 5%, the mixture is put into a cylinder granulator and an appropriate amount of water is added for granulation.

[0061] (2) Sprinkle an appropriate amount of base material on the bottom of the sintering machine trolley, and then continuously transport the granulated mixture to the horizontally moving trolley. The thickness of the cloth is 900mm. The trolley passes through the Drying, preheating, sintering, and cooling to obtain qualified lightweight aggregate; the ignition temperature is 1050°C, and the ignition time is 2min; the sintering temperature is 1250°C, and the sintering time is 4min; the sintering speed is 22mm / ...

Embodiment 2

[0064] (1) Take different types of crushed coal gangue, mix CG1, CG2, CG3, and CG4 according to 1:5:1:3, and the content of the mixed material after mixing is: SiO 2 +Al 2 o 3 = 64.4%; Fe 2 o 3 +CaO+MgO=23.9%; CaO-SiO 2 -Al 2 o 3 The relative content of each component in the system is: 23.6%: 60.1%: 16.3%; the carbon content is 4%, the mixture is put into a cylinder granulator and an appropriate amount of water is added for granulation.

[0065] (2) Sprinkle an appropriate amount of base material on the bottom of the sintering machine trolley, and then continuously transport the granulated mixture to the horizontally moving trolley. The thickness of the cloth is 700mm. The trolley passes through the Drying preheating, sintering and cooling to obtain qualified lightweight aggregate; the ignition temperature is 1100°C, ignition 1min; sintering temperature is 1190°C, high temperature time is 3.2min; sintering speed is 20mm / min; The discharge temperature is 150°C. The ligh...

Embodiment 3

[0068] (1) Take different types of coal gangue after crushing, mix CG1, CG2, CG3, and CG4 according to 1:4:2:3, and the content of the mixed material after mixing is: SiO 2 +Al 2 o 3 = 64.3%; Fe 2 o 3 +CaO+MgO=23.7%; CaO-SiO 2 -Al 2 o 3 The relative content of each component in the system is: 23.6%: 57.2%: 19.3%; the carbon content is 3%. Put the mixture into a cylinder granulator and add appropriate amount of water for granulation.

[0069] (2) Sprinkle an appropriate amount of base material on the bottom of the sintering machine trolley, and then continuously transport the granulated mixture to the horizontally moving trolley. The thickness of the cloth is 800mm. The trolley passes through the Drying, preheating, sintering, and cooling to obtain qualified lightweight aggregate; the ignition temperature is 1000°C, ignition 1min; the temperature of the sintering section is 1100°C, the high temperature time is 2min, and the sintering speed is 17mm / min; the cooling method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com