Low-density high-strength andalusite fracturing proppant and production method thereof

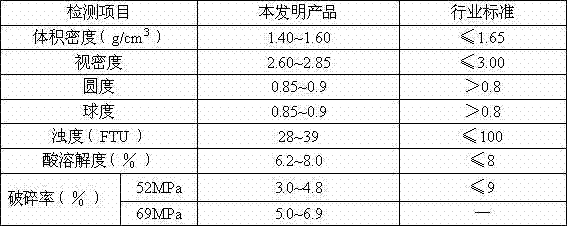

A technology for fracturing proppants and production methods, which is applied in earthwork drilling, production fluids, wellbore/well components, etc. It can solve problems such as failure to meet performance requirements, low pressure bearing capacity of proppants, and unstable product quality. Achieve the effects of easy promotion and implementation, low cost and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0019] Example 1: High-strength andalusite fracturing proppant and its production method

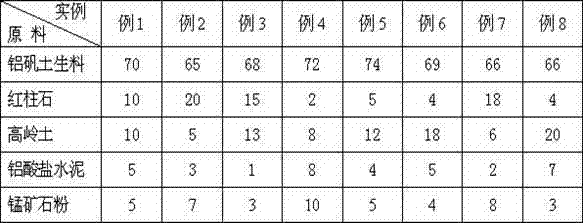

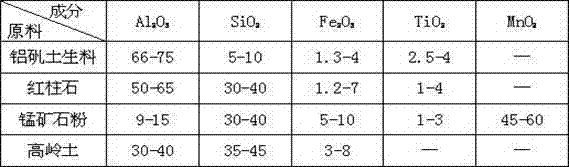

[0020] Raw material requirements and proportions are shown in Table 1 and 2, in terms of weight percentage, that is, bauxite raw meal 70%, andalusite 10%, kaolin 10%, calcium aluminate cement 5%, manganese ore powder 5%.

[0021] Production method: Weigh each raw material, grind them into fine powder respectively, pass through a 320-mesh sieve, and the sieve rate is greater than 98.5%, mix and stir the raw materials evenly, under the one-way uniform rotation of the granulator, the mixture is continuously and evenly added to the granulator At the same time, add atomized water vapor until the mixture forms round particles of different sizes; pass through a 18-30 mesh sieve, and the sieve rate is required to be greater than 80%, then rotate for 10-15 minutes, and pass through a 18-30 mesh sieve to obtain Semi-finished products; the semi-finished products are dried and screened in the dryer,...

example 2

[0022] Example 2: See Tables 1 and 2 for raw material requirements and proportioning, the production method is basically the same as Example 1, the difference is:

[0023] When the semi-finished product is fired in the rotary kiln, the temperature at the kiln head is 1320~1360°C, and the temperature at the end of the kiln is 310~320°C. After firing for 6 hours, the finished product is obtained.

example 3

[0024] Example 3: The raw material composition is shown in Table 2, and the production method is basically the same as Example 1, the difference being:

[0025] When the semi-finished product is fired in the rotary kiln, the temperature at the kiln head is 1380~1400°C, the temperature at the end of the kiln is 300~310°C, and it will leave the kiln after firing for 7 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com