Ammonia flue gas mixing apparatus used in stern exhaust gas processing system

A technology for exhaust gas treatment and flue gas mixing, which is applied to the separation of dispersed particles, chemical instruments and methods, and separation methods. It can solve problems such as complex structure and unsatisfactory work performance, and achieve good work performance, reasonable structure and low pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

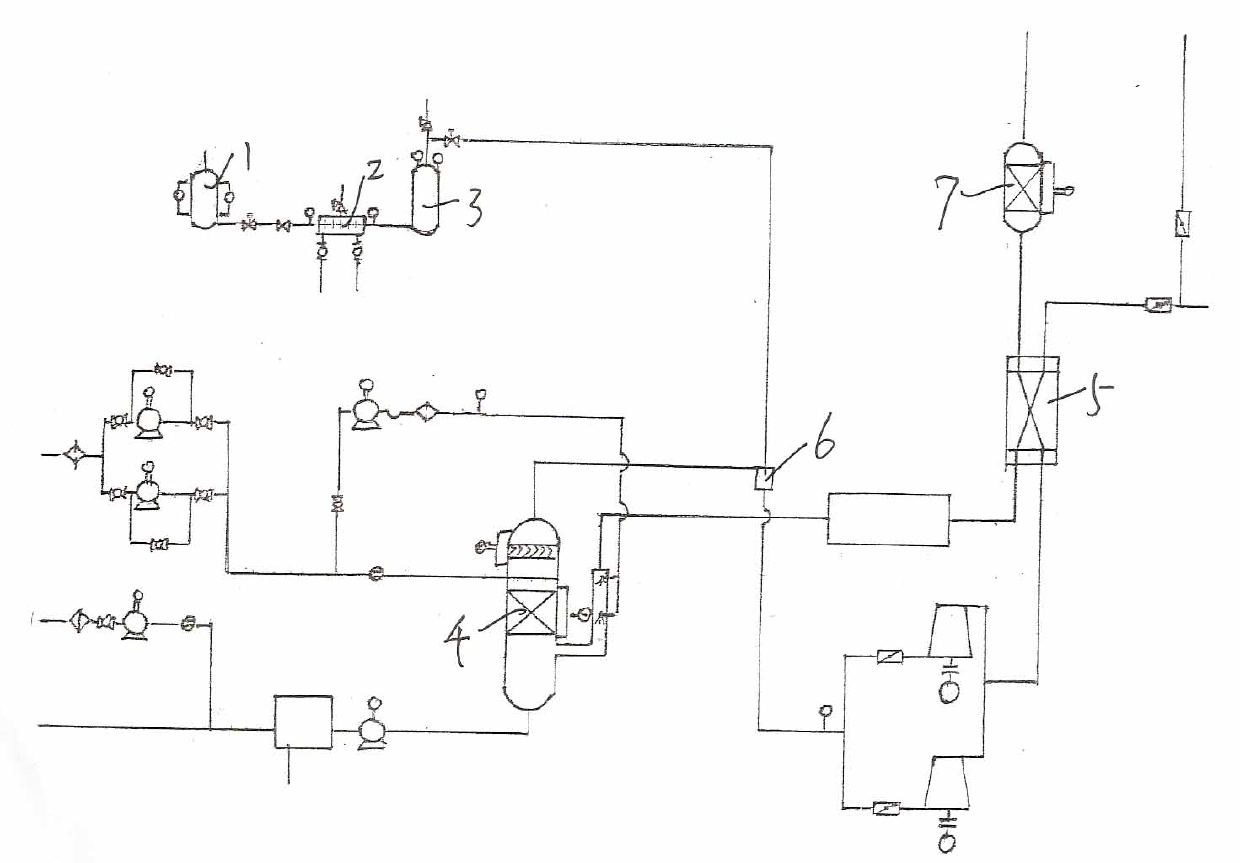

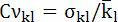

[0014] An ammonia flue gas mixing device for a stern exhaust treatment system, comprising an evaporator 2 connected to an ammonia storage tank 1, the evaporator connected to an ammonia buffer tank 3, the ammonia buffer tank and a desulfurization device 4, and the flue gas is exported to the gas- The mist eliminator 6 between the gas heat exchangers 5 is connected, and the mist eliminator is connected to the cold end inlet of the gas-gas heat exchanger through a pipe, and the cold end outlet of the gas-gas heat exchanger is connected to the SCR denitrification device 7, and the SCR Inhomogeneity coefficient of flue gas flow velocity on the inlet interface of the first layer of catalyst in the denitrification device Less than 15%; Uneven coefficient of ammonia nitrogen ratio Less than 5%; the temperature difference is less than ±10 K; before the inlet of the SCR denitration device, the temperature difference on the catalyst inlet interface is less than ±1 K; the non-uniformity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com