Automatic descaling control system of electric heating steam generator

A steam generator and automatic descaling technology, applied in boiler cleaning control devices and other directions, can solve the problems of control circuit out of control, poor thermal conductivity, affecting the normal production of the factory, etc., and achieve the effect of reasonable structure and good working performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

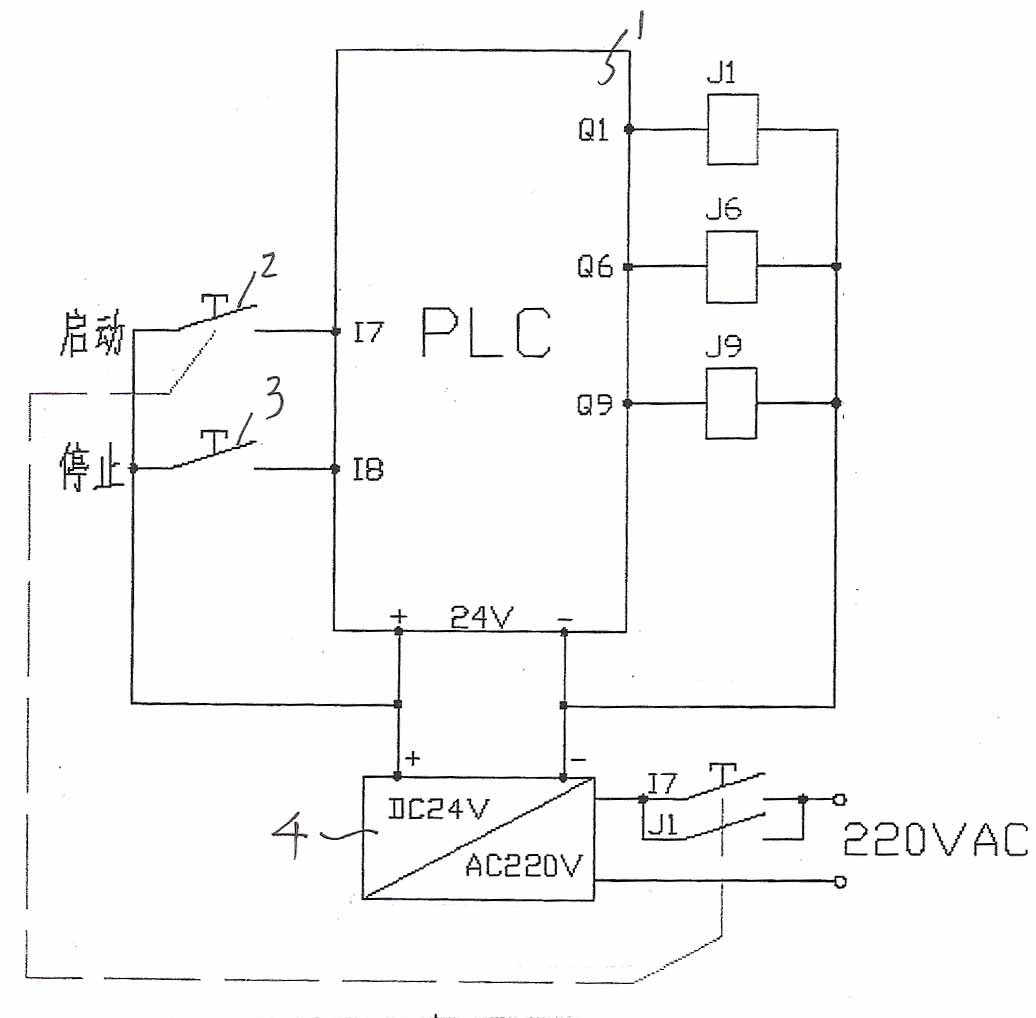

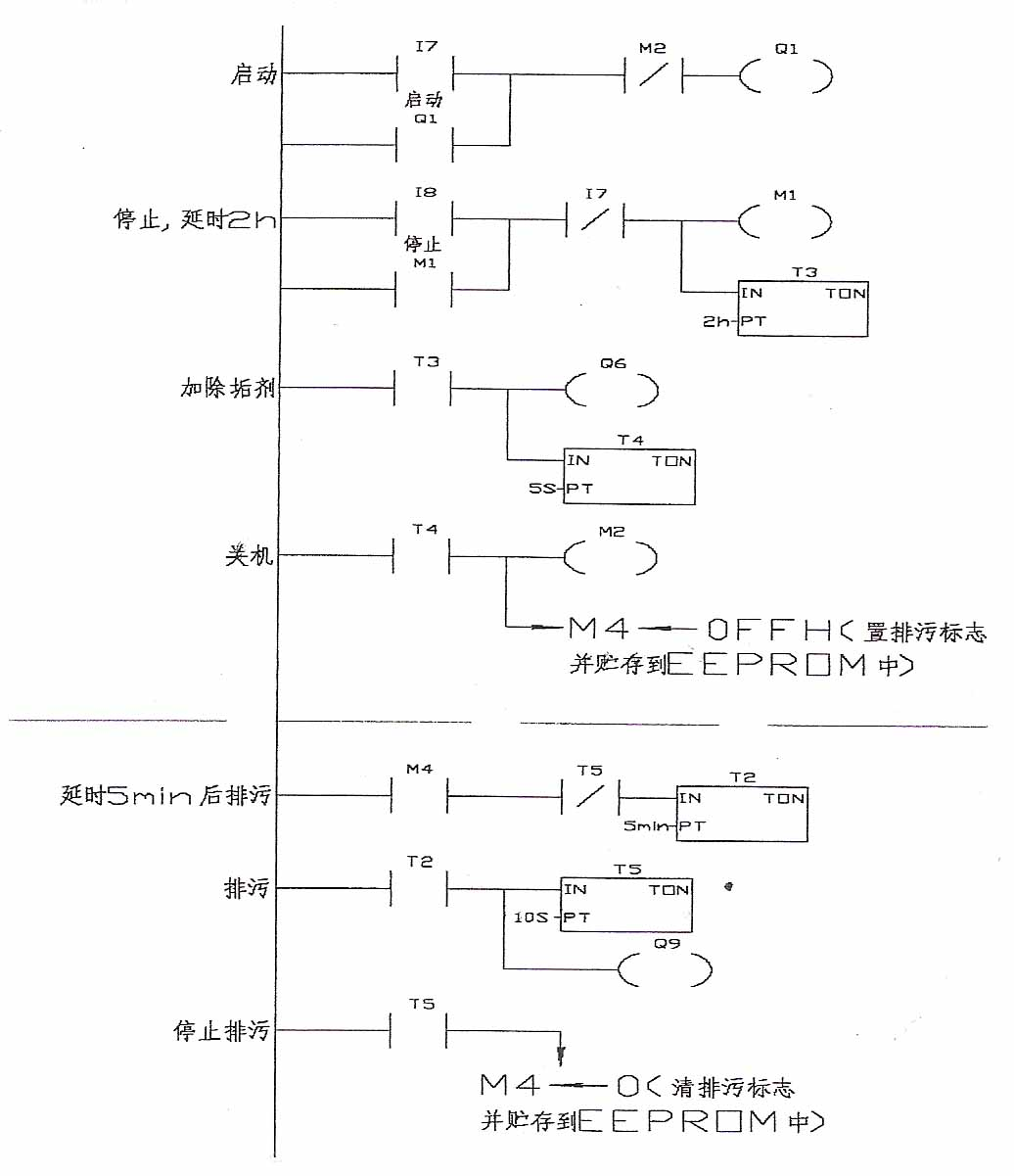

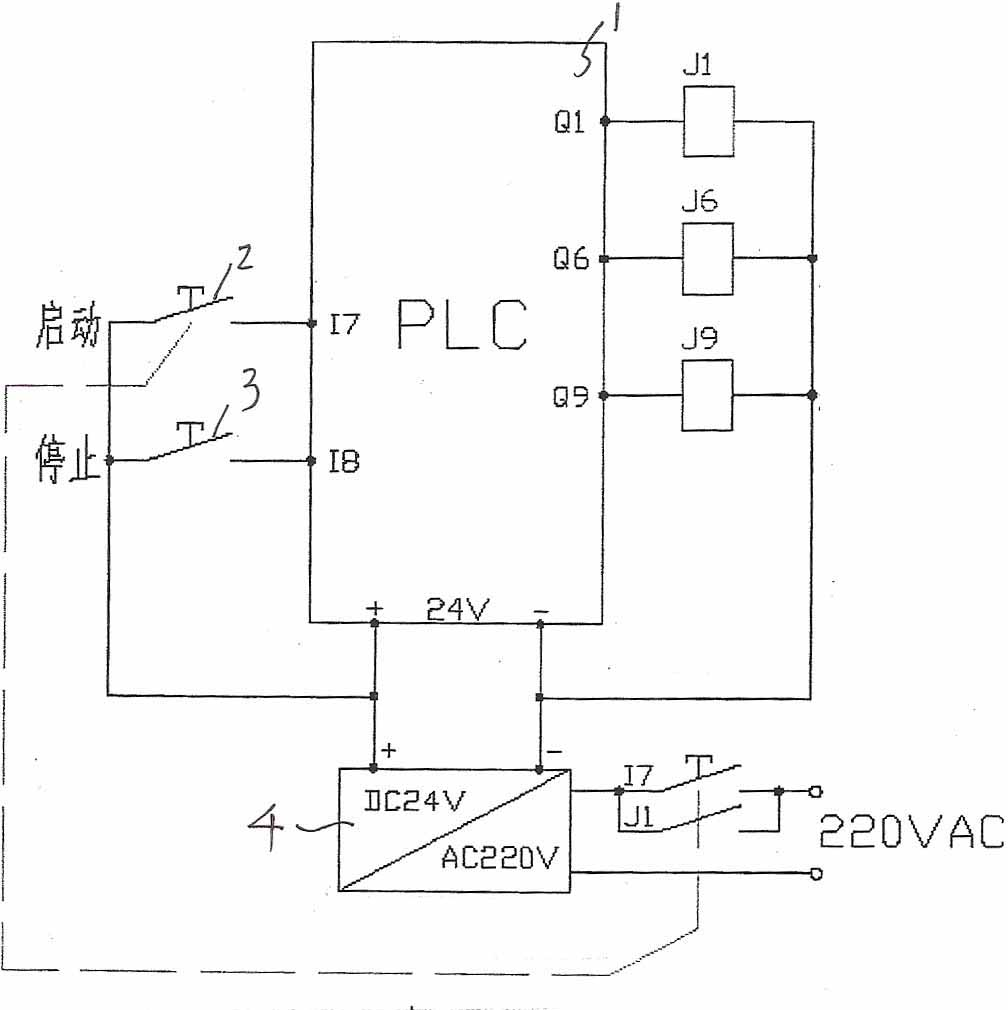

[0012] An automatic descaling control system for an electric heating steam generator, comprising a PLC controller 1 connected with switch devices 2 and 3 for controlling the start or stop of the PLC controller, an output pole Q1 of the PLC controller and controlling steam Generator working power relay J1 is connected, the other output pole Q6 of the PLC controller is connected with the descaling agent control valve J6 which adds descaling agent in the control item steam generator, and another output pole Q9 of the PLC controller is connected with the control steam generator. The blowdown electromagnetic valve J9 of generator blowdown work is connected.

[0013] The descaling control valve is a solenoid valve that is delayed and controlled by the PLC controller after receiving the stop signal of the switching device that controls the PLC controller to stop.

[0014] The sewage discharge electromagnetic valve is an electromagnetic valve that is controlled to open and close with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com