Anti-crack corrosion-resistant concrete admixture as well as preparation and application of anti-crack corrosion-resistant concrete admixture

A concrete admixture and anti-corrosion technology, applied in the field of building materials, can solve the problems of lack of anti-cracking performance of coastal hydraulic concrete, affecting project safety and benefit performance, and corrosion and damage of concrete structure, so as to prevent the growth of cracks and reduce harmful effects. Ion erosion, the effect of improving the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

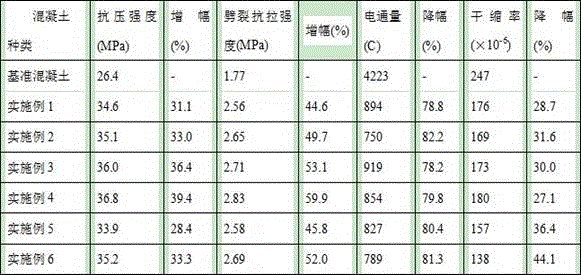

Examples

Embodiment 1

[0022] An anti-crack and anti-corrosion concrete admixture is prepared from the following raw materials in parts by weight: 1.5 parts of polypropylene fiber, 60 parts of fly ash, 35 parts of metakaolin and 3.5 parts of nano-dysprosium oxide.

Embodiment 2

[0024] An anti-crack and anti-corrosion concrete admixture is prepared from the following raw materials in parts by weight: 2.5 parts of polyethylene fiber, 50 parts of fly ash, 42.5 parts of metakaolin and 5 parts of nano-dysprosium oxide.

Embodiment 3

[0026] An anti-crack and anti-corrosion concrete admixture is prepared from the following raw materials in parts by weight: 2 parts of carbon fiber, 52.5 parts of fly ash, 40 parts of silica fume and 5.5 parts of nanometer lanthanum oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com