Natural gas distributed energy flue gas denitrification catalyst and its preparation process

A distributed energy and denitrification catalyst technology, which is applied in the field of natural gas distributed energy flue gas denitrification catalyst and its preparation, can solve the problems of active component loss, low denitrification efficiency, catalyst deactivation, etc., and achieve high temperature resistance and denitrification High efficiency and high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

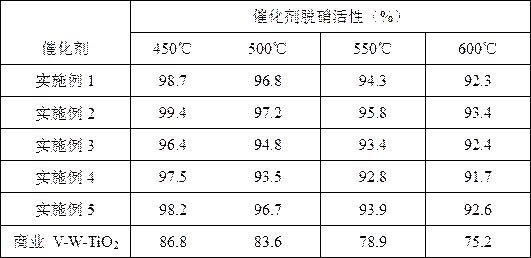

Examples

Embodiment 1

[0021] 1) Grind activated alumina, zeolite molecular sieves containing transition metal oxides, and iron-nickel-chromium composite oxides into composite powders with a particle size of less than 5 μm, an average particle size of 1.5 μm, and a grain size of less than 10 nm by high-energy ball milling, and then add 2 parts by mass of silica sol, 1 part by mass of mannose gum, 0.5 parts by mass of silica fine powder, 2 parts by mass of water-soluble phenolic resin and 280 parts by mass of deionized water, mixed to obtain plastic clay;

[0022] The consumption of described activated alumina is 2 mass parts;

[0023] The zeolite molecular sieve contains 3 parts by mass of cerium oxide, 2 parts by mass of tungsten oxide and 1 part by mass of zirconia;

[0024] The iron-nickel-chromium composite oxide is prepared by plasma technology; the iron-nickel-chromium composite oxide contains 5 parts by mass of iron oxide, 3 parts by mass of nickel oxide and 2 parts by mass of chromium oxide;...

Embodiment 2

[0030] 1) Grind activated alumina, zeolite molecular sieves containing transition metal oxides, and iron-nickel-chromium composite oxides into composite powders with a particle size of less than 5 μm, an average particle size of 1.5 μm, and a grain size of less than 10 nm by high-energy ball milling, and then add 4 parts by mass of silica sol, 3 parts by mass of mannose gum, 1.5 parts by mass of silica fine powder, 4 parts by mass of water-soluble phenolic resin and 320 parts by mass of deionized water, mixed to obtain plastic mud;

[0031] The consumption of described activated alumina is 3 mass parts;

[0032] In the zeolite molecular sieve, cerium oxide accounts for 5 parts by mass, tungsten oxide accounts for 4 parts by mass, and zirconia accounts for 4 parts by mass;

[0033] The iron-nickel-chromium composite oxide is prepared by plasma technology; in the iron-nickel-chromium composite oxide, iron oxide accounts for 8 parts by mass, nickel oxide accounts for 5 parts by m...

Embodiment 3

[0039] 1) Grind activated alumina, zeolite molecular sieves containing transition metal oxides, and iron-nickel-chromium composite oxides into composite powders with a particle size of less than 5 μm, an average particle size of 1.5 μm, and a grain size of less than 10 nm by high-energy ball milling, and then add 4 parts by mass of silica sol, 3 parts by mass of mannose gum, 1.5 parts by mass of silica fine powder, 4 parts by mass of water-soluble phenolic resin and 320 parts by mass of deionized water, mixed to obtain plastic mud;

[0040] The consumption of described active aluminum oxide is 2.3 mass parts;

[0041] In the zeolite molecular sieve, cerium oxide accounts for 4 parts by mass, tungsten oxide accounts for 3 parts by mass, and zirconia accounts for 2 parts by mass;

[0042] The iron-nickel-chromium composite oxide is prepared by plasma technology; in the iron-nickel-chromium composite oxide, iron oxide accounts for 6 parts by mass, nickel oxide accounts for 4 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com