Zinc-nickel-zirconium mesoporous composite oxide catalyst for hydrogen production by autothermal reforming of acetic acid

A composite oxide, autothermal reforming technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical/physical process, etc. It is easy to be oxidized and other problems to achieve the effect of improving catalytic activity, improving anti-sintering and inhibiting oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] Weigh 3.009g of Ni(NO 3 ) 2 ·6H 2 O, 9.236g of Zn(NO 3 ) 2 ·6H 2 O and 3.688g of ZrO(NO 3 ) 2 2H 2 O, add 55mL of deionized water to prepare solution #1; weigh 7.727g of NaOH and 1.280g of anhydrous Na 2 CO 3 , add 102mL of deionized water to prepare solution #2; under the condition of 78°C and pH of the solution at 10.5±0.5, add solution #1 and solution #2 dropwise into the beaker and keep stirring for co-precipitation reaction, and continue Stir and age for 18 hours; after the aging, the mixture was suction filtered and washed three times, and the resulting precipitate was dried in a 105°C oven for 24 hours, and the precipitate was calcined at 700°C for 4 hours to obtain CDUT-ZNZ-101 catalyst. The chemical composition of the catalyst is (ZnO) 2.25 (NiO) 0.75 ZrO 2 , The weight percentage is: zinc oxide is 50.5%, nickel oxide is 15.5%, zirconium oxide is 34.0%.

[0026] The reactivity evaluation of autothermal reforming of acetic acid was carried out in a ...

Embodiment 1

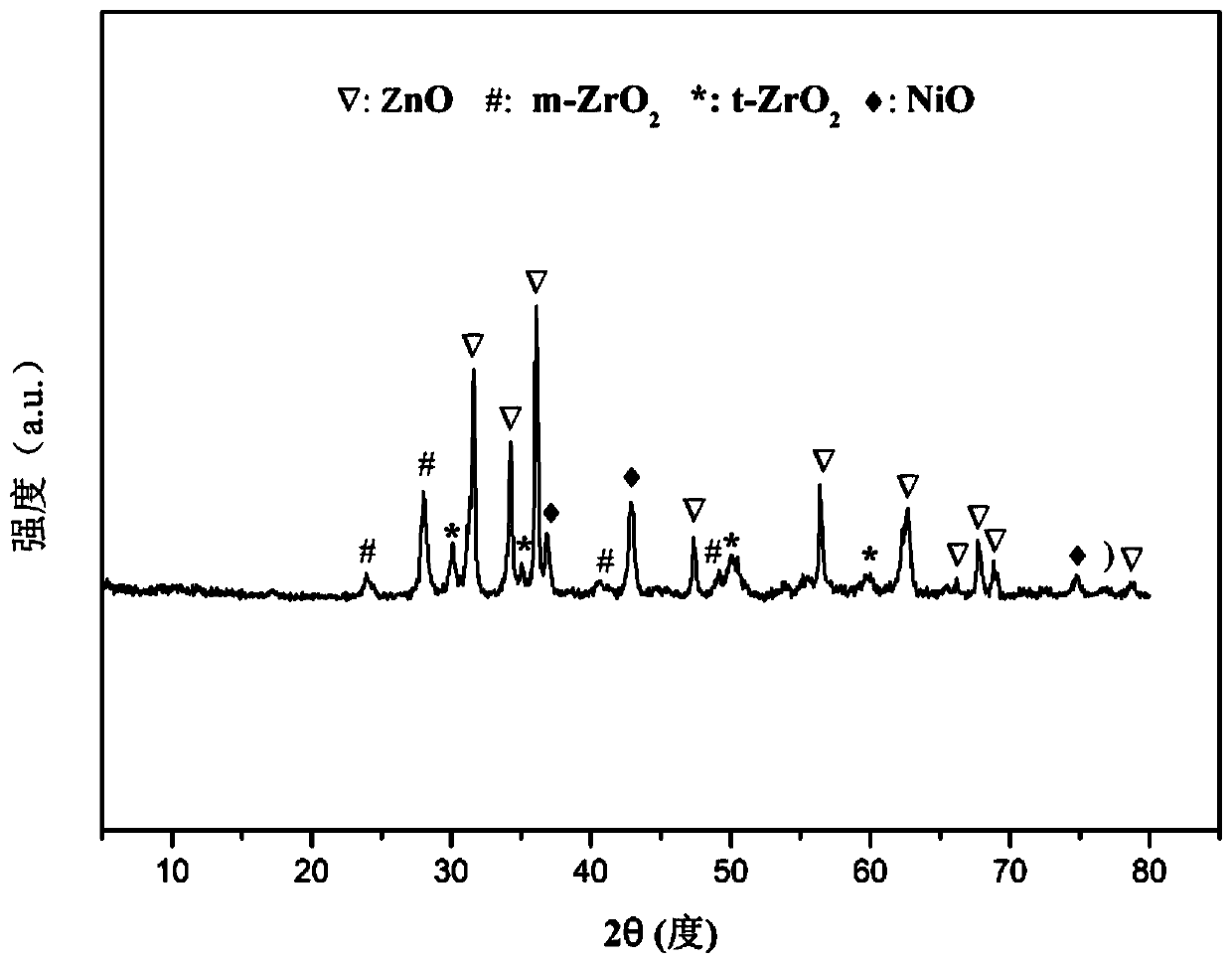

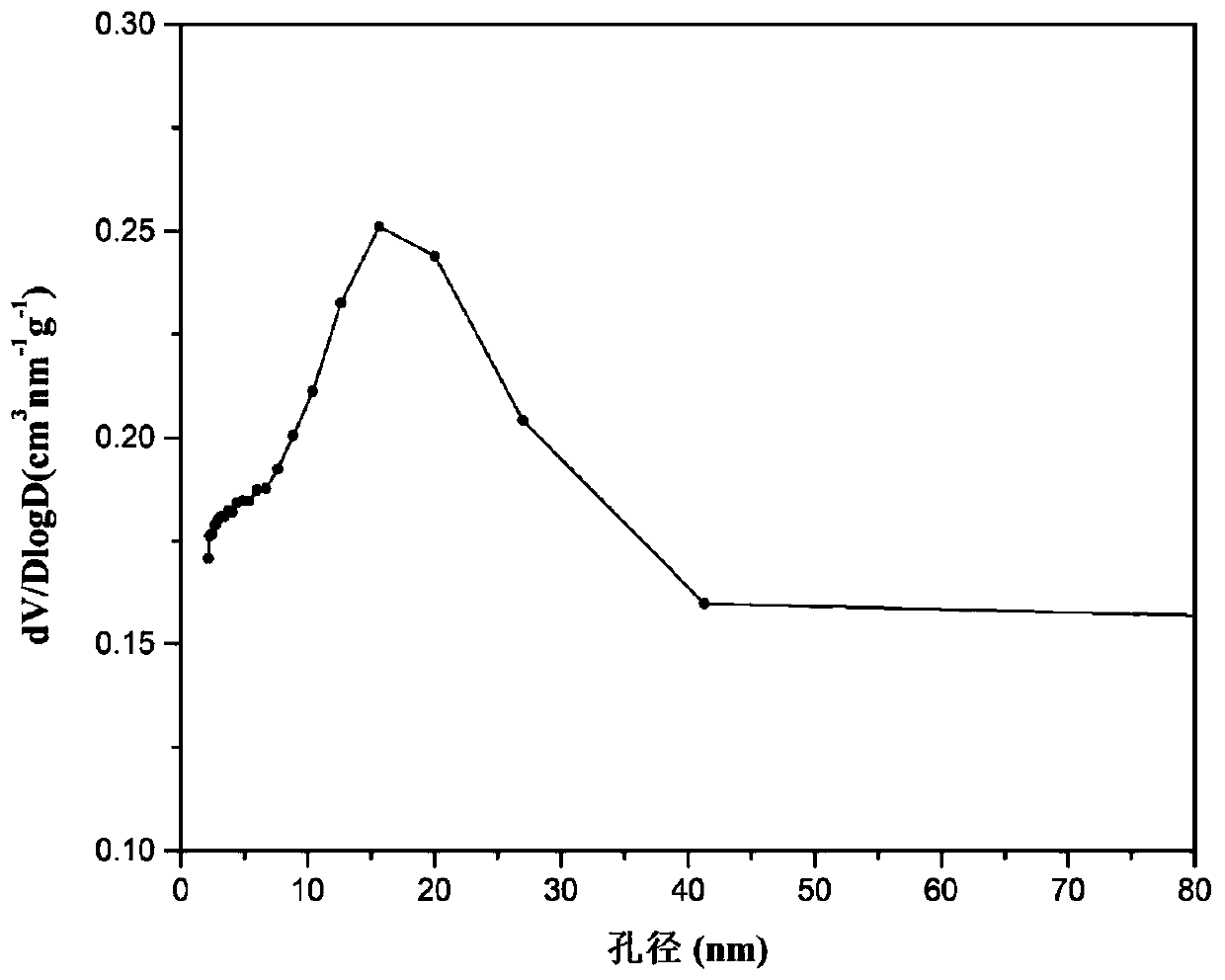

[0029] Weigh 3.094g of Ni (NO 3 ) 2 ·6H 2 O, 7.385g of Zn (NO 3 ) 2 ·6H 2 O and 4.739g of ZrO(NO 3 ) 2 2H 2 O, add 53mL of deionized water to prepare solution #1; weigh 9.079g of NaOH and 1.504g of anhydrous Na 2 CO 3 , add 121mL of deionized water to prepare solution #2; under the condition of 78°C and pH of the solution at 10.5±0.5, add solution #1 and solution #2 dropwise into the beaker and keep stirring for co-precipitation reaction, and continue Stirring and aging for 18 hours; after the aging, the mixture was suction filtered and washed 3 times, and the obtained precipitate was dried in a 105°C oven for 24 hours, and the precipitate was roasted at 700°C for 4 hours to obtain a compound containing ZnO, t-ZrO 2 , m-ZrO 2 and NiO Ni / ZnO-ZrO 2 Composite oxide catalyst, the typical structure of its composite oxide is as attached figure 1 As shown, the CDUT-ZNZ-102 catalyst is obtained; the catalyst is a mesoporous material, and the typical pore size distribution ...

Embodiment 2

[0032] Weigh 2.880g of Ni(NO 3 ) 2 ·6H 2 O, 4.420g of Zn (NO 3 ) 2 ·6H 2 O and 6.618g of ZrO(NO 3 ) 2 2H 2 O, add 50.5mL of deionized water to prepare solution #1; weigh 11.093g of NaOH and 1.837g of anhydrous Na 2 CO 3 , add 148mL of deionized water to prepare solution #2; under the condition of 78°C and pH of the solution at 10.5±0.5, add solution #1 and solution #2 dropwise into the beaker and keep stirring for co-precipitation reaction, and continue Stirring and aging for 18 hours; after the aging, the mixture was suction filtered and washed 3 times, and the obtained precipitate was dried in a 105°C oven for 24 hours, and the precipitate was roasted at 700°C for 4 hours to obtain Ni / ZnO-ZrO 2 Composite oxide catalyst, the typical structure of its composite oxide is as attached figure 1 As shown, the CDUT-ZNZ-103 catalyst is obtained; the catalyst is a mesoporous material, and the typical pore size distribution of its mesoporous structure is shown in the attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com