Method for preparing high-purity superfine palladium powder from waste palladium-carbon catalyst

A technology of palladium-carbon catalyst and ultra-fine palladium powder, applied in the direction of improving process efficiency, etc., can solve the problems of dioxin risk, easy-to-corrosion equipment, increased energy consumption, etc., to avoid high energy consumption and small footprint of complete equipment , the effect of less time spent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

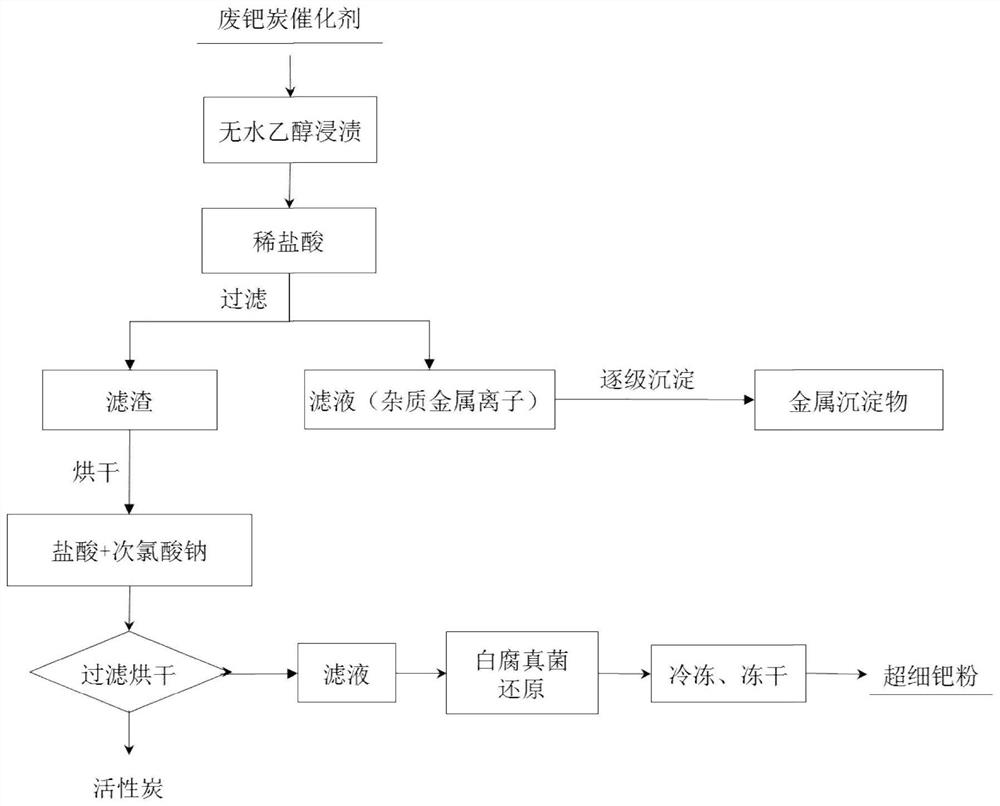

Method used

Image

Examples

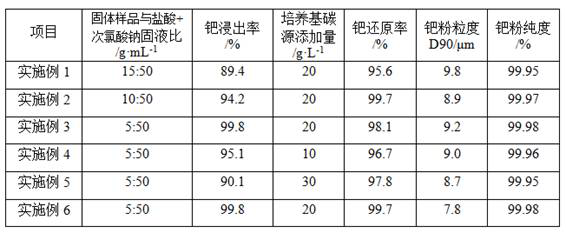

Embodiment 1

[0028] In this example, 150 g of spent palladium-carbon catalyst powder was weighed into a 500 mL thick-walled beaker, 150 mL of absolute ethanol was slowly added, and placed in a 40 Hz ultrasonic instrument for 30 min and then left to stand. Add 50 ml of 5wt% hydrochloric acid solution to it, stir at 100-200 rpm, react for 1 hour, filter, wash, and dry. Then add 4 mol / L of hydrochloric acid and 250 mL of 2 mol / L sodium hypochlorite successively to the filter residue, react for 40 minutes under the condition of stirring speed of 80 rpm, filter and separate to obtain the filter residue and palladium-containing filtrate, the filter residue is washed with water and dried to obtain Activated carbon, palladium-containing filtrate was further processed.

[0029] Inject Phaneroderma chrysosporium (inoculum size 5vol%) into 50 mL of culture medium (glucose 20 g / L, sucrose 15 g / L, yeast powder 2 g / L, wheat bran 15 g / L, sulfuric acid heptahydrate Magnesium 0.5 g / L, potassium dihydrogen...

Embodiment 2

[0031] In this example, 100 g of spent palladium-carbon catalyst powder was weighed into a 500 mL thick-walled beaker, slowly added with 150 mL of absolute ethanol, and placed in a 40 Hz ultrasonic instrument for 30 minutes of sonication and then left to stand. Add 50 mL of 5wt% hydrochloric acid solution to it, stir at 100-200 rpm, react for 1 hour, filter, wash, and dry. Add 4 mol / L of hydrochloric acid and 250ml of sodium hypochlorite of 2 mol / L successively in the filter residue, react for 60min under the condition of stirring speed of 80 rpm, filter and separate to obtain filter residue and palladium-containing filtrate, filter residue is washed with water and dried to obtain activated carbon, and the filtrate is further processed.

[0032] Take the above filtrate, put Phaneroderma chrysosporium (10vol% inoculum) into 50 mL culture solution (glucose 20g / L, sucrose 15g / L, yeast powder 2g / L, wheat bran 15g / L, sulfuric acid heptahydrate Magnesium 0.5g / L, potassium dihydroge...

Embodiment 3

[0034] In this example, 50 g of spent palladium-carbon catalyst powder was weighed into a 500 mL thick-walled beaker, 150 mL of absolute ethanol was slowly added, and placed in a 40 Hz ultrasonic instrument for 30 minutes of sonication and then left to stand. Add 50 ml of 5wt% hydrochloric acid solution to it, stir at 100-200 rpm, react for 1 hour, filter, wash, and dry. Add 4 mol / L of hydrochloric acid and 250ml of sodium hypochlorite of 2 mol / L successively in the filter residue, react for 90min under the condition of stirring speed of 80 rpm, filter and separate to obtain filter residue and palladium-containing filtrate, filter residue is washed with water and dried to obtain Activated carbon, palladium-containing filtrate was further processed.

[0035] Inject Phaneroderma chrysosporium (15vol% inoculum) into 50 mL of culture medium (glucose 20 g / L, sucrose 15 g / L, yeast powder 2 g / L, wheat bran 15 g / L, magnesium sulfate heptahydrate 0.5 g / L, potassium dihydrogen phosphat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com