Hyperbranched UV (ultraviolet) resin as well as preparation method and application of hyperbranched UV resin in coating

A technology of hyperbranched polyester and terminal hydroxyl hyperbranching, which is applied in coatings and other directions, can solve the problems of high viscosity, poor physical and chemical properties, and poor reactivity of light-cured resins, and achieve small shrinkage in curing volume, excellent weather resistance, and solvent resistance. less volatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

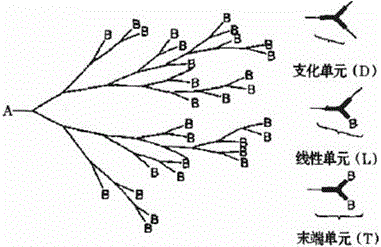

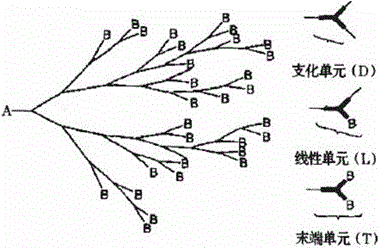

Method used

Image

Examples

Embodiment 1

[0024] In a 1-ton reactor equipped with mechanical stirring, thermometer and reflux condenser, add 480.7Kg of dimethylolpropionic acid and 122Kg of pentaerythritol, add 3Kg of stannous octoate catalyst, and heat to 160℃ for 6h under the protection of nitrogen. ; Under vacuum conditions, continue the reaction, when the acid value of the reaction is less than 30mgKOH / g, the reaction is over, and cool to obtain a colorless and transparent solid, which is the first generation of hydroxyl-terminated hyperbranched polyester, denoted as HBPE-10, hydroxyl-terminated The number is 8.

[0025] Take 30.6g of the first-generation hydroxyl-terminated hyperbranched polyester (HBPE-10) prepared by the above method, 11.76g of acrylic acid, and 64g of solvent. After heating to dissolve at 120°C, add 0.21g of the catalyst p-toluenesulfonic acid and add the barrier Polymerizing agent hydroquinone 0.21g, separated water and refluxed for 8 hours to obtain the initial product; after the reaction, the ...

Embodiment 2

[0029] In a 1-ton reactor equipped with mechanical stirring, thermometer and reflux condenser, add 225KgHBPE-10 and 402Kg dimethylolpropionic acid, add 3.135Kg p-toluenesulfonic acid, and heat to 160℃ under the protection of nitrogen. 4h; under vacuum conditions, continue the reaction, when the acid value of the reaction is less than 30mgKOH / g, the reaction is over, and cool to obtain a colorless and transparent solid, which is the second generation of hydroxyl-terminated hyperbranched polyester, denoted as HBPE-20, which The number of terminal functional groups is 16.

[0030] Take 30.6g of the second-generation hydroxyl-terminated hyperbranched polyester (HBPE-20) prepared by the above method, 9.2g acrylic acid, and 60g solvent. After heating to dissolve at 150°C, add 0.04g catalyst and 0.054g polymerization inhibitor After the reaction is completed, the initial product is poured into 5L of water while it is hot, stirred for 1 hour, and then allowed to stand for 2 hours; the up...

Embodiment 3

[0033] In a 1 ton reactor equipped with mechanical stirring, thermometer and reflux condenser, add 260Kg of HBPE-20 and 364Kg of dimethylolpropionic acid, add 3.12Kg of p-toluenesulfonic acid, and heat to 160℃ under the protection of nitrogen. 4h; under vacuum condition, continue the reaction, when the acid value of the reaction is less than 30mgKOH / g, the reaction is over, cool, and obtain a colorless and transparent solid, which is the third generation of hydroxyl-terminated hyperbranched polyester, denoted as HBPE-30, The number of hydroxyl groups is 32.

[0034] Take 15.3g of the third-generation hydroxyl-terminated hyperbranched polyester (HBPE-30) prepared by the above method, 4.17g acrylic acid, and 28g solvent. After heating to dissolve at 90°C, add 0.1g catalyst and 0.1g polymerization inhibitor After the reaction is completed, the initial product is poured into 5L of water while it is hot, stirred for 0.5h, and then allowed to stand for 1h; the upper water layer is sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com