Synthesis method of red-mud-based high-temperature-resistant inorganic coating

A technology of high temperature resistant coatings and synthesis methods, applied in the direction of fireproof coatings, coatings, etc., can solve the problems of poor water resistance, high price, strict requirements for substrate surface treatment, etc., and achieve low cost, easy operation, and obvious price advantages Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

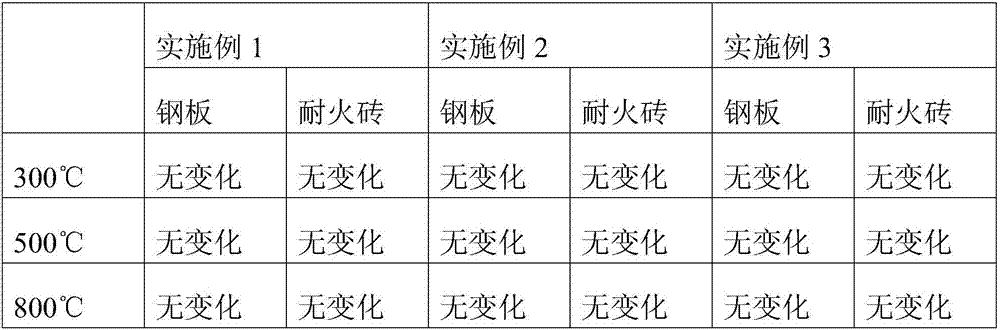

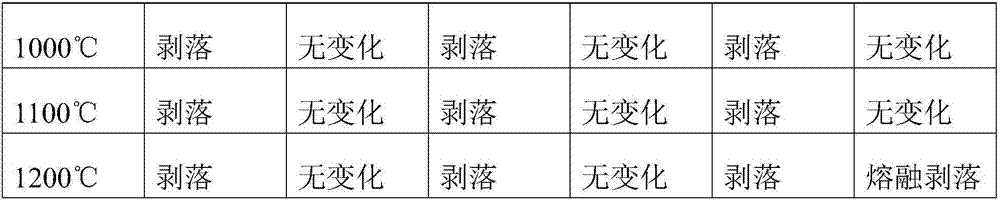

Embodiment 1

[0016] The red mud is calcined at 800°C for 2 hours, ball milled and passed through a 200-mesh sieve after calcination, and then calcined according to the mass ratio of red mud: phosphoric acid: deionized water: metakaolin: defoamer = 5:5:2:0.5:0.5 Add phosphoric acid, deionized water, metakaolin and defoamer in an appropriate amount, and stir evenly to obtain the product.

[0017] Taking adhesion as the main inspection index, the adhesion performance is tested according to the cross-cut method of the national standard GB / T9286-1998, and the adhesion performance reaches level 1.

Embodiment 2

[0019] Red mud is first calcined at 700°C for 2 hours, after calcining, ball milled and passed through a 180-mesh sieve, and then calcined according to the mass ratio of red mud: phosphoric acid: deionized water: metakaolin: defoamer = 5:5:2:1:0.5 Add phosphoric acid, deionized water, metakaolin and defoamer in an appropriate amount, and stir evenly to obtain the product.

[0020] Taking adhesion as the main inspection index, the adhesion performance is tested according to the cross-cut method of the national standard GB / T9286-1998, and the adhesion performance reaches level 1.

Embodiment 3

[0022] Red mud is first calcined at 900°C for 1 hour, ball milled and passed through a 220-mesh sieve after calcination, and then calcined according to the mass ratio of red mud: phosphoric acid: deionized water: metakaolin: defoamer = 5:5:2:1:0.5 Add phosphoric acid, deionized water, metakaolin and defoamer in an appropriate amount, and stir evenly to obtain the product.

[0023] Taking adhesion as the main inspection index, the adhesion performance is tested according to the cross-cut method of the national standard GB / T9286-1998, and the adhesion performance reaches level 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com