Early strength asater resistant dispersion and anti-dissolving shielding tunnel back lining filling material and its preparation method

A water-resistant dispersion, shield tunneling technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of low strength, strength shrinkage, reduced service life, etc. Highly durable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

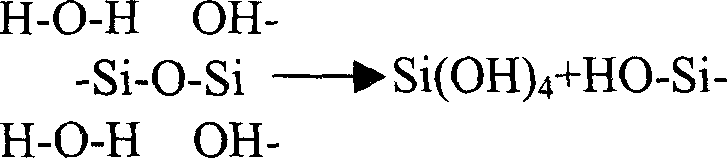

Method used

Image

Examples

Embodiment Construction

[0045] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

[0046] A method for preparing an early-strength anti-water dispersion and anti-corrosion shield tunnel backing grouting material, comprising the following steps: first weighing fly ash, slag, steel slag, metakaolin, sodium fluorosilicate, silica fume, Hydroxyethylmethyl cellulose, sand and water, then pour them into a stirring container and stir for 1 minute (min), form A liquid and transport it to the site; at the same time prepare the required water glass solution (B liquid) and store it in another In the container, but the storage time shall not exceed 1 day (d); then mix the water B liquid and A liquid in another container for 10 seconds (s) and then pour it immediately. The specific implementation examples and results are shown in T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com