Cutterhead supporting device

A support device and cutter head technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of inconvenient repair and replacement, limited space, and high procurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

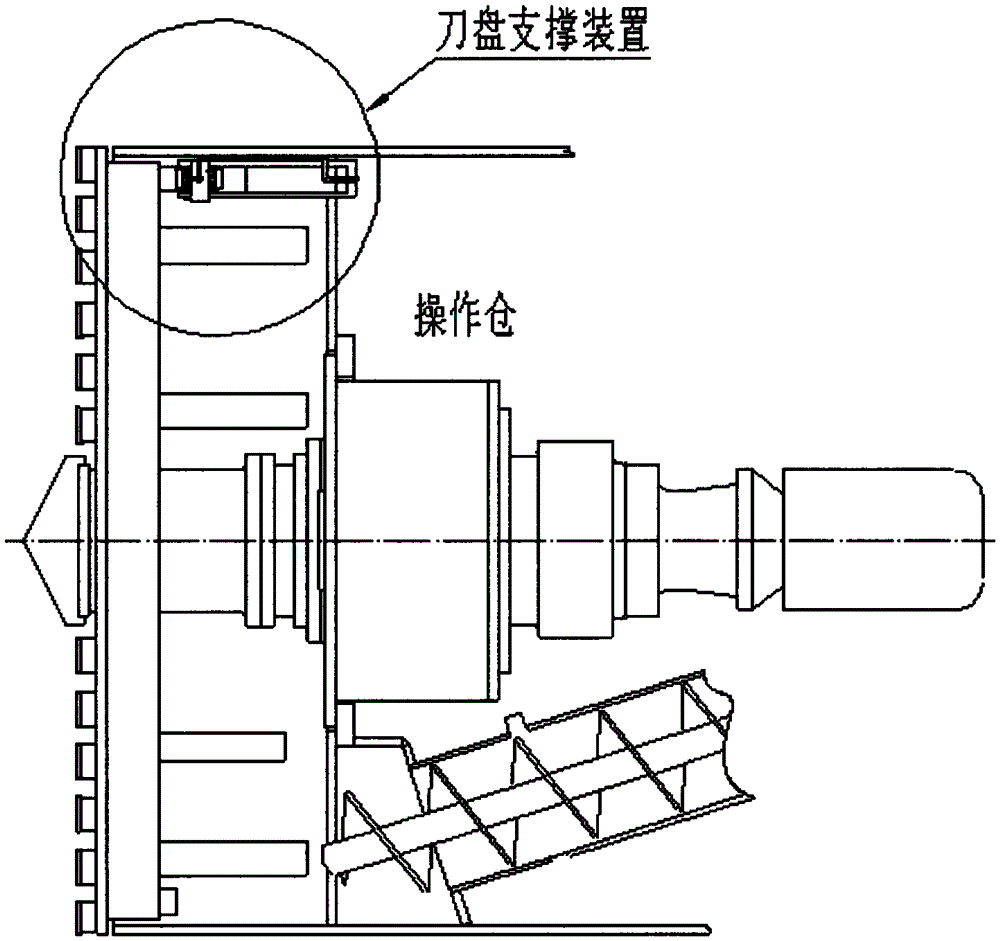

[0018] Such as figure 1 As shown: the cutterhead supporting device provided by the present invention needs to be provided with a circular track 1 behind the cutterhead, and several cutterhead supporting devices are respectively arranged along the circumference on the partition plate of the roadheader to support the cutterhead.

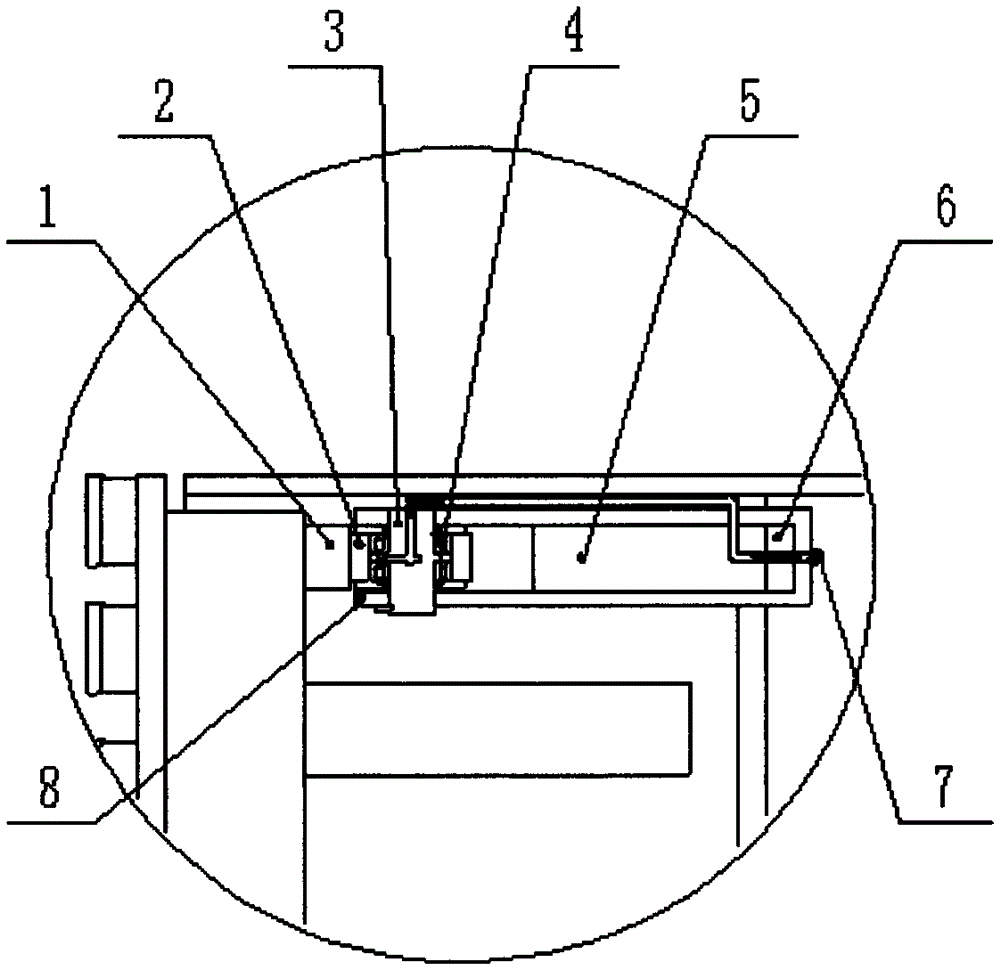

[0019] Such as figure 2 Shown: the cutter head supporting device provided by the present invention is composed of roller 2, roller shaft 3, bearing 4, bracket 5, inclined iron 6, oil nozzle 7, clamping plate 8 and circular track 1.

[0020] The roller 2 is supported on the roller shaft 3 by the bearing 4, and the roller shaft 3 is installed on the support 5 and fixed by the clamping plate 8.

[0021] The support 5 passes through the dividing plate of the working chamber of the roadheader and is fixed by the wedge iron 6 .

[0022] A lubricating oil path is provided on the support 5, and when the roadheader is working, oil can be supplied to the bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com