Fabricated single-slope type bridge anti-collision guardrail

An anti-collision guardrail and assembled technology, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of poor energy absorption and buffering effect, general guidance, large impact force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

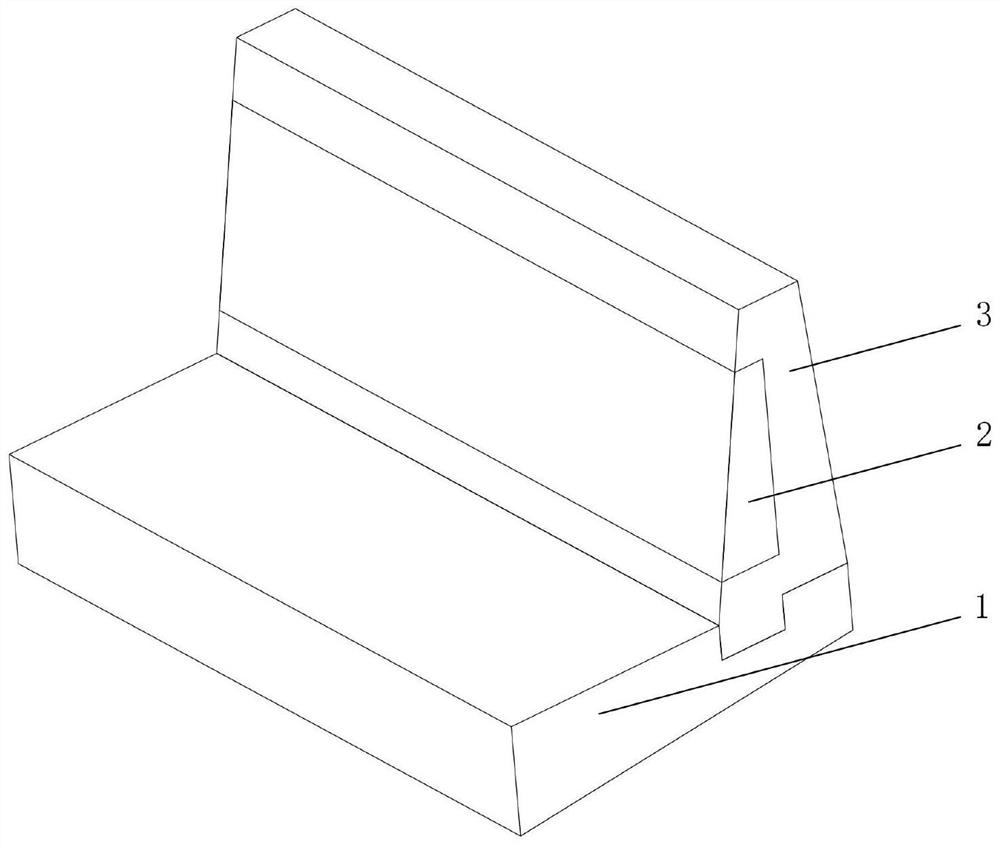

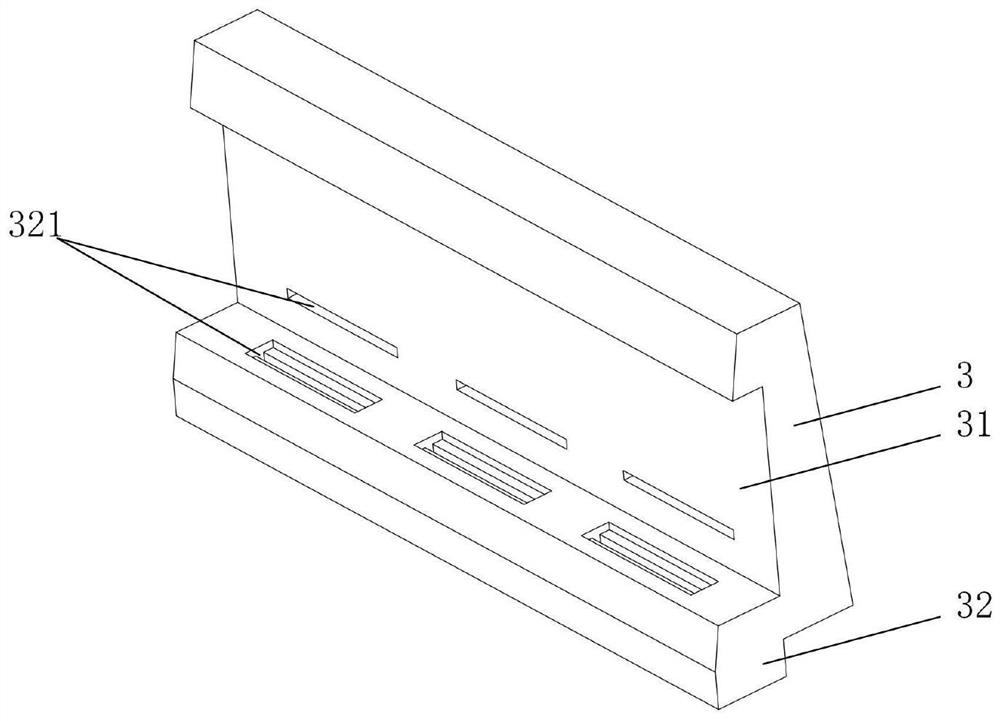

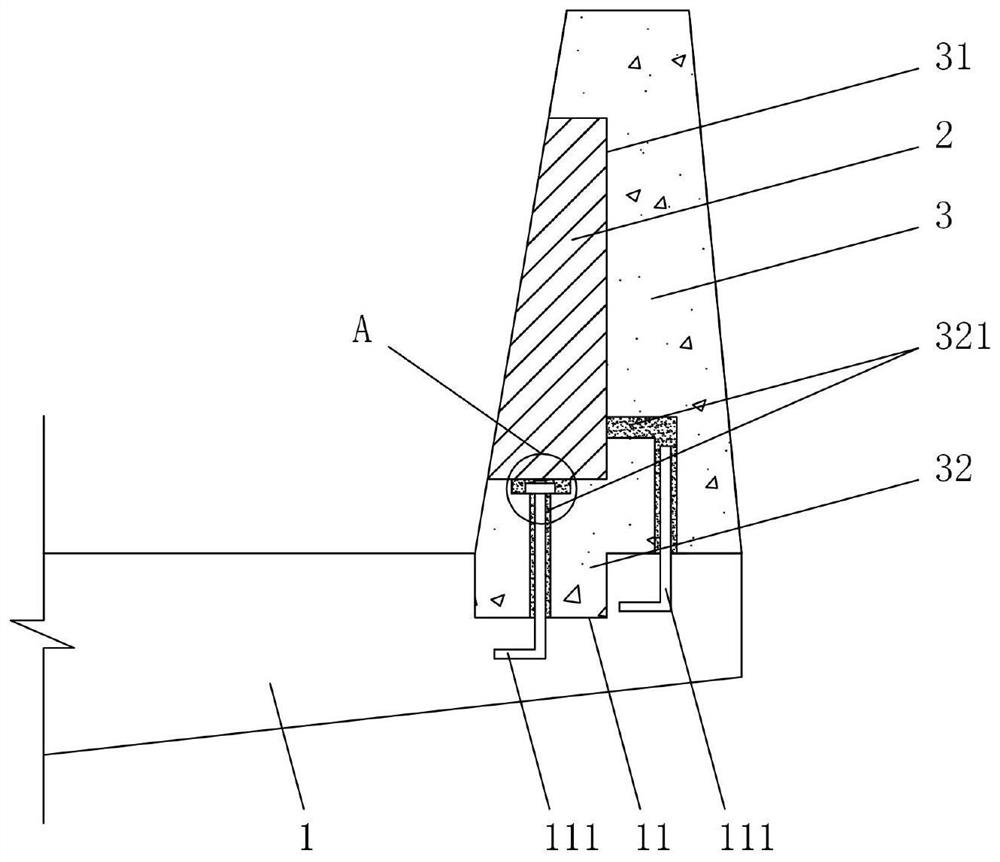

[0025] Such as Figure 1 to Figure 3 As shown, the prefabricated single-slope bridge anti-collision guardrail of this embodiment is installed on the cantilever edge 1 provided on the edge of the bridge road surface, and includes a buffer block 2 and at least one guardrail segment 3 arranged longitudinally along the bridge. The guardrail segment 3 The side facing the road surface of the bridge is provided with a buffer groove 31 along the longitudinal direction of the bridge, that is, the buffer groove 31 opens toward the collision surface inside the bridge, covering most of the area where the two contact when the vehicle hits the guardrail. The buffer block 2 is embedded in the In the buffer tank 31, and can move relative to the buffer tank 31 along the bridge longitudinal direction.

[0026] Since the buffer block 2 and the guardrail segment 3 are fit together, the overall strength of the bridge guardrail is reduced very little, ensuring its blocking effect. And the sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com