Patents

Literature

30results about How to "Reduce edge stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

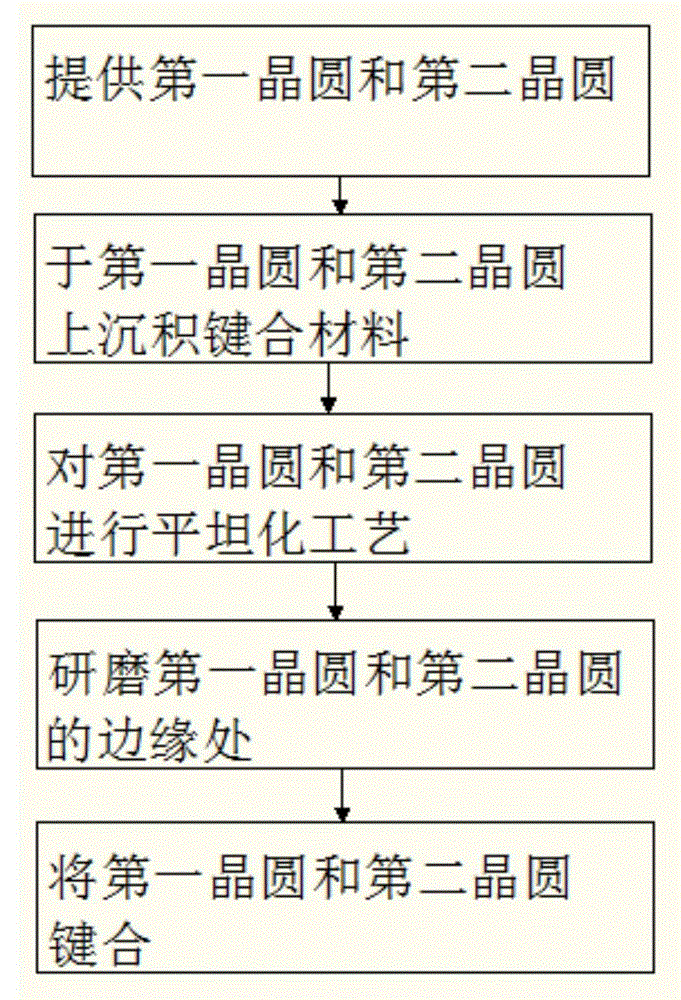

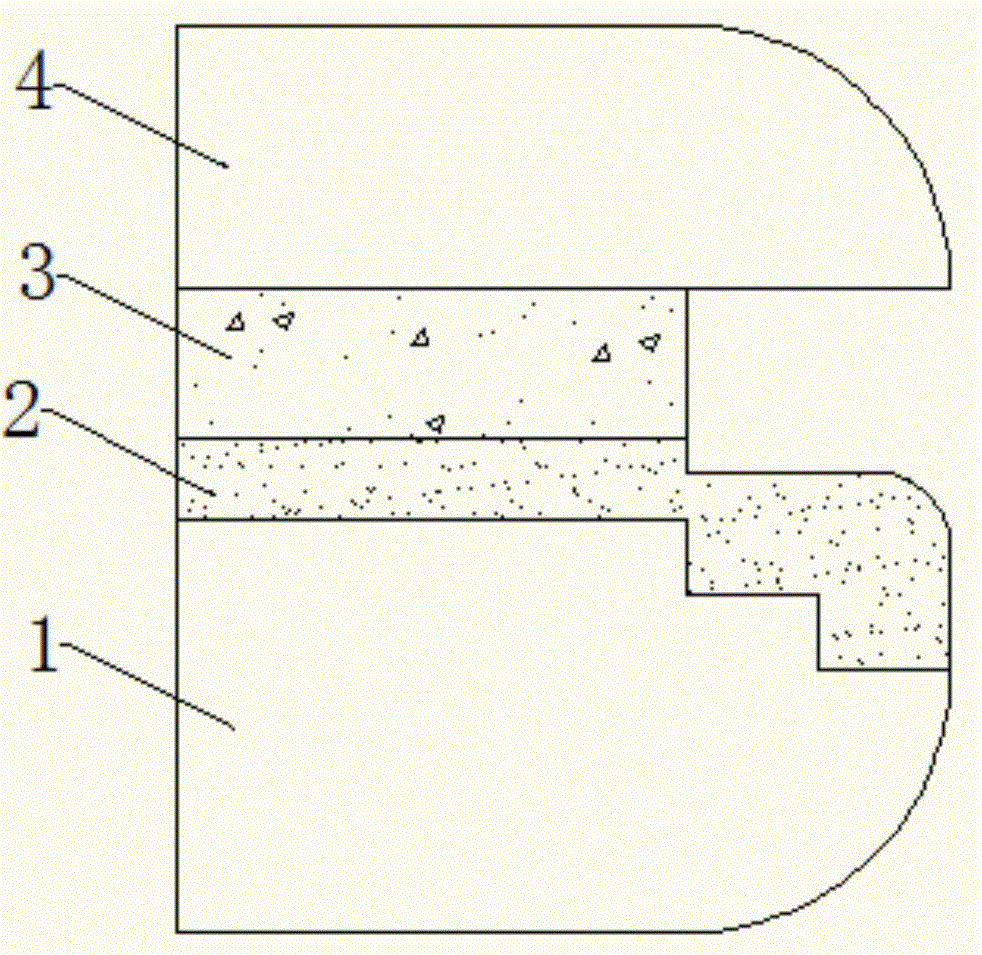

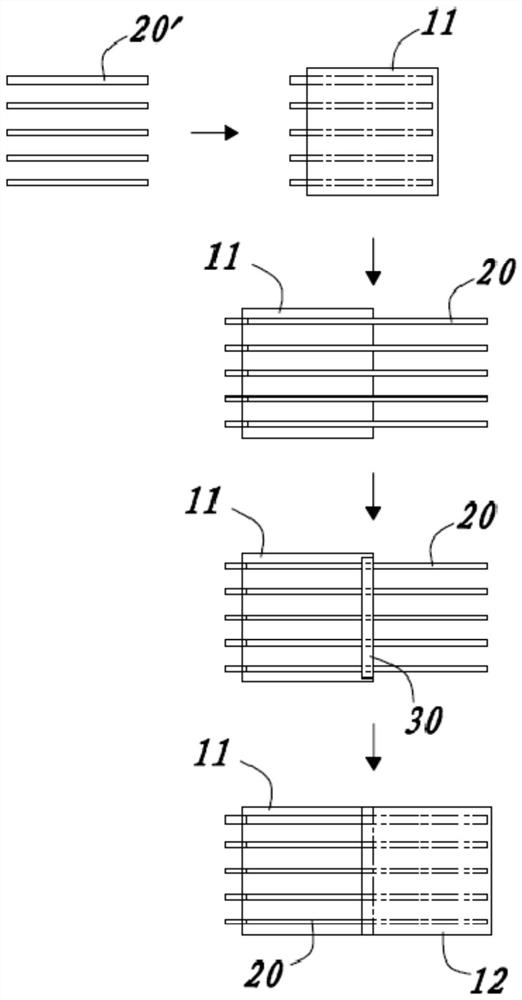

Wafer-level chip packaging method

ActiveCN105070668AReduce edge stressReduce warpageSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorSemiconductor device

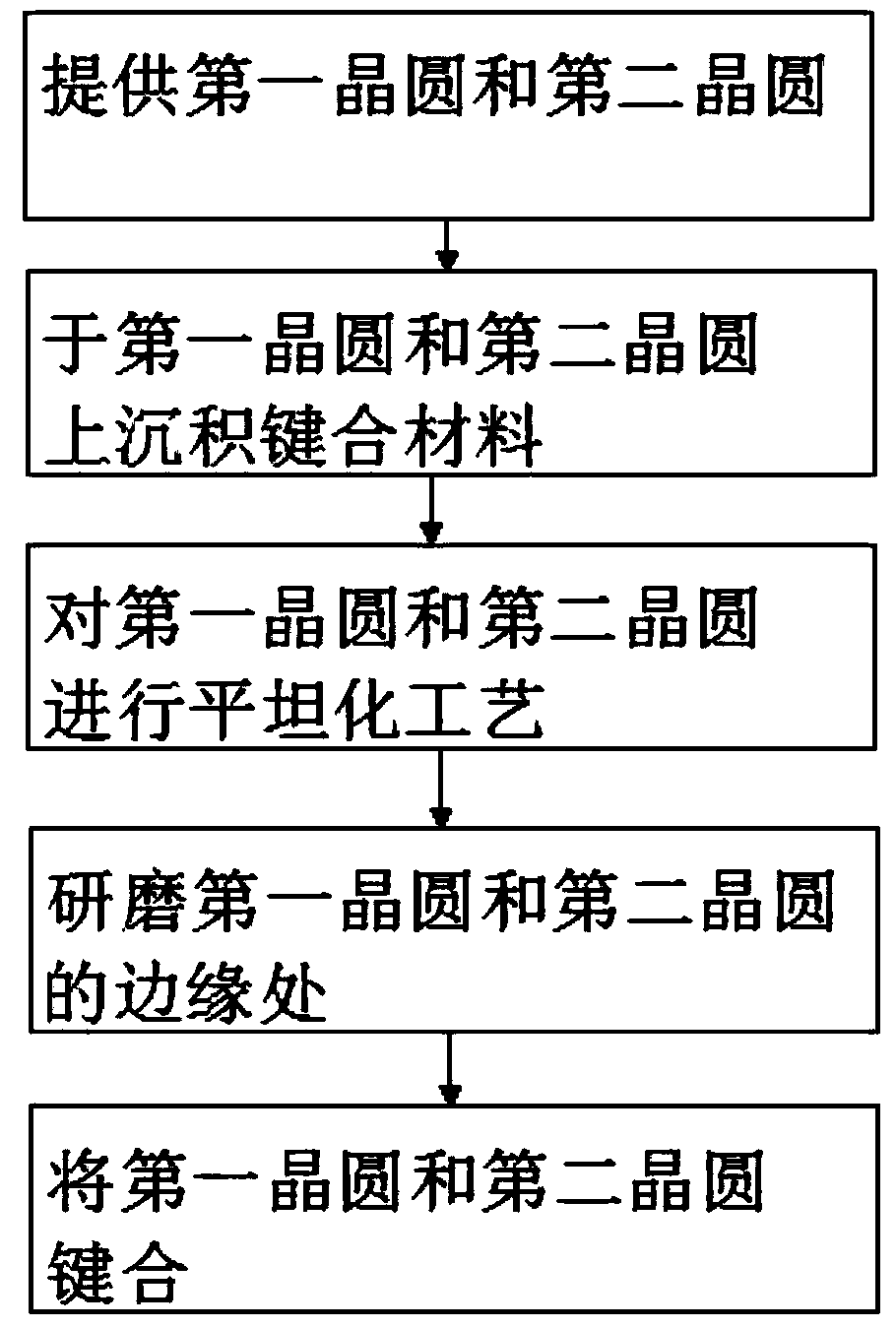

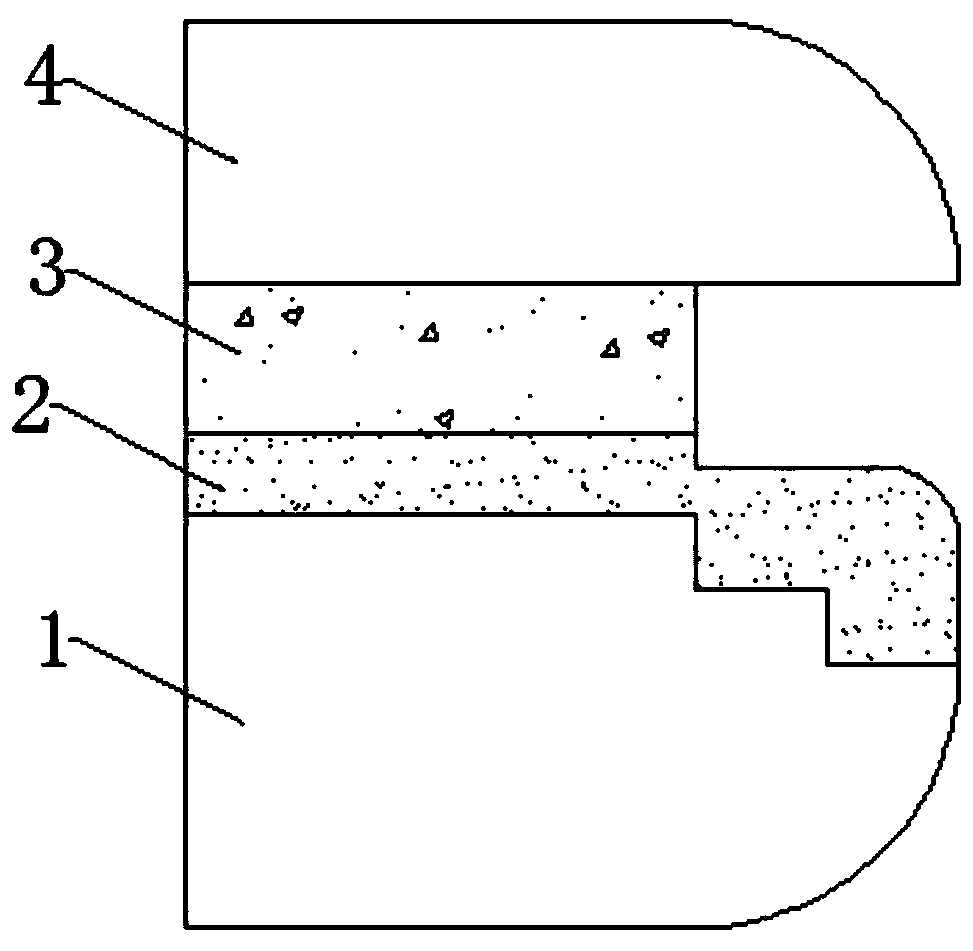

The invention relates to the field of the fabrication of a semiconductor device, in particular to a wafer-level chip package method. The wafer-level chip package method comprises the following steps of: arranging a bonding material on the supper surface of a first wafer and the upper surface of a second wafer; carrying out a planarization process on the bonding material; and finally, carrying out a grinding process on the edges of the first wafer and the second wafer to reduce the edge stress of the wafers so as to make warping degrees lower and make no crack at a bonding position of the first wafer and the second wafer. By changing the sequences of planarization and grinding, the edge warping degrees of the wafers are reduced so as to improve the wafer quality.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

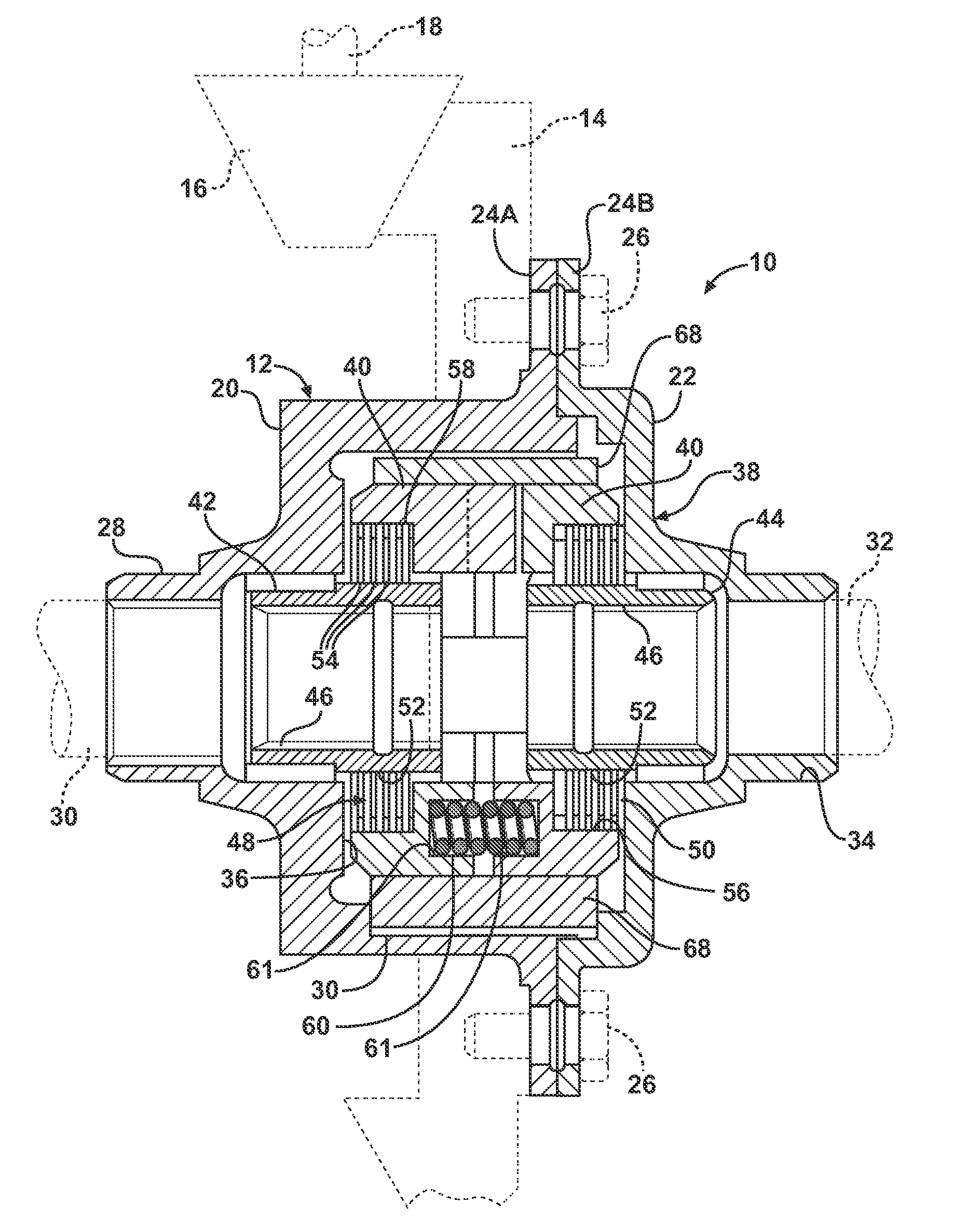

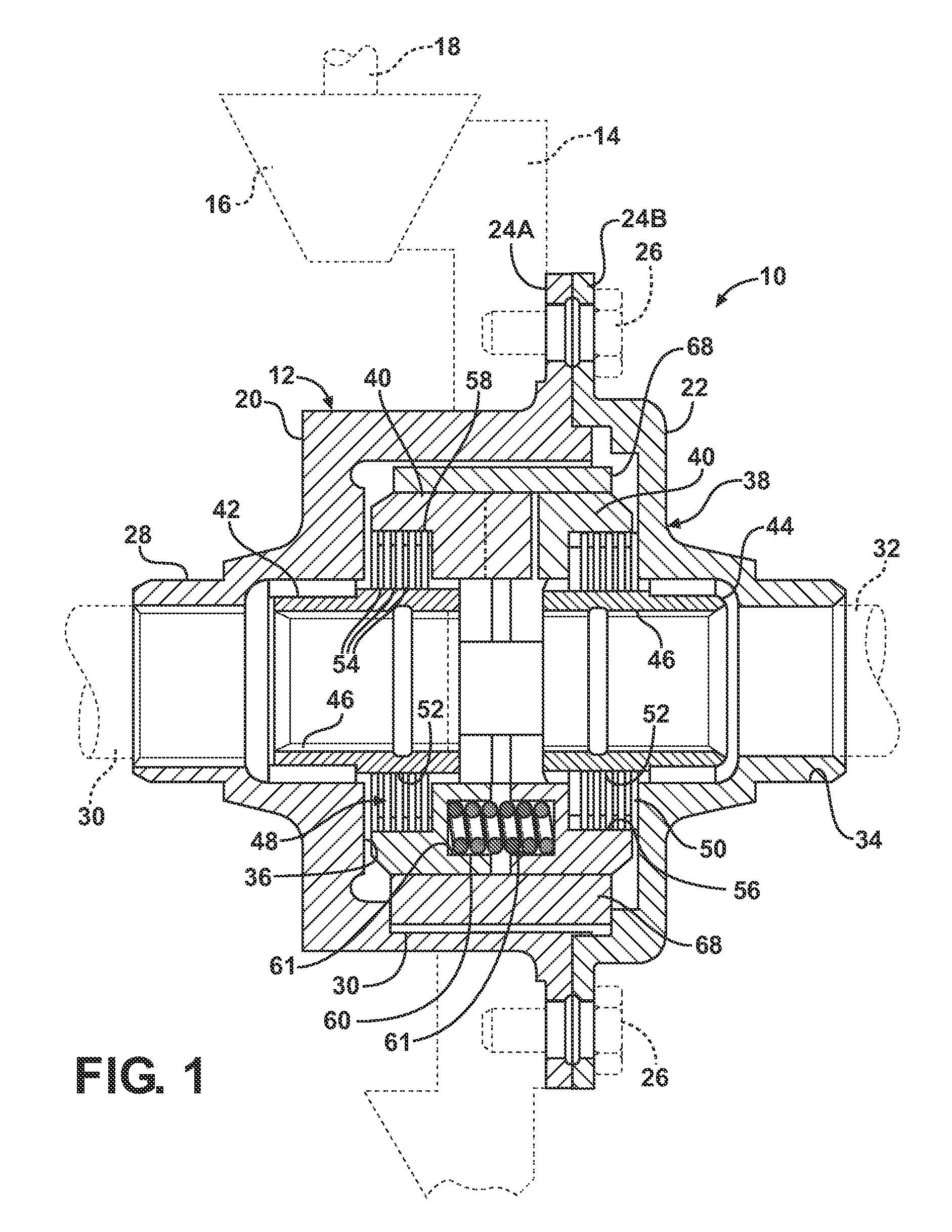

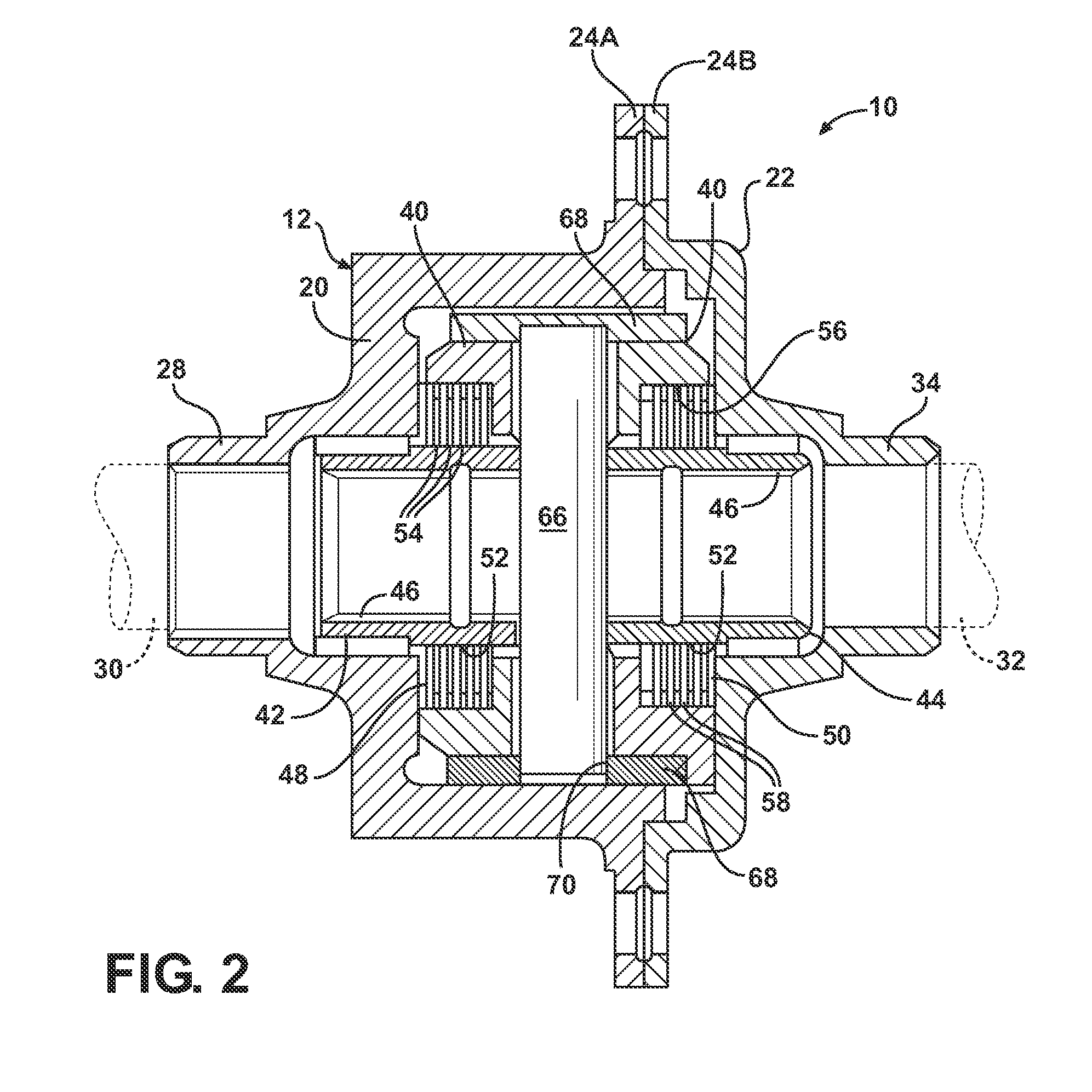

Locking differential having improved torque capacity

ActiveUS8146458B2Reduce edge stressIncreased torque densityDifferential gearingsControl devicesEngineeringLateral extension

A locking differential for an automotive vehicle including a housing and a differential mechanism supported in the housing. The differential mechanism includes a pair of clutch members disposed in spaced axial relationship with respect to each other wherein each clutch member includes a groove disposed in an opposed inwardly directing face that is adapted to receive a cross pin. Each of the grooves includes a working surface extending laterally relative to each other. Each of the working surfaces defines a screw involute surface such that the cross pin contacts the working surface along a line extending in the direction of the cross pin in the event of differential rotation of an axle half shaft relative to the housing. Alternatively, each of the working surfaces defines a slightly convex surface in one plane such that the cross pin contacts the working surface at a point defined thereon. In another embodiment, the working surface defines a slightly convex surface in two planes such that the cross pin contacts the working surface at a point defined thereon.

Owner:EATON INTELLIGENT POWER LTD

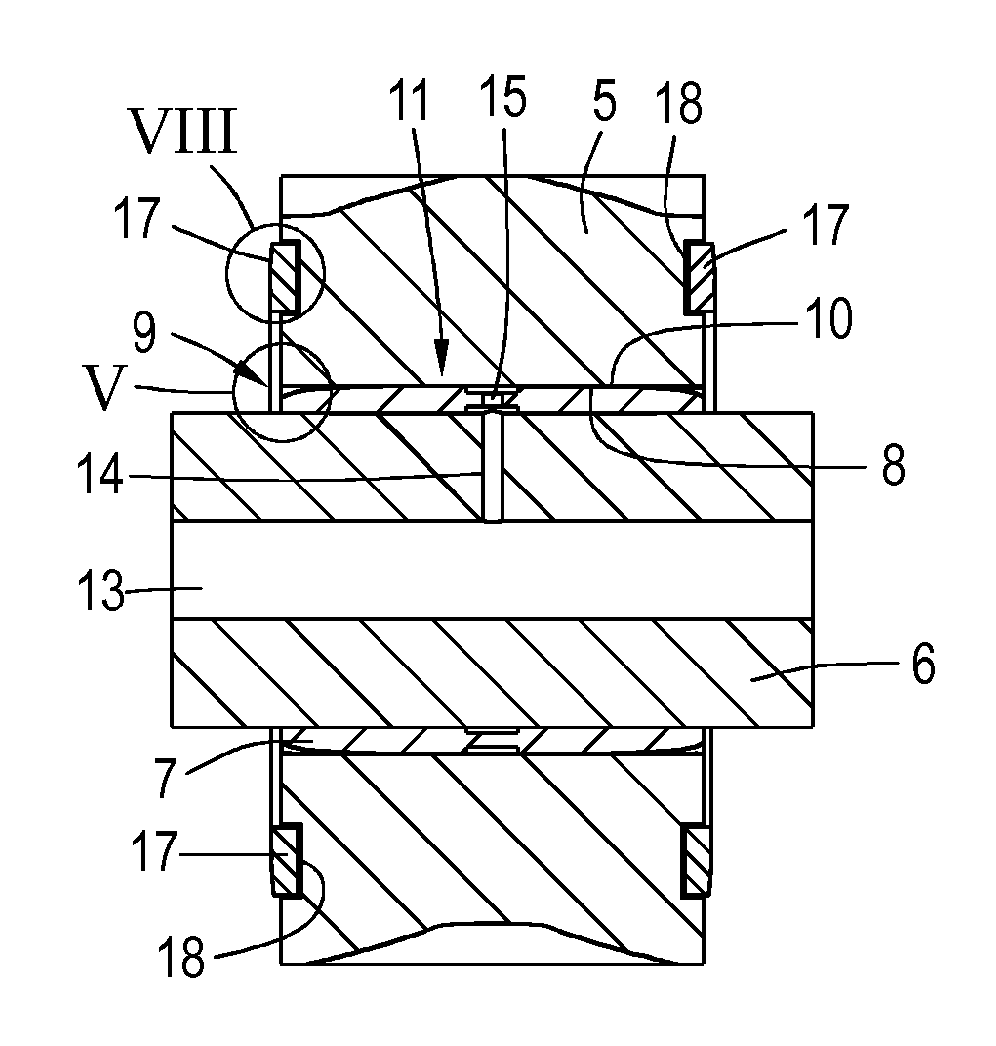

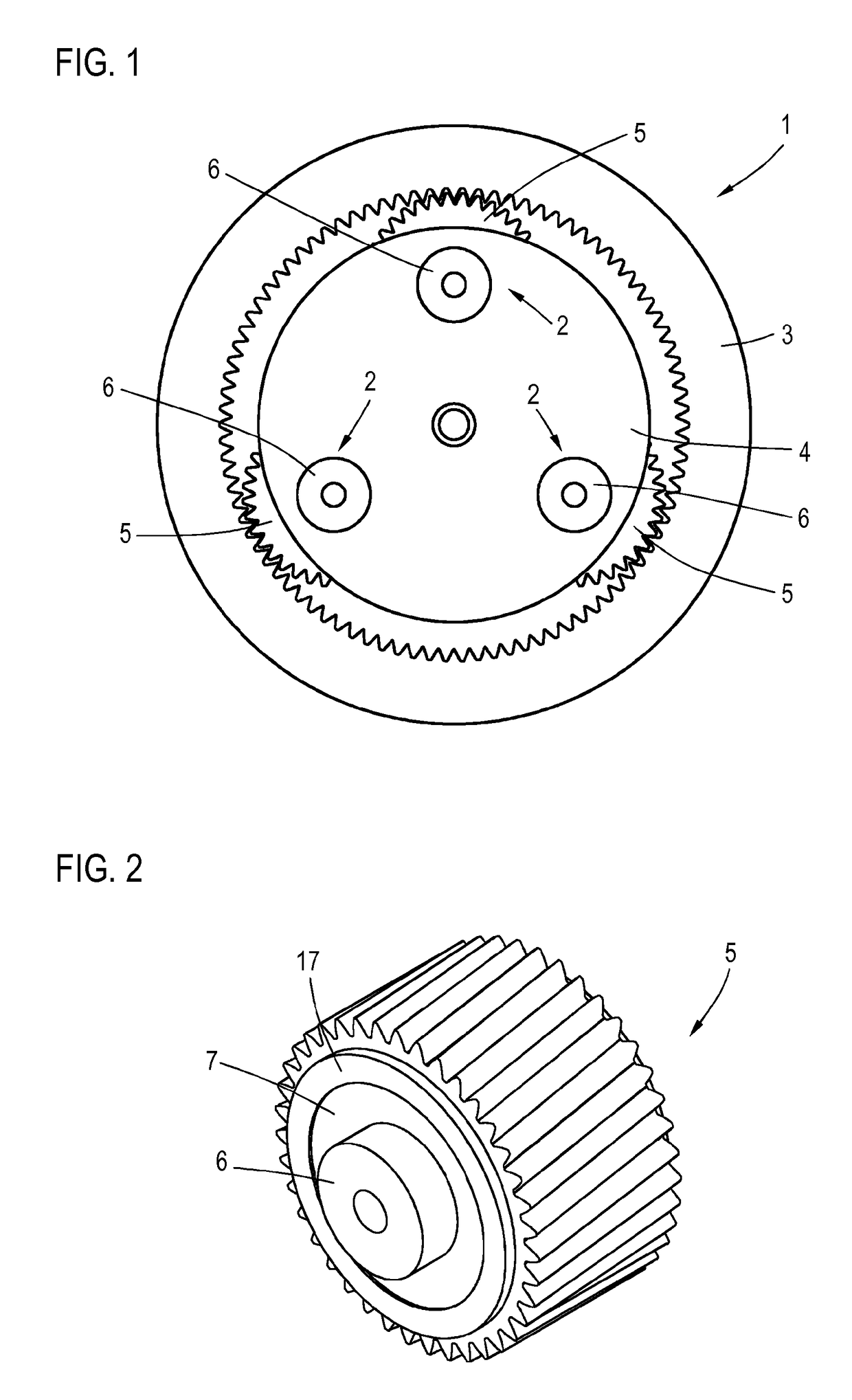

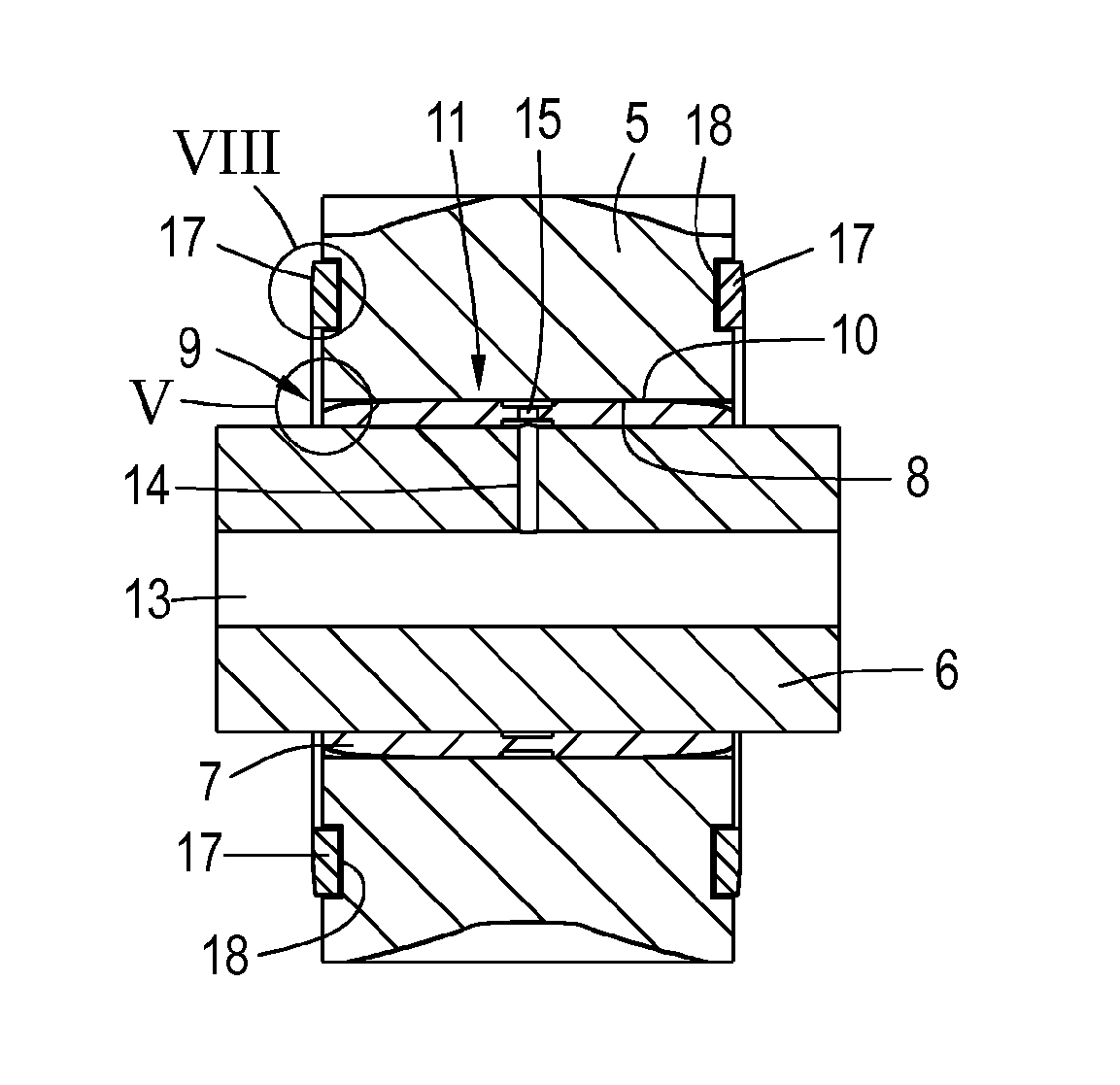

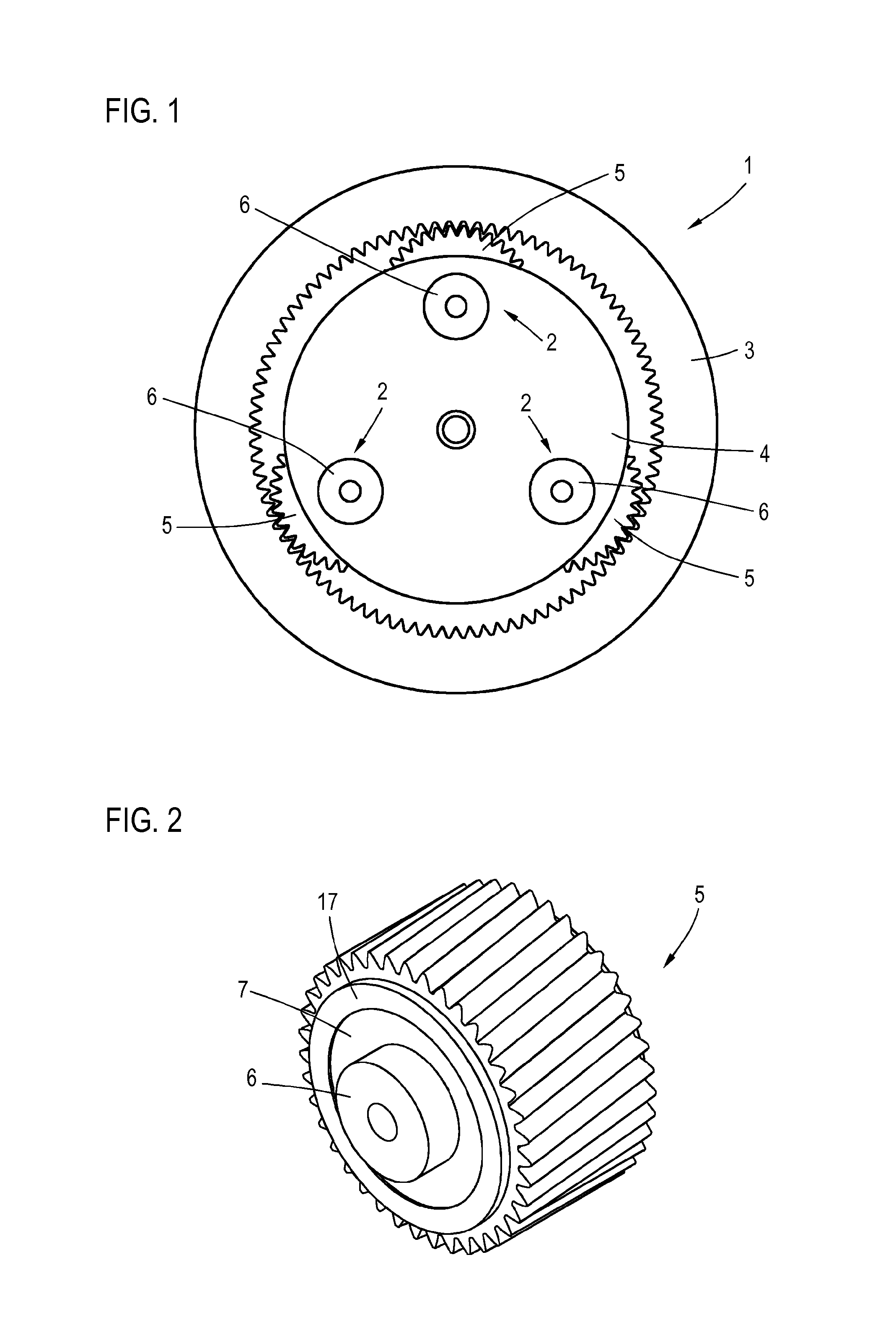

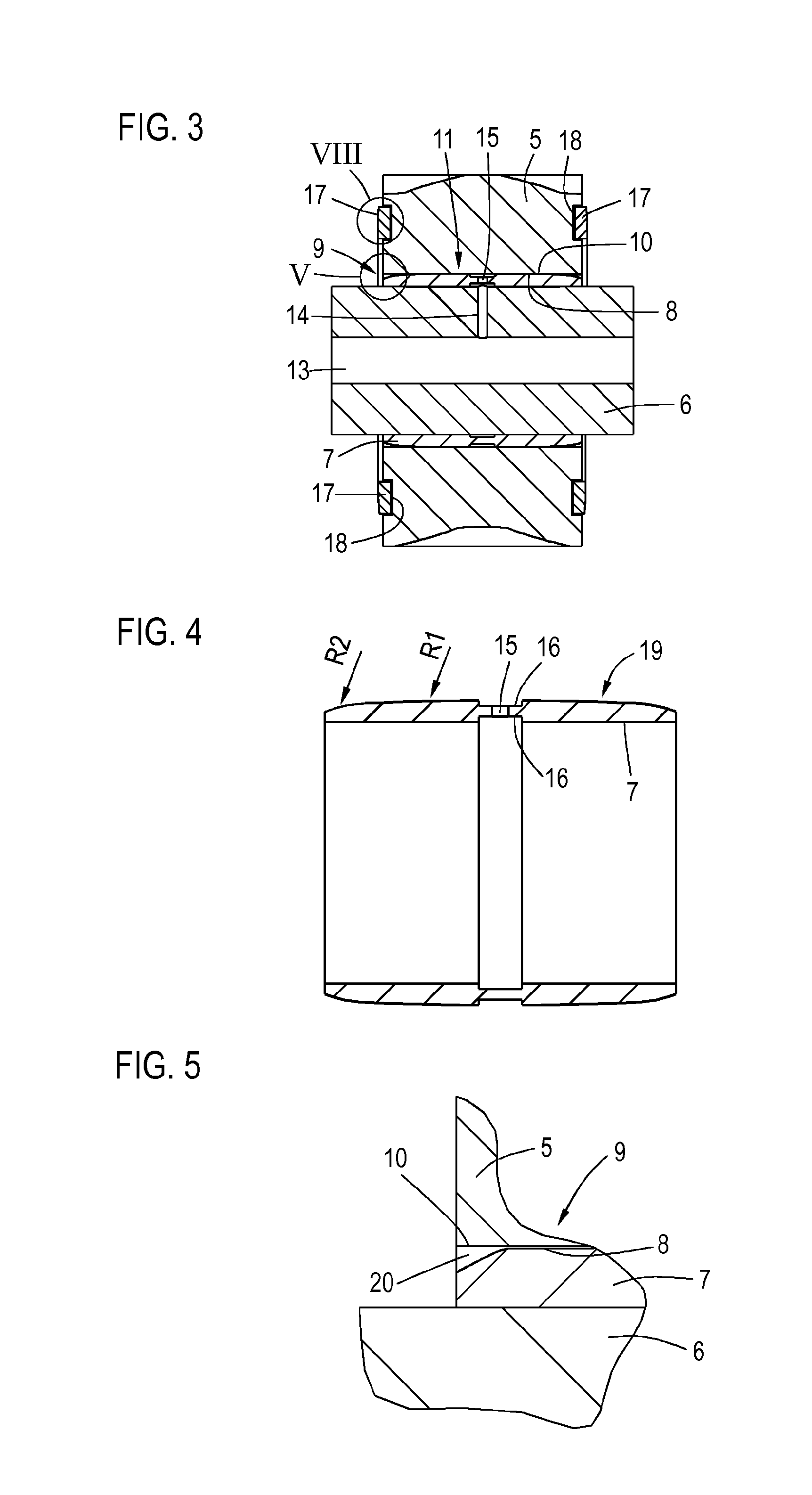

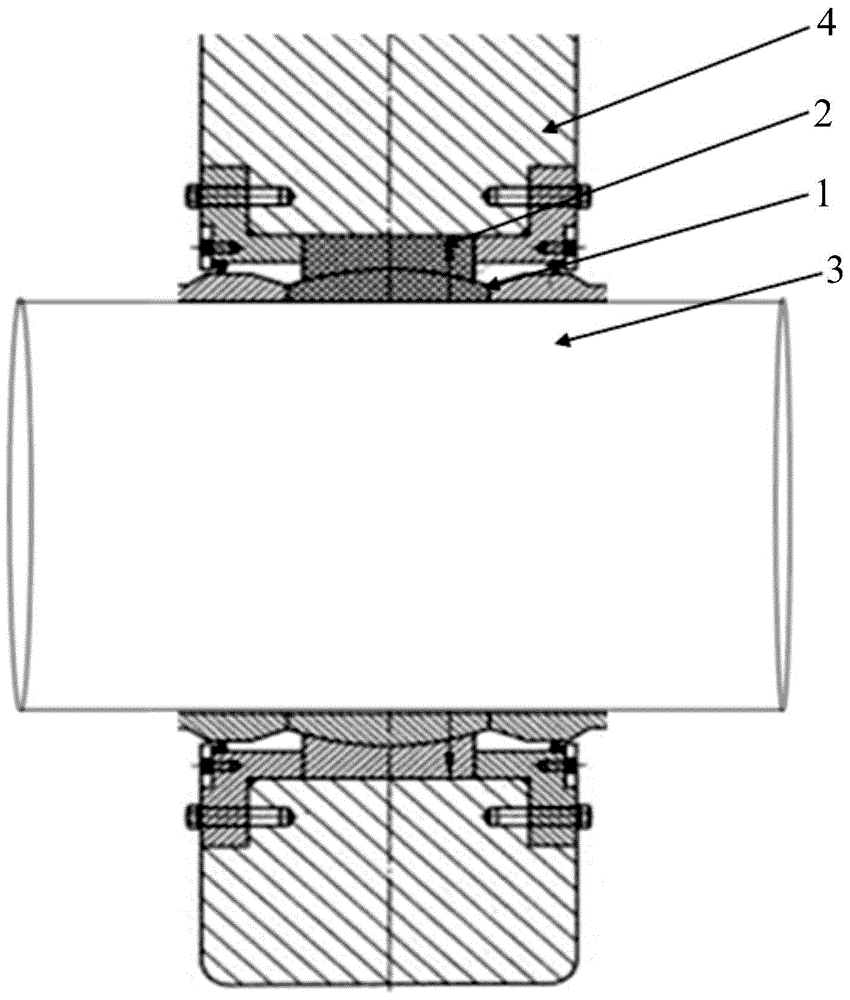

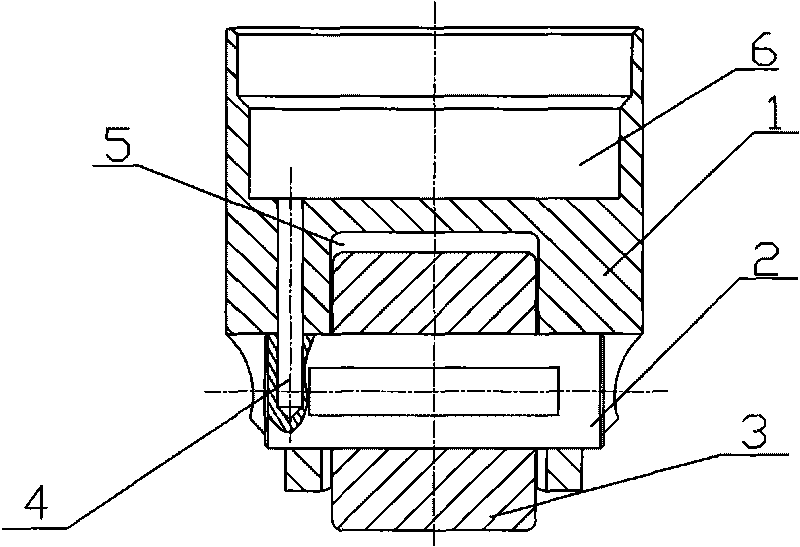

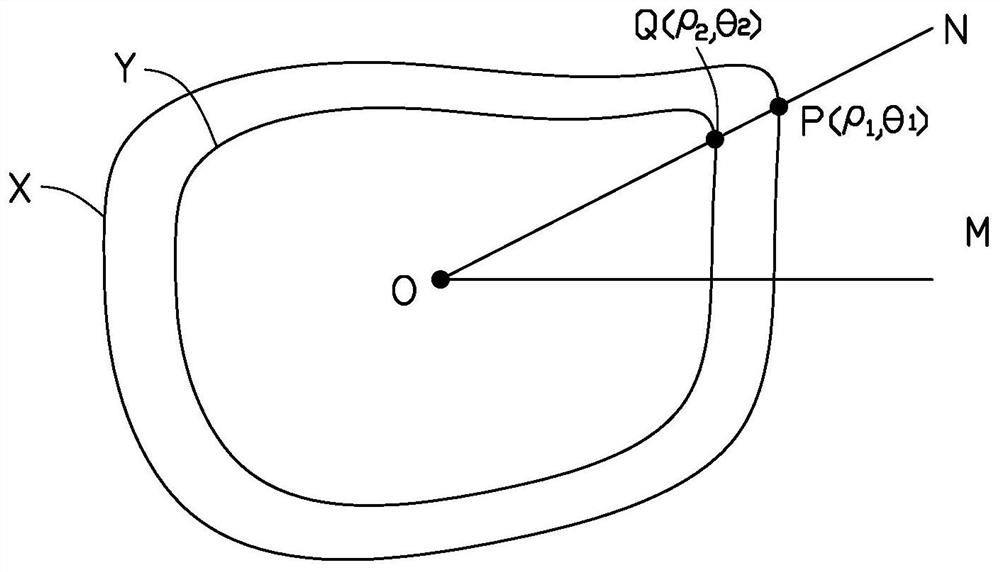

Planetary gear bearing arrangement

ActiveUS10047792B2Reduce edge stressExtreme wear resistanceEngine fuctionsShaftsFixed bearingGear wheel

A planetary gear bearing arrangement, including a planet carrier provided with a fixed bearing axis on which a planet gear is rotatably mounted via a sliding bearing that has a first antifriction layer on the axis side and a second antifriction layer on the gear side, wherein one of the two antifriction layers (8, 11) is created on a surface (10, 19) which is at least partially domed in the sliding region to reduce the edge pressure.

Owner:SCHAEFFLER TECH AG & CO KG

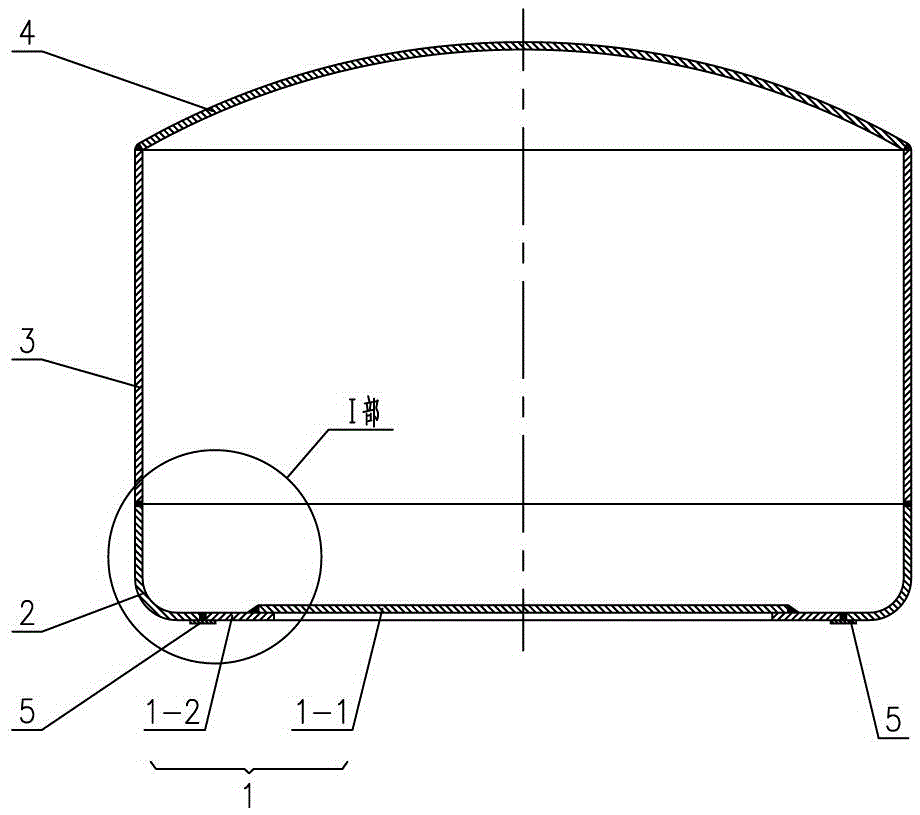

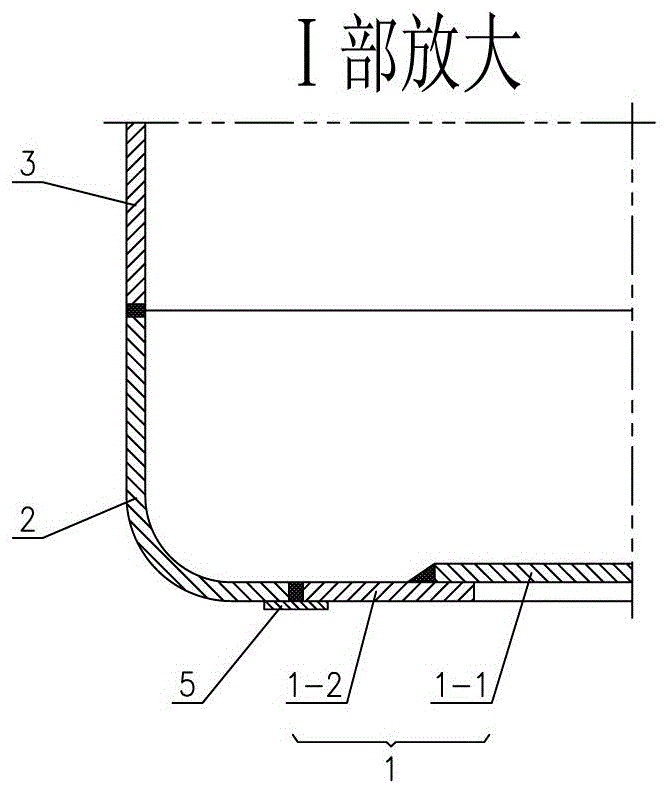

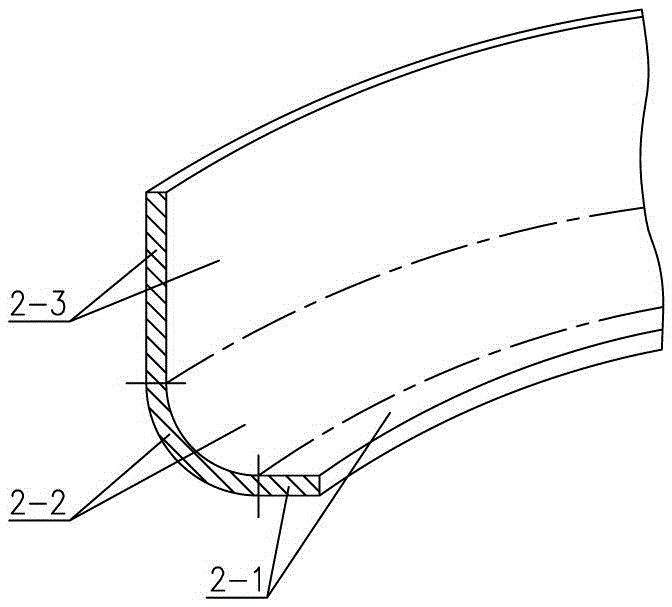

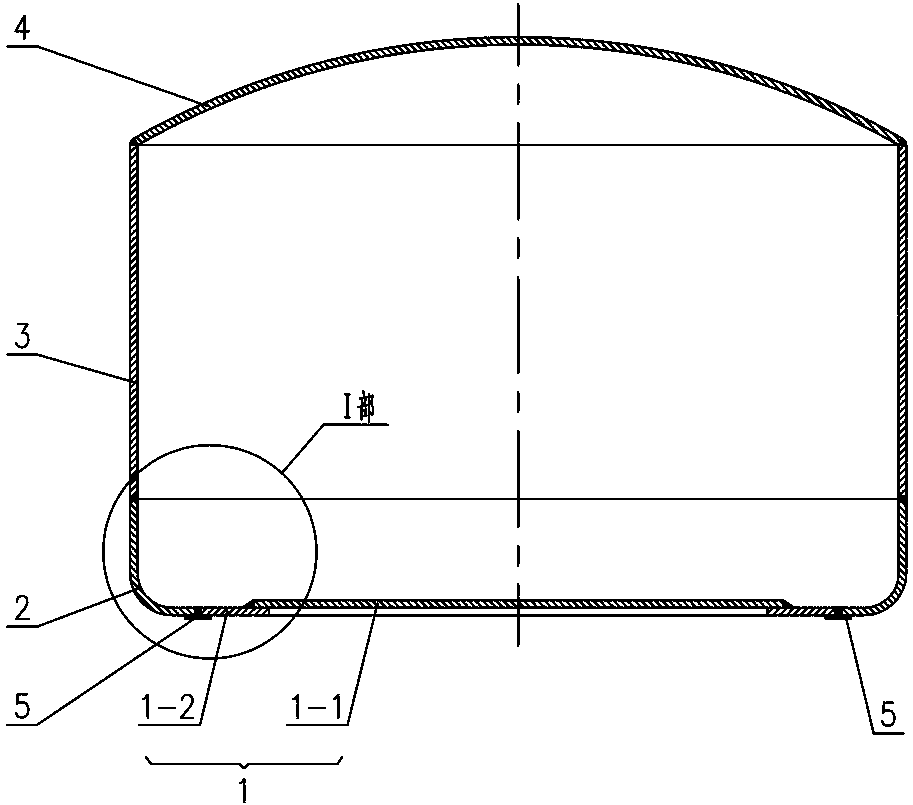

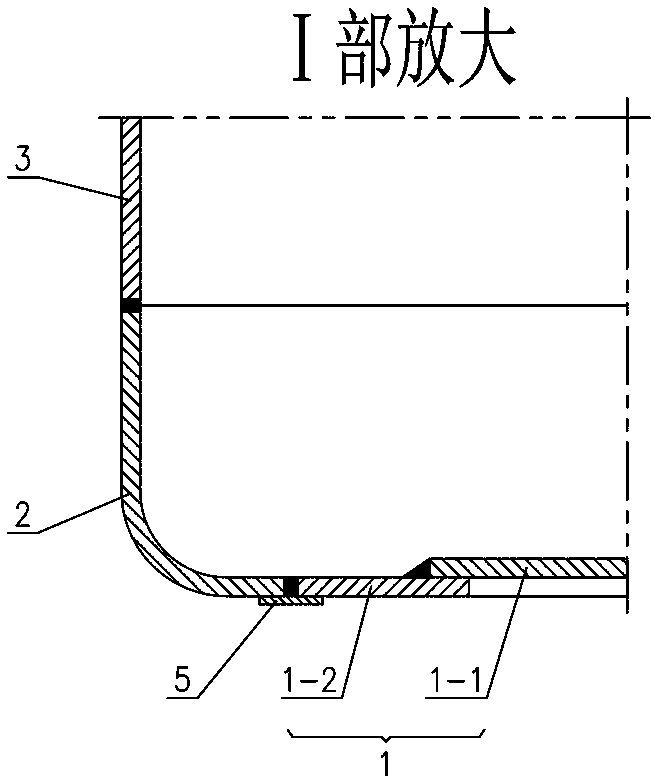

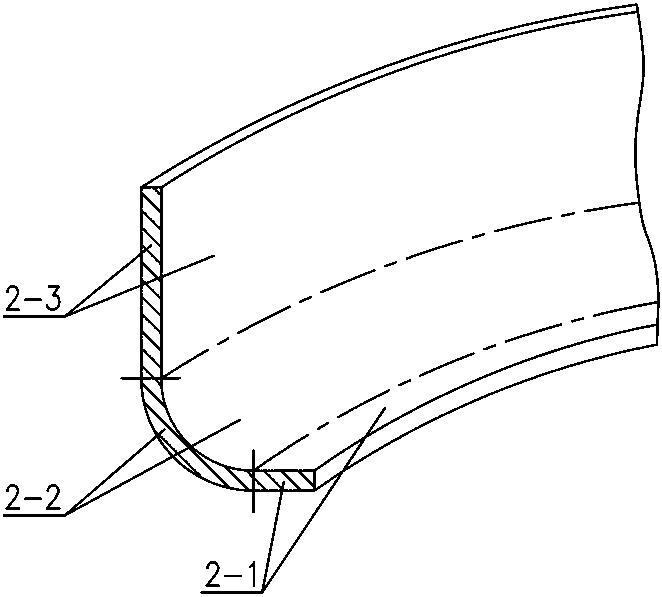

Large steel welded vertical oil tank

ActiveCN105600205AReduce edge stressEliminate welding residual stressLarge containersSafe operationWaste management

The invention provides a large steel welded vertical oil tank. The large steel welded vertical oil tank is provided with a tank bottom, a tank wall and a tank top. A transition connecting ring is arranged between the tank bottom and the tank wall and provided with an annular bottom section, an arc-shaped transition section and a vertical cylindrical section. The tank bottom is connected with the annular bottom section of the transition connecting ring in a welded mode. The tank wall is connected with the vertical cylindrical section of the transition connecting ring in a welded mode. The tank top can be a fixed top and can also be an outwards-floating top. The large steel welded vertical oil tank has the advantages that T-shaped joints of a tank wall and a tank bottom of an existing large oil tank and large fillet welds on the joints are omitted, main danger points of the whole oil tank are eliminated, and safe operation of the large oil tank is guaranteed, wherein the transition position between the tank wall and the tank bottom is not prone to low-cycle fatigue damage, an attachment weld of the transition portion between the tank wall and the tank bottom is not prone to tearing damage, the anti-seismic property of the large oil tank is greatly improved, and the anti-seismic property of the large oil tank is good.

Owner:JIANGSU CHEM EQUIP MFG & INSTALLATION CO LTD

Planetary gear bearing arrangement

ActiveUS20160341248A1Reduce edge stressExtreme wear resistanceEngine fuctionsShaftsFixed bearingGear wheel

A planetary gear bearing arrangement, including a planet carrier provided with a fixed bearing axis on which a planet gear is rotatably mounted via a sliding bearing that has a first antifriction layer on the axis side and a second antifriction layer on the gear side, wherein one of the two antifriction layers (8, 11) is created on a surface (10, 19) which is at least partially domed in the sliding region to reduce the edge pressure.

Owner:SCHAEFFLER TECH AG & CO KG

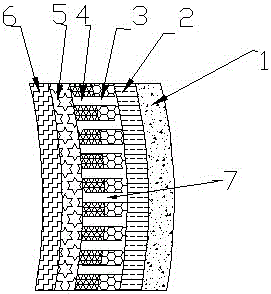

Valve tappet device of engine

ActiveCN101737109AGuaranteed up and down motionIncrease contact stressValve arrangementsMachines/enginesFriction reductionEngine valve

The invention relates to a valve tappet device of an engine, which belongs to the technical field of mechanical structures. According to the technical scheme of the invention, the valve tappet device of the engine comprises a tappet body and is characterized in that a positioning groove is formed at the lower end of the tappet body, and concentric through holes which are vertical to the axial line of the tappet body are formed on two side wings forming the positioning groove; two ends of a roller pin are respectively positioned in the through holes of the two side wings; and a roller is arranged on the roller pin, and the roller is positioned in the positioning groove. The valve tappet device removes a bush between the roller and the roller pin, thereby reducing the number of parts, reducing the friction, reducing the cost and facilitating the production. The valve tappet device can increase the diameter and the width of the roller and the roller pin, improve the strength of the roller and the roller pin, reduce the contact stress between the roller and a cam, increase the reliability of a product, arrange an ejector rod slot on the tappet body, effectively increase the contact area between an ejector rod and the tappet body, significantly reduce the edge stress, greatly enhance the performances of abrasion resistance, tension resistance and pressure resistance and effectively prolong the service life of the tappet body.

Owner:WUXI XIZHOU MACHINERY

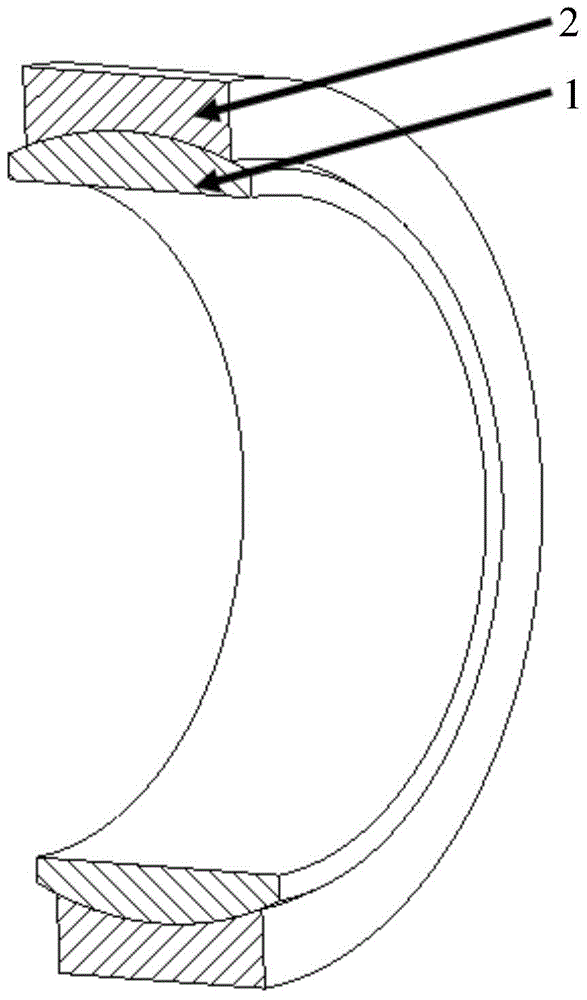

Spherical plain bearing

InactiveCN104791384AReduce edge stressReduce stiffnessRotary bearingsBearing componentsStructural engineeringMechanical engineering

A spherical plain bearing comprises an inner ring with an outer spherical surface and an outer ring which sleeves the inner ring. The outer ring has an inner spherical surface which is in sliding fit with the outer spherical surface of the inner ring and an annular end face which is axially positioned at two sides of the inner spherical surface. The annular end face is provided with a slot. With the application of the spherical plain bearing of the technical scheme, the purpose of reducing edge stress of the outer ring and a bearing pedestal without the use of additional sleeves. Costs are reduced, and the step of installing sleeves is also omitted.

Owner:SCHAEFFLER TECH AG & CO KG

Preparation method of solar photovoltaic module

PendingCN113257934ASolve the problem of current mismatchReduce package lossFinal product manufacturePhotovoltaic energy generationEngineeringSilicon chip

The invention discloses a preparation method of a solar photovoltaic module. First batteries and second batteries which are different in area and identical in current are obtained; and the electrodes of the first batteries and the second batteries are reversely arranged at intervals. According to the preparation method, current matching of the module is achieved by adjusting the area of the batteries, the problem of module current mismatching caused by the difference of silicon wafer substrates used by the batteries and the difference of battery preparation processes is solved, the packaging loss of the module is reduced, and the output power of the module is improved.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

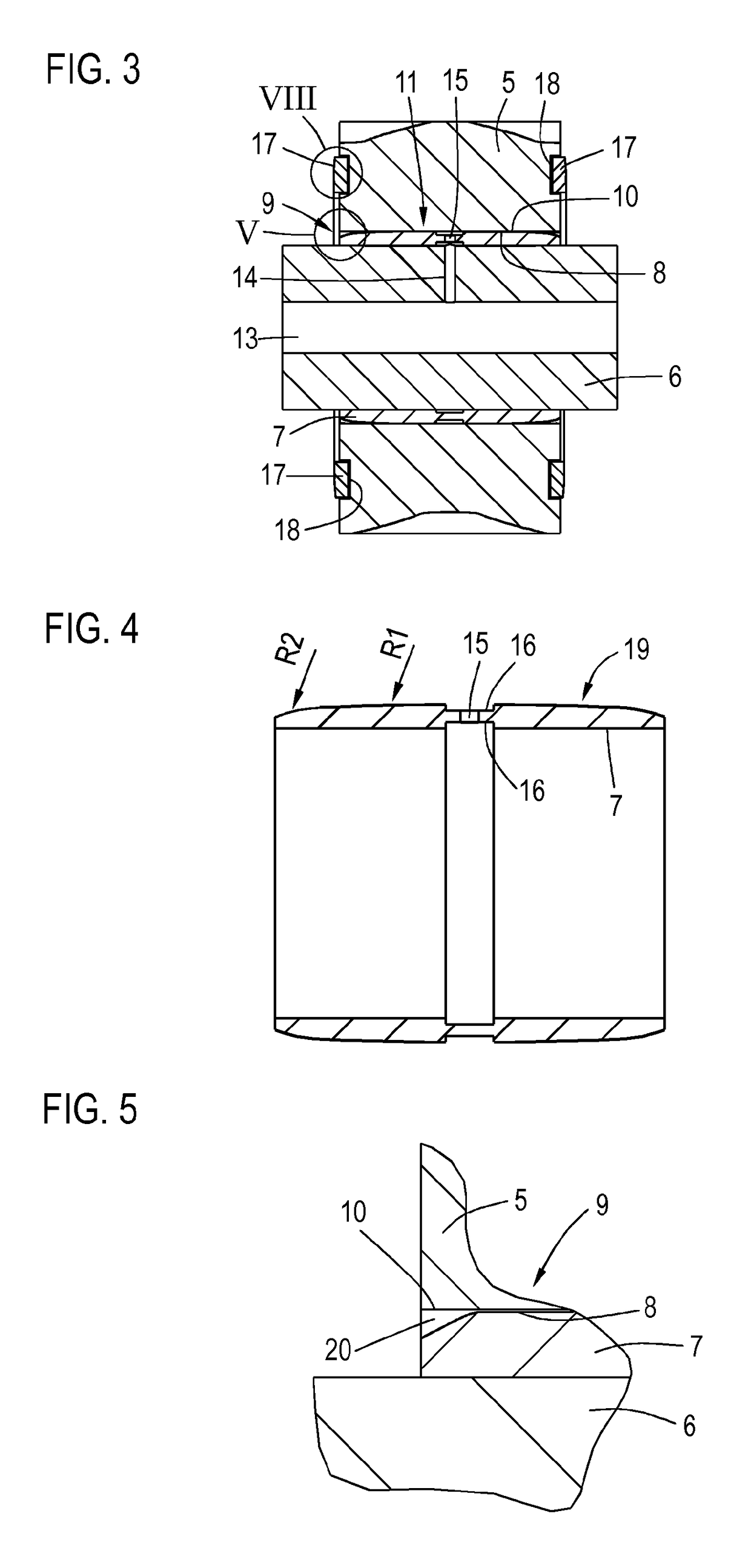

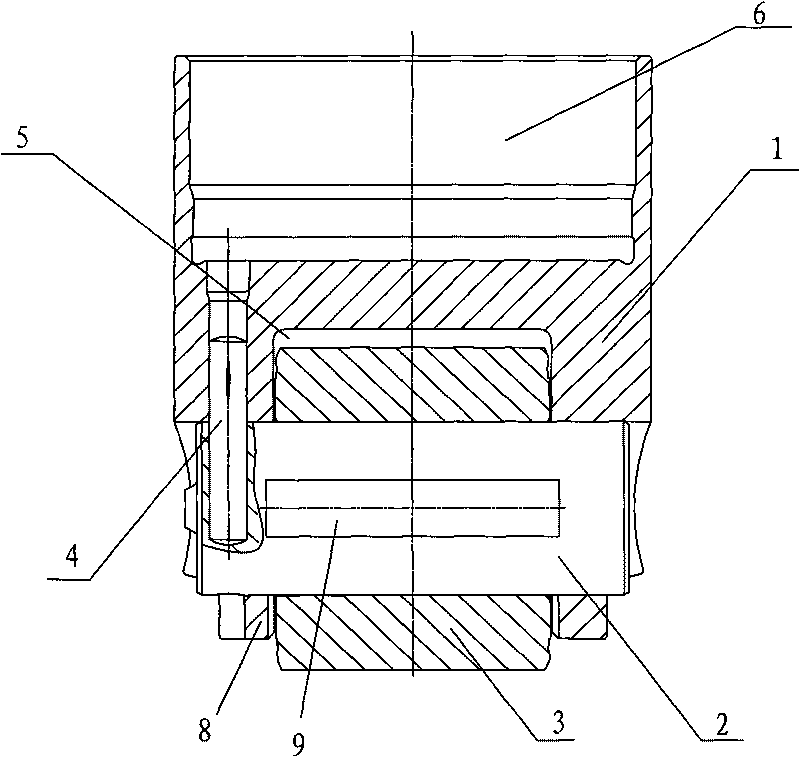

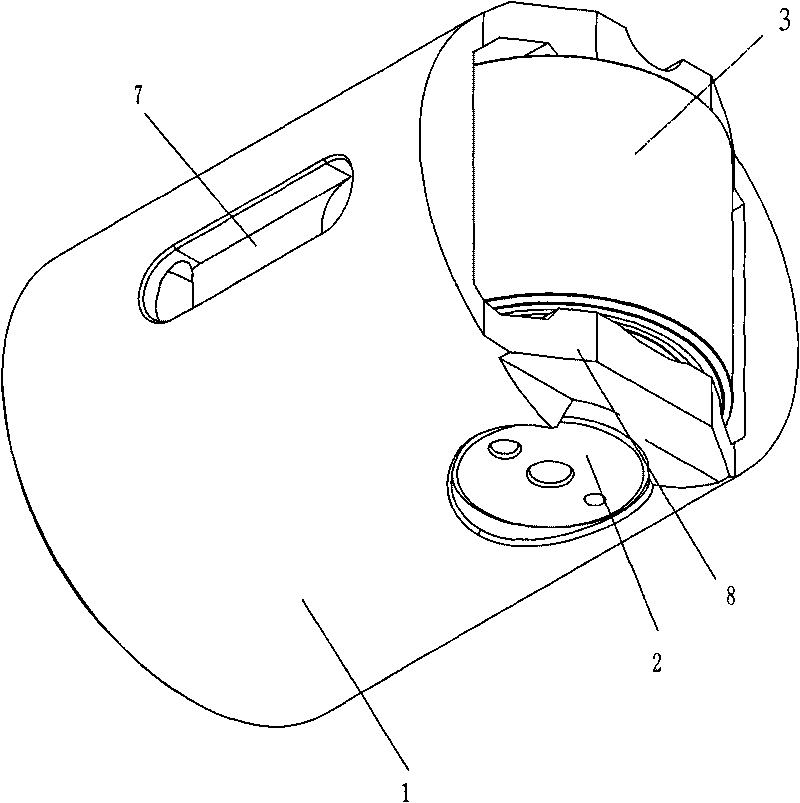

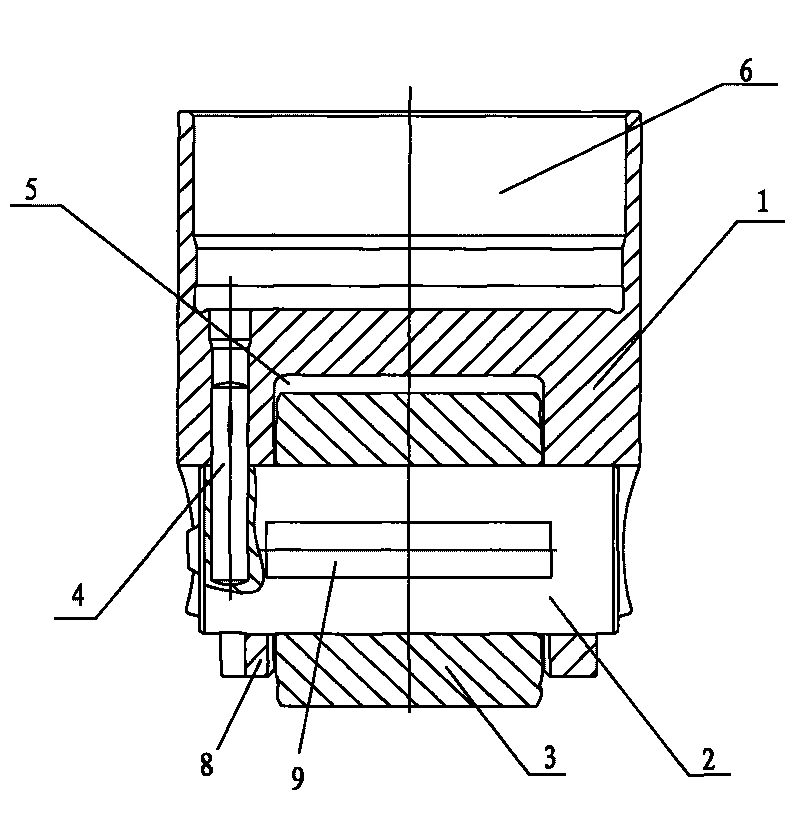

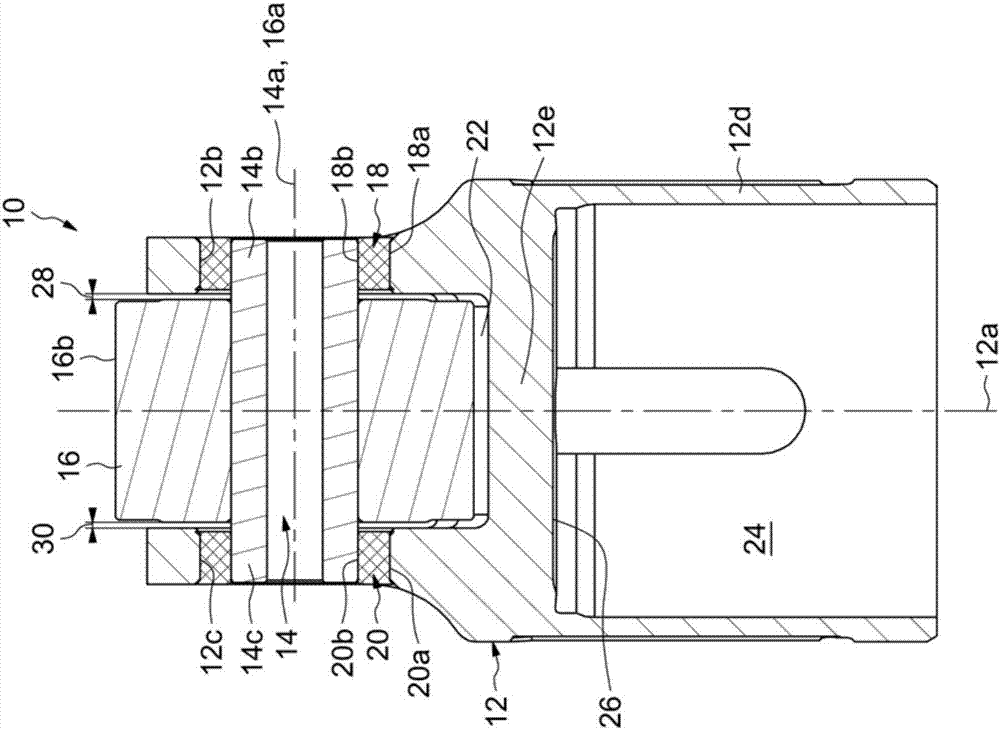

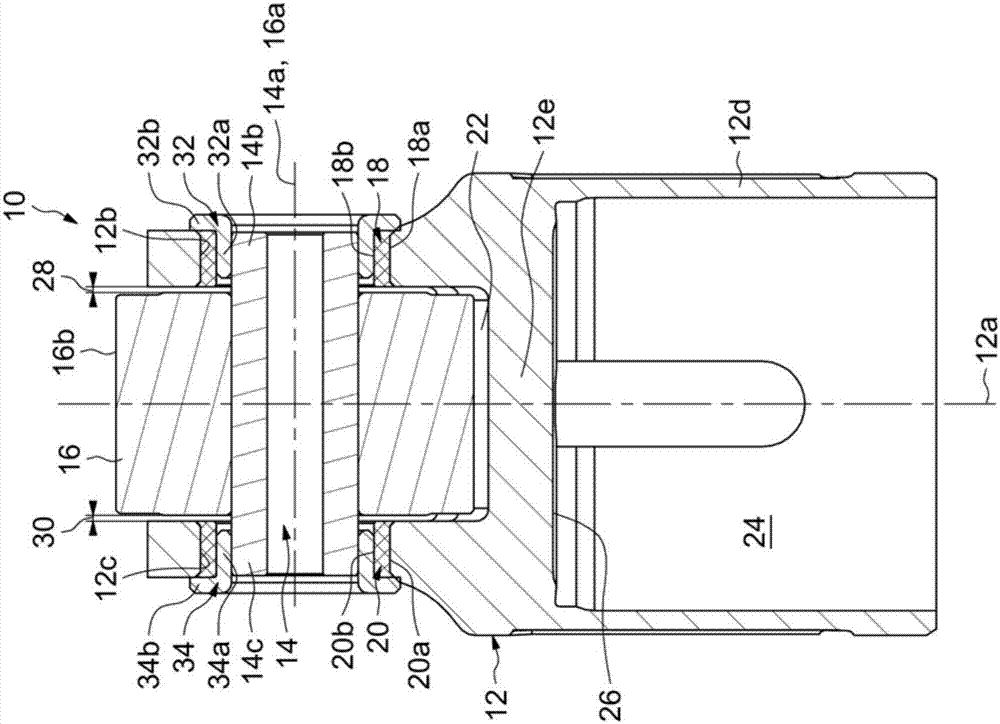

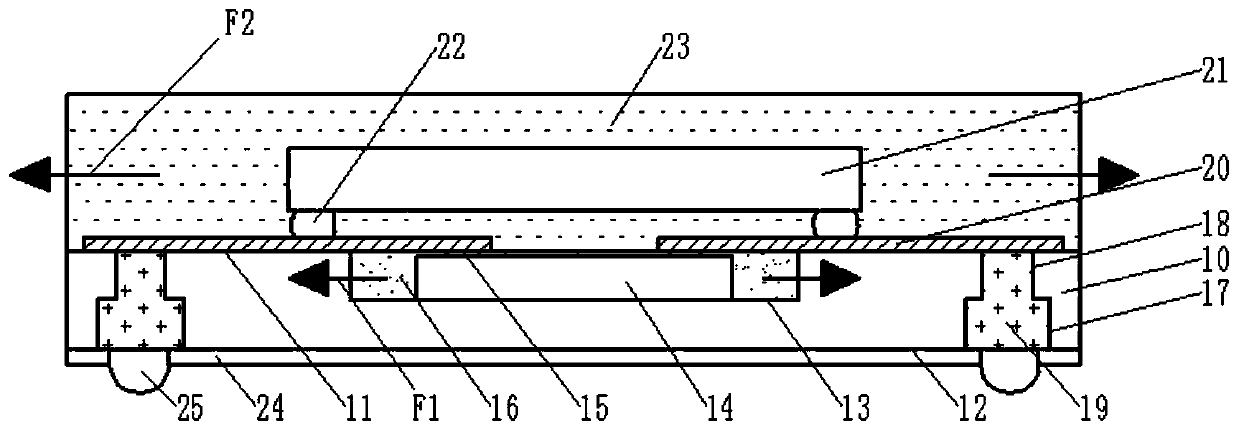

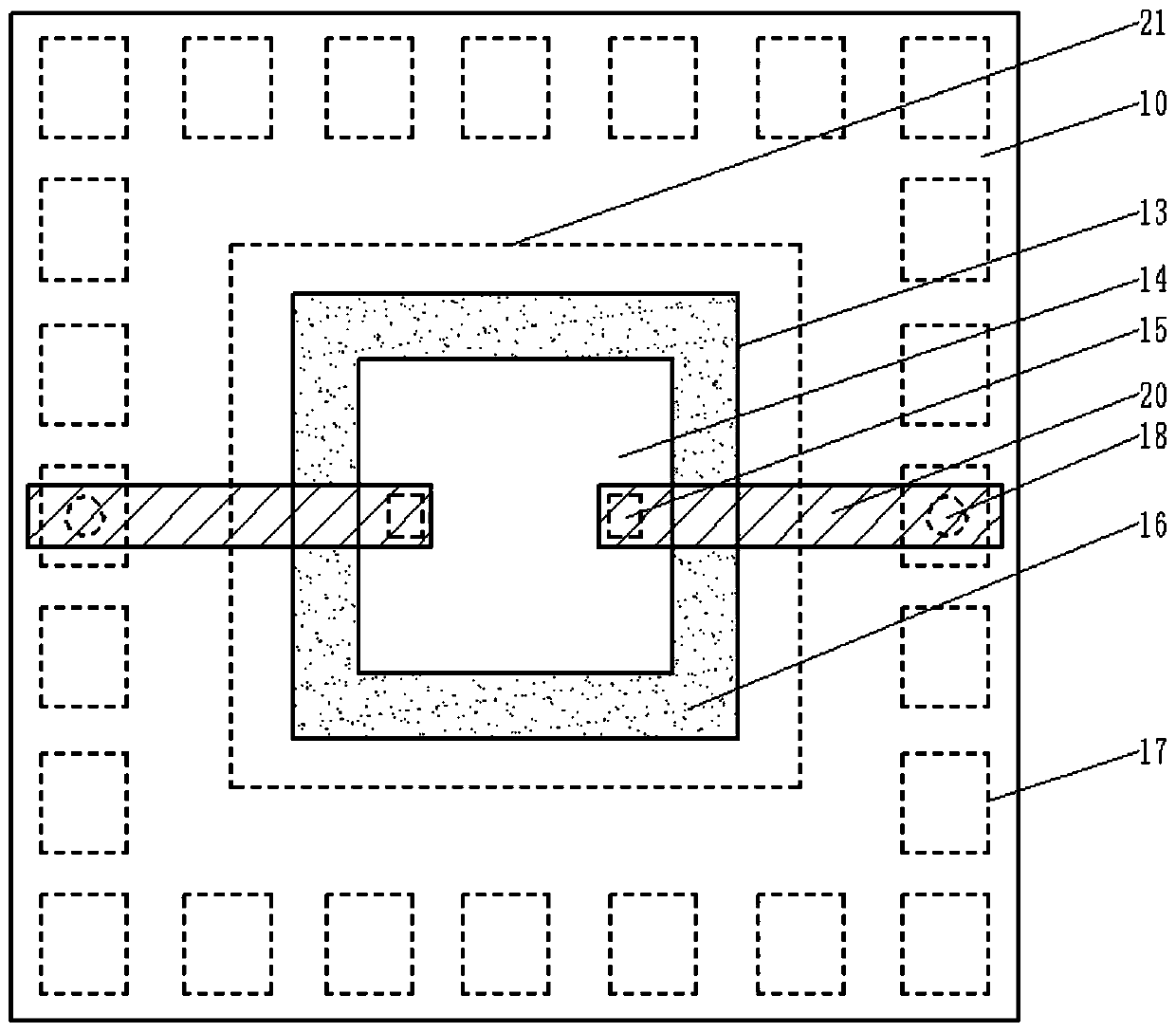

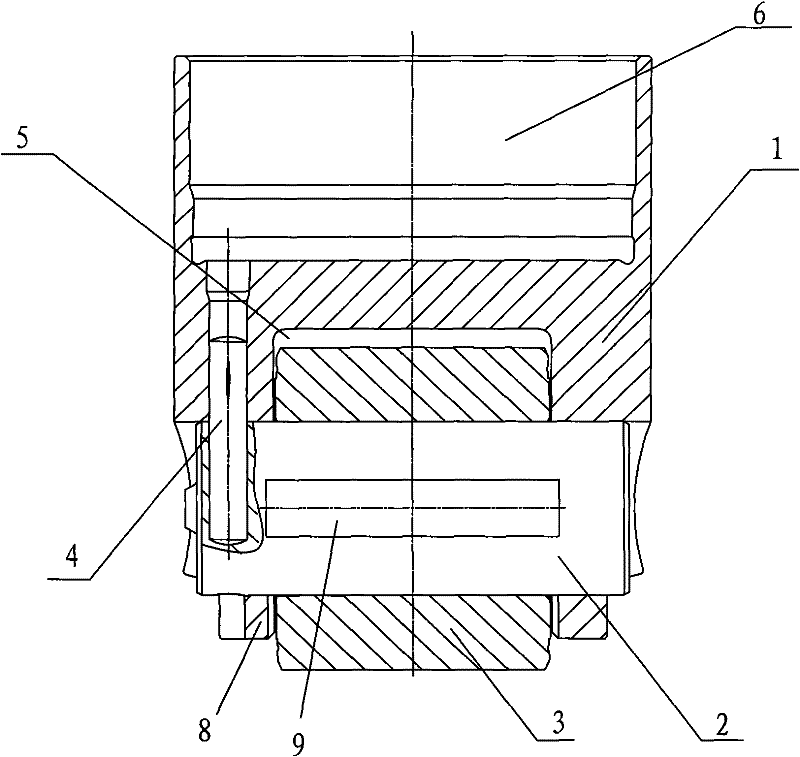

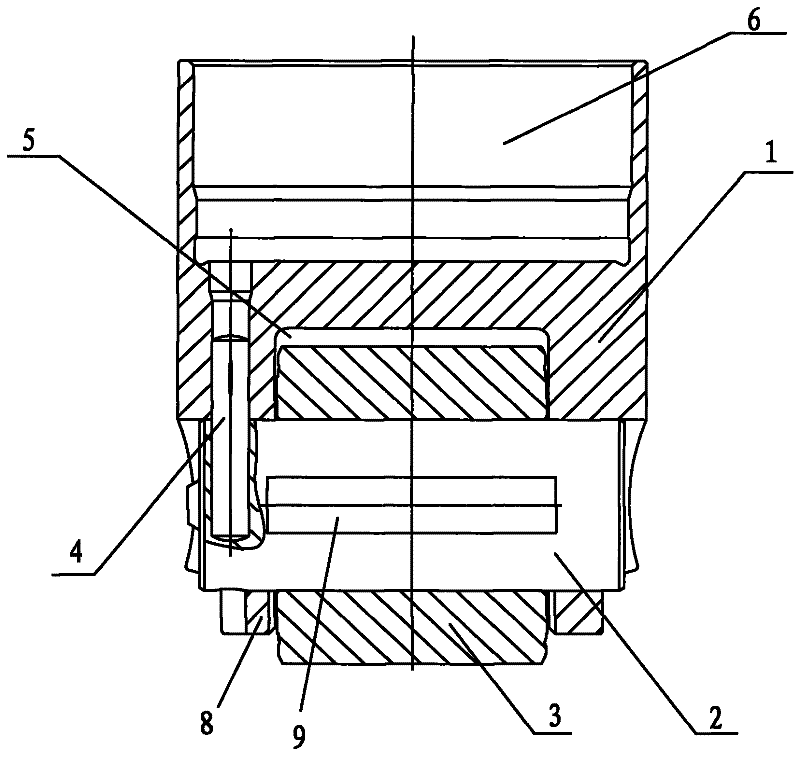

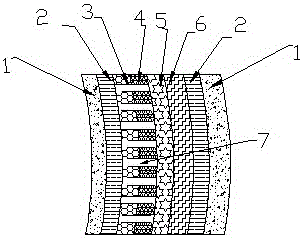

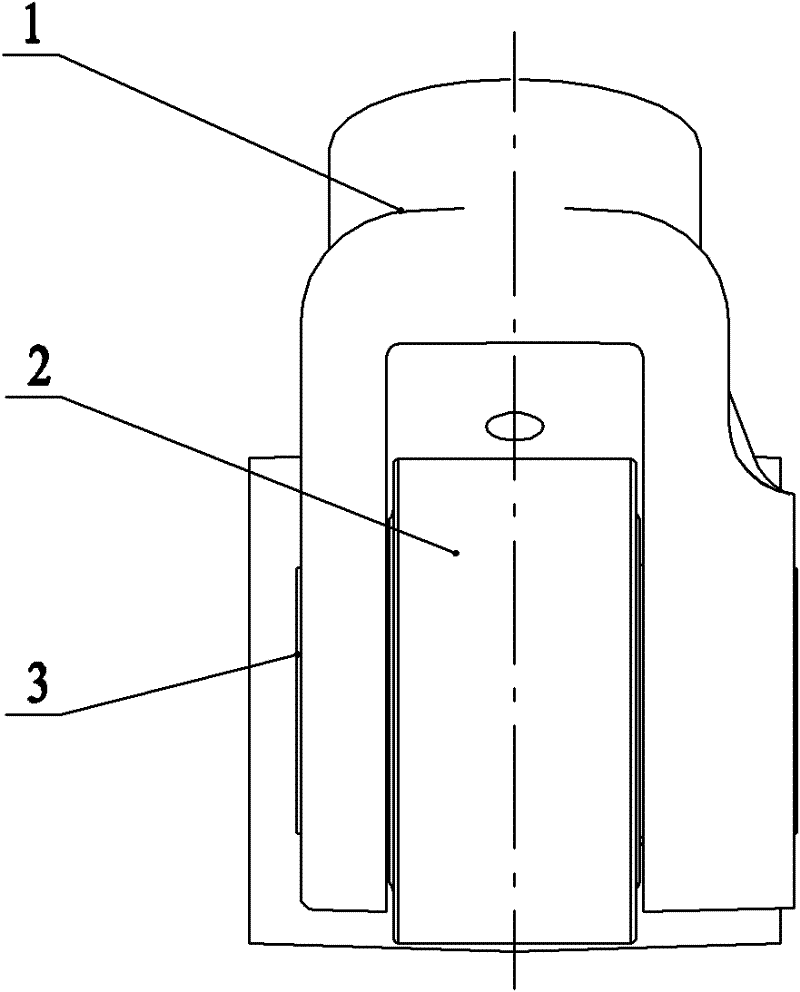

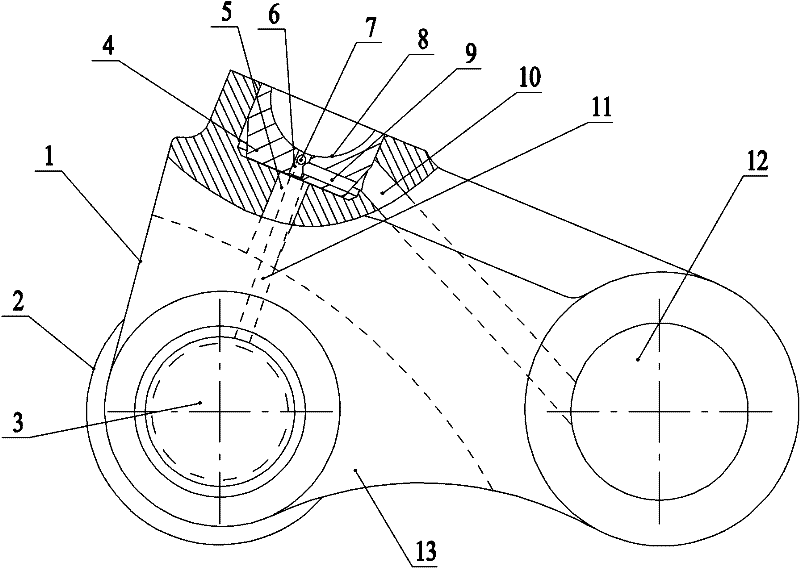

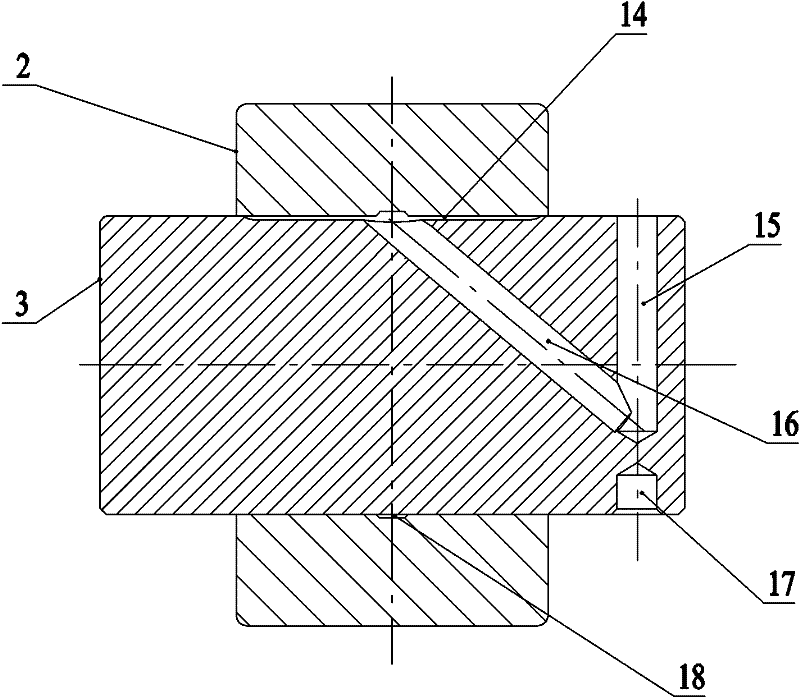

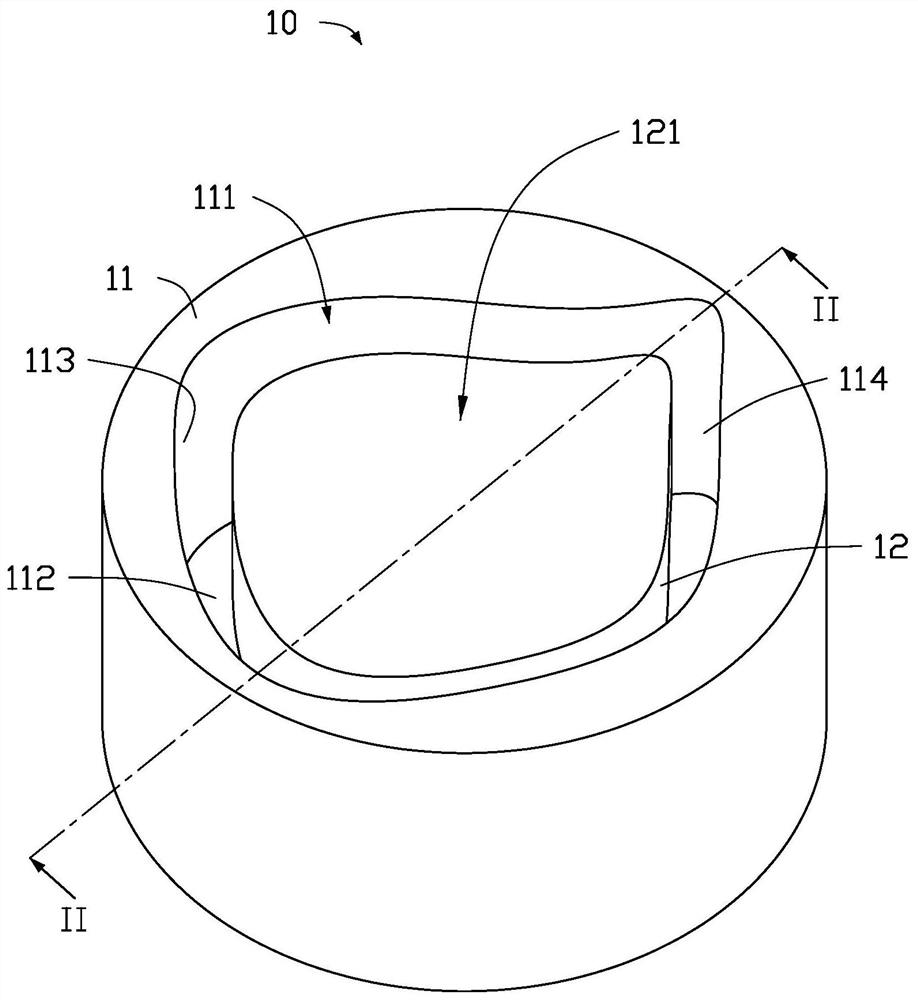

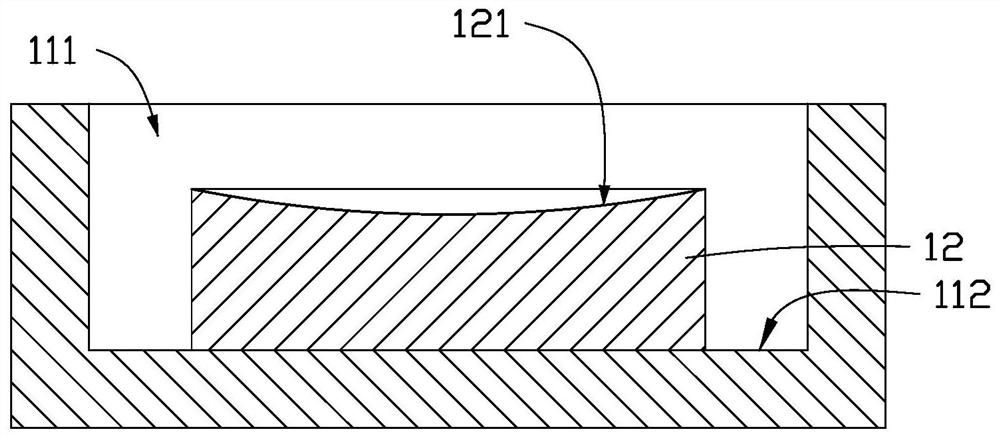

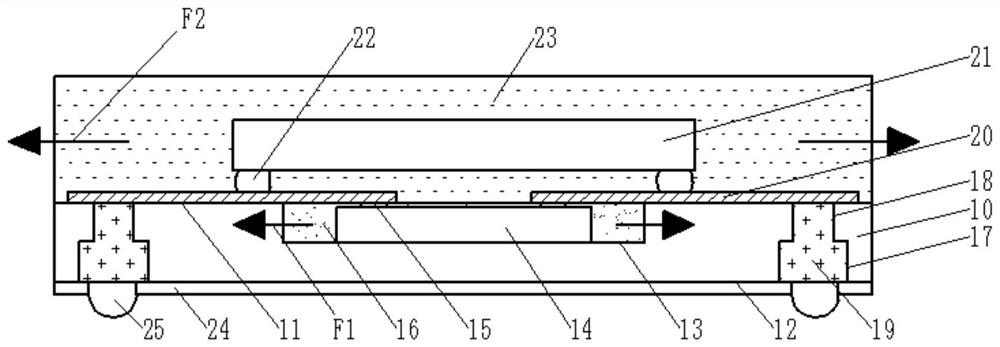

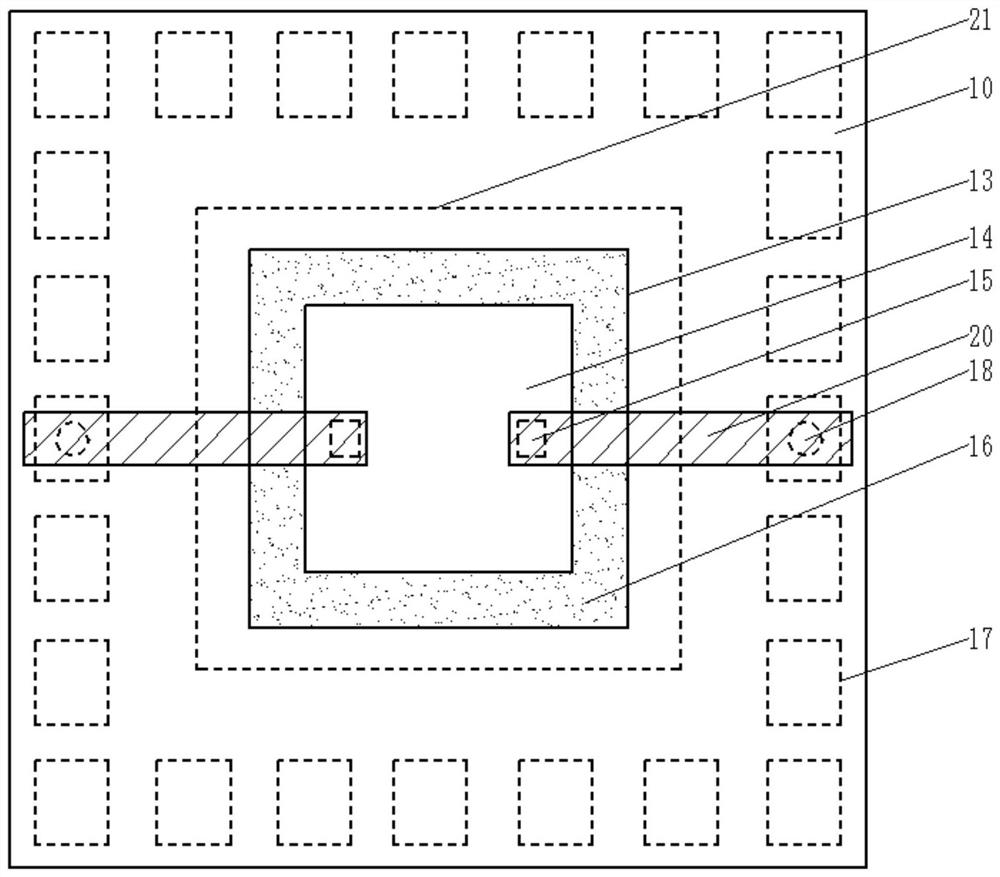

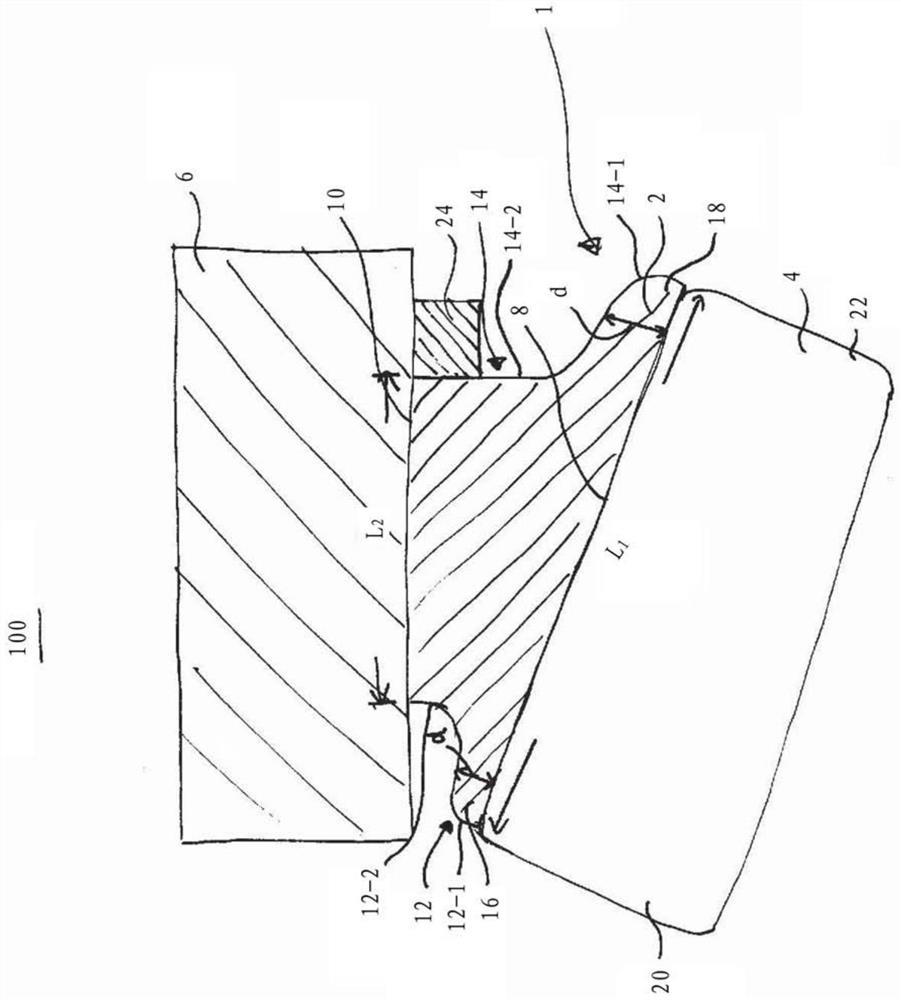

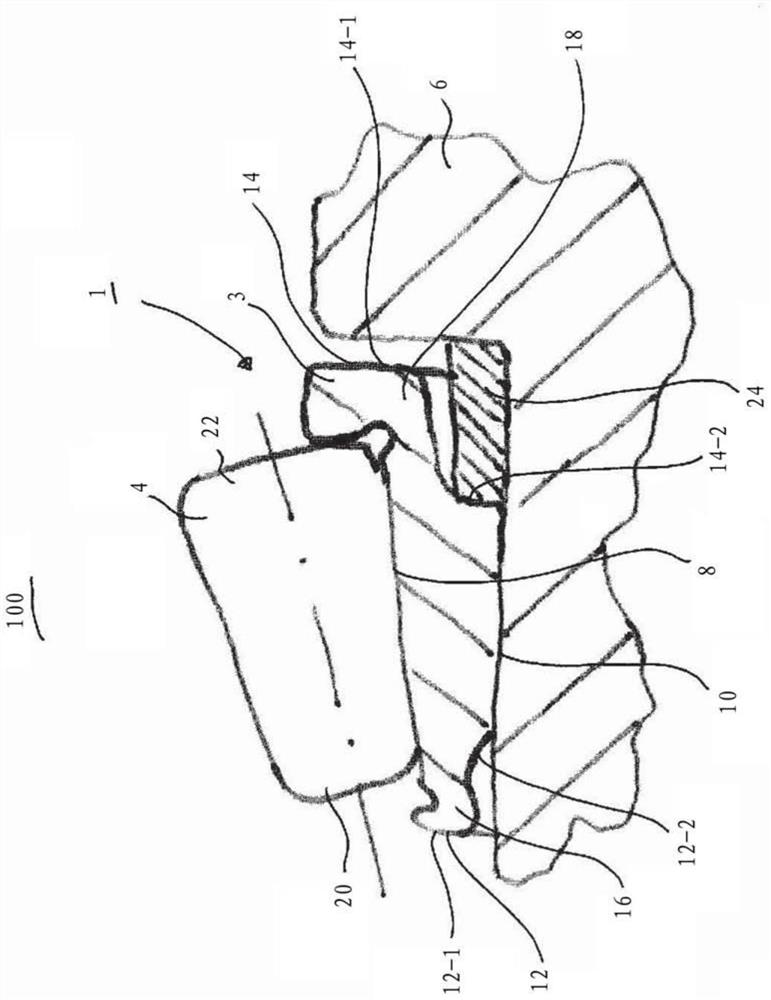

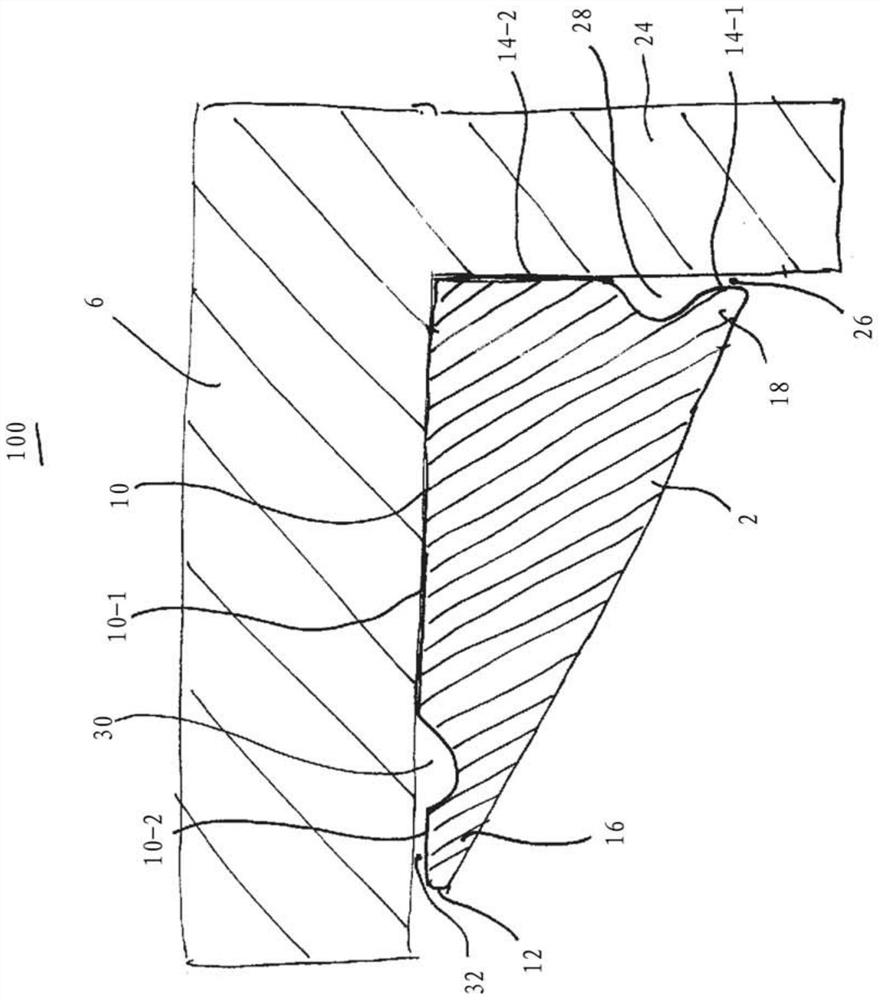

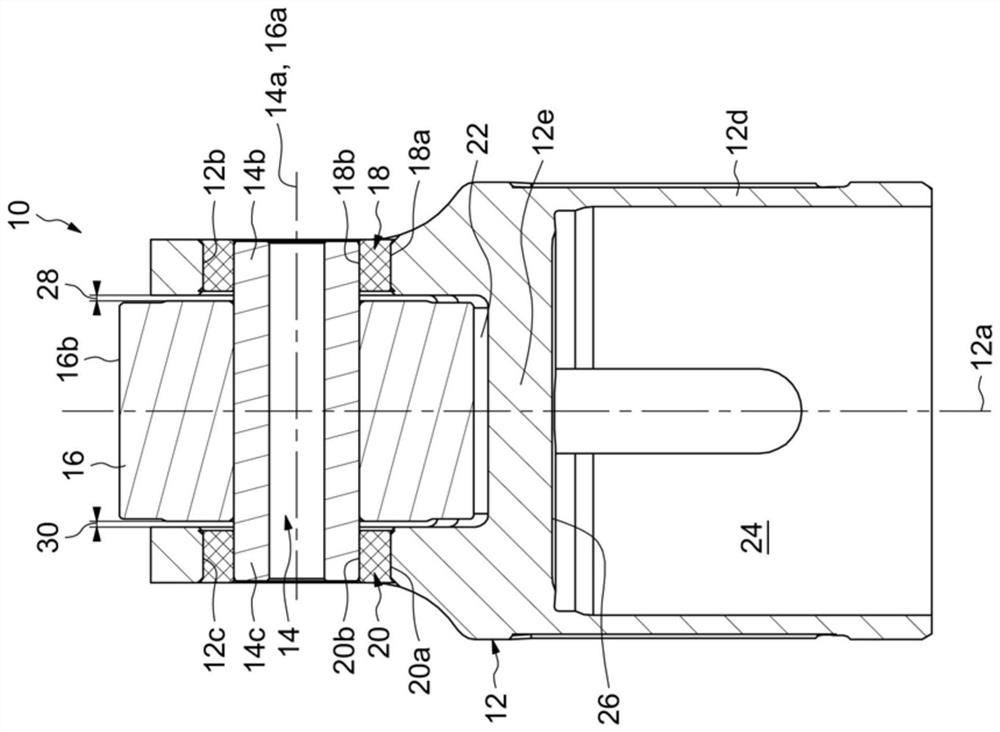

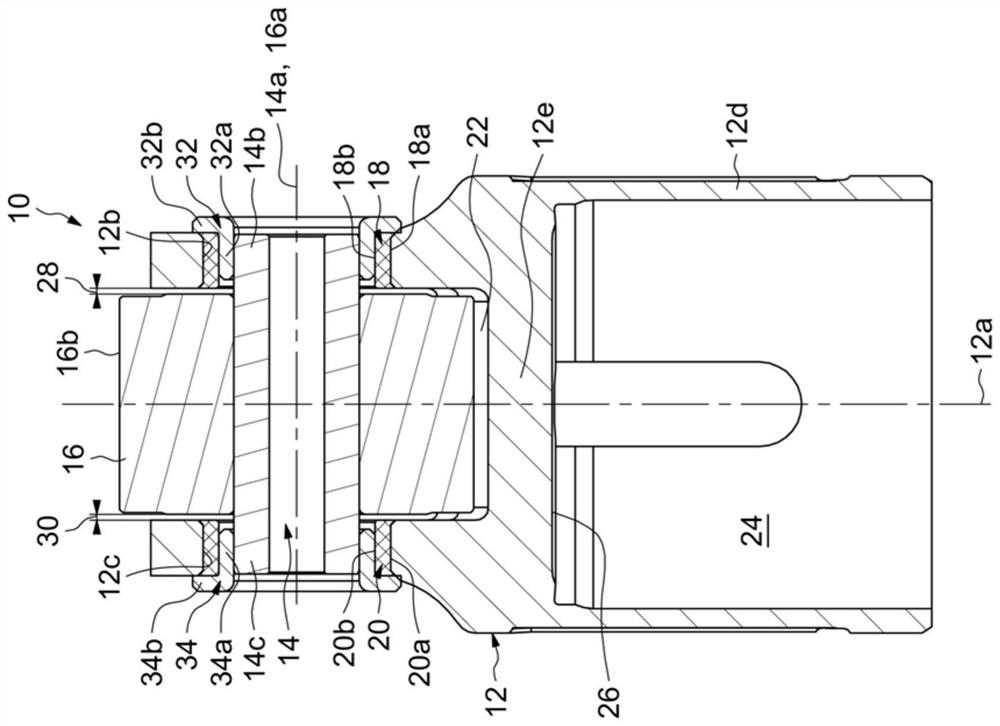

Cam follower roller device

ActiveCN106948985AReduce pressure contactReduce edge stressValve drivesFuel injecting pumpsEngineeringCam

The cam follower roller device comprises a tappet body 12, a pin 14 and a roller 16 mounted on said pin, the tappet body comprising holes 12b, 12c for mounting pin ends 14b, 14c of said pin on said tappet body. The device further comprises one deformable ring 18, 20 disposed between each pin end 14b, 14c of said pin and an inner wall of the associated hole 12b, 12c of said tappet body.

Owner:AB SKF

Metal magnetic pump plane bearing structure

PendingCN107664129AExtended downtimeExtension of timePump componentsPump controlMagnetic bearingHigh stiffness

The invention discloses a metal magnetic pump plane bearing structure. The structure comprises a bearing box, a controller and a magnetic pump body, the controller is arranged on one side of the magnetic pump body, a motor is arranged on one side of the controller, and an alarm is arranged at the upper end of the motor; a rear bearing gland is arranged on one side of the alarm, and the bearing boxis arranged on one side of the rear bearing gland; a plurality of plane bearings are arranged in the bearing box, a driving shaft is arranged on the inner sides of the plane bearings, and the drivingshaft is connected with the motor; a front bearing gland is arranged on one side of the driving shaft, and an outer magnetic rotor is arranged on one side of the front bearing gland; the outer magnetic rotor is connected with the driving shaft, an isolation sleeve is arranged on one side of the outer magnetic rotor, and a heat dissipation pipe is arranged in the isolation sleeve. The plane bearings are arranged in the bearing box, so that the contact length is increased, the bearings can obtain the high-load capacity and high rigidity in a small space, the edge stress can be reduced, and theservice life is prolonged.

Owner:ANHUI NANFANG CHEM PUMP IND

Integrated circuit structure and manufacturing method thereof

ActiveCN111490019AIncrease stressAvoid layeringSemiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

The invention provides an integrated circuit structure and a manufacturing method thereof. A first sealing layer is formed in a substrate, a second sealing layer is formed on the substrate, and the first sealing layer and the second sealing layer provide pressure stress so as to counteract the warping force of the substrate. Moreover, the filling ratios of inorganic fillers of the first sealing layer and the second sealing layer are different such that the first sealing layer and the second sealing layer have a pressure stress difference, and the binding force of the first sealing layer and the second sealing layer can be ensured while the substrate is not warped.

Owner:TIANJIN HENGLIYUANDA INSTR

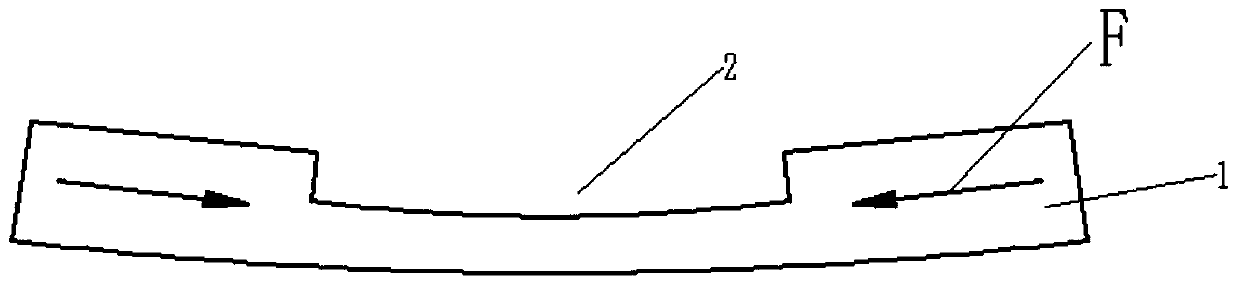

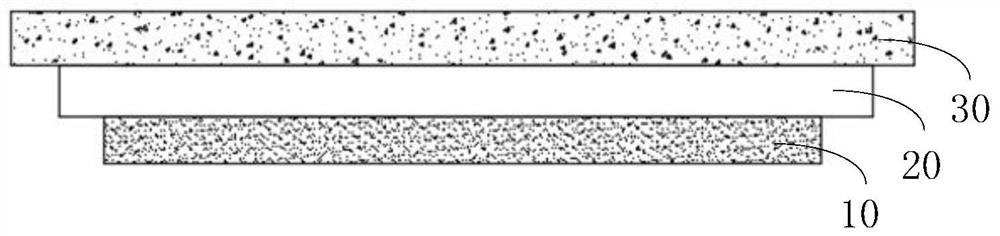

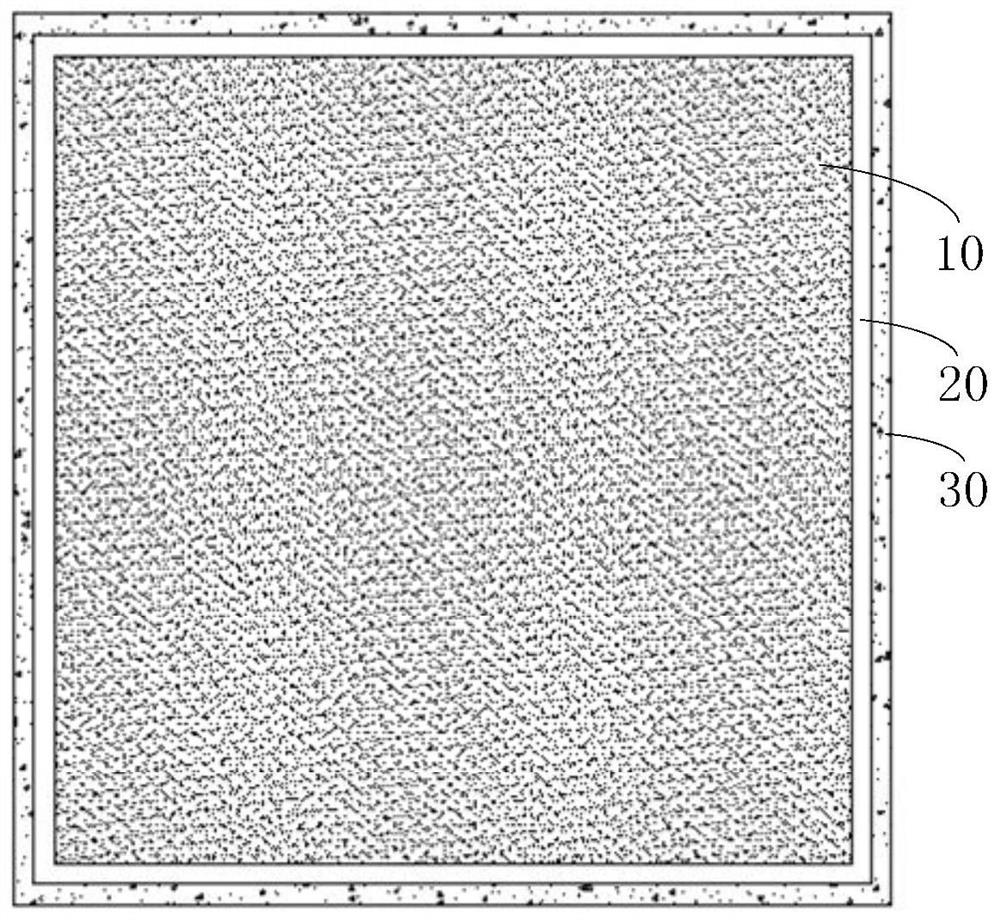

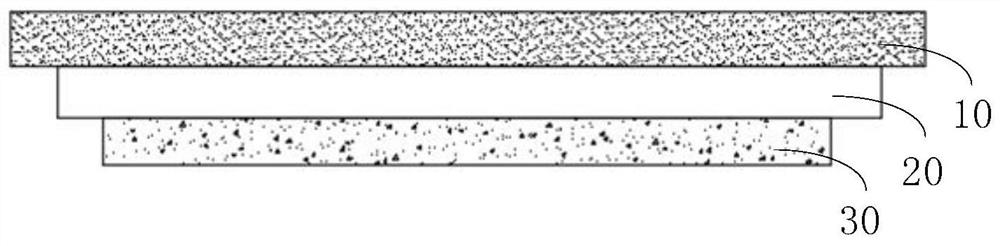

Manufacturing method of photovoltaic module

PendingCN112216752AReduce edge stressReduced risk of crackingFinal product manufacturePhotovoltaic energy generationEngineeringSolar cell

The embodiment of the invention provides a manufacturing method for a photovoltaic module, and the method comprises the steps: obtaining a conductive part which comprises a first conductive segment which is electrically connected with the front surface of a first solar cell, and a second conductive segment which is electrically connected with the back surface of a second solar cell; arranging a buffer material at the edge of the front surface of the first solar cell and / or the edge of the back surface of the second solar cell, wherein the buffer material is contacted with the middle conductivesection of the conductive piece; stacking the edge of the back surface of the second solar cell to the edge of the front surface of the first solar cell to form an overlapping region, wherein at least part of the buffer material is located in the overlapping region between the first solar cell and the second solar cell. According to the photovoltaic module manufactured through the manufacturing method, the stress of the edge positions of the adjacent solar cells is reduced through the buffer materials, and the subfissure phenomenon is improved; and the photovoltaic module is well matched withthe existing process and is easy to popularize and implement in the industry.

Owner:CSI CELLS CO LTD +2

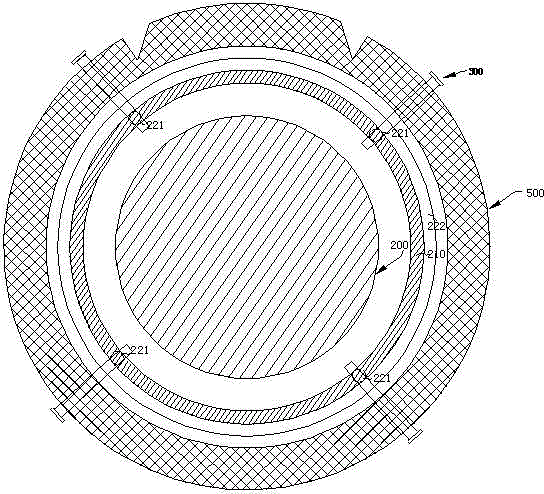

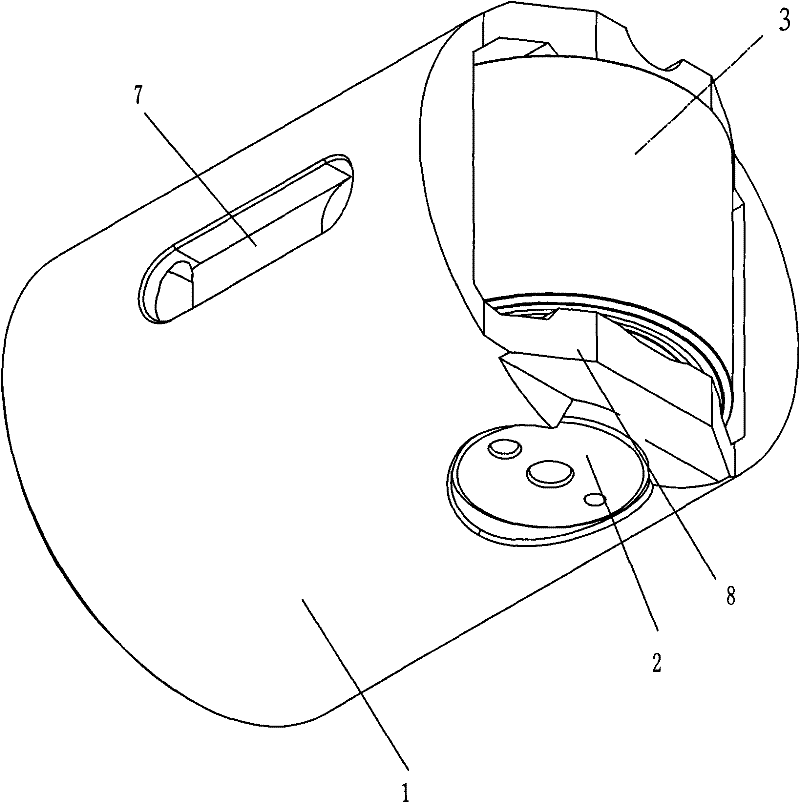

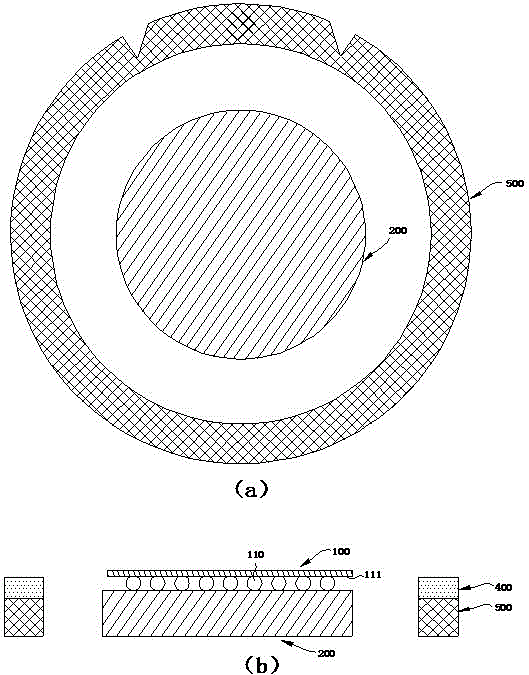

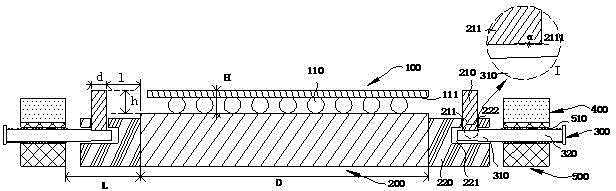

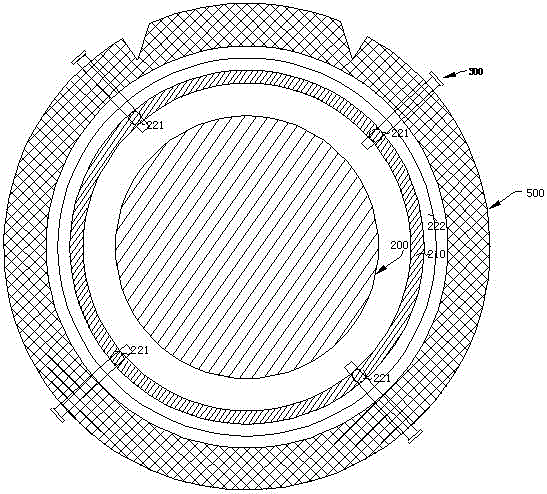

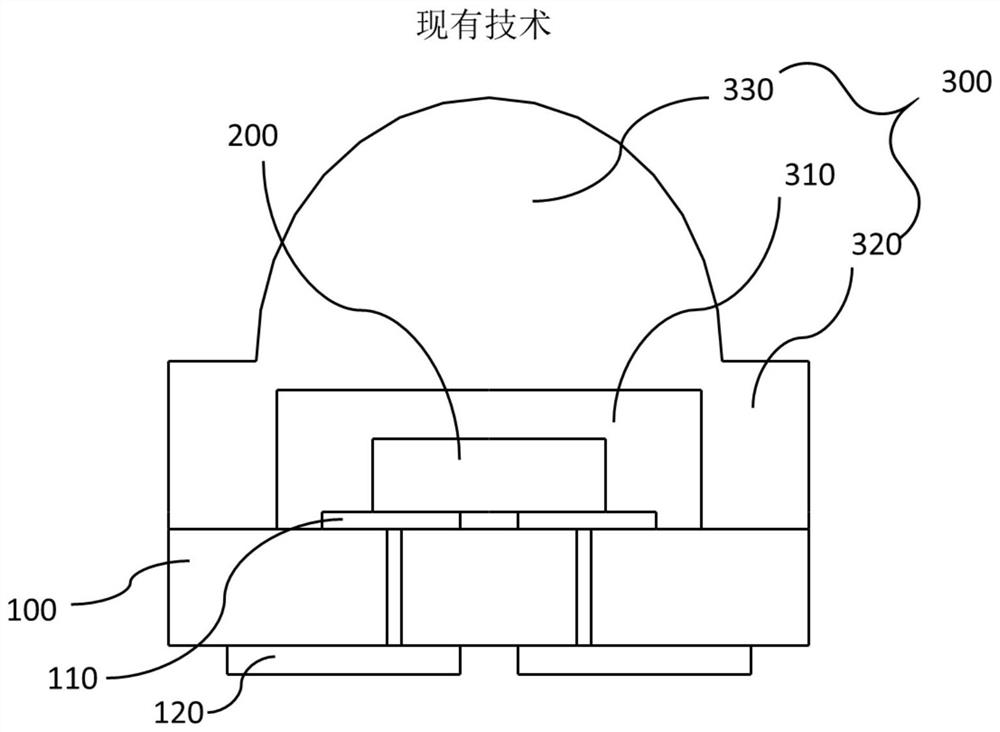

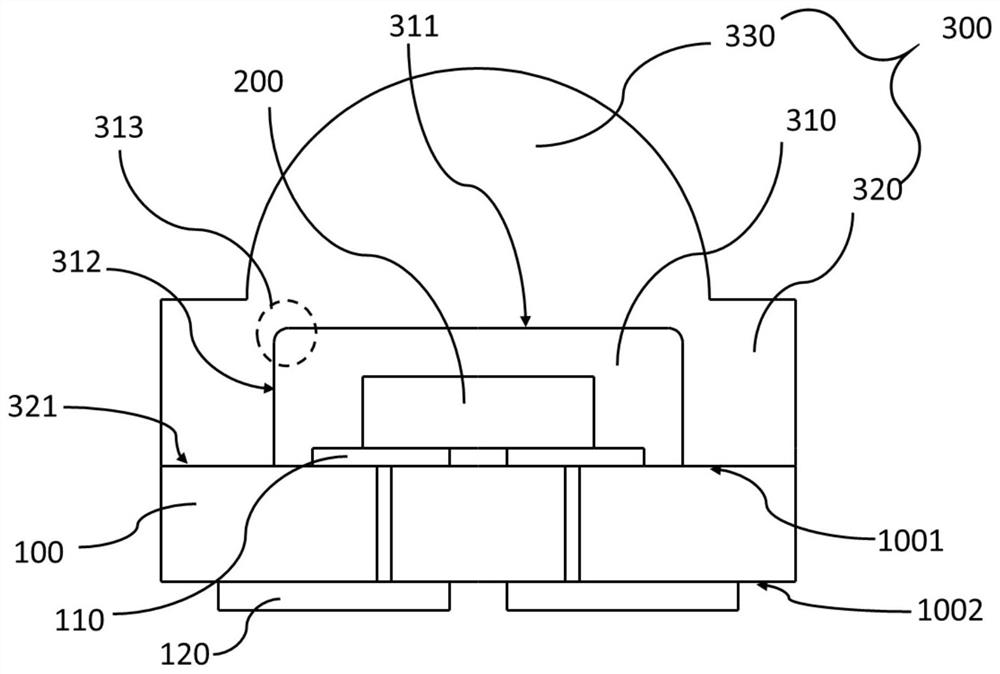

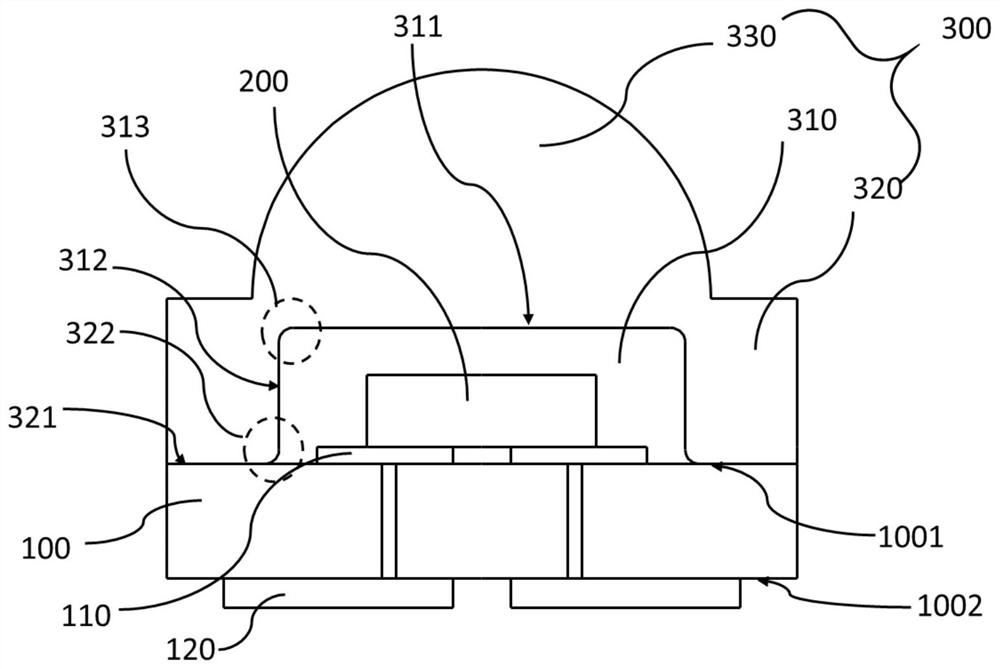

Chip mounter for bump wafer

ActiveCN104409373AConvenient up and down heightAdjust the height up and down at any timeSemiconductor/solid-state device manufacturingSemiconductorBlind hole

The invention discloses a chip mounter for a bump wafer, and belongs to the technical field of semiconductor packaging. The chip mounter comprises a chip mounting base for bearing the bump wafer to be mounted, a Waferring platform mounted around the chip mounting base, and a coffer dam arranged between the chip mounting base and the Waferring platform, wherein a threaded through hole facing to the center of the chip mounting base is formed in the side surface of the Waferring platform; the height difference between the top of the coffer dam and the top of the chip mounting base is h, and the value of H-h is not less than 0 micron and not more than 50 microns; a boss which extends down is arranged at the lower part of the coffer dam; the coffer dam is connected with the chip mounting base through a fixing device; a blind hole facing to the center of the chip mounting base is formed in the outer side surface of the fixing device; a through hole perpendicular to the blind hole and a flat screw for connecting the through hole with the blind hole are formed over the blind hole, and the tail of the blind hole is matched with the boss. According to the chip mounter, the chip mounting base and the Waferring platform are designed and the coffer dam is added between the chip mounting base and the Waferring platform, so that the problems of easy fragmenting, cracking and the like of edges in a bump wafer mounting process are solved.

Owner:JIANGYIN CHANGDIAN ADVANCED PACKAGING CO LTD

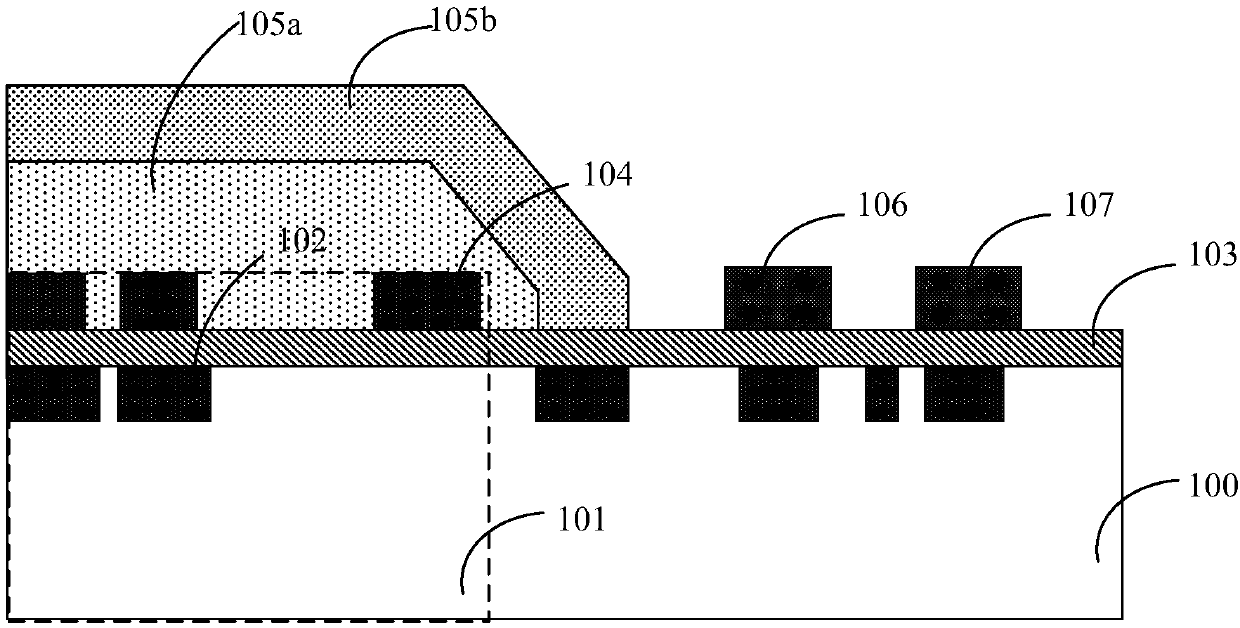

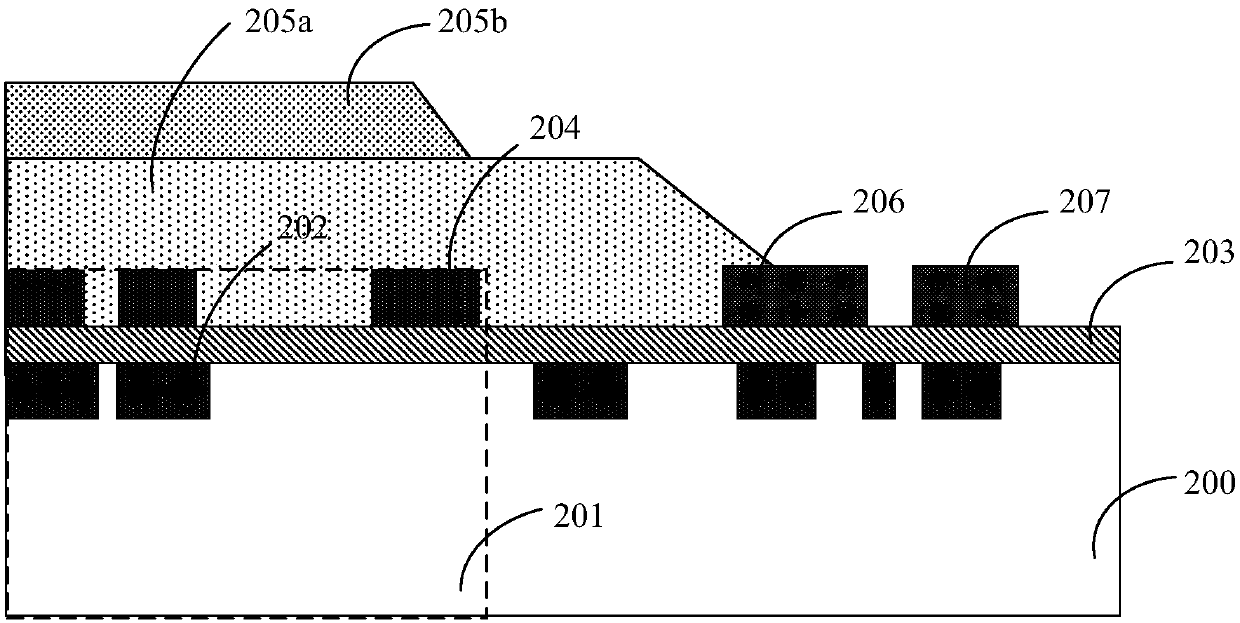

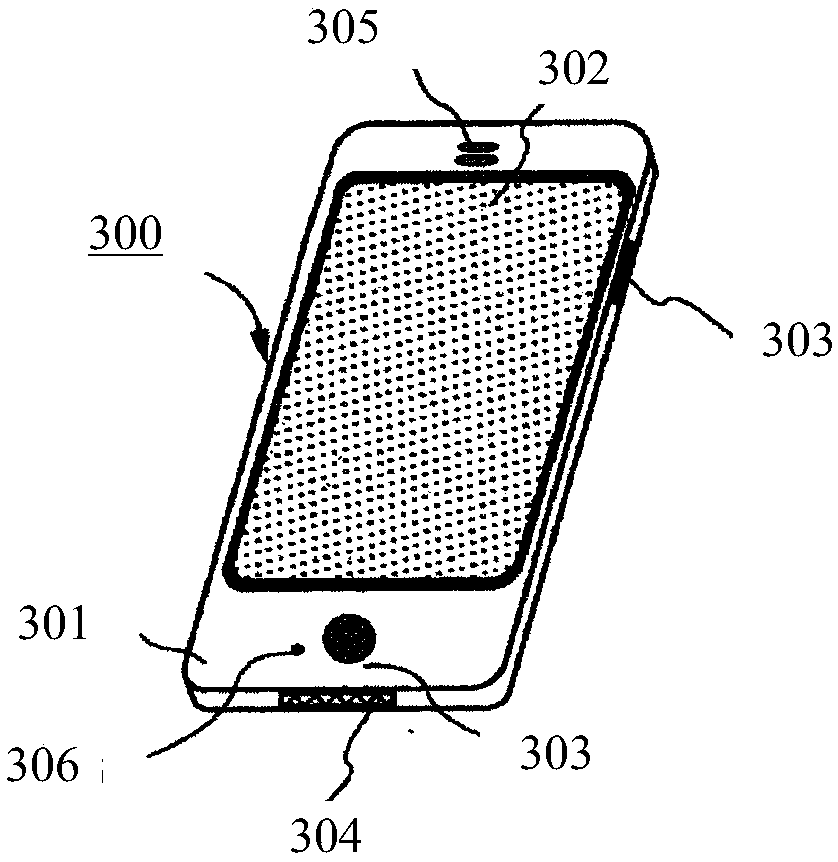

Semiconductor device and electronic device

InactiveCN110310938AReduce edge stressAvoid damageSemiconductor/solid-state device detailsSolid-state devicesRedistribution layerEngineering

The invention provides a semiconductor device and an electronic device. The semiconductor device comprises a semiconductor substrate, a first redistribution dielectric layer and a second redistribution dielectric layer, wherein the semiconductor substrate comprises a main chip region, an interconnection layer is formed on the semiconductor substrate in the main chip region, and a sealing ring is formed between the main chip region and a cutting channel; the first redistribution dielectric layer is formed on the interconnection layer and the second redistribution dielectric layer is formed on the first redistribution layer; a redistribution layer electrically connected with the interconnection layer is formed in the first redistribution dielectric layer; the edge of the first redistributiondielectric layer is located above the sealing ring; and the edge of the second redistribution dielectric layer is located above the first redistribution dielectric layer. According to the semiconductor device provided in the invention, the edge stress of the redistribution dielectric layer can be reduced, the risk of cracking is reduced, and the chip can be prevented from being damaged.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Valve tappet device of engine

ActiveCN101737109BGuaranteed up and down motionIncrease contact stressValve arrangementsMachines/enginesFriction reductionCam

The invention relates to a valve tappet device of an engine, which belongs to the technical field of mechanical structures. According to the technical scheme of the invention, the valve tappet device of the engine comprises a tappet body and is characterized in that a positioning groove is formed at the lower end of the tappet body, and concentric through holes which are vertical to the axial line of the tappet body are formed on two side wings forming the positioning groove; two ends of a roller pin are respectively positioned in the through holes of the two side wings; and a roller is arranged on the roller pin, and the roller is positioned in the positioning groove. The valve tappet device removes a bush between the roller and the roller pin, thereby reducing the number of parts, reducing the friction, reducing the cost and facilitating the production. The valve tappet device can increase the diameter and the width of the roller and the roller pin, improve the strength of the roller and the roller pin, reduce the contact stress between the roller and a cam, increase the reliability of a product, arrange an ejector rod slot on the tappet body, effectively increase the contact area between an ejector rod and the tappet body, significantly reduce the edge stress, greatly enhance the performances of abrasion resistance, tension resistance and pressure resistance and effectivelyprolong the service life of the tappet body.

Owner:WUXI XIZHOU MACHINERY

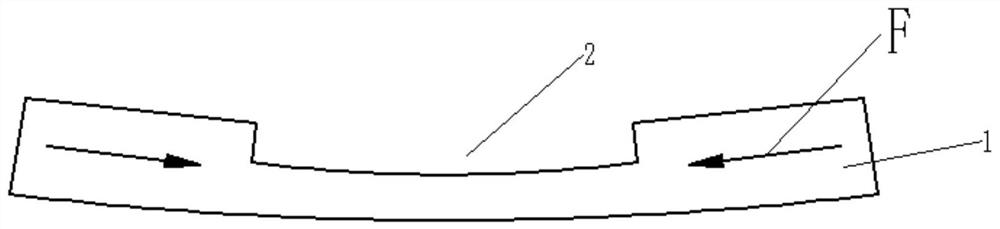

Curved solar car sunroof and manufacturing method thereof

ActiveCN104916722BExtend warm-up timeReduce damage and other problemsFinal product manufactureElectric/fluid circuitElectrical batteryEngineering

The invention discloses a curved surface solar energy automobile skylight and a manufacture method for the same, and particularly relates to a curved surface solar energy automobile skylight and the manufacture method for the same. The curved surface solar energy automobile skylight has curved-surface-shaped single layer or double-layer skylight glass; a solar energy battery sheet is composited on the inner side of the single layer skylight or between the double-layer glass; the solar energy battery sheet comprises a super-thin glass substrate, the curved surface shape of which is identical to or similar to the skylight glass; a first electrode, a photoelectric conversion layer and a second electrode are successively plated on the super-thin glass substrate; and the solar energy battery sheet is adhered to the skylight glass through a adhesive layer. The curved surface solar energy automobile skylight and the manufacture method for the same disclosed by the invention can greatly reduce the cracking and damage caused by the strain force in the process of lamination, can improve the yield and can reduce the manufacture cost.

Owner:安徽山迪光能技术有限公司

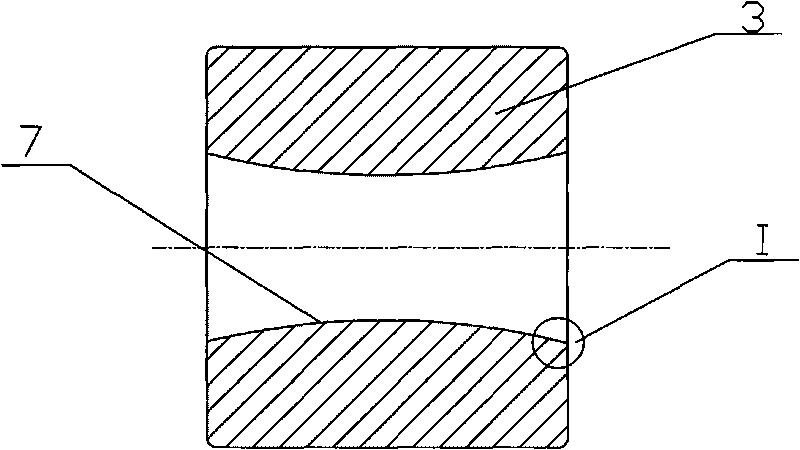

Idler wheel with drum inner bore

InactiveCN101725693AReduce edge stressReduce wearPortable liftingGearing elementsEngineeringIdler-wheel

The invention relates to an idler wheel, in particular to an idler wheel with a drum inner bore, and belongs to the technical field of mechanical structure. According to the technical scheme provided in the invention, the idler wheel with a drum inner bore comprises an idler wheel main body, wherein the inner bore is arranged in the idler wheel main body, the vertical section of the inner wall of the inner bore is arched, and the middle of the inner wall is protruded towards the central line of the inner bore so that the inner diameter of the middle of the inner bore is smaller than the inner diameter of the end of the inner bore. The inner surface of the idler wheel in the invention is drum-shaped so as to reduce the boundary stress of the idler wheel and abrasion. The idler wheel and the idler wheel pin use clearance fit so that the lubricating oil can further enter the space between the idler wheel and the idler wheel pin adequately for carrying out lubrication, so as to reduce the abrasion between the idler wheel and the idler wheel pin and prolong the service life of the idler wheel and the idler wheel pin.

Owner:WUXI XIZHOU MACHINERY

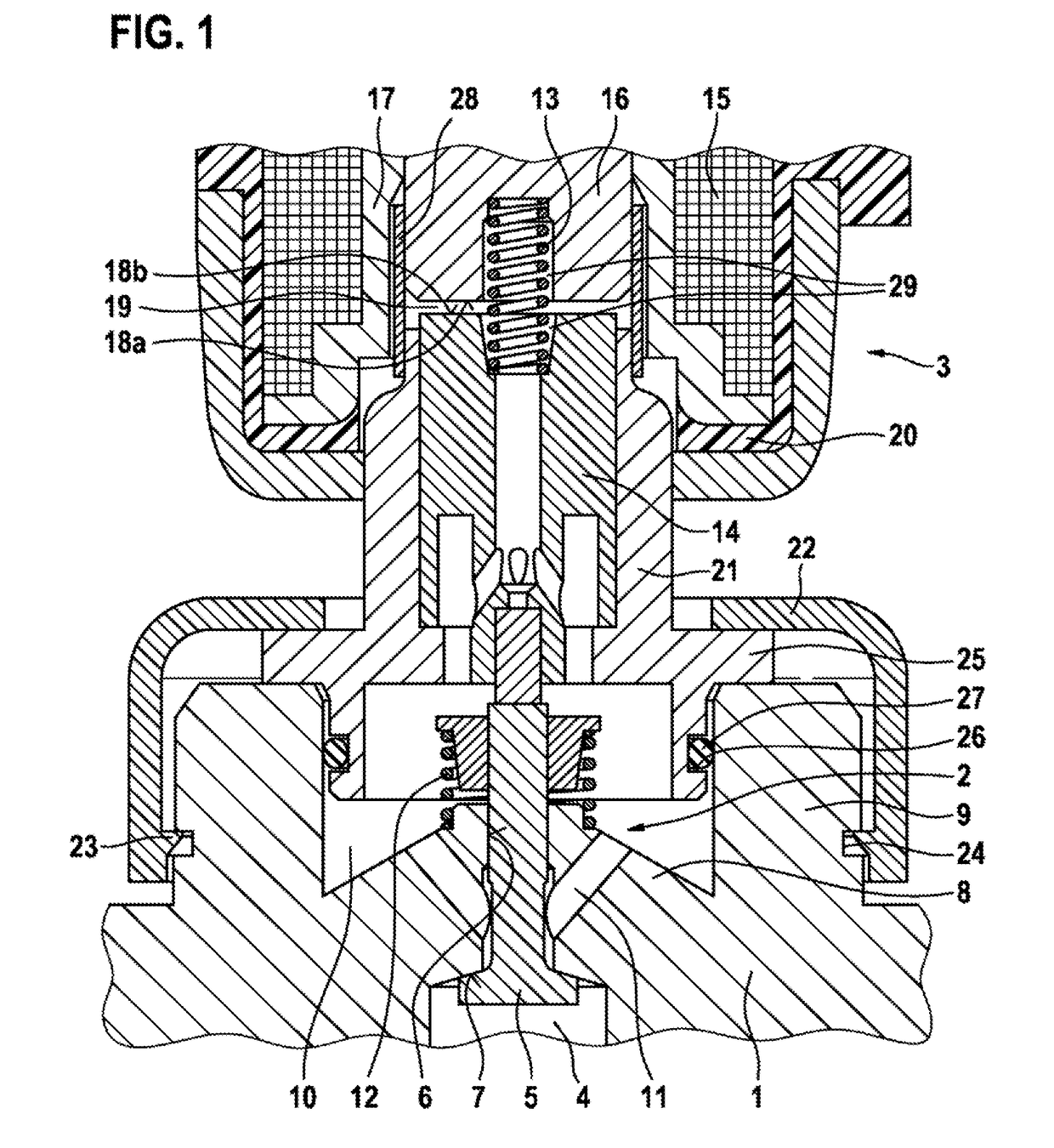

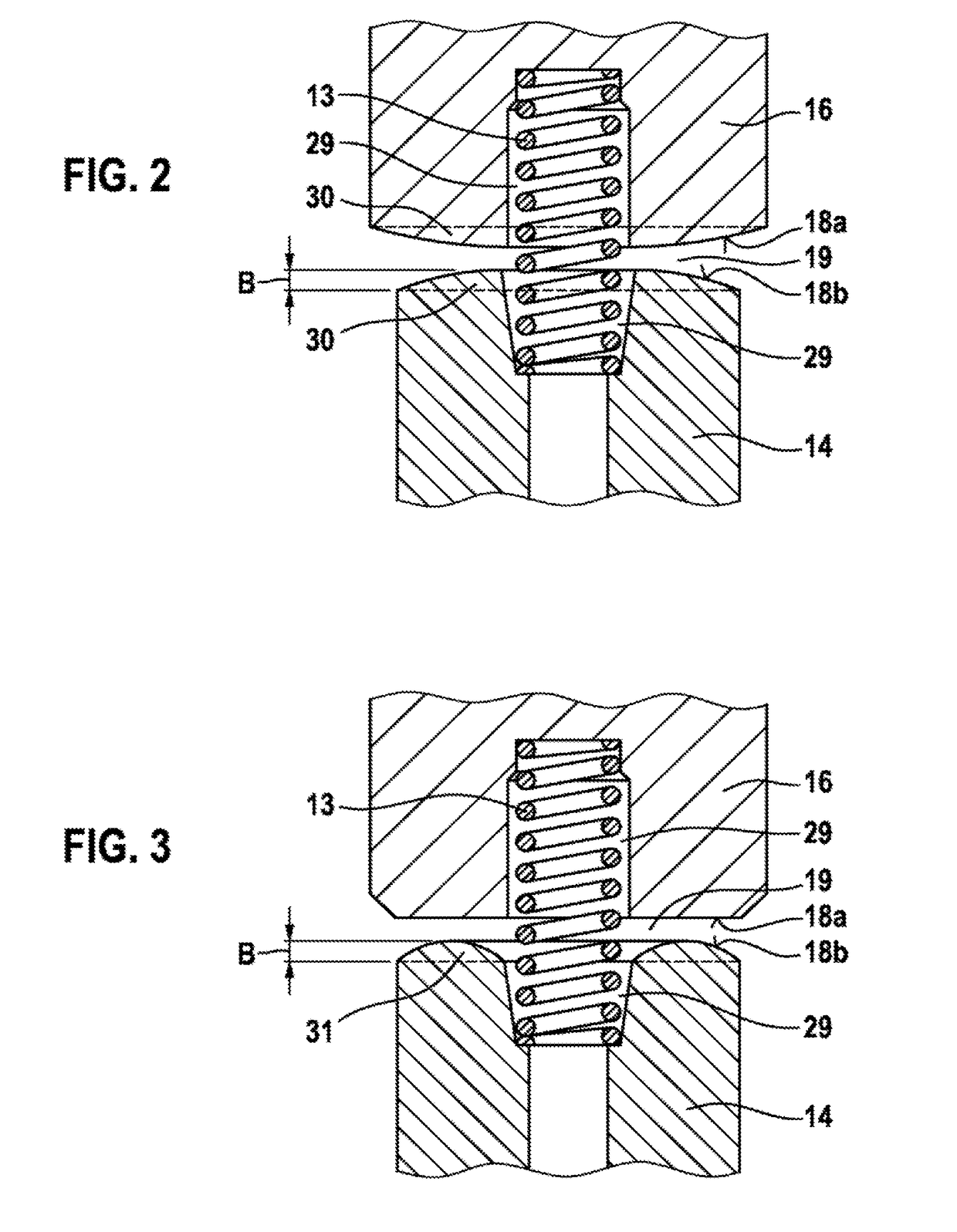

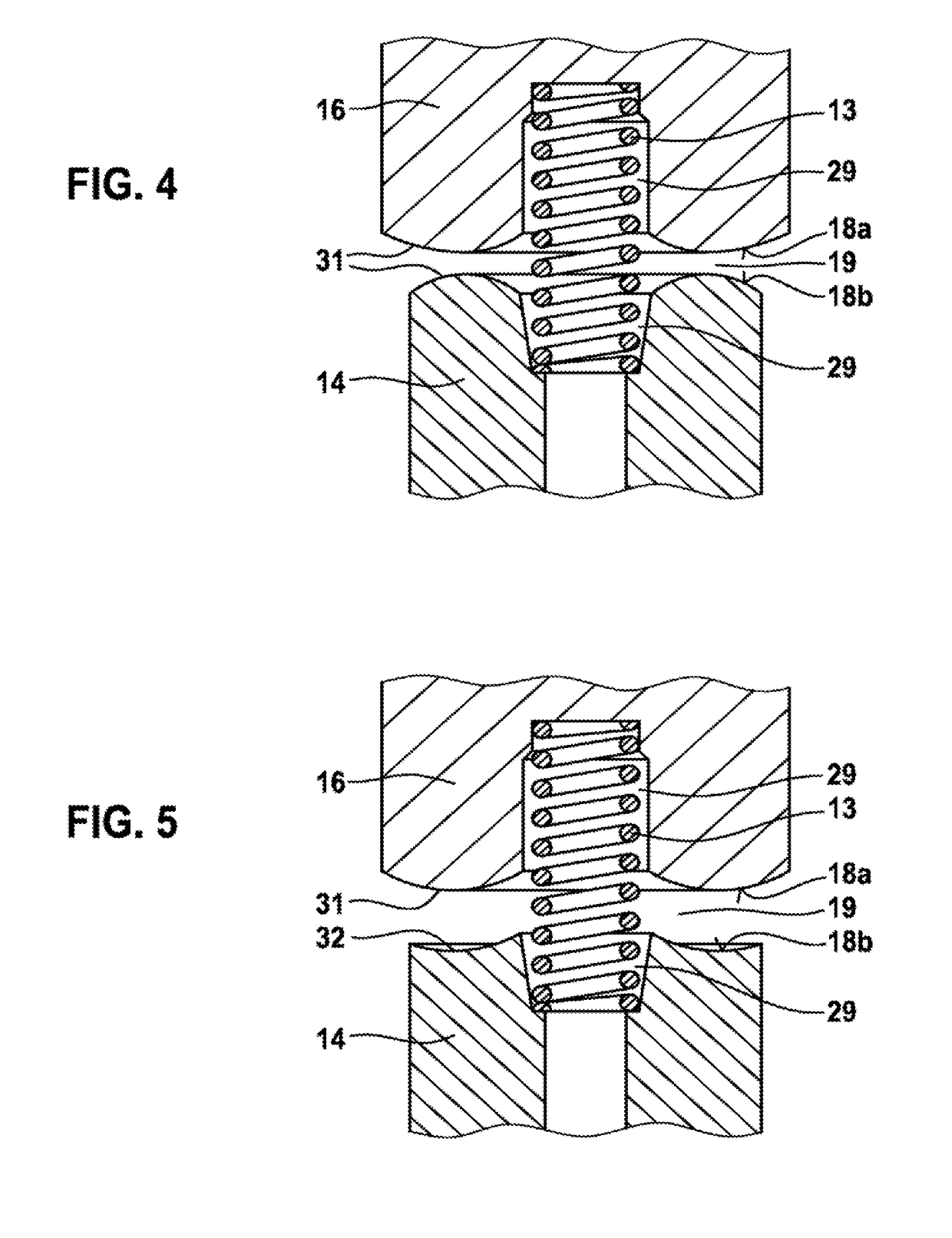

Solenoid valve

InactiveUS20190051439A1Reduce edge stressEasy to switchOperating means/releasing devices for valvesWear reducing fuel injectionSolenoid valveSpring force

The invention relates to a solenoid valve having an actuator body (17), in which a magnet coil (15) that interacts with a magnet core (16) is arranged and which interacts with an armature (14) that can be moved relative to the magnet core between two end positions and is acted upon by the spring force of an armature spring (13) in a movement direction pointing away from the magnet core (16). The magnet core and the armature have stop surfaces (18a, 18b) which are interrupted by a recess (29) that receives the armature spring. According to the invention, a solenoid valve is provided which is improved with respect to the function of the solenoid valve and the stress on the stop surfaces (18a, 18b) that causes wear. This is achieved in that the magnet core (16) and / or the armature (14) have / has a design (30, 31), in particular a spherical or toroidal design, which reduces the stress on the edges in the region of the stop surfaces (18a, 18b).

Owner:ROBERT BOSCH GMBH

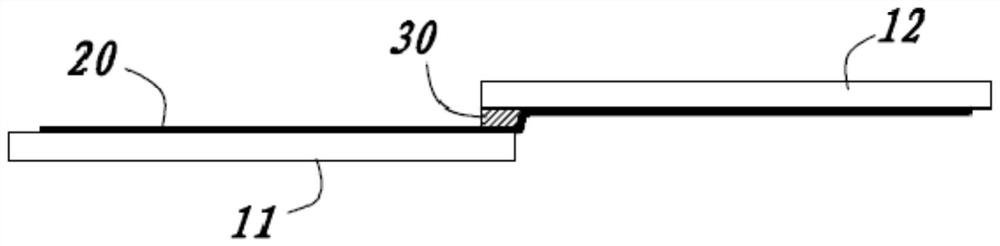

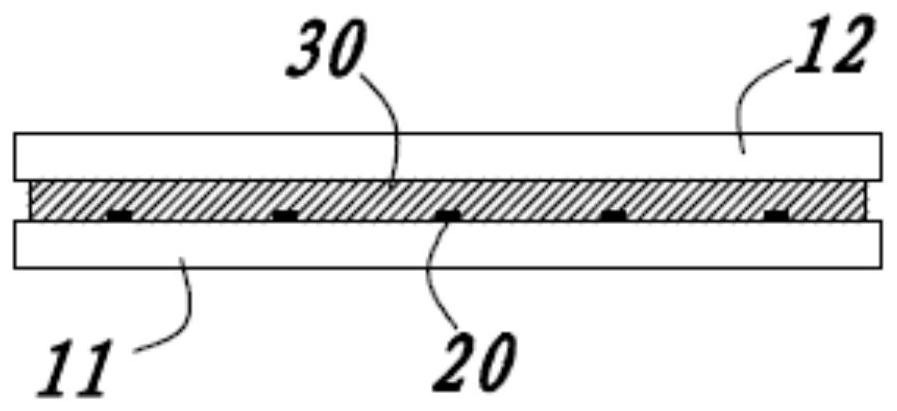

A wafer level chip packaging method

ActiveCN105070668BReduce edge stressReduce warpageSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The invention relates to the field of semiconductor device preparation, in particular to a wafer-level chip packaging method. In the wafer-level chip packaging method, bonding materials are arranged on the upper surface of the first wafer and the upper surface of the second wafer, and the bonding material is first subjected to a planarization process, and then the first wafer and the second wafer are The edge of the wafer is subjected to a grinding process, so that the edge stress of the wafer is reduced, so that the warpage becomes smaller, so that there is no crack at the bonding of the first wafer and the second wafer. By changing the order of flattening and grinding, Reduce wafer edge warpage to improve wafer quality.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

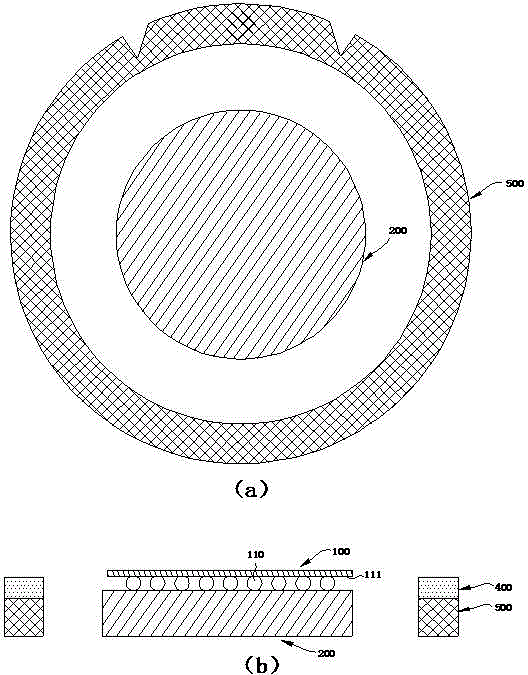

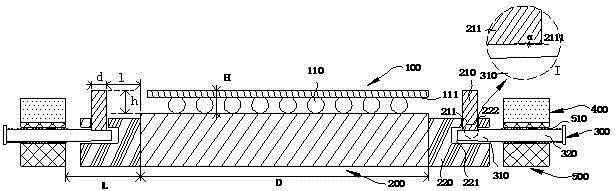

A placement machine for bumped wafers

ActiveCN104409373BAdjust the height up and down at any timeReduce edge stressSemiconductor/solid-state device manufacturingSemiconductor packageHeight difference

The invention discloses a chip mounter for a bump wafer, and belongs to the technical field of semiconductor packaging. The chip mounter comprises a chip mounting base for bearing the bump wafer to be mounted, a Waferring platform mounted around the chip mounting base, and a coffer dam arranged between the chip mounting base and the Waferring platform, wherein a threaded through hole facing to the center of the chip mounting base is formed in the side surface of the Waferring platform; the height difference between the top of the coffer dam and the top of the chip mounting base is h, and the value of H-h is not less than 0 micron and not more than 50 microns; a boss which extends down is arranged at the lower part of the coffer dam; the coffer dam is connected with the chip mounting base through a fixing device; a blind hole facing to the center of the chip mounting base is formed in the outer side surface of the fixing device; a through hole perpendicular to the blind hole and a flat screw for connecting the through hole with the blind hole are formed over the blind hole, and the tail of the blind hole is matched with the boss. According to the chip mounter, the chip mounting base and the Waferring platform are designed and the coffer dam is added between the chip mounting base and the Waferring platform, so that the problems of easy fragmenting, cracking and the like of edges in a bump wafer mounting process are solved.

Owner:JIANGYIN CHANGDIAN ADVANCED PACKAGING CO LTD

Display panel and display device

PendingCN112185260AImprove bending performanceReduce warpageSolid-state devicesIdentification meansDisplay deviceEngineering

The invention provides a display panel and a display device, the display panel comprises a support layer, a display layer and a cover plate; the display layer is arranged at one side of the support layer, and the cover plate is arranged at one side, deviating from the support layer, of the display layer. The display panel comprises a bending area, and when the bending form of the display panel isconfigured to be bent outwards, at least the orthographic projection of the bending area of the display layer on the cover plate is located in the cover plate; when the bending form of the display panel is configured to be bent inwards, at least the orthographic projection of the bending area of the display layer on the supporting layer is located in the supporting layer. According to the displaypanel provided by the invention, the situation that the flexible display panel is broken is improved, and the bending capability and the reliability are improved.

Owner:BOE TECH GRP CO LTD +1

LED packaging device

PendingCN114744102AReduce edge stressReduced risk of ruptureSemiconductor devicesPhysicsLed packaging

The invention provides an LED packaging device, and the device comprises a packaging substrate which is provided with a first surface and a second surface, and the first surface and the second surface are opposite to each other; the LED chip is arranged on the first surface of the packaging substrate; the light-transmitting unit is arranged on the first surface of the packaging substrate, the light-transmitting unit is provided with an inner cavity, and the LED chip is located in the inner cavity; wherein the inner cavity is provided with an upper surface and a side surface, the upper surface and the side surface are provided with a first connecting part, and the first connecting part is a curved surface or an inclined surface or a combination of the curved surface and the inclined surface. The structure can reduce the edge stress of the light-transmitting unit and reduce the risk that the light-transmitting unit is broken along the edge while the light-emitting efficiency of the LED chip is not influenced.

Owner:QUANZHOU SANAN SEMICON TECH CO LTD

Cam follow-up device of engine

ActiveCN101929362BReduce wearReduce mechanical wearValve arrangementsLubrication of auxillariesPulp and paper industryCam

The invention relates to a cam follow-up device of an engine, comprising a follow-up body, a roller and a roller pin, wherein one end of the follow-up body is connected to an engine cylinder body through a mounting shaft arranged in a mounting shaft through hole, the lower part of the other end of the follow-up body is provided with a roller mounting slot, and the roller is arranged in the rollermounting slot through the roller pin. The device is characterized in that the upper part of the other end of the follow-up body is fixedly provided with a ball socket base, and the upper end surface of the ball socket base is concavely provided with a ball socket groove matched with the ball end surface of a push rod; the ball socket base is provided with an axial through hole, a radial hole and an inclined hole; the axial through hole is communicated with a first oil containing hole and communicated to the roller mounting slot; the radial hole is communicated with a second oil containing hole and communicated to the inner wall of the mounting shaft through hole; and the inclined hole is communicated with a third oil containing hole and communicated to the inner wall of a roller pin mounting hole as well as communicated to an oil containing tank through a radial straight oil hole and an inclined oil hole. The invention has the advantages of artful and reasonable structure, excellent property, wear resistance, high pitting corrosion resistance, good lubricating property and long service life.

Owner:WUXI XIZHOU MACHINERY

Forming device

ActiveCN109571916BReduce edge stressImprovement of affected issues such as optical propertiesFlat articlesOptical propertyThin membrane

The invention provides a forming device, comprising: a bearing part, a groove is arranged on the bearing part, the groove has a bottom wall and a side wall connected with the bottom wall; and a forming part, the forming part Set on the bottom wall and spaced from the side wall, the forming part has a top surface away from the bottom wall, the top surface is used to carry the product to be formed; the opening profile of the groove is the same as The contours of the edges of the top surface are the same. The molding device provided by the present invention, by setting the contour of the opening of the groove of the molding part to be the same as the contour of the edge of the top surface of the molding part, helps to improve the stress on the film material during the thermoplastic molding process, which causes the optical properties of the film material to be affected. The problem.

Owner:INTERFACE TECH CHENGDU CO LTD +2

An integrated circuit structure and its manufacturing method

ActiveCN111490019BDifferent stress valuesIncrease stressSemiconductor/solid-state device detailsSolid-state devicesMechanical engineeringBinding force

The present invention provides an integrated circuit structure and its manufacturing method, which utilizes forming a first sealing layer in a substrate and forming a second sealing layer on the substrate, and making the first sealing layer and the second sealing layer both For the compressive stress, to counteract the warping force of the substrate. Moreover, the filling ratios of the inorganic fillers in the first sealing layer and the second sealing layer are different, so that the two have a difference in compressive stress, which can ensure that the substrate does not warp while ensuring the stability of the first sealing layer and the second sealing layer. Binding force.

Owner:TIANJIN HENGLIYUANDA INSTR

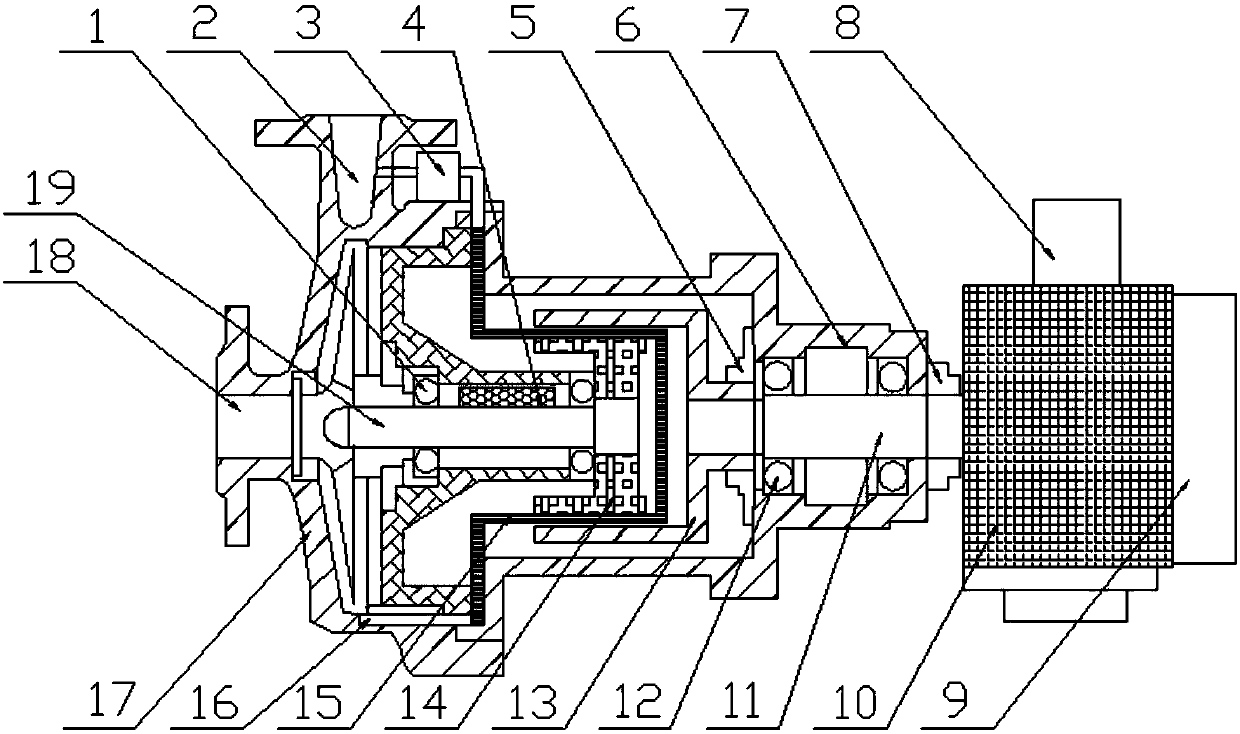

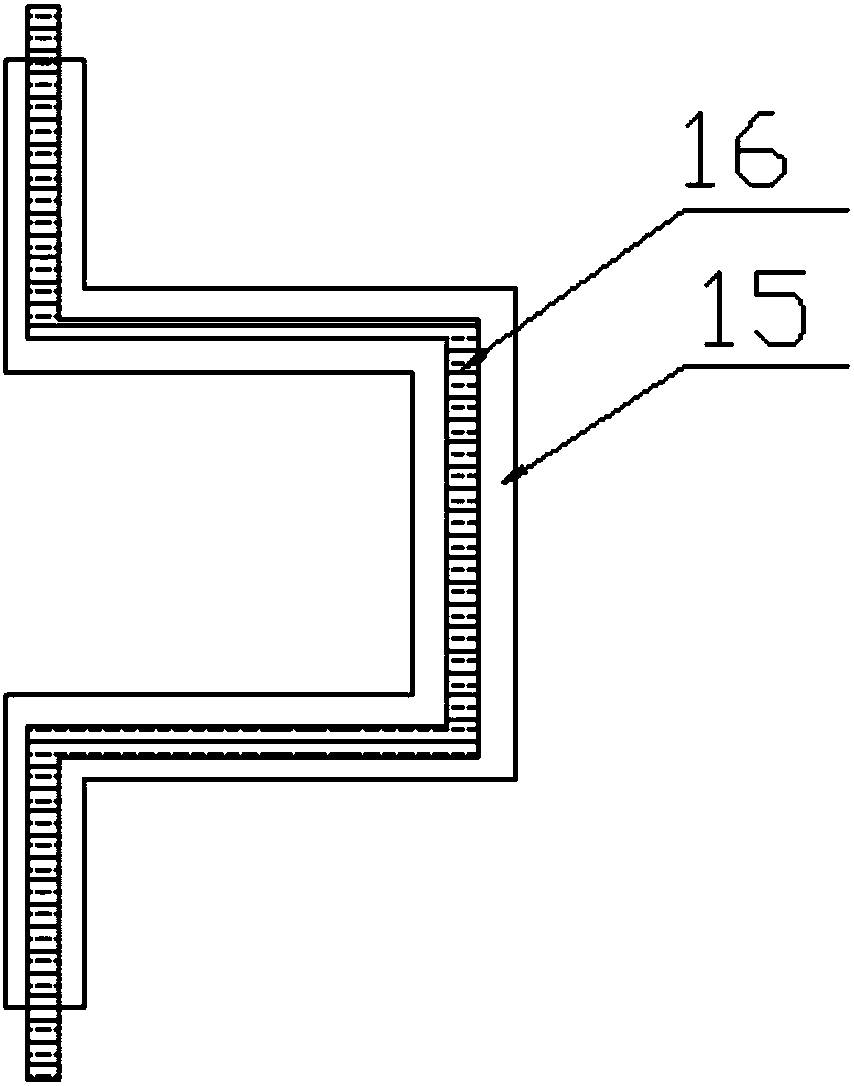

High-pressure pump

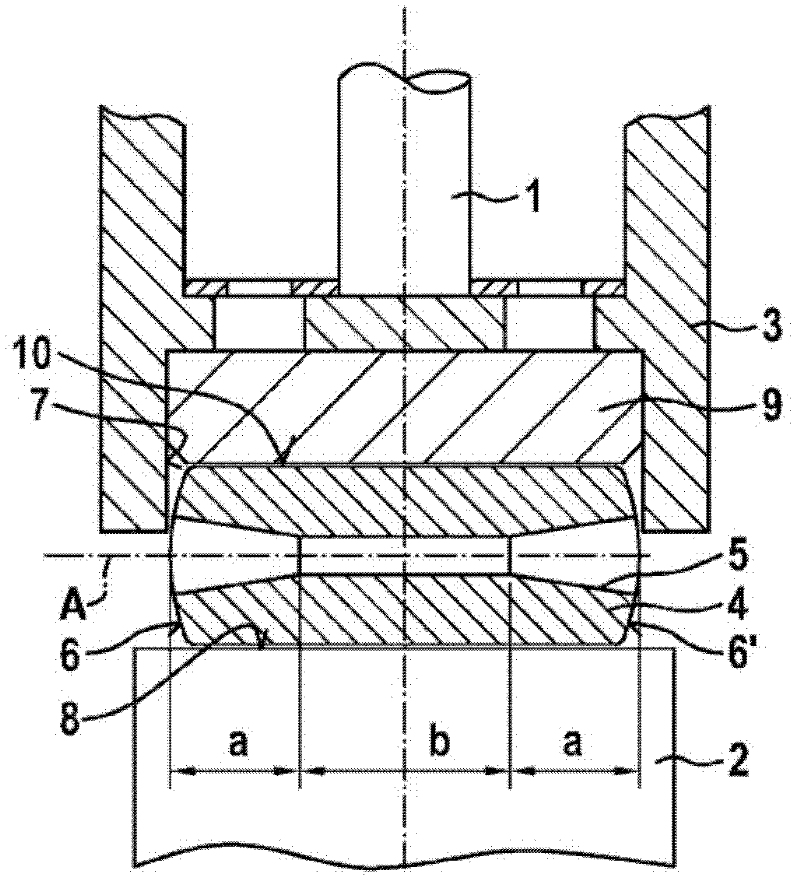

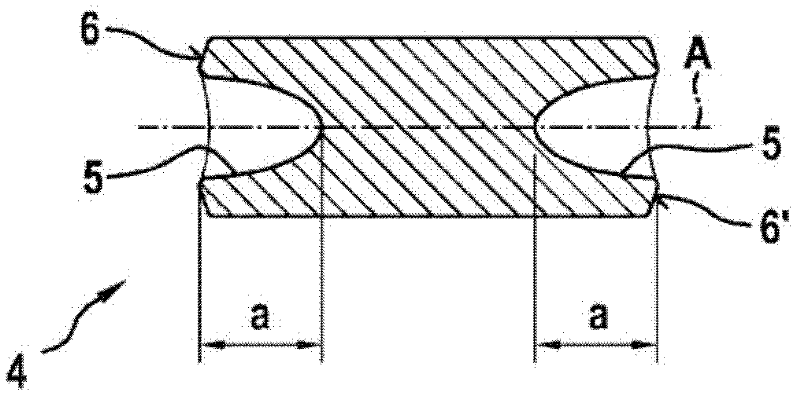

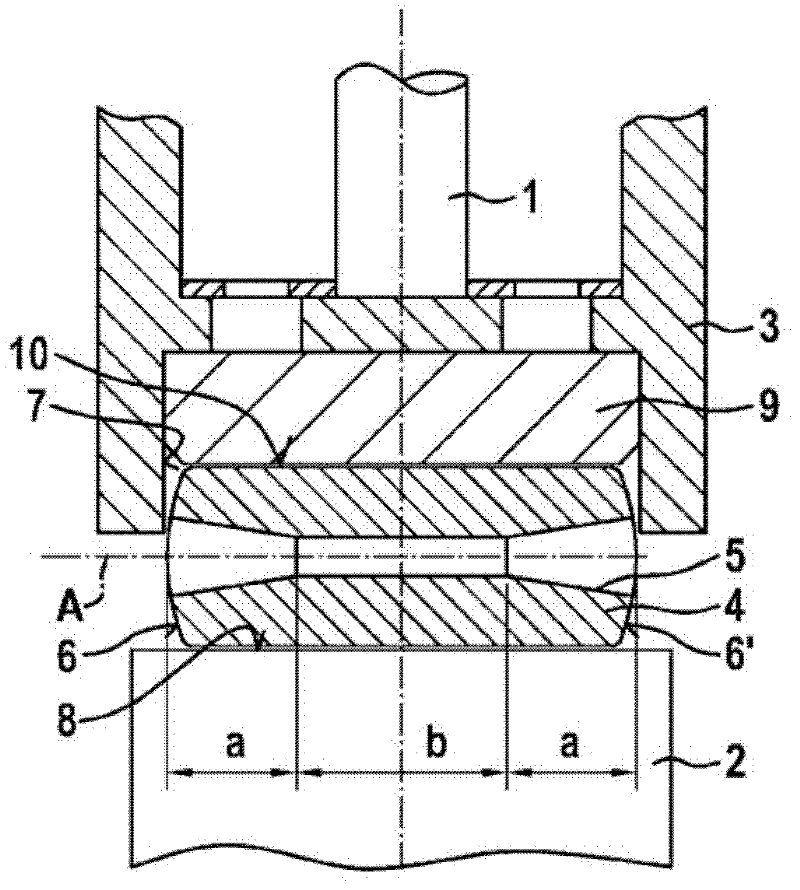

InactiveCN102472221AAdjustable stiffnessReduce weightFuel injecting pumpsPiston pumpsReciprocating motionDrive shaft

The invention relates to a high-pressure pump for a fuel injection device of an internal combustion engine, comprising at least one pump element having a pump piston (1) that can be driven via a cam (2) or eccentric disk of a drive shaft in a stroke movement, wherein the pump piston (1) is directly supported via a tappet (3) and a roller (4) on the cam (2) or eccentric disk of the drive shaft. According to the invention, the roller (4) comprises at least one central bore (5), which extends along the longitudinal axis (A) of the roller (4) and comprises at least one cone-shaped, partially spherical and / or partially elliptical sub-section (a) for forming an inner contour.

Owner:ROBERT BOSCH GMBH

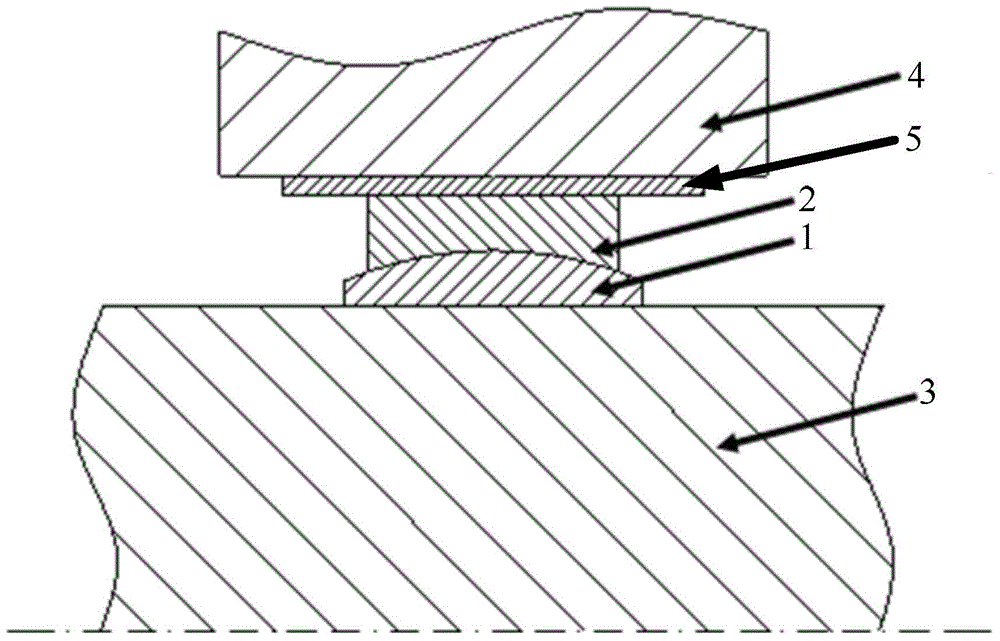

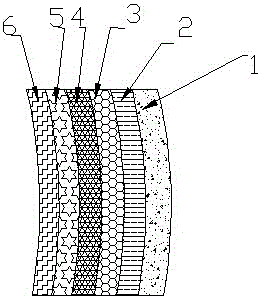

bearing ring

ActiveCN105465182BReduce edge stressEasy to manufactureRoller bearingsBearing assemblyEdge surfaceRolling-element bearing

The invention relates to a bearing ring (2, 3) for a rolling bearing (1), in particular for a tapered roller bearing, which has a rolling surface (8) for rolling bodies and an essentially axially extending outer surface (10), which is designed to be fixedly connected to the element to be supported in a torsionally fixed manner, and the bearing ring has first and second substantially radially extending axially delimiting the bearing ring (2; 3) Two edge surfaces (12; 14), wherein an edge (16; 18) is formed on at least one edge surface (12; 14), said edge being designed to be flexible under pressure loading. The invention also relates to a rolling element (4) with a flexibly designed end region (20; 22) and a rolling bearing with a bearing ring (2; 3) of this type and / or a rolling bearing (4) of this type.

Owner:AB SKF

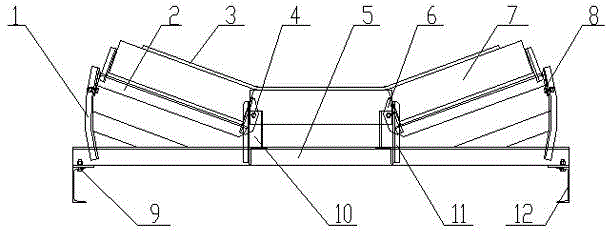

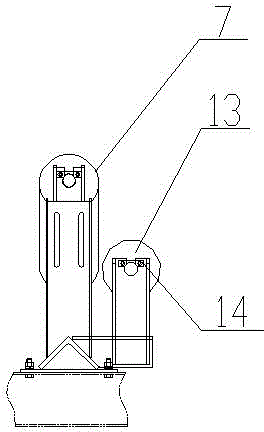

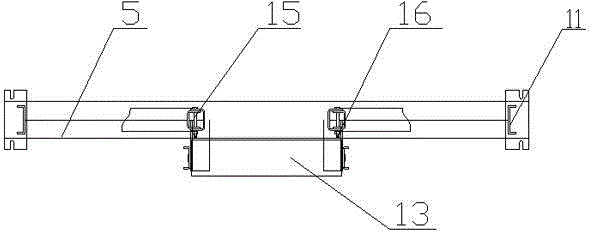

Combined type deviation rectifying device for transition section

The invention discloses a combined type deviation rectifying device for a transition section. The combined type deviation rectifying device comprises a middle beam bracket, center pillars, side pillars, regulating brackets and connecting profile steel; the middle beam bracket is arranged on a middle frame; the side pillars are respectively arranged at two ends of the middle beam bracket; two rows of kidney-shaped slot holes are formed in each side pillars; the center pillars are arranged in the middle of the middle beam bracket, and a through hole used for connecting the corresponding regulating bracket is formed in each center pillar; two ends of each regulating bracket are respectively provided with a first connecting plate and a second connecting plate; the U-shaped open end of each first connecting plate is connected with the through hole of the corresponding center pillar to form a hinged shaft for the corresponding regulating bracket to rotate; two fixing holes are formed in each second connecting plate, and each second connecting plate is fixedly arranged in the kidney-shaped slot holes of the corresponding side pillar through fasteners penetrating through the fixing holes, so that the corresponding regulating bracket can rotate a certain angle vertically around the hinged shaft; the connecting profile steel is welded at one side of the middle beam bracket, and is used for regulating the spacing between the central axis of a middle roll and the central axis of a side roll. The deviation rectifying device is simple in structure, convenient in operation and long in service life, and has a good automatic deviation rectifying effect.

Owner:HENGYANG CONVEYING MACHINERY

Cam follower roller unit

ActiveCN106948985BReduce pressure contactReduce edge stressValve drivesFuel injecting pumpsEngineeringCam

The cam follower roller device includes a tappet body 12, a pin 14, and a roller 16 mounted on the pin. The tappet body includes holes for mounting the pin ends 14b, 14c of the pin on the tappet body. 12b, 12c. The device also includes a deformable ring 18, 20 arranged between each pin end 14b, 14c of the pin and the inner wall of the associated bore 12b, 12c of the tappet body.

Owner:AB SKF

Steel welded vertical large oil tank

ActiveCN105600205BGuaranteed safe operationEliminate danger pointsLarge containersFillet weldLow-cycle fatigue

The invention provides a large steel welded vertical oil tank. The large steel welded vertical oil tank is provided with a tank bottom, a tank wall and a tank top. A transition connecting ring is arranged between the tank bottom and the tank wall and provided with an annular bottom section, an arc-shaped transition section and a vertical cylindrical section. The tank bottom is connected with the annular bottom section of the transition connecting ring in a welded mode. The tank wall is connected with the vertical cylindrical section of the transition connecting ring in a welded mode. The tank top can be a fixed top and can also be an outwards-floating top. The large steel welded vertical oil tank has the advantages that T-shaped joints of a tank wall and a tank bottom of an existing large oil tank and large fillet welds on the joints are omitted, main danger points of the whole oil tank are eliminated, and safe operation of the large oil tank is guaranteed, wherein the transition position between the tank wall and the tank bottom is not prone to low-cycle fatigue damage, an attachment weld of the transition portion between the tank wall and the tank bottom is not prone to tearing damage, the anti-seismic property of the large oil tank is greatly improved, and the anti-seismic property of the large oil tank is good.

Owner:JIANGSU CHEM EQUIP MFG & INSTALLATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com