A placement machine for bumped wafers

A placement machine and bump technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as fragments, hidden cracks, and hidden dangers left by the process, so as to reduce deformation, reduce edge pressure, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

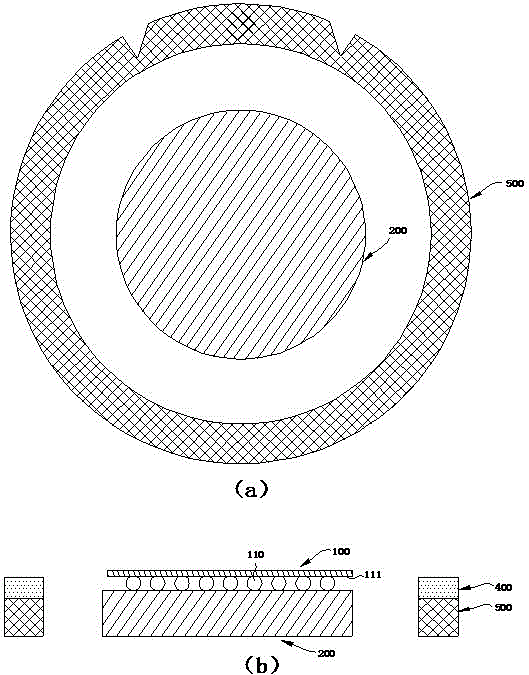

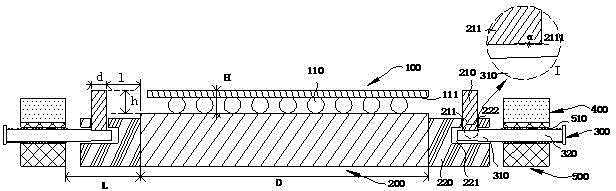

[0046] Embodiment one, see Figure 2 to Figure 4

[0047] A kind of placement machine for bump wafer of the present invention, as figure 2 and image 3 As shown, the bump wafer 100 to be mounted is carried on the mount chassis 200, and the bump wafer 100 is temporarily fixed by vacuum suction to facilitate the mount. Wherein, the thickness of the bump wafer 100 and its bump 110 is H. The wafer ring platform 500 is installed around the patch chassis 200, and there is a gap of width L with the patch chassis 200. The side of the wafer ring platform 500 is provided with a threaded through hole 510 pointing to the center of the patch chassis 200. The through holes 510 are evenly distributed, and there are at least three. The wafer ring 400 is also temporarily fixed above the wafer ring platform 500 by vacuum suction.

[0048] A dam 210 is set between the patch chassis 200 and the wafer ring platform 500 . The dam 210 is ring-shaped, and the gap between it and the chip chassi...

Embodiment 2

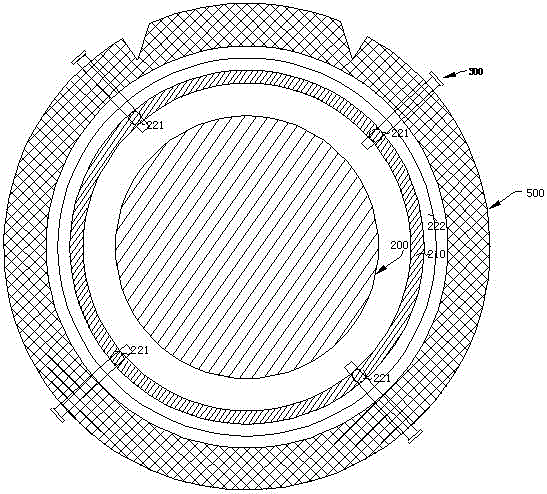

[0053]Embodiment two, see Figure 5

[0054] The structure of this embodiment is similar to that of Embodiment 1, the difference is that: the fixing device 220 is a discontinuous fan-shaped block, and there are at least three, evenly distributed, to simplify the structure, and each fixing device 220 corresponds to a flat head screw 300 . Figure 5 4 fixing devices 220 are shown in , generally only need to adjust three flat head screws 300 among them to meet the requirement of height level.

[0055] When the mounter for bump wafers of the present invention starts filming, as Image 6 As shown, the patch chassis 200 drives the dam 210 to rise together, the patch roller 600 carries the diaphragm and presses down to the bump wafer 100, and then the patch roller 600 rolls from one side of the bump wafer 100 to the bump wafer at a constant speed On the other side of 100, complete the film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com