Combined type deviation rectifying device for transition section

A deviation correction device and composite technology, applied in the direction of transportation and packaging, conveyor objects, rollers, etc., can solve the problems of complex structure of photoelectric deviation correction device, inability to realize automatic deviation correction, lagging of deviation correction process, etc., to ensure contact and prevent material Dropping, reducing the effect of edge stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

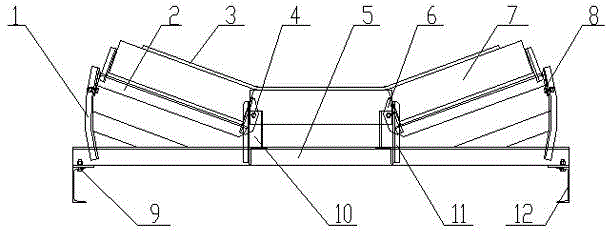

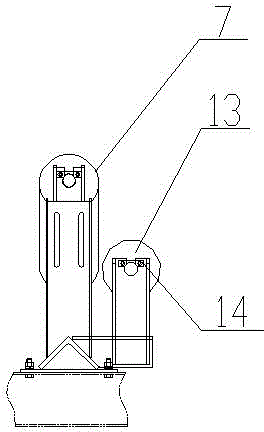

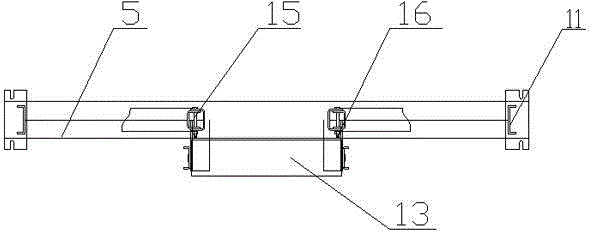

[0025] Reference Figure 1 ~ 3 , A transitional composite correction device in this embodiment, including the central beam bracket 6, mid -pillar 11, edge pillar 1, two adjustment bracket 2 and connecting steel, which is installed on the middle frame 12;The edge pillar 1 is installed at both ends of the central beam stent 6; the border pillar 1 has two rows of waist -shaped long holes;; The mid -pillar 11 has a passing hole for connecting to adjusting the bracket 2; the adjustment of the side roller 7 is installed on the bracket 2;The first connection board 6 is a U -shaped branch board. The connection of the U -shaped opening end with the pillar 11 to form a hinge axis 4 for adjusting the bracket 2 rotation, and the U line opening end of the first connection board 6 and the first connection board 6 and the first connection board 6The U -shaped opening end of the mid -pillar 11 is relatively installed; there are two fixed holes on the second connector 8, and the fastener 9 that pas...

Embodiment 2

[0033] Reference Figure 1 ~ 3, A transitional composite correction device in this embodiment, including the central beam bracket 6, mid -pillar 11, edge pillar 1, two adjustment bracket 2 and connecting steel, which is installed on the middle frame 12;The edge pillar 1 is installed at both ends of the central beam stent 6; the border pillar 1 has two rows of waist -shaped long holes;Mid -roller 13 is fixed connection, and there is a passing hole for connecting to adjusting the bracket 2; the adjustment of the side roller 7 is installed on the bracket 2;8; The first connection board 6 is a U -shaped branch board, and its U -shaped opening end and the pillar 11 -pillar connection to form a hinge shaft 4 for adjusting the bracket 2, and the U line opening of the first connecting board 6 6The U -shaped opening end of the end and the mid -pillar 11 is relatively installed; there are two fixed holes on the second connector 8, and the fastener 9 that passes through the fixed hole 9 is fi...

Embodiment 3

[0041] Reference Figure 1 ~ 3 , A transitional composite correction device in this embodiment, including the central beam bracket 6, mid -pillar 11, edge pillar 1, two adjustment bracket 2 and connecting steel, which is installed on the middle frame 12;The edge pillar 1 is installed at both ends of the central beam stent 6; the border pillar 1 has two rows of waist -shaped long holes;Mid -roller 13 is fixed connection, and there is a passing hole for connecting to adjusting the bracket 2; the adjustment of the side roller 7 is installed on the bracket 2;8; The first connection board 6 is a U -shaped branch board, and its U -shaped opening end and the pillar 11 -pillar connection to form a hinge shaft 4 for adjusting the bracket 2, and the U line opening of the first connecting board 6 6The U -shaped opening end of the end and the mid -pillar 11 is relatively installed; there are two fixed holes on the second connector 8, and the fastener 9 that passes through the fixed hole 9 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com