Idler wheel with drum inner bore

A technology of rollers and inner holes, applied in the direction of elements with teeth, belts/chains/gears, portable lifting devices, etc., can solve the problems that the economic benefits of the rollers are not very high, the wear and tear of the rollers, etc., to reduce edge stress and wear. , the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific drawings and embodiments.

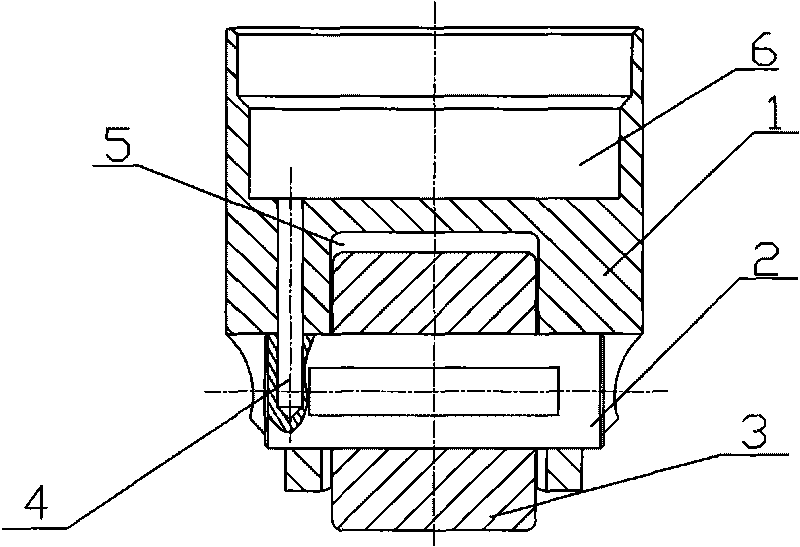

[0012] Such as Figure 1 ~ Figure 3 Shown: the present invention comprises a tappet body 1, a roller pin 2, a roller body 3, a groove pin 4, a positioning groove 5, a push rod groove 6 and an inner hole 7.

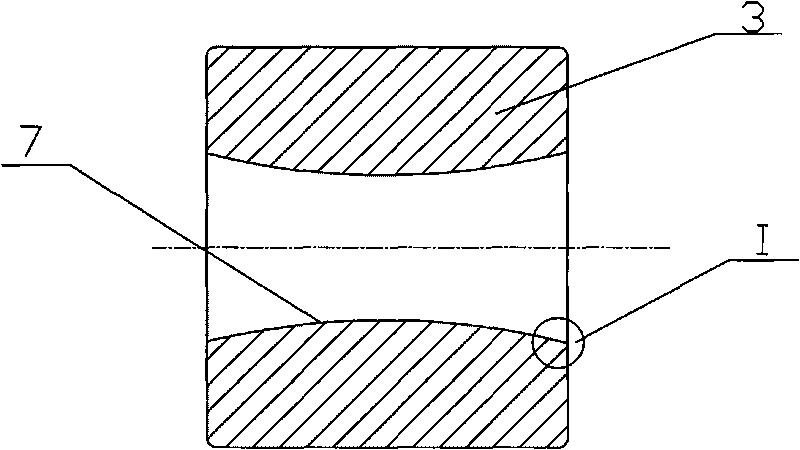

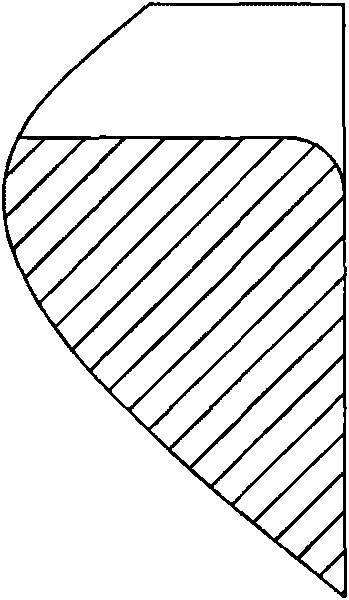

[0013] Such as figure 2 and image 3 Shown: the present invention is used in the fuel injection pump of automobile engine. The surface of the inner hole 7 of the roller body 3 is drum-shaped, and the outer surface of the roller body 3 is also drum-shaped.

[0014] Such as figure 1 Shown: including the roller body 3, it is characterized in that: there is an inner hole 7 in the roller body 3, the longitudinal section of the inner wall of the inner hole 7 is arc-shaped, and the middle part of the inner wall protrudes toward the center line of the inner hole 7, The inner diameter of the middle part of the inner hole 7 is smaller than the inner diameter of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com