High-pressure pump

A high-pressure pump and pump piston technology, applied in the field of high-pressure pumps, can solve the problems of increased wear and tear in the contact area, and achieve the effects of reduced weight and good pressing force characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

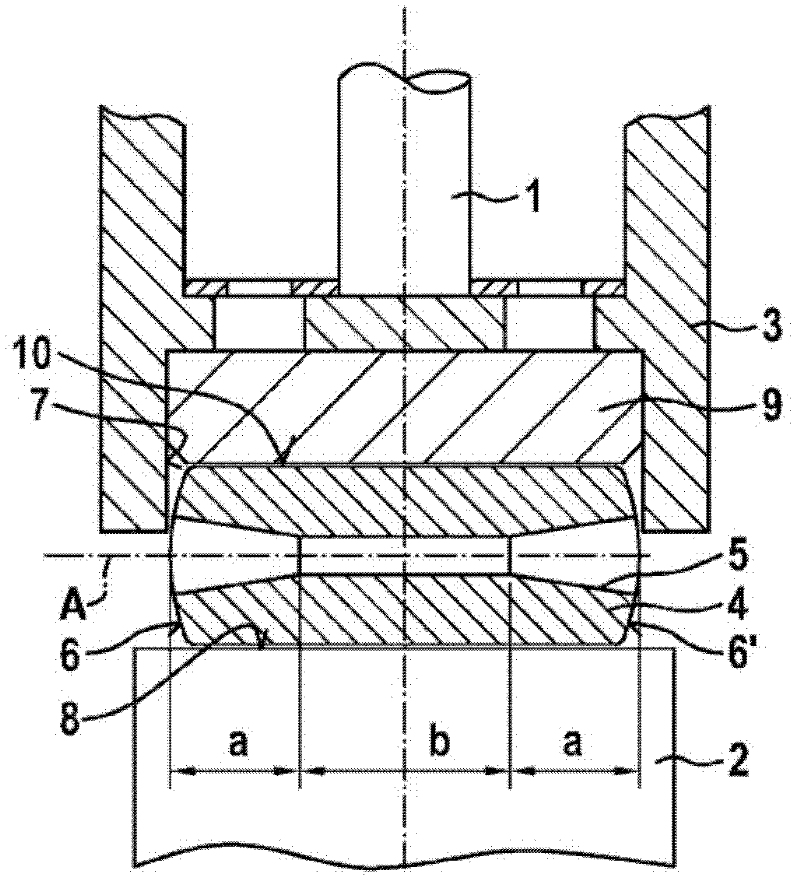

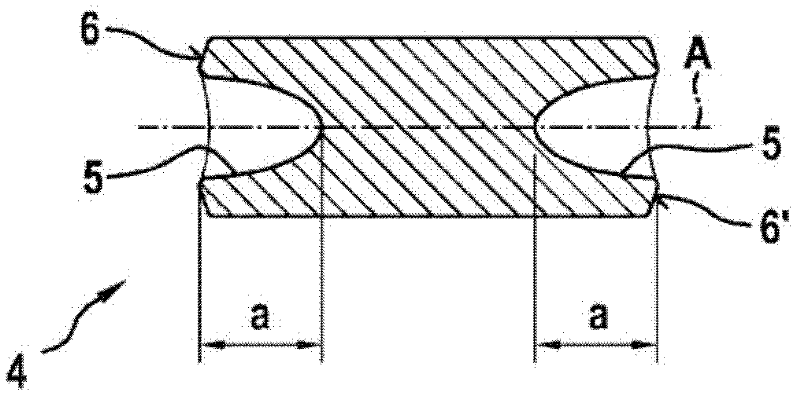

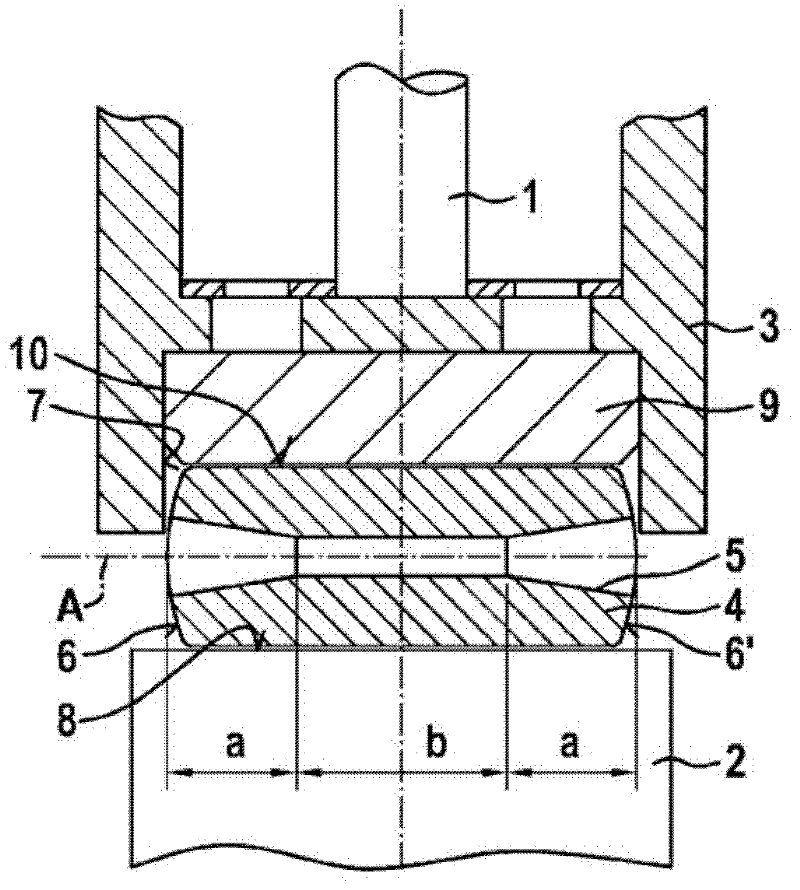

[0019] exist figure 1 The pump part of the high-pressure pump according to the invention shown in section in the middle has a pump piston 1 which is indirectly supported via a roller 4 on a cam 2 of a drive shaft (not shown). The roller 4 is received at least partially in a push rod 3 which has a pot-shaped end. For additional support of the roller 4 , a roller shoe 9 is also provided, which is arranged between the push rod 3 and the roller 4 . The rotation of the drive shaft is transmitted to the roller 4 through the cam 2, and the outer peripheral side of the roller rolls on the cam 2. The outer peripheral side of the cam 2 thus forms a rolling surface 8 . Due to the eccentricity of the cam 2 relative to the longitudinal axis of the drive shaft its rotational movement is converted into a linear movement of the pump piston 1 by the roller 4 held in the push rod 3 . In this case, especially the contact area of the roller 4 on the push rod 3 and on the running surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com