Patents

Literature

37results about How to "Reduce package loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

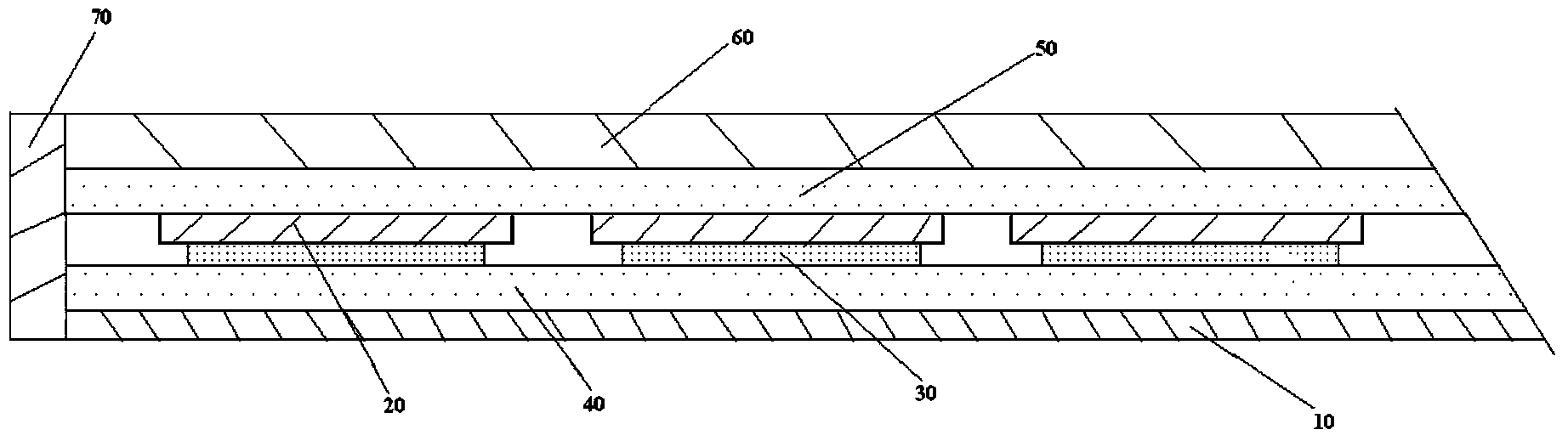

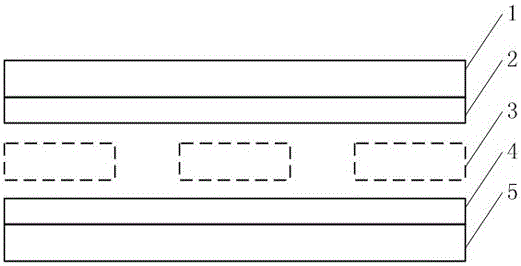

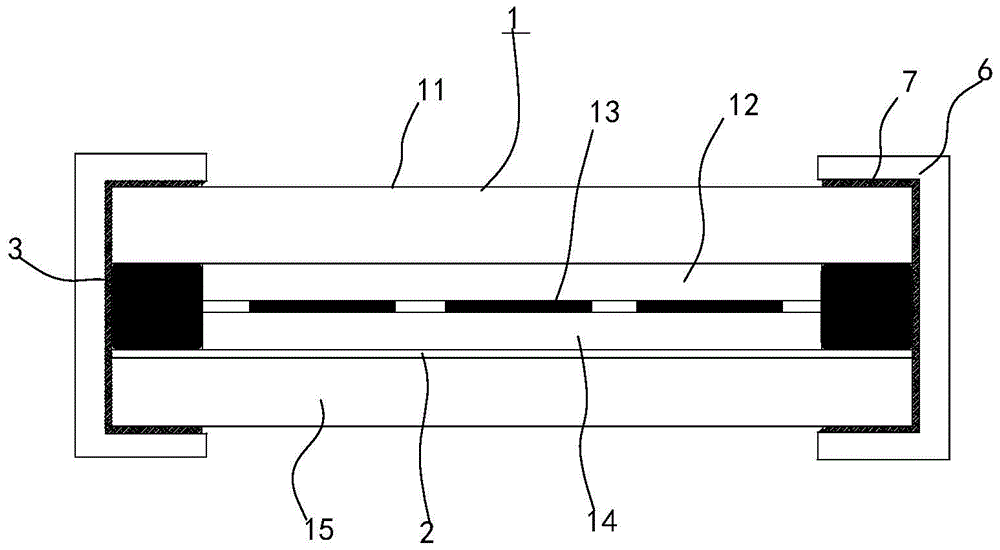

Photovoltaic cell assembly with two glass layers

InactiveCN104752538AExtend your lifeSolution to short lifePhotovoltaicsPhotovoltaic energy generationCell assemblyEngineering

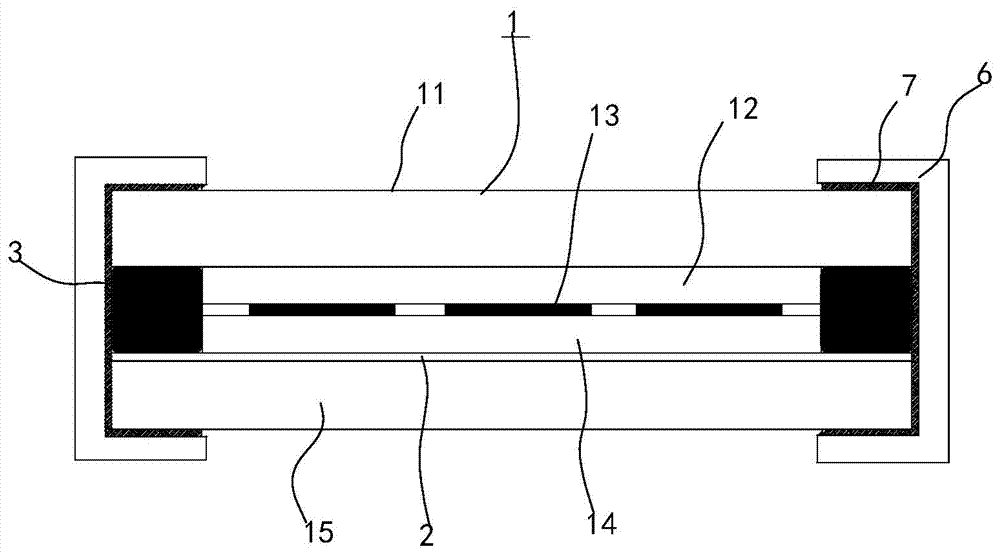

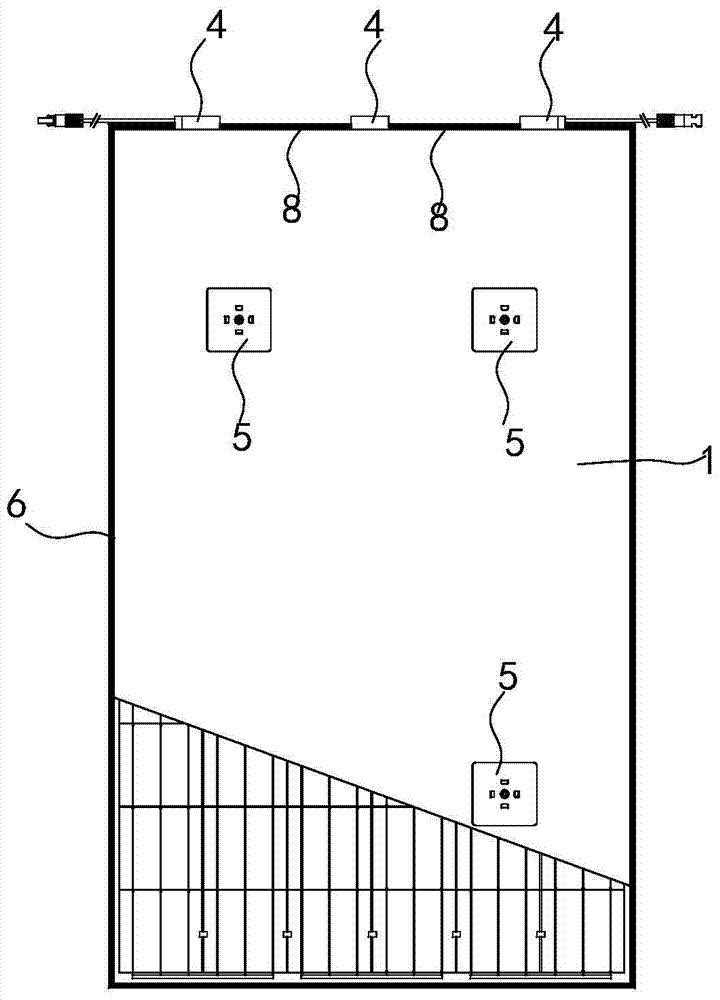

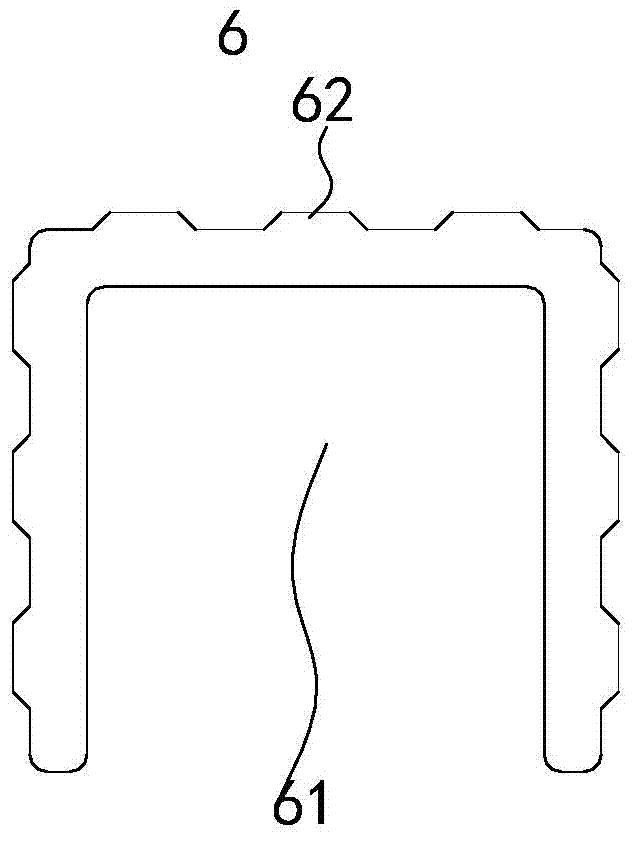

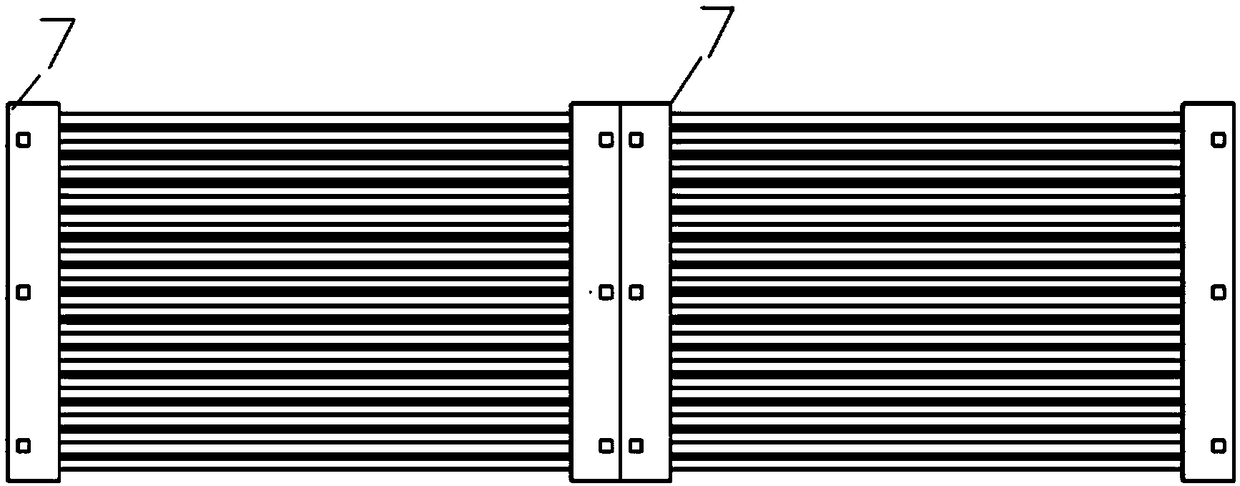

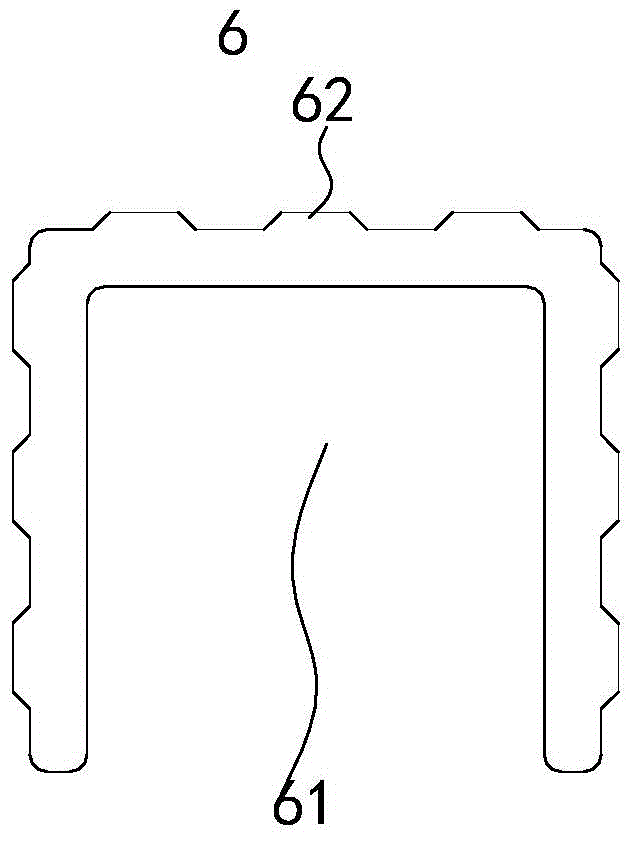

A dual-glass photovoltaic cell module, comprising: a body (1), said body (1) comprising a first glass layer (11), a first encapsulation layer (12), a cell group layer (13), a second encapsulation layer (14), and a second glass layer (15) arranged in a sequential stack, the outer edges of the first glass layer (11) and the second glass layer (15) extending past the outer edges of the cell group layer (13); a layer of reflective coating being disposed on the second glass layer (15); an end sealing block, said end sealing block being arranged between the first glass layer (11) and the second glass layer (15) at the outer periphery of the first encapsulation layer (12), the cell group layer (13), and the second encapsulation layer (14); a rim (6) encapsulating the outer perimeter of the body (1), said rim (6) having a notch (60); and a junction box (4) being disposed at the notch (60).

Owner:BYD CO LTD

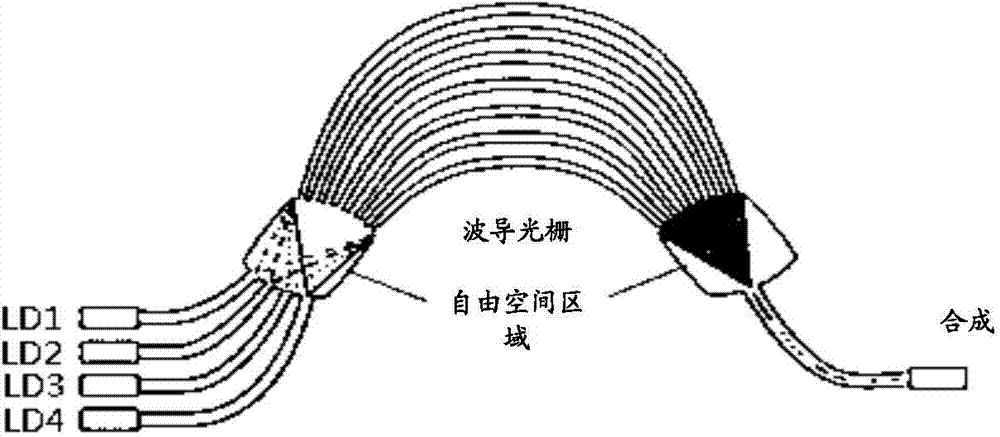

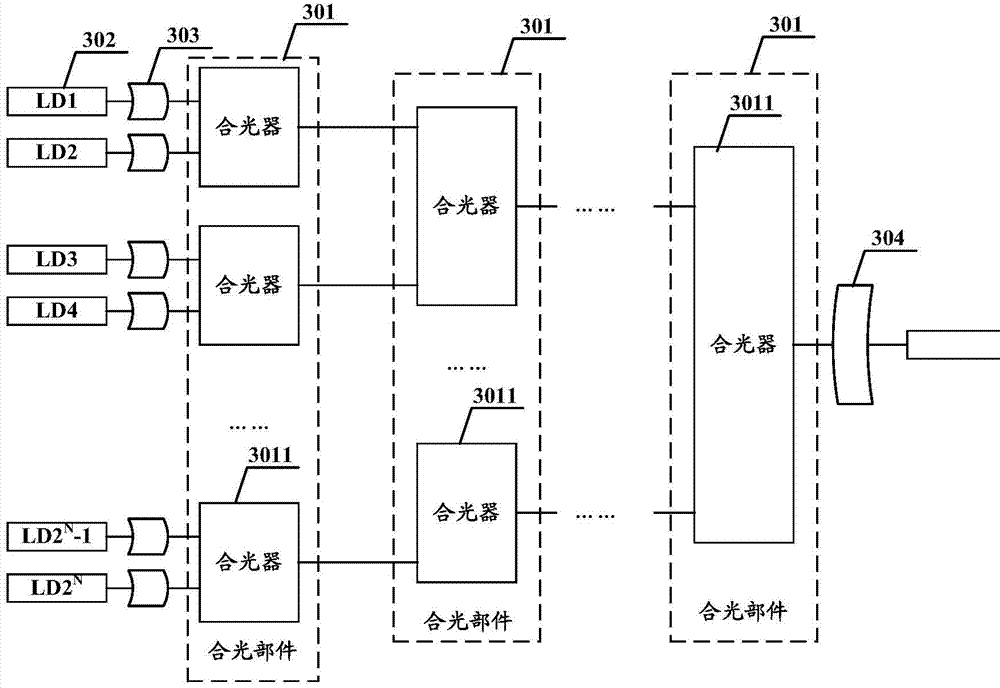

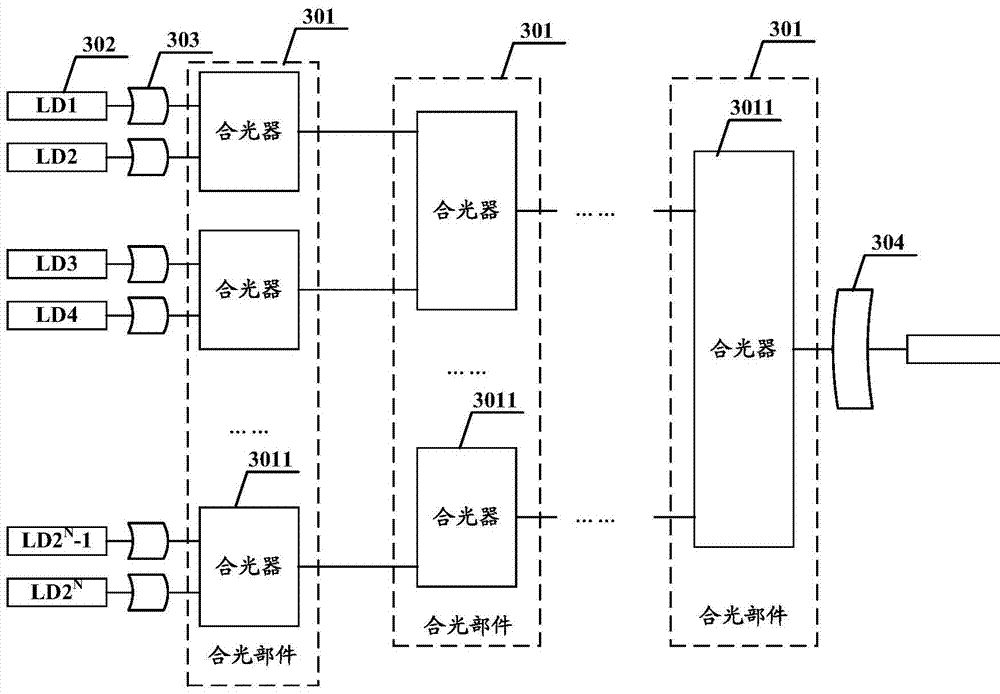

Optical multiplexer and emitting light device

ActiveCN104734800AReduce package sizeReduce package lossPolarisation multiplex systemsTime-division optical multiplex systemsMultiplexerProcess complexity

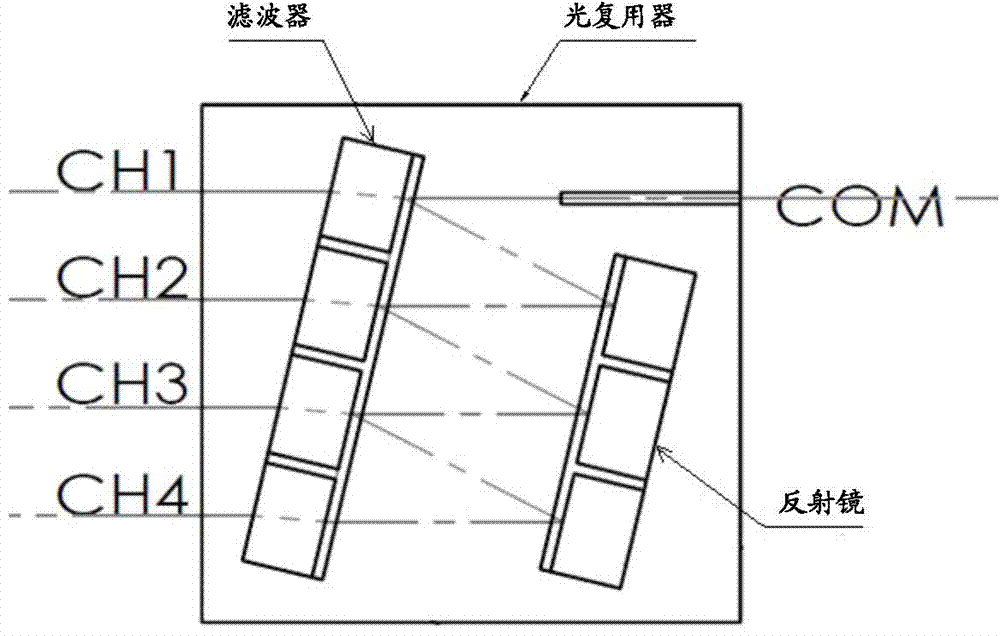

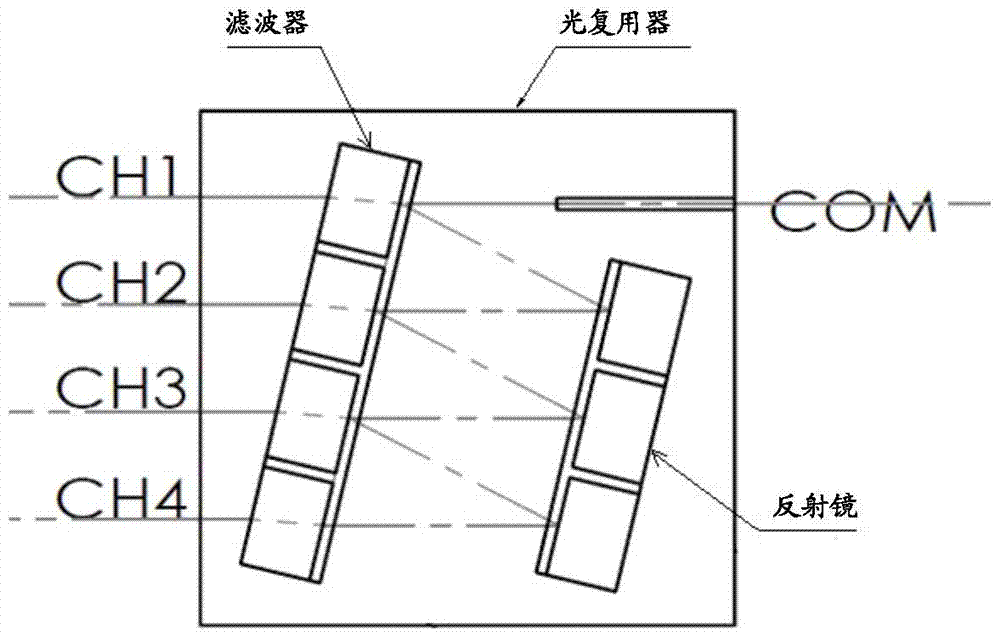

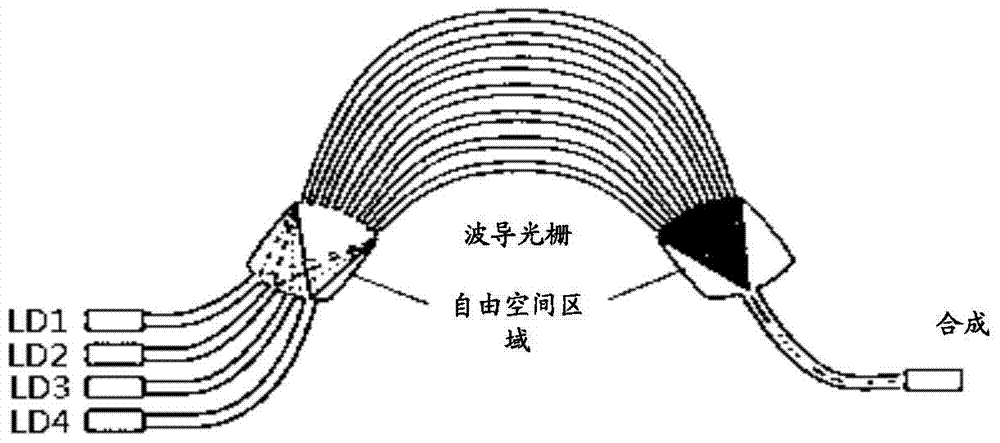

The present invention discloses an optical multiplexer and a transmitter optical subassembly, and relates to the field of optics communications. A light-combining part is formed by using at least one light combiner that can combine two beams of light into one beam of light, and at least two levels of light-combining parts are used to constitute an optical multiplexer, so that 2 N beams of light are combined into one beam by using N level of light-combining parts, thereby reducing a package size and packaging loss, and reducing the complexity of a manufacturing process.

Owner:HUAWEI TECH CO LTD

Black solar battery component

InactiveCN103400885AReduce package lossIncrease powerPhotovoltaic energy generationSemiconductor devicesEngineeringSolar battery

The invention provides a black solar battery component. The black solar battery component comprises a black back panel and a plurality of cells arranged on the black back panel at intervals, wherein a reflection enhancing structure facing to reflection of the cells is arranged between the cells and the black back panel. When the black solar battery component is in use, after light irradiated on the cells is refracted to the reflection enhancing structure through the cells, the reflection enhancing structure with high reflectivity can reflect light to the cells to be absorbed, so that the package loss of the whole solar battery component is reduced and the power of the black solar battery component per unit area is improved.

Owner:YINGLI GRP

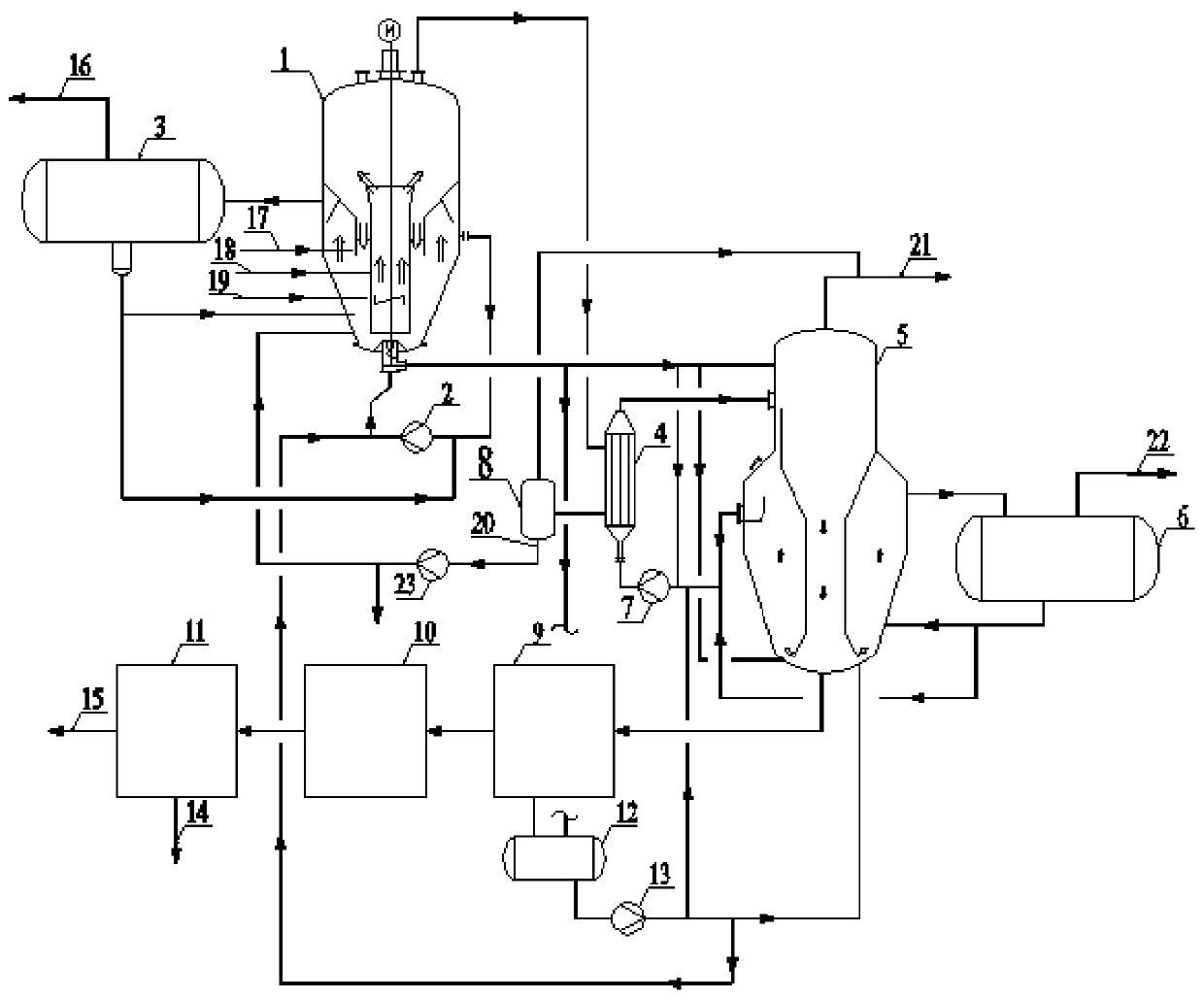

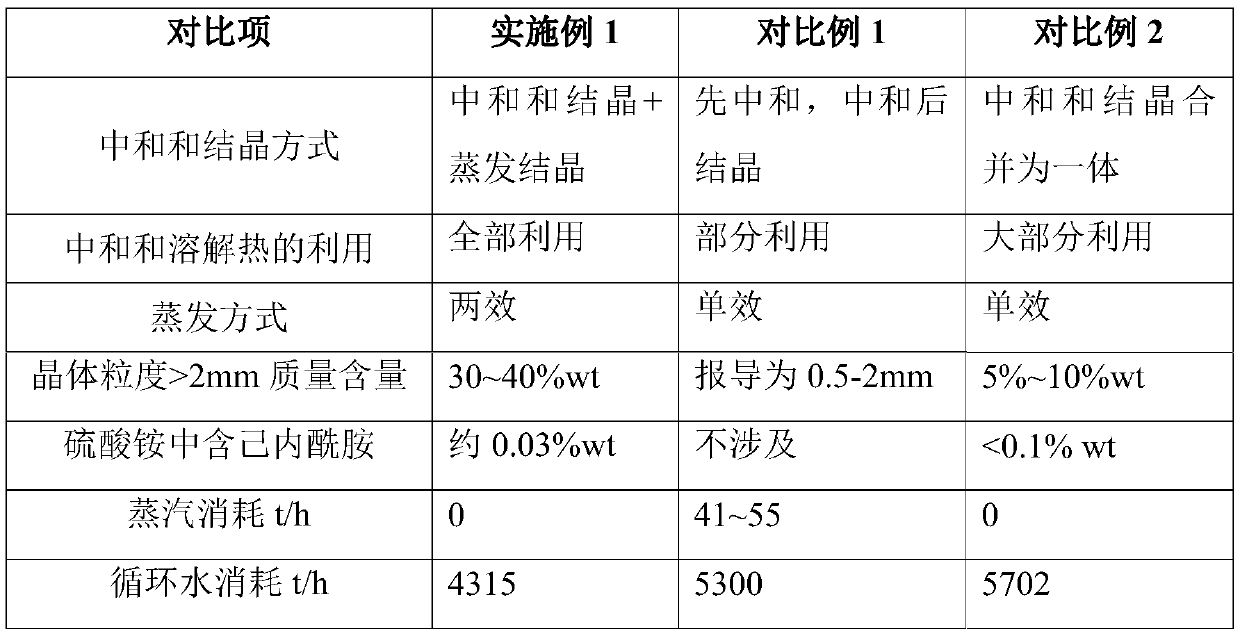

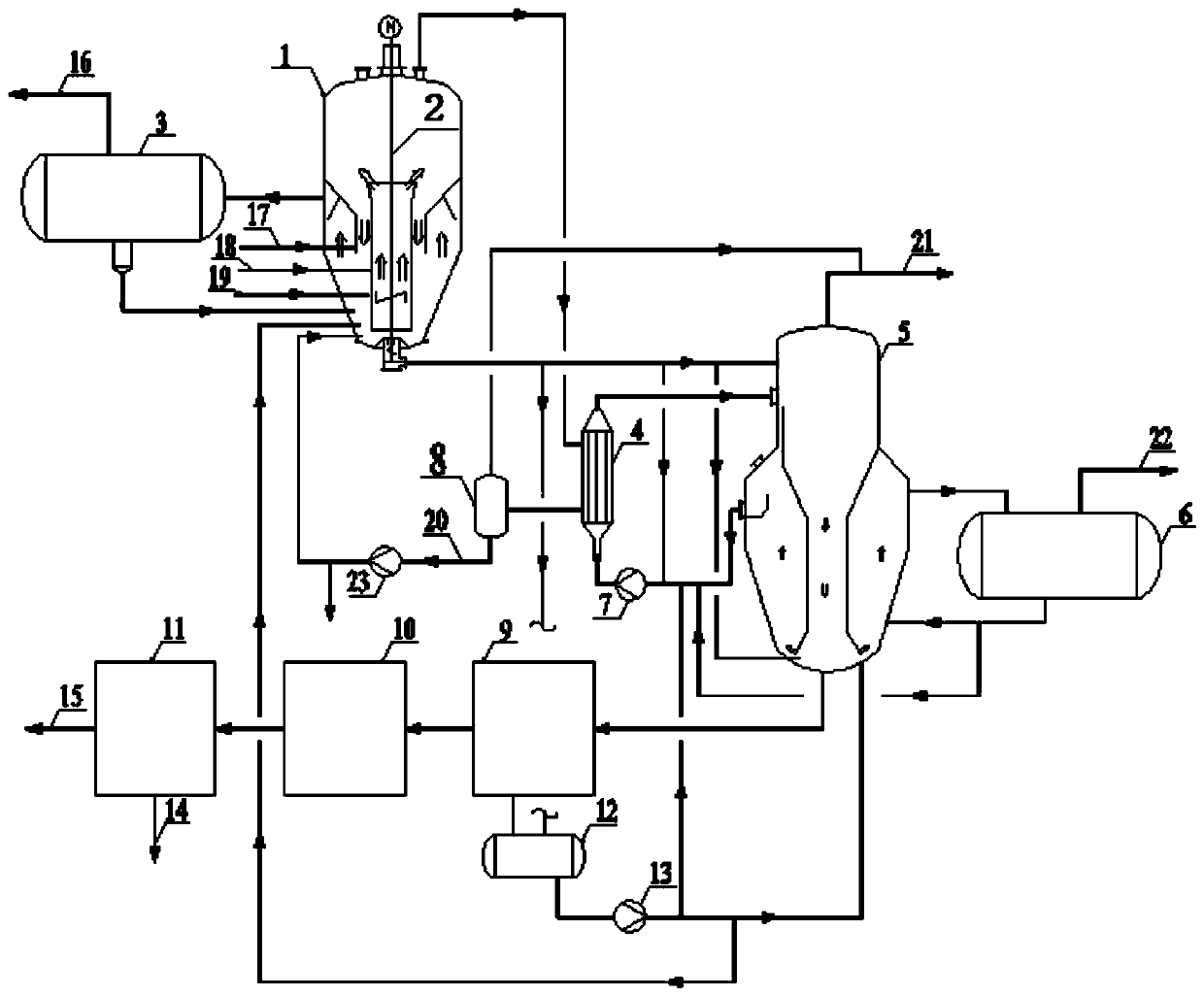

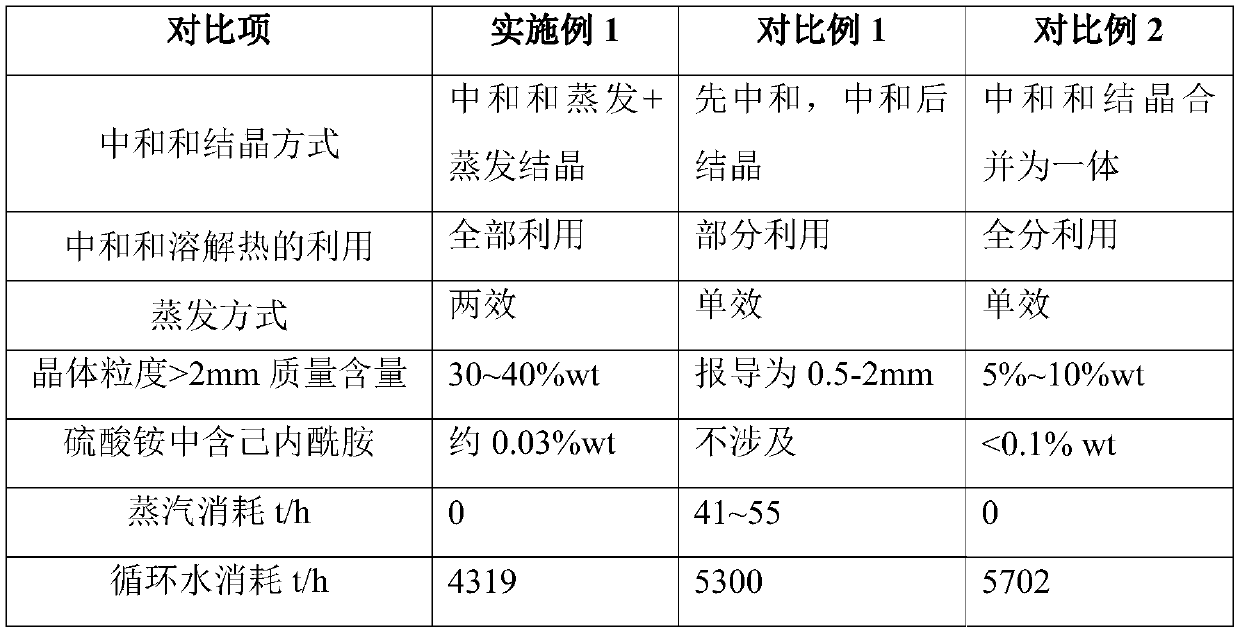

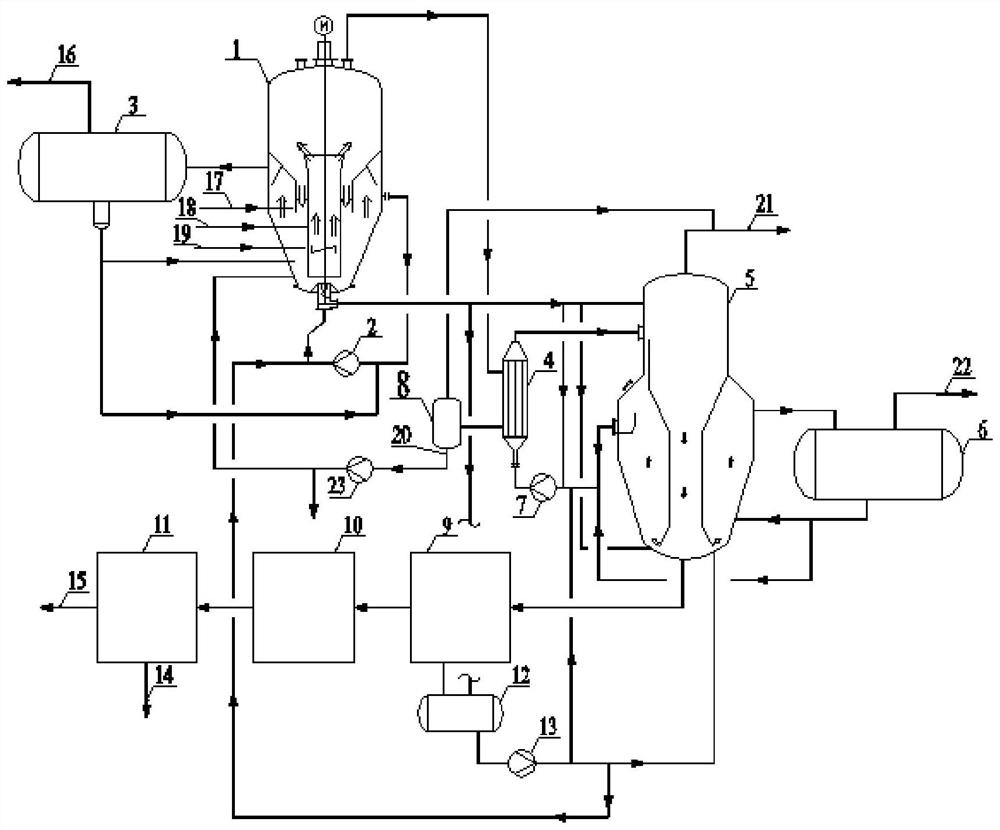

Ammonium sulfate crystallization method and device

ActiveCN111408157AReduce consumptionRaise the ratioCrystallization conditions screeningSolution crystallizationPhysical chemistrySlurry

The invention discloses an ammonium sulfate crystallization method and device, and belongs to the field of chemical engineering. According to the device, two crystallizers connected in series are used, a two-effect vacuum crystallization process is adopted, the first effect is neutralization crystallization, and the second effect is evaporation crystallization. The first effect is slurry which isgenerated by neutralization and crystallization and contains fine crystal particles in a large proportion, and the second effect is an evaporation and crystallization system to obtain ammonium sulfatewith a large-particle ammonium sulfate proportion. According to the device, gas ammonia dissolution heat and neutralization heat of sulfuric acid and ammonia neutralization reaction are fully utilized, and secondary steam of the neutralization crystallizer is used as a heat source, so that the consumption of circulating water is reduced, the proportion of large-particle ammonium sulfate is increased, and meanwhile, the coating loss of caprolactam is reduced.

Owner:SINOPEC NANJING ENG & CONSTR +1

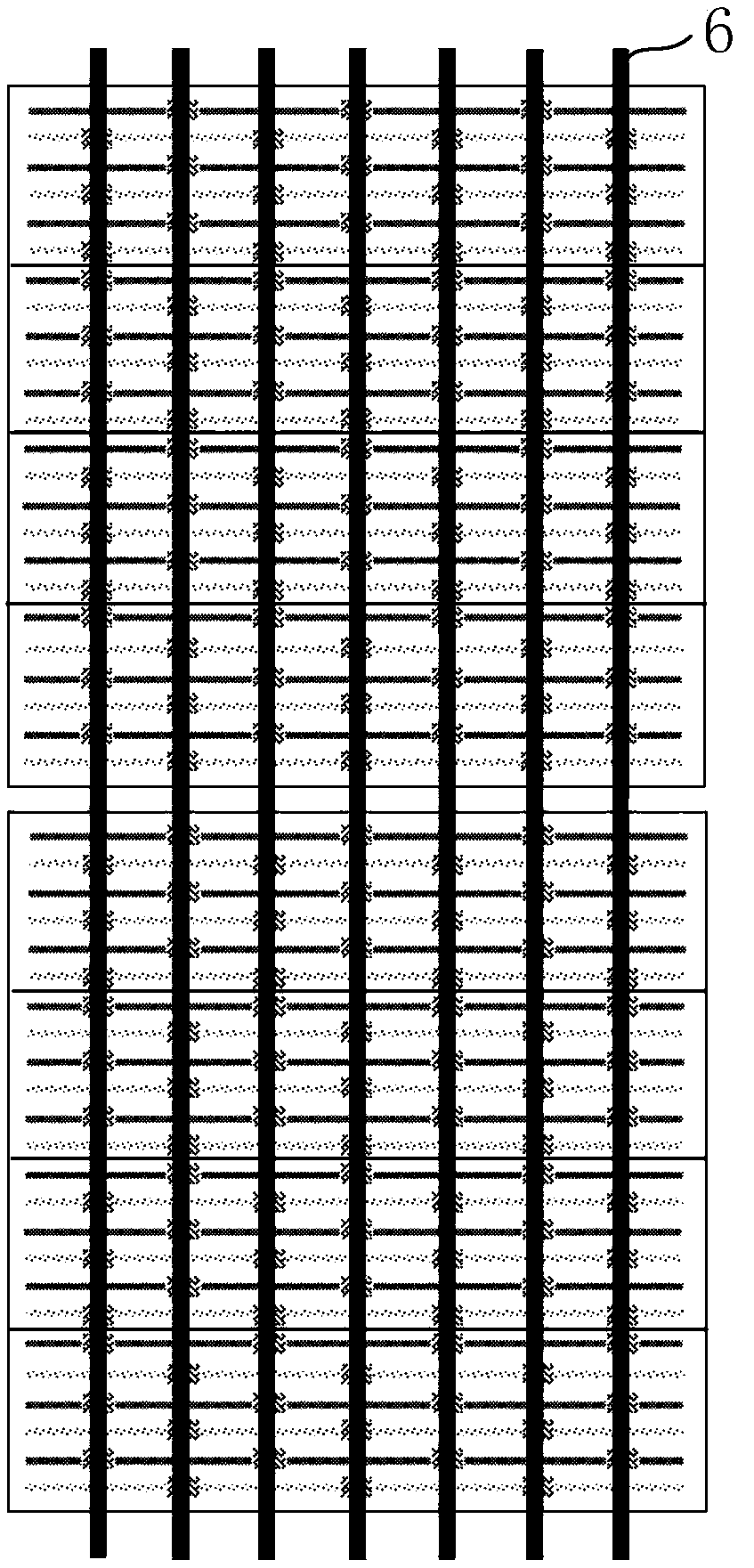

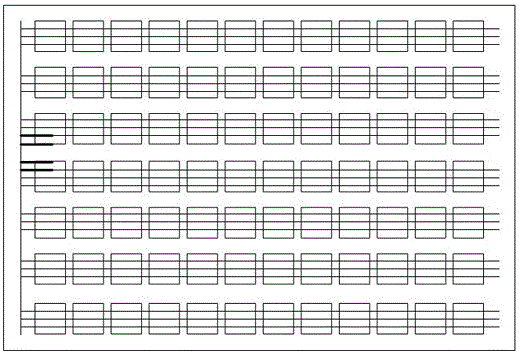

Back contact solar cell string and preparation method thereof, component and system

ActiveCN106653881AImprove fill factorLow costFinal product manufacturePhotovoltaic energy generationElectrical batteryEngineering

The invention relates to a back contact solar cell string and preparation method thereof, a component, and a system. The back contact solar cell string comprises a back contact solar cell and a conductive part electrically connected with the back contact solar cell; an emitter segmented electrode of an emitter p+ region and the segmented electrode of a base n+ region are arranged on the back surface of the segmented electrode of the emitter; an emitter metal wire electrode is arranged on the emitter segmented electrode, a base metal wire electrode is arranged on the base segmented electrode, the emitter metal wire electrode and the base metal wire electrode reversely extend out a battery piece; the emitter metal wire electrode of the back contact solar cell is electrically connected with the base metal wire electrode of an adjacent back contact solar battery through the conductive piece. The back contact solar cell string disclosed by the invention has the advantages that the operation is simple, the high-precision welding equipment alignment is unnecessary, the horizontal transmission loss of the carrier between the electrodes is reduced, a fill factor of the cell is improved, the short-circuit current of the component is lowered, thereby obviously lowering the component encapsulation loss.

Owner:TAIZHOU ZHONGLAI PHOTOELECTRIC TECH CO LTD

Battery string in N-type IBC (Interdigitated Back Contact) solar cell spliced connection, preparation method of battery string, assembly and system

ActiveCN106816486AReduce gapIncrease powerFinal product manufacturePhotovoltaic energy generationOhmSolar cell

The invention relates to a battery string in N-type IBC solar cell spliced connection, a preparation method of the battery string, an assembly and a system. The battery string comprises strip-shaped N-type IBC solar cells and conductive parts used for Ohm connection among the strip-shaped N-type IBC solar cells, wherein the back surfaces of the strip-shaped N-type IBC solar cells comprise emitter p+ regions and base n+ regions which are alternately arranged with one another; p+ emitter contact electrodes are arranged in the emitter p+ regions; n+ base contact electrodes are arranged in the base n+ regions; the battery string further comprises p+ electrode conjunction points arranged on the p+ emitter contact electrodes and n+ electrode conjunction points arranged on the n+ base contact electrodes; insulating barrier layers are arranged in surrounding regions of the conjunction points; the conductive parts are arranged between adjacent N-type IBC solar cells. The battery string disclosed by the invention has the beneficial effects that the battery string in N-type IBC solar cell spliced connection is realized by adopting the insulating barrier layers and using the conductive part method; because the gap between two battery cells can be controlled to be 0.2mm or lower, the battery string disclosed by the invention has high assembly power compared with that adopting the traditional battery string connection manner. In addition, the assembly manufacturing process is simple, and the cost is low.

Owner:TAIZHOU ZHONGLAI PHOTOELECTRIC TECH CO LTD

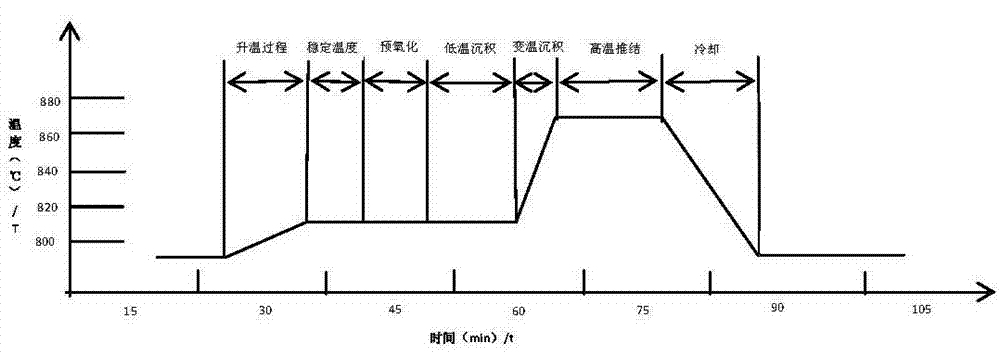

Surface passivation technology of crystalline silicon solar cell

InactiveCN105374899AImprove conversion efficiencyReduce component packaging lossFinal product manufacturePhotovoltaic energy generationCrystalline siliconMetallurgy

The invention discloses a surface passivation technology of a crystalline silicon solar cell. The surface passivation technology specifically comprises the following two processes: (a) a low-temperature surface thermal oxidation process and (b) a surface oxidizing and doping process, wherein in the low-temperature surface thermal oxidation process, the oxidation temperature is controlled under 800 DEG C on the premise that excellent surface passivation quality is ensured, a dead layer formed in a diffusion process is activated, and good matching with an emitter junction diffusion process is achieved; and in the surface oxidizing and doping process, impurity doping is simultaneously carried out in an oxidizing process, and doped impurities are identical with emitter junctions in conductive type. The surface passivation technology of the crystalline silicon solar cell has the advantages that the conversion efficiency of the cell is improved, and the assembly packaging loss is effectively lowered; in addition, the oxidizing process can be applied in the case that the square resistance of the emitter junctions is higher than 100 [omega], and the FF deterioration problem of the PERA cell is solved.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

PECVD film coating method

InactiveCN104762610APromote absorptionReduce package lossFinal product manufactureChemical vapor deposition coatingElectricityManufacturing technology

The invention discloses a PECVD film coating method capable of reducing solar cell module packaging loss. The PECVD film coating method is characterized in that by a conventional crystalline silicon solar cell manufacturing technology, based on arrangement of a N2O gas passage on conventional PECVD equipment, an antireflection film containing SiO2 and SiNx is deposited on PECVD, and the film coating method comprises 1, SiO2 layer deposition: under the conditions of a certain pressure and power, feeding 4200-10800sccm of SiH4, NH3 and N2O into equipment and carrying out deposition for some time, and 2, SiNx layer deposition: carrying out two-step deposition to obtain a first SiNx layer and a second SiNx layer, under conditions of the same certain pressure and power, feeding different flows of SiH4 and NH3 into the equipment and carrying out deposition for some time. The PECVD film coating method has the advantages that based on arrangement of the N2O gas passage on the conventional PECVD equipment, the antireflection film containing SiO2 and SiNx is deposited on PECVD, through control of thickness and refractive indexes of the two films, light absorption is improved, and through use of SiO2 physical stability, electricity loss is reduced, module packaging loss is reduced, a production cost is not increased and feasibility is high.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

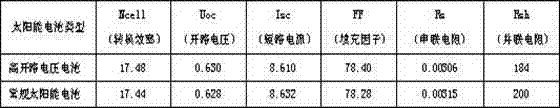

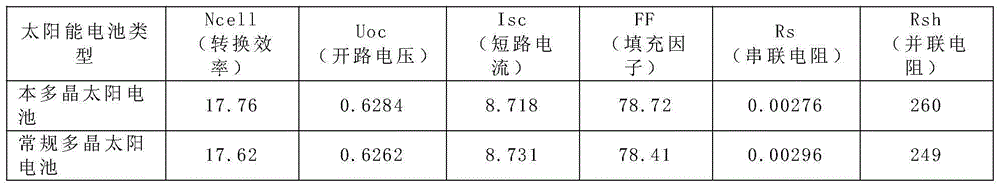

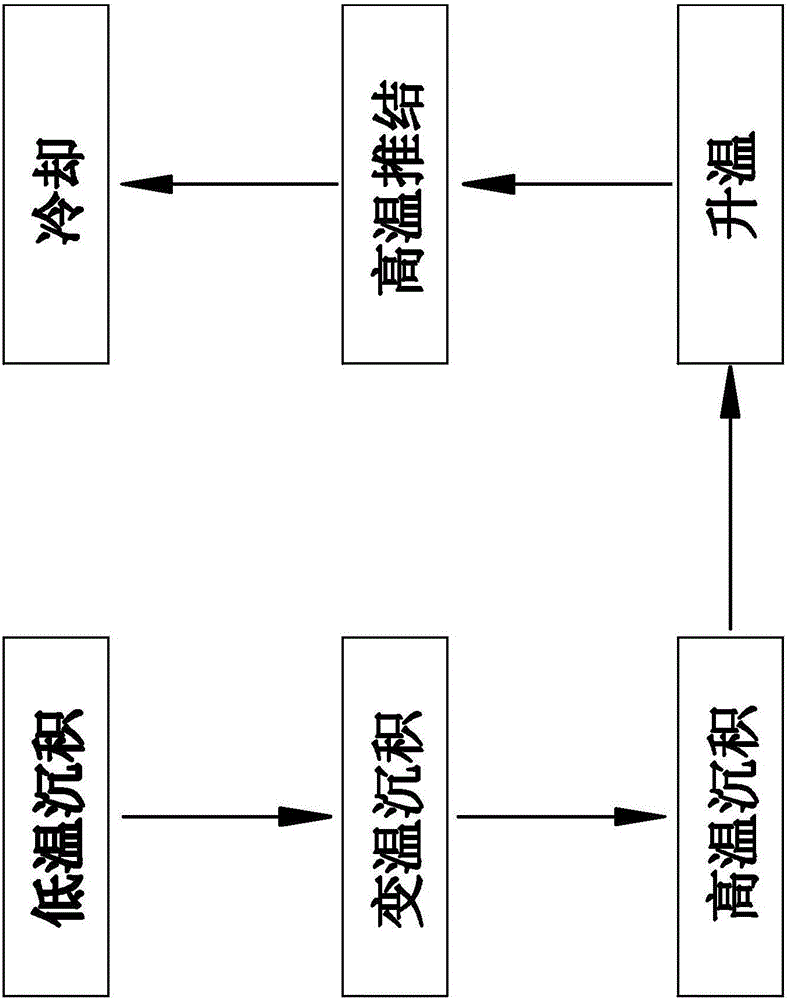

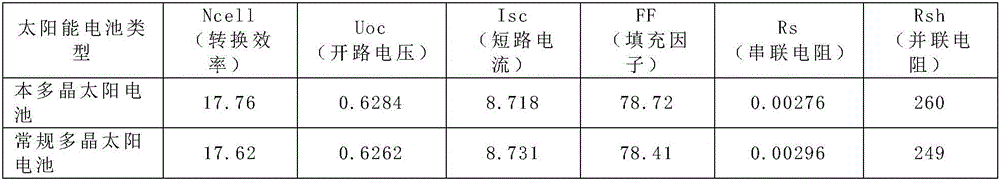

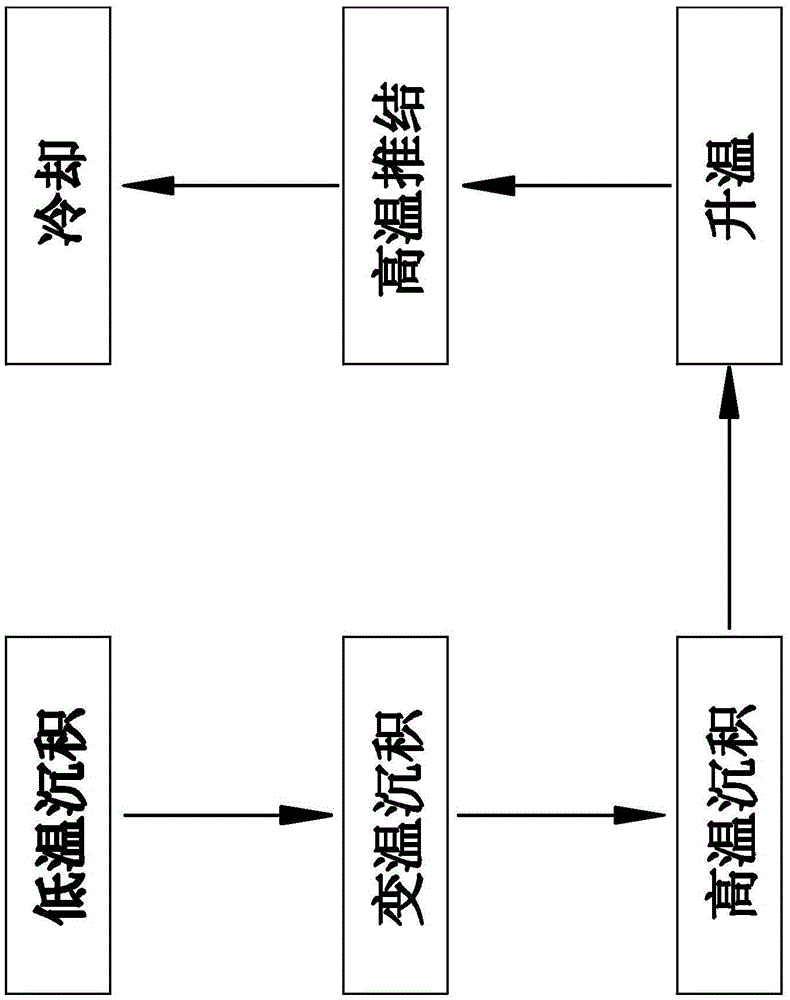

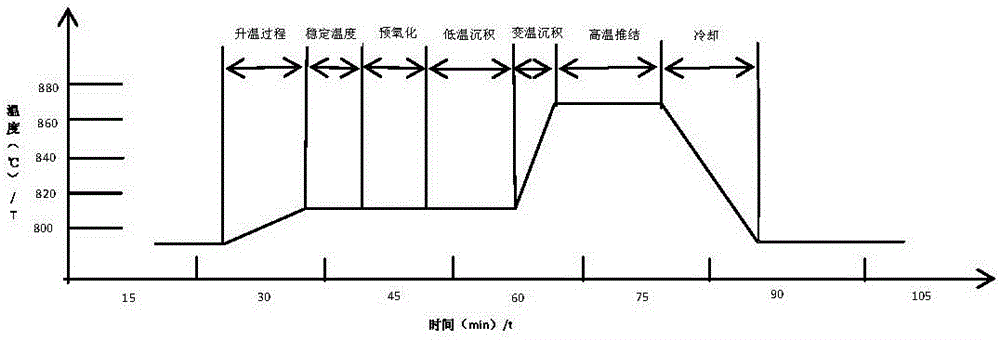

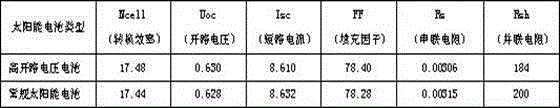

Preparation method for high open-circuit voltage polycrystalline solar cells

ActiveCN103618032AIncrease the open circuit voltageLow costFinal product manufacturePhotovoltaic energy generationPush technologyElectrical resistance and conductance

The invention relates to a preparation method for high open-circuit voltage polycrystalline solar cells. A temperature-variable deposition high-temperature knot pushing technology is adopted in the diffusion process, and the dense grid design of 90 fine grids is adopted by positive pole printing patterns during the positive-pole printing process. The temperature-variable deposition is the process of increasing the temperature to 860 DEG C, temperature-variable deposition for 10 min is conducted on a silicon wafer during the temperature-increasing process, the mixture gas of large N2, O2 and small N2 is led in, and the proportion, by volume, of the small N2 is 7%; the high-temperature knotting pushing process is that the temperature is kept at 860 DEG C stably, the small N2 is stopped being led in, the large N2 and the O2 are led in for impurity re-distribution, the time is controlled to be within 17 min, and the proportion, by volume, of the O2 is 15%. The preparation method enables the square resistance of the silicon wafer to be from 90omega / sq to 95omega / sq, and compared with one-time constant-temperature deposition diffusion, the polycrystalline solar cells produced under the situation that the cost is not increased can obtain the higher open-circuit voltage.

Owner:ZHEJIANG NUOOUBO NEW MATERIAL CO LTD

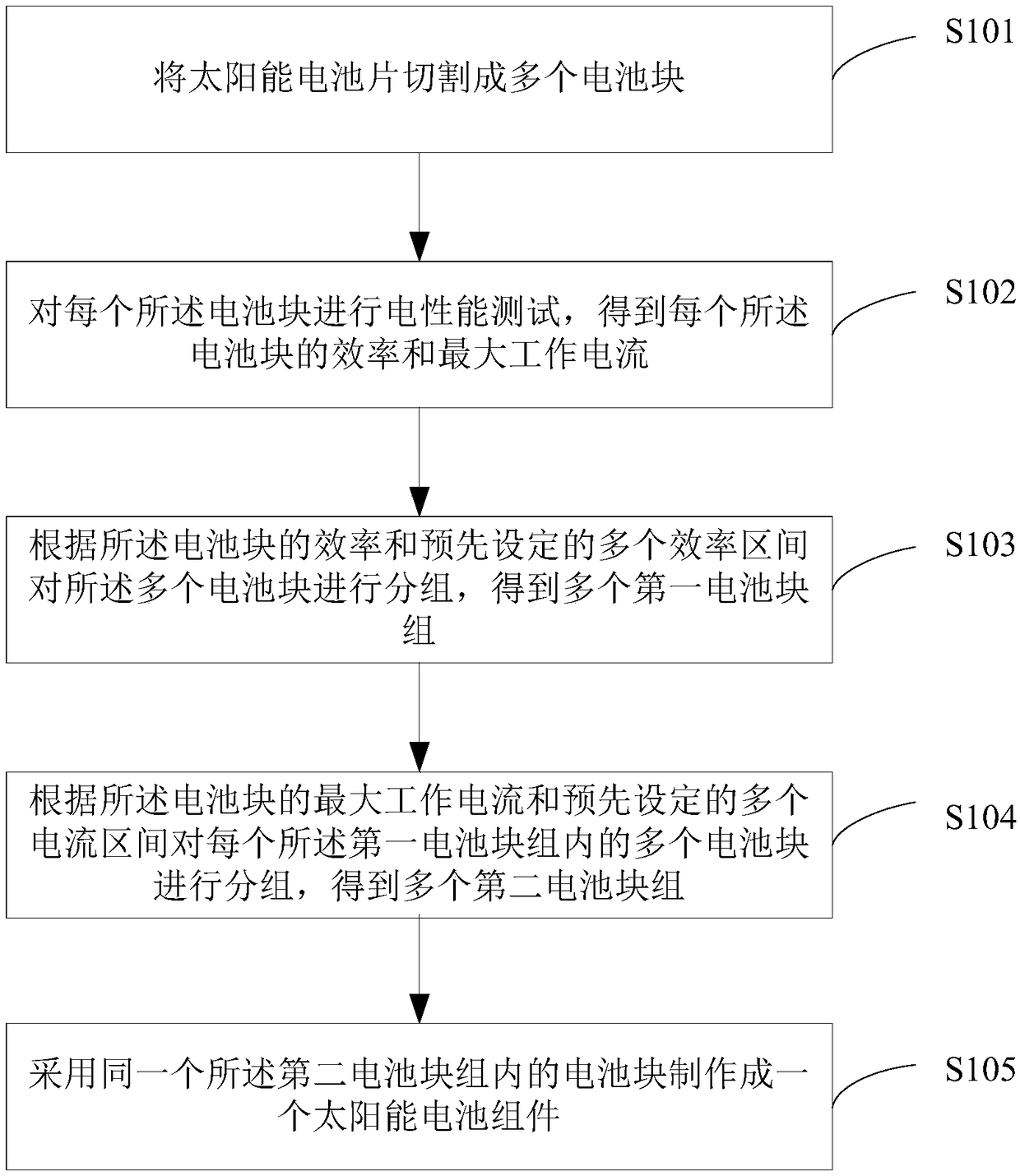

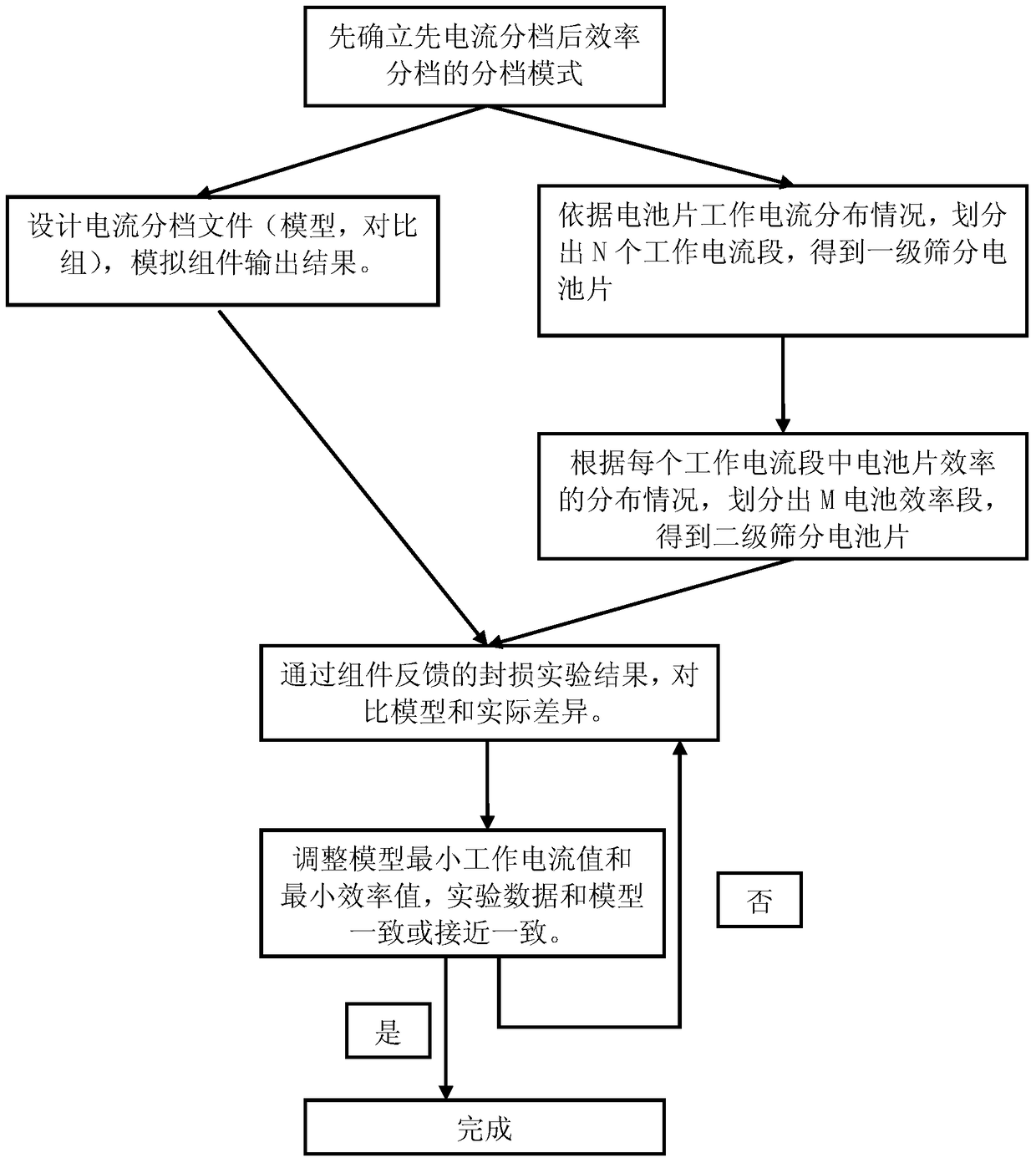

Preparation method of solar photovoltaic module

PendingCN113257934ASolve the problem of current mismatchReduce package lossFinal product manufacturePhotovoltaic energy generationEngineeringSilicon chip

The invention discloses a preparation method of a solar photovoltaic module. First batteries and second batteries which are different in area and identical in current are obtained; and the electrodes of the first batteries and the second batteries are reversely arranged at intervals. According to the preparation method, current matching of the module is achieved by adjusting the area of the batteries, the problem of module current mismatching caused by the difference of silicon wafer substrates used by the batteries and the difference of battery preparation processes is solved, the packaging loss of the module is reduced, and the output power of the module is improved.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

Electronic tag destroyed by once tearing

InactiveCN103049782AImprove qualityImprove electrical performanceRecord carriers used with machinesAdhesivePolyethylene glycol

The invention relates to an electronic tag, and aims to provide the electronic tag destroyed by once tearing with low relative cost, low packaging loss and capability of ensuring high quality of the electronic tag. The electronic tag comprises a piece of body paper and a chip, a conductive adhesive, an antenna and a PET ((polyethylene glycol terephthalate) layer combined together from top to bottom orderly, wherein a first glue layer is arranged between the chip and the body paper; and a second glue layer is arranged between the antenna and the PET layer. The electronic tag destroyed by once tearing provided by the invention is manufactured by pure aluminium, and has the advantages of excellent electrical performance and good product uniformity, therefore, the high quality of the electronic tag can be ensured; and at the same time, the low cost of the electronic tag of the technology is embodied in the low relative cost of the raw materials, the low packaging loss, the simpler fitting process, one material saving and the like.

Owner:ZHEJIANG JUNMP TECH

Solar cell module and manufacture method thereof

InactiveCN108735860AImprove light and shadeReduce package lossFinal product manufacturePhotovoltaic energy generationElectricityPower flow

The invention provides a solar cell module and a manufacture method thereof, comprising: cutting a solar cell piece into a plurality of blocks; testing the electric properties of each block to obtainthe efficiency and the maximum working current of each block; grouping the plurality of bocks according to the efficiencies of the blocks and a plurality of predetermined efficiency intervals to obtain a plurality of first block groups; grouping a plurality of blocks in each first block group according to the maximum working currents of the blocks and a plurality of predetermined current intervalsto obtain a plurality of second block groups; and manufacturing a solar cell module by using blocks in the same second block group. The current difference between blocks in the same solar cell modulecan be reduced, thus not only reducing the luminance difference between the blocks and improving the luminance of the module, but also ensuring that the parameters of the electric properties of the blocks are highly matched, so as to reduce the packaging loss of the module and improve the power output of the module.

Owner:ZHEJIANG JINKO SOLAR CO LTD +1

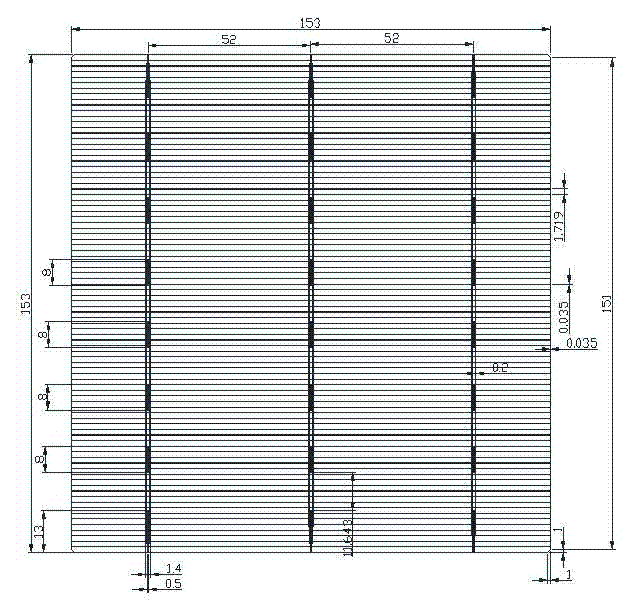

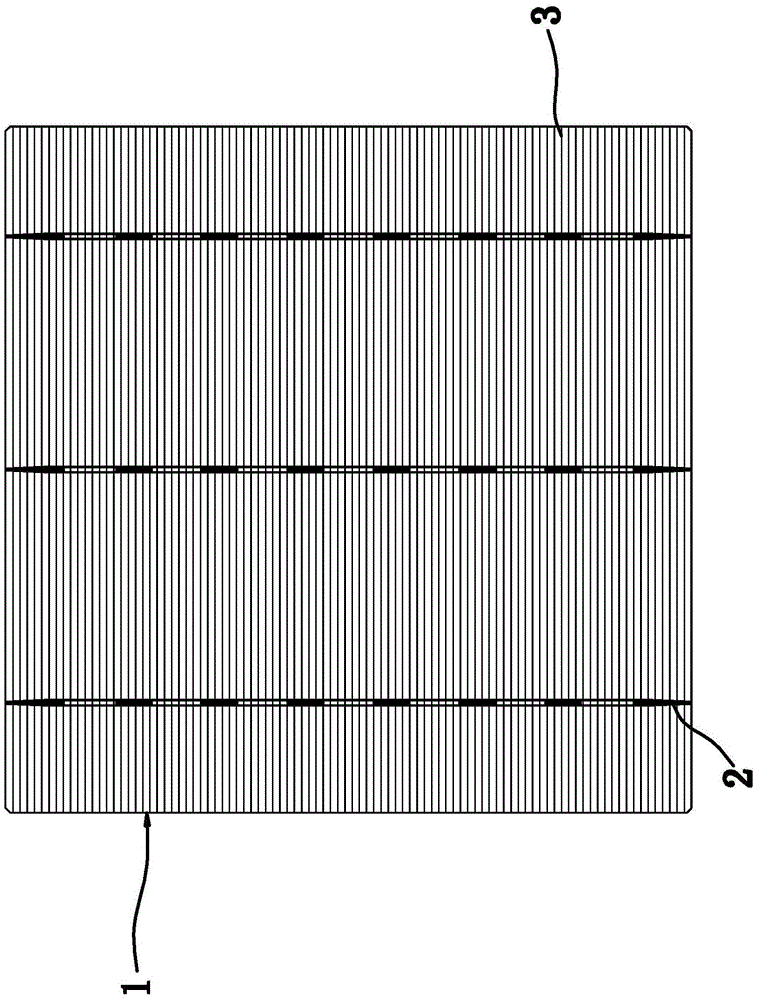

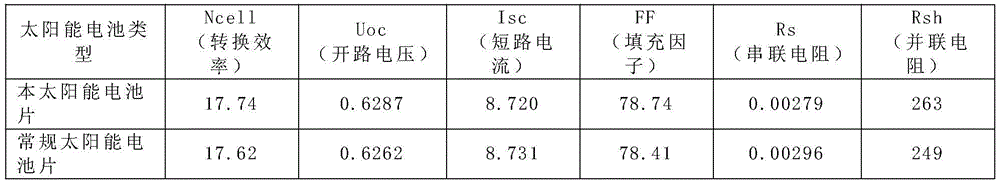

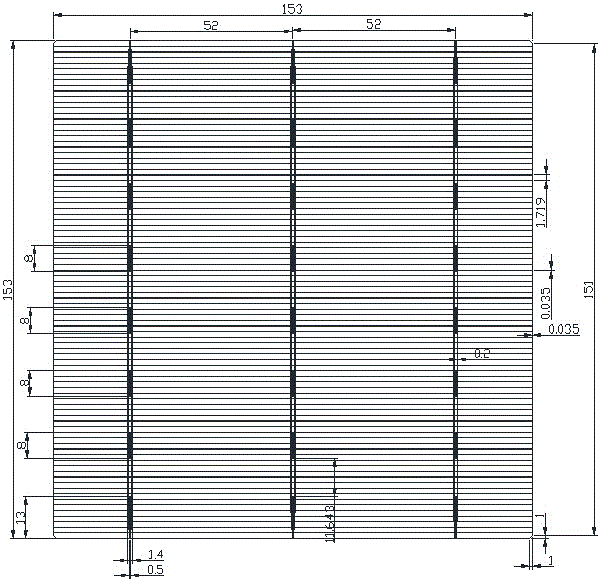

Polycrystalline solar cell and diffusion technology thereof

ActiveCN104538467AImprove conversion efficiencyImprove conversion rateFinal product manufactureSemiconductor/solid-state device manufacturingDiffusion methodsSolar cell

The invention provides a polycrystalline solar cell and a diffusion technology of the polycrystalline solar cell and belongs to the technical field of solar cells. According to the polycrystalline solar cell and the diffusion technology of the polycrystalline solar cell, the technical problem that in the prior art, the conversion efficiency of a solar cell based on the one-step diffusion method is generally low and other technical problems are solved. The polycrystalline solar cell includes a platy body. A positive electrode is arranged on one side of the body, and a negative electrode is arranged on the other side of the body. Four main grids and ninety fine grids are evenly distributed on the positive electrode. The main grids are perpendicular to the fine grids and are in electric connection with the fine grids. The distances between all the main grids are 35 mm-42 mm, the width of the main grids is 0.8 mm-1.2 mm, the distances between the fine grids are 1.4 mm-2.0 mm, and the width of the fine grids is 0.035 mm-0.045 mm. The polycrystalline solar cell and the diffusion technology of the polycrystalline solar cell have the advantages that encapsulation loss is low, and the conversion efficiency of the polycrystalline solar cell is high.

Owner:ZHEJIANG GUANGLONG ENERGY TECH

Tandem ammonium sulfate crystallization method and device

ActiveCN111530119AReduce consumptionRaise the ratioCrystallization conditions screeningLactams preparationPhysical chemistryAmmonia

The invention discloses a tandem ammonium sulfate crystallization method and device, and belongs to the field of chemical engineering. According to the device, two crystallizers connected in series are used, a two-effect vacuum crystallization process is adopted, the first effect is neutralization evaporation, and the second effect is evaporation crystallization. An ammonium sulfate solution withthe concentration of about 40% neutralized and evaporated is fed into the second effect section of an evaporative crystallization system so that ammonium sulfate with a large-particle ammonium sulfateproportion is obtained. According to the device, gas ammonia dissolution heat and neutralization heat of sulfuric acid and ammonia neutralization reaction are fully utilized, and secondary steam of the neutralization evaporator is used as a heat source, so that the consumption of circulating water is reduced, the proportion of large-particle ammonium sulfate is increased, and meanwhile, the coating loss of caprolactam is reduced.

Owner:SINOPEC NANJING ENG & CONSTR +1

IBC solar cell and its preparation method

ActiveCN108269873BIncrease opening pressureReduce short circuit currentFinal product manufacturePhotovoltaic energy generationElectrical resistance and conductanceEngineering

The invention provides an IBC (Interdigitated back contact) solar cell and a preparation method of the same, and belongs to the solar cell field. The IBC solar cell is characterized in that an ICB cell is equally divided into even number of same cell units through laser scribing lines, and the adjacent cell units are insulated from each other; printing of insulated slurry is performed along the solder strip connection positions, so as to enable a plurality of solder strips to connect P type metalized grid lines and N type metalized grid lines in the horizontal direction successively at intervals; and each of the plurality of solder strips is connected with the anode and the cathode of the adjacent cell units in the vertical direction, so that one continuous solder strip can connect each cell unit in series. Therefore, for the IBC solar cell, on the premise of not changing the cells, the assembly equipment and the technology, the effect of improving open-circuit voltage and reducing short circuit current can be obtained, so that during the assembly packaging process, the open-circuit voltage can be increased and the short circuit current can be reduced, and then the packaging loss caused by the current and the resistance can be reduced.

Owner:YINGLI ENERGY CHINA

IBC solar cell and preparation method of the same

ActiveCN108269873AIncrease opening pressureReduce short circuit currentFinal product manufacturePhotovoltaic energy generationElectrical batteryEngineering

The invention provides an IBC (Interdigitated back contact) solar cell and a preparation method of the same, and belongs to the solar cell field. The IBC solar cell is characterized in that an ICB cell is equally divided into even number of same cell units through laser scribing lines, and the adjacent cell units are insulated from each other; printing of insulated slurry is performed along the solder strip connection positions, so as to enable a plurality of solder strips to connect P type metalized grid lines and N type metalized grid lines in the horizontal direction successively at intervals; and each of the plurality of solder strips is connected with the anode and the cathode of the adjacent cell units in the vertical direction, so that one continuous solder strip can connect each cell unit in series. Therefore, for the IBC solar cell, on the premise of not changing the cells, the assembly equipment and the technology, the effect of improving open-circuit voltage and reducing short circuit current can be obtained, so that during the assembly packaging process, the open-circuit voltage can be increased and the short circuit current can be reduced, and then the packaging loss caused by the current and the resistance can be reduced.

Owner:YINGLI ENERGY CHINA

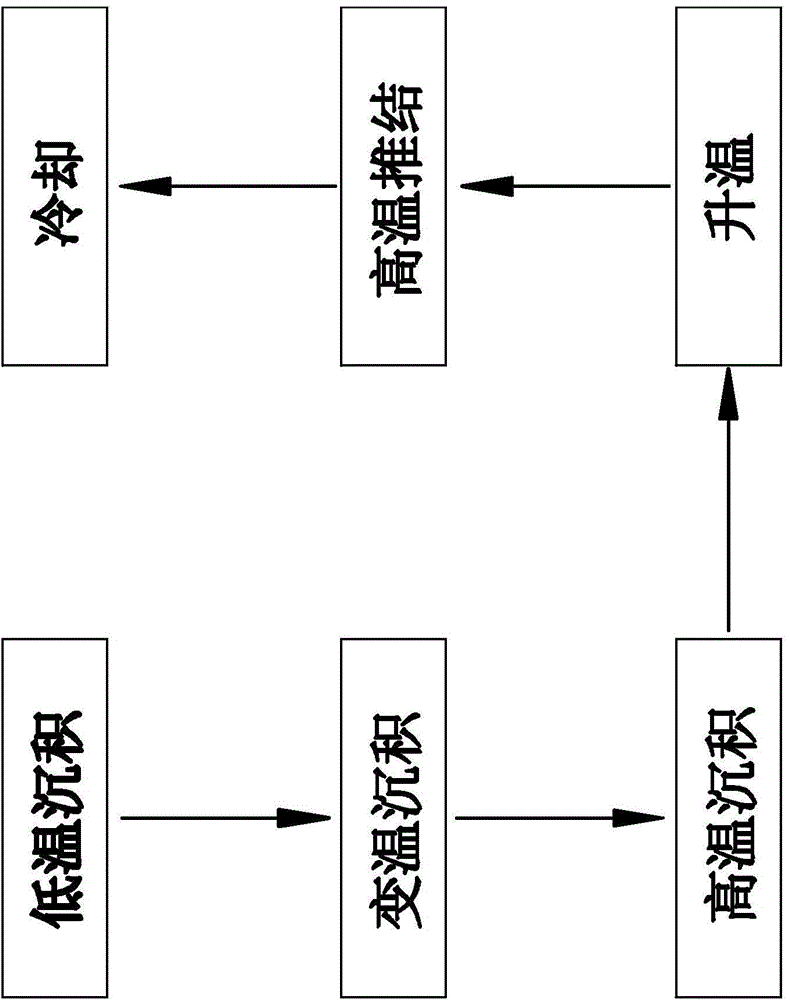

Improved diffusion technology of polycrystalline solar cell

ActiveCN105870217AImprove conversion efficiencyImprove conversion rateFinal product manufactureSemiconductor/solid-state device manufacturingHigh cellDiffusion methods

The invention provides an improved diffusion technology of a polycrystalline solar cell, belongs to the technical field of solar cells and solves the technical problems of generally lower solar cell conversion efficiency with the adoption of a one-step diffusion method and the like in the prior art. The improved diffusion technology of the polycrystalline solar cell comprises steps as follows: A, low-temperature deposition; B, variable-temperature deposition; C, high-temperature deposition; D, warming; E, high-temperature diffusion; F, cooling. The polycrystalline solar cell prepared with the technology has the advantages of low encapsulating loss and high cell conversion ratio.

Owner:ZHEJIANG GUANGLONG ENERGY TECH

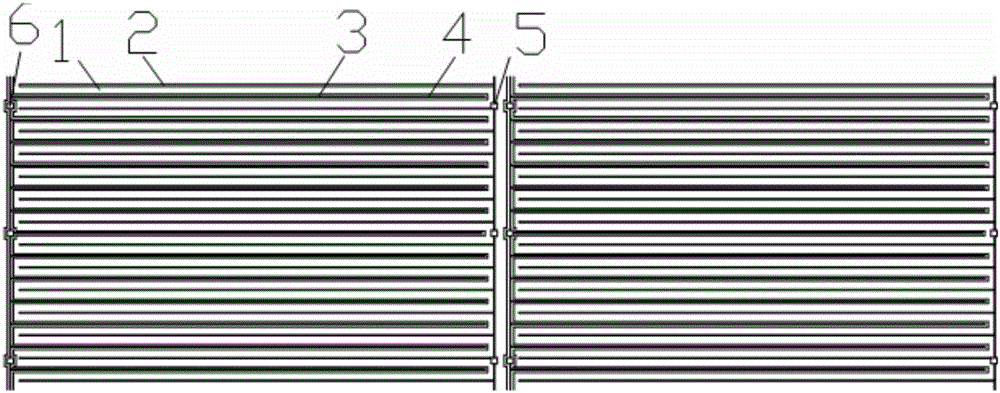

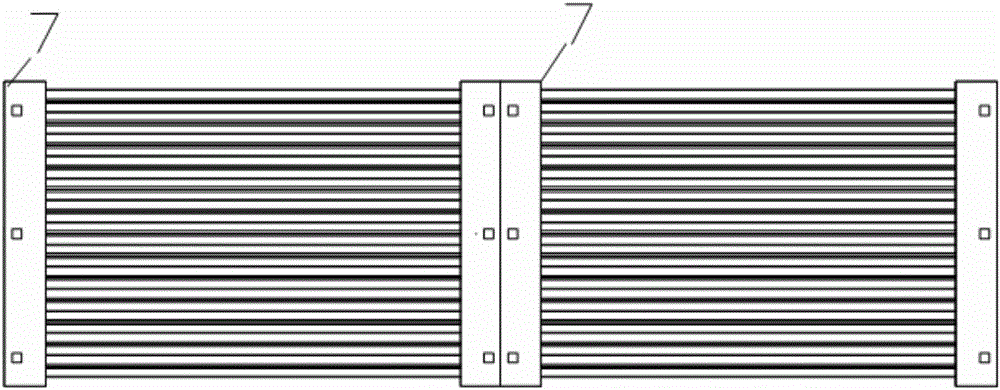

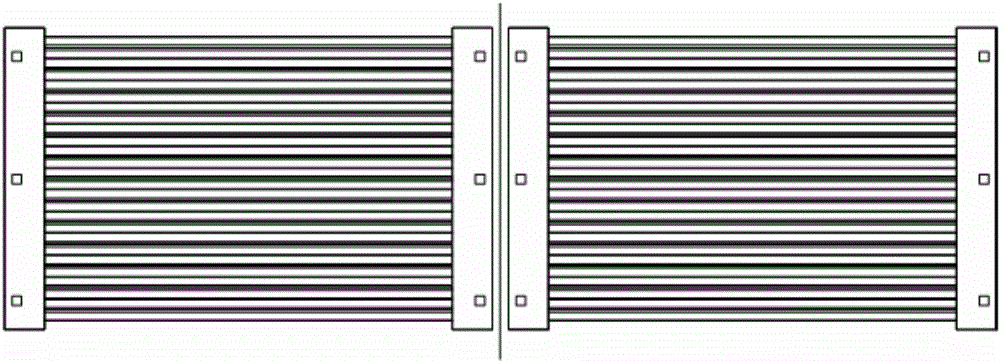

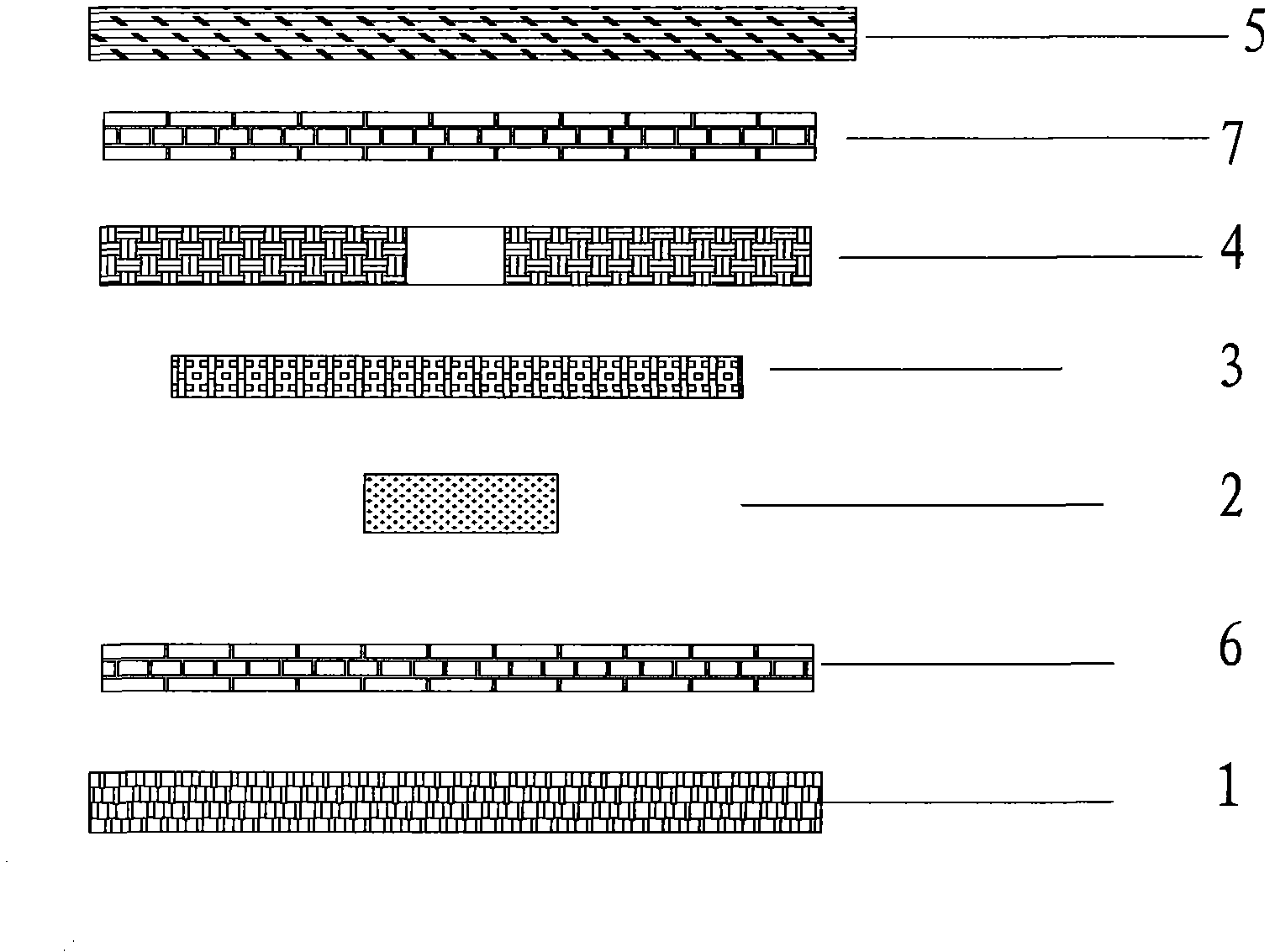

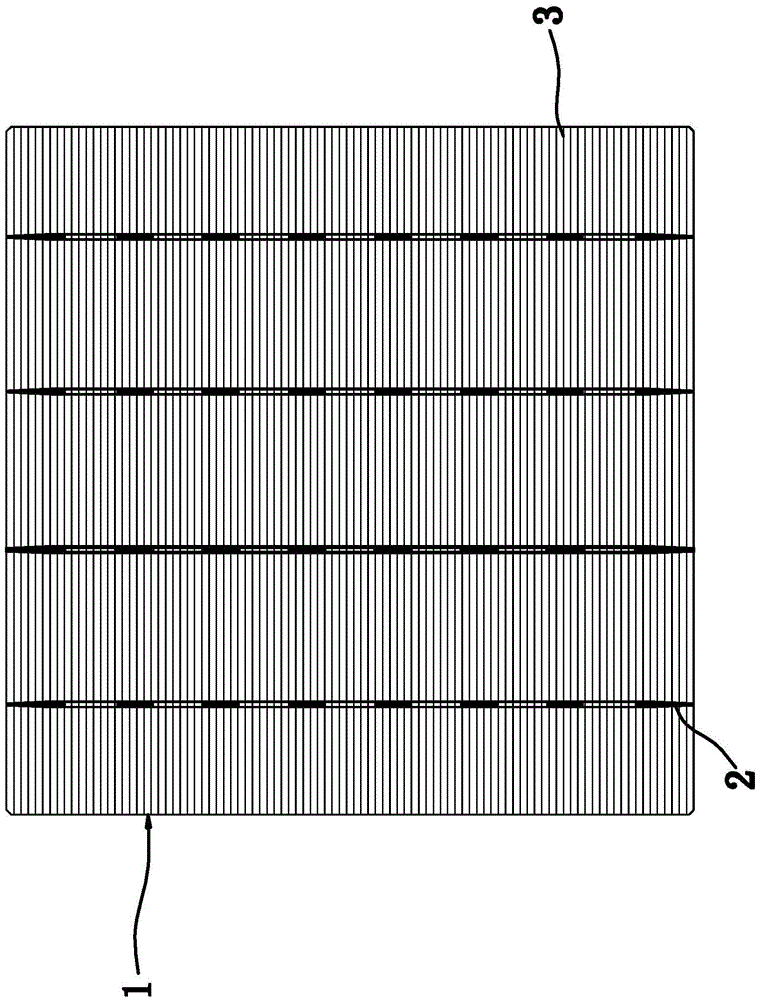

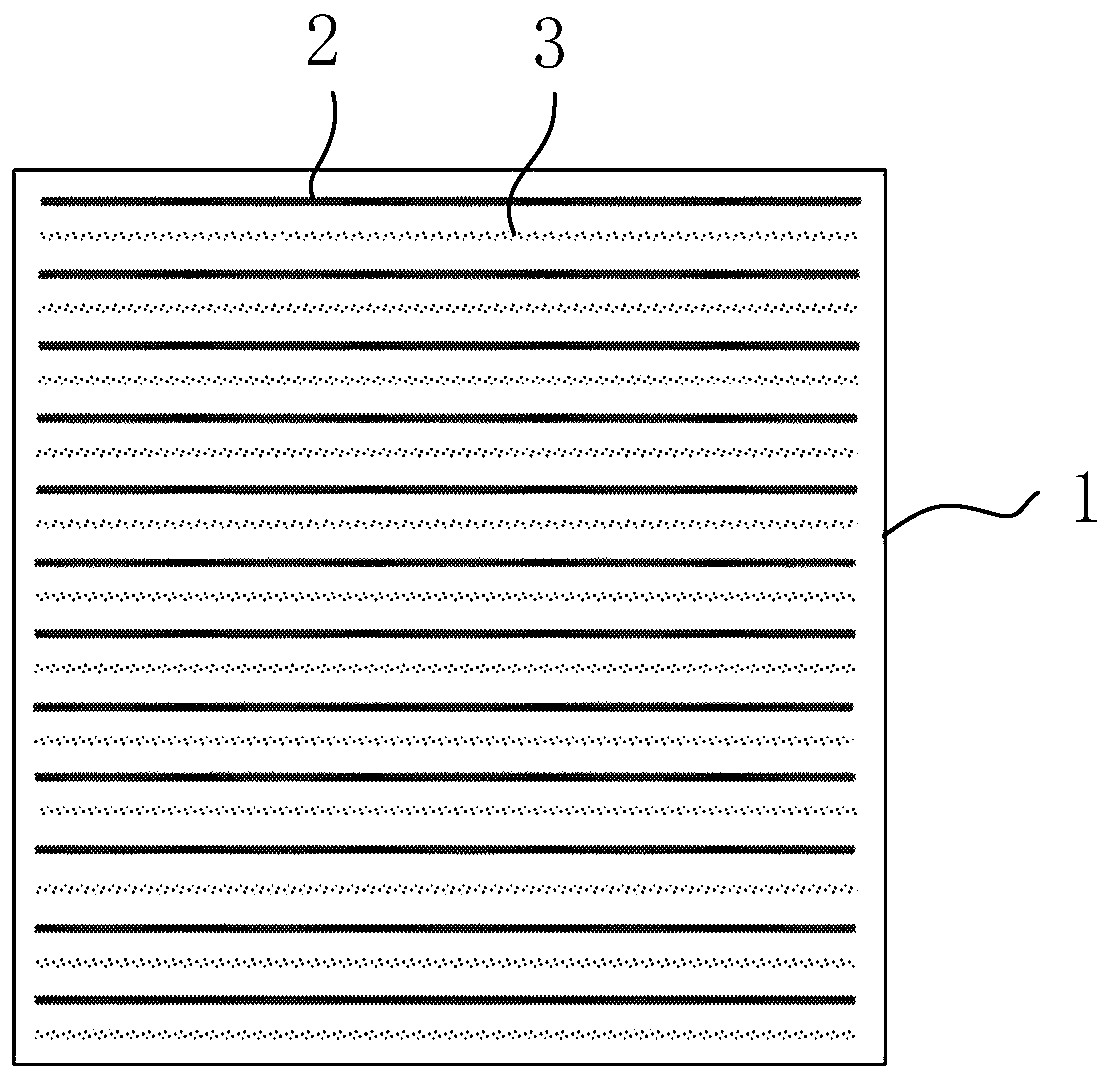

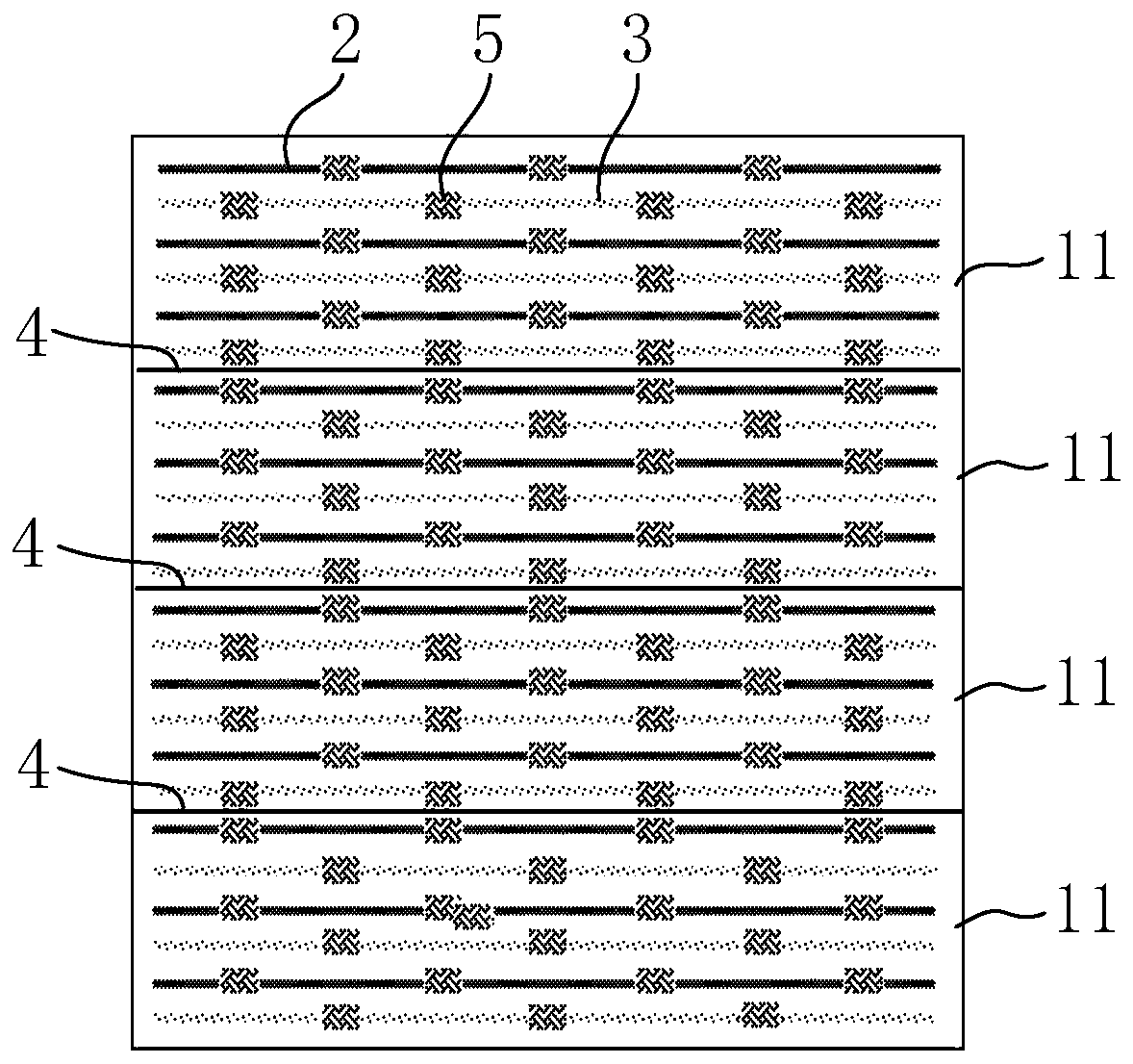

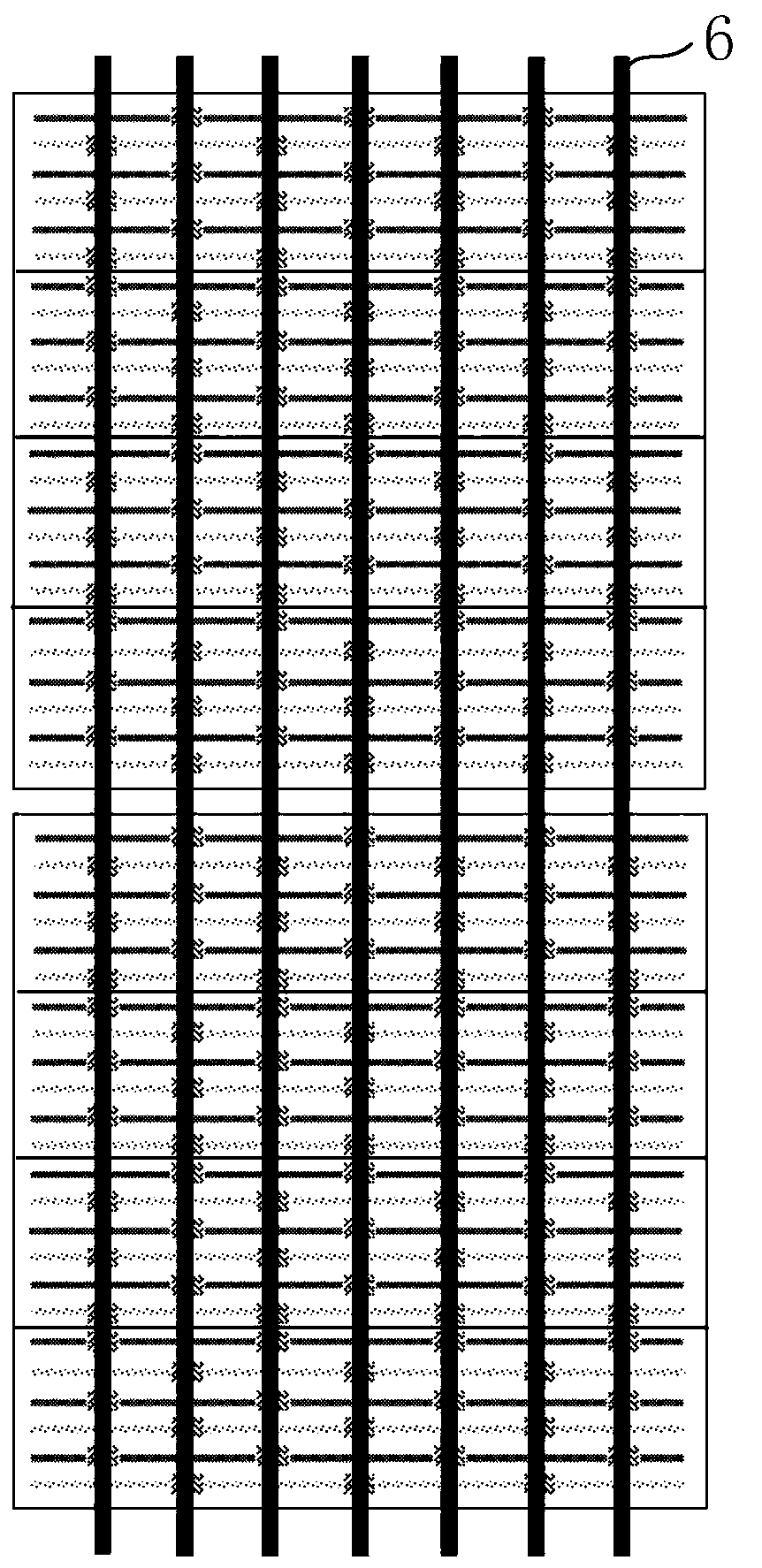

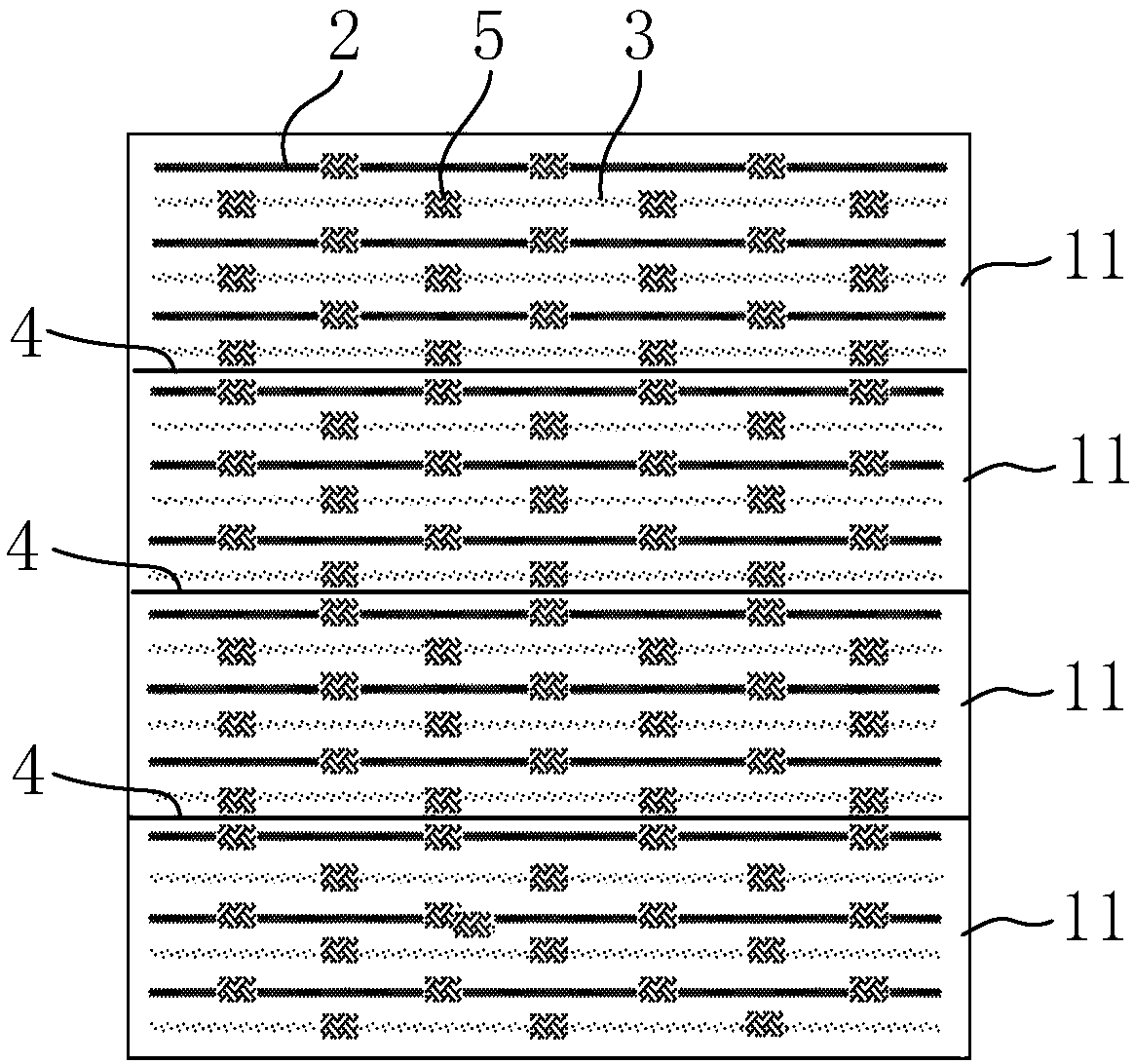

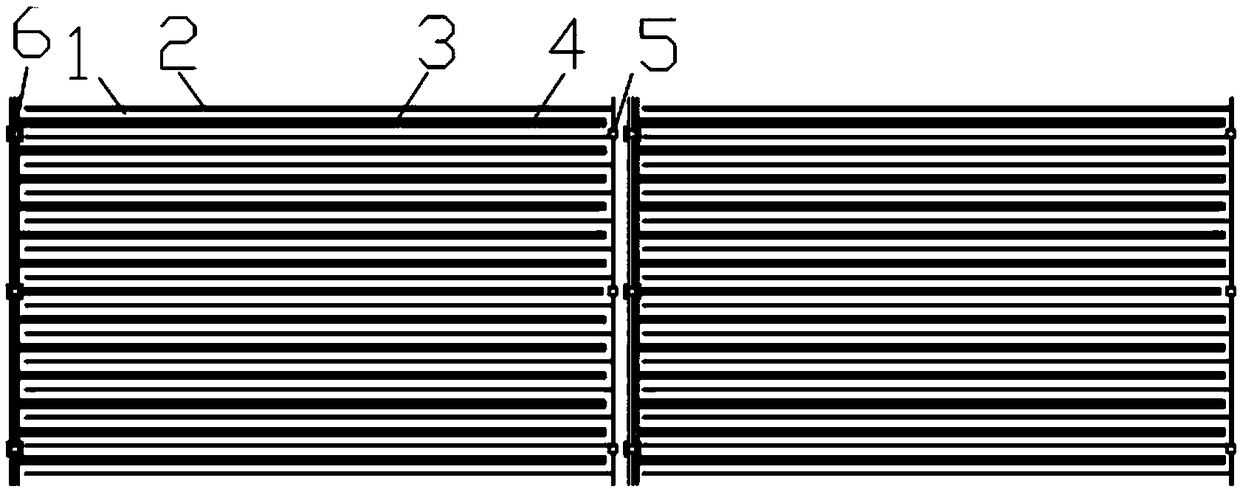

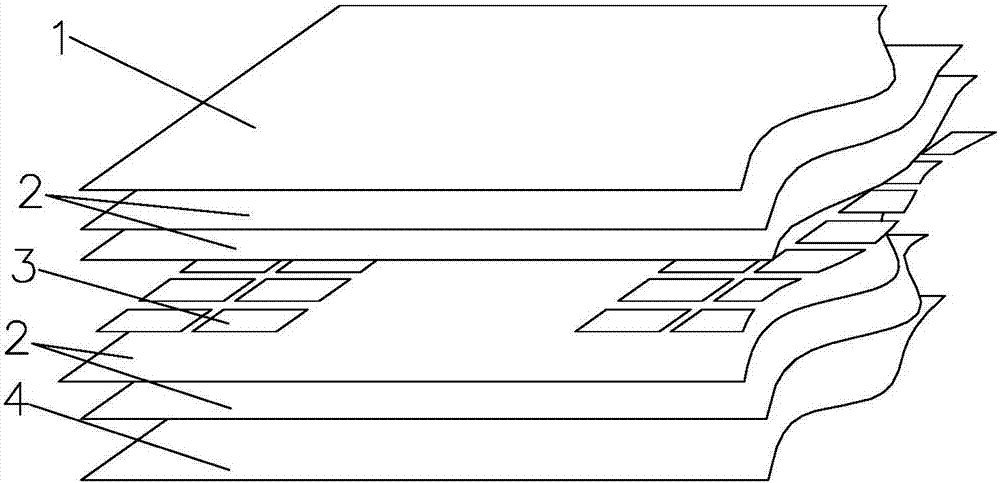

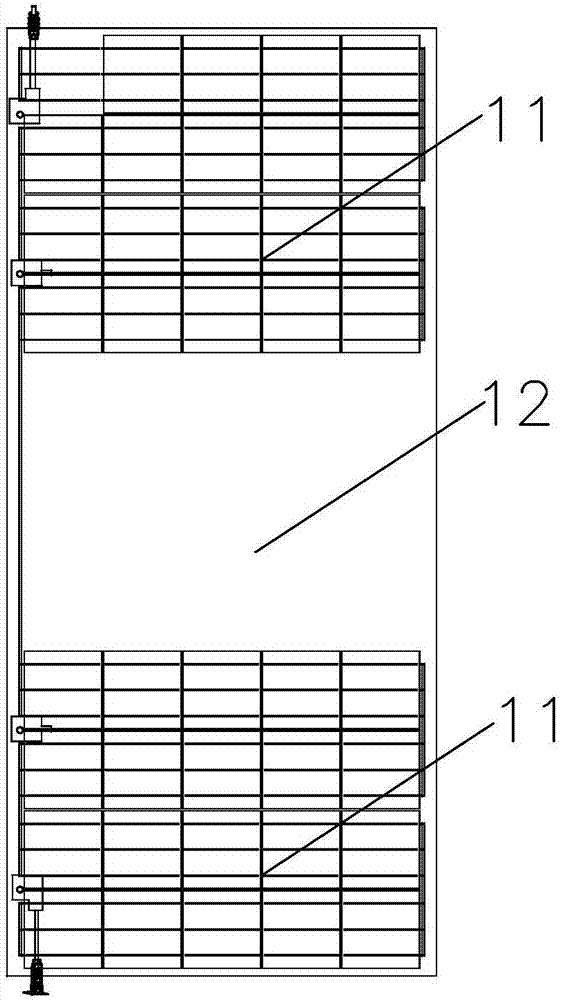

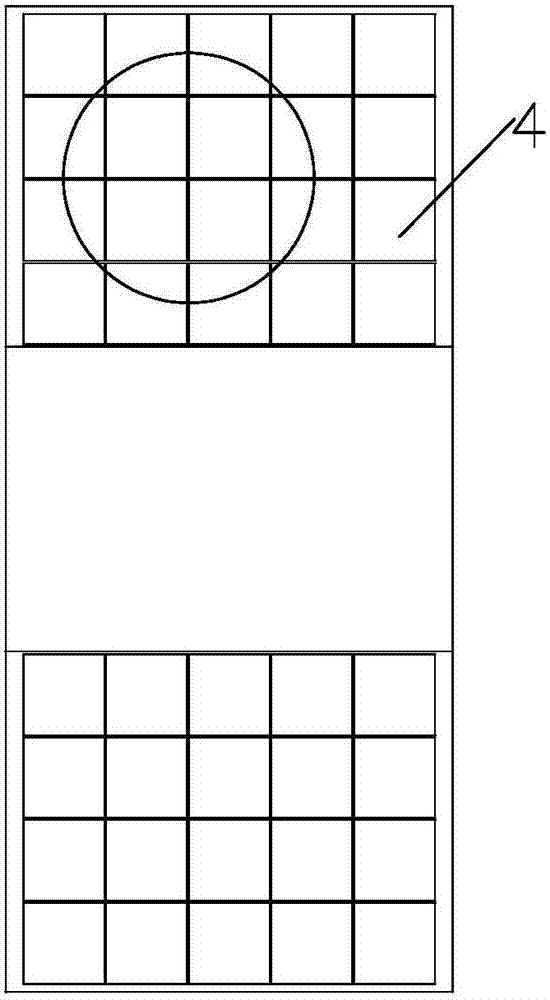

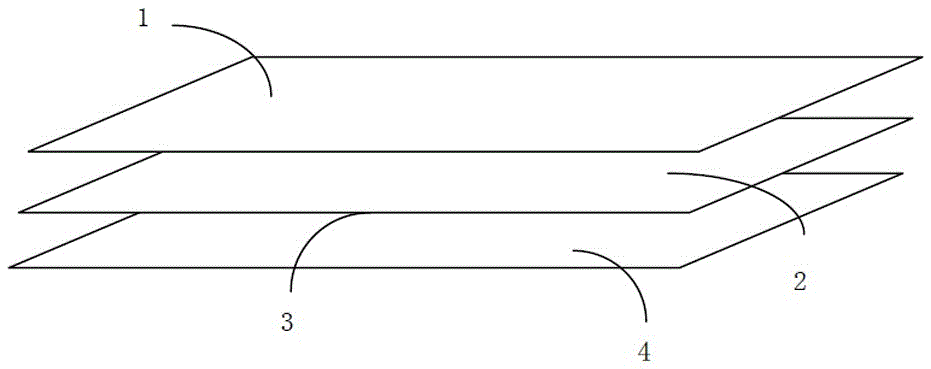

Long-service-life polycrystal PVB laminated glass curtain wall assembly high in light transmission

The invention belongs to the technical field of building energy conservation, and particularly relates to a long-service-life polycrystal PVB laminated glass curtain wall assembly high in light transmission. The laminated glass curtain wall assembly is formed by laminating coated tempered glass (1), an outer layer PVB packaging film (2), silicon cell pieces (3), an inner layer PVB packaging film (4) and tempered glass (5) in a kettle type double pump high temperature and pressure mode. The coated tempered glass and the tempered glass are rectangular, the silicon cell pieces are packaged by the outer layer PVB packaging film and the inner layer PVB packaging film and uniformly distributed between the coated tempered glass and the tempered glass, and silicon cell piece sets formed by connecting all the silicon cell pieces together in series through a wire are connected in parallel and collected at the lead end. When the laminated glass curtain wall assembly is impacted from outside, as the middle elastic layer has the function of absorbing impact, an impact object can be prevented from penetrating the laminated glass curtain wall assembly. The PVB material is used for replacing the EVA material, packaging consumption in the packaging process of a polycrystalline silicon assembly is smaller, and the use ratio of crystalline silicon is increased greatly.

Owner:浙江金诺新能源科技有限公司

Application of dry paste powder of Ardisia brevicaulis Diels in preparation of anti-inflammatory and analgesic drugs

ActiveCN113712999AReduce package lossGood anti-inflammatory and analgesic effectAntipyreticAnalgesicsAcetic acidGranuloma

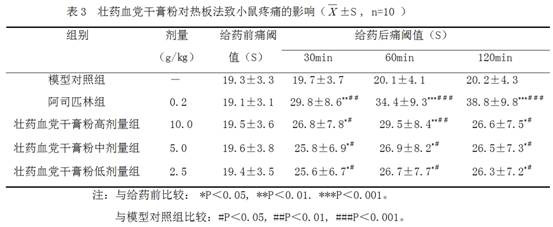

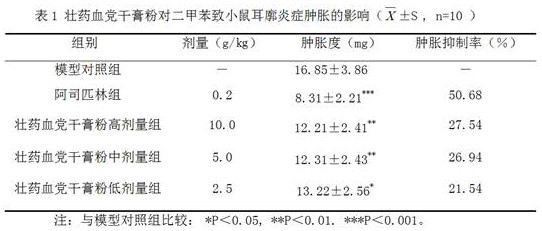

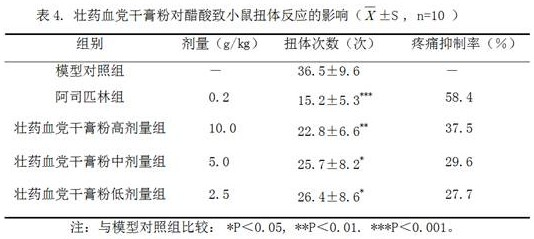

The invention belongs to the technical field of Zhuang medicines of traditional Chinese medicines, and particularly relates to application of dry paste powder of Ardisia brevicaulis Diels in preparation of anti-inflammatory and analgesic drugs. The Ardisia brevicaulis Diels is a whole dry plant of Ardisia brevicaulis Diels, and the dry paste powder of Ardisia brevicaulis Diels is extracted by adopting a water extraction and alcohol precipitation method. The invention discloses the application of the dry paste powder of Ardisia brevicaulis Diels in preparation of the anti-inflammatory and analgesic drugs for the first time. Pharmacological tests show that the dry paste powder of Ardisia brevicaulis Diels can obviously reduce the xylene-induced mouse auricle inflammation swelling degree, obviously reduce the mouse cotton ball granuloma quality, obviously improve the mouse hot plate pain threshold and obviously reduce the acetic acid-induced mouse pain writhing reaction frequency, has obvious anti-inflammatory and analgesic effects, and can be applied to preparation of the anti-inflammatory and analgesic drugs.

Owner:GUANGXI INST OF CHINESE MEDICINE & PHARMA SCI

A battery string connected by n-type IBC solar cell pieces and its preparation method, component and system

ActiveCN106816486BReduce gapImprove fill factorFinal product manufacturePhotovoltaic energy generationEngineeringSolar cell

The present application relates to a cell string formed by spliced N-type IBC solar cells and a preparation method thereof, a solar cell module, and a solar cell system. The cell string comprises narrow N-type IBC solar cells and a conducting member configured to realize Ohmic connection between the narrow N-type IBC solar cells, with emitter p+ regions and base n+ regions being alternately arranged on a back surface of each of the narrow N-type IBC solar cells, p+ emitter contact electrodes being arranged in the emitter p+ regions, n+ base contact electrodes being arranged in the base n+ regions, further comprising p+ electrode current convergence points arranged on the p+ emitter contact electrodes and n+ electrode current convergence points arranged on the n+ base contact electrodes, with an insulating barrier layer being arranged around the current convergence points, and the conducting member being arranged between the adjacent narrow N-type IBC cells. The present application has the following beneficial effect. In the present application, a cell string formed by spliced N-type IBC solar cells is realized by the use of an insulating barrier layer and a conducting member. Since the gap between the cells may be controlled to be less than 0.2 mm, the power of the solar cell module will be far higher when compared with the conventional connection methods for cell strings. In addition, the manufacturing process of the solar cell module is simple and less costly.

Owner:TAIZHOU ZHONGLAI PHOTOELECTRIC TECH CO LTD

An optical multiplexer and an optical emitting device

ActiveCN104734800BReduce package sizeReduce package lossPolarisation multiplex systemsTime-division optical multiplex systemsMultiplexerOptical communication

The invention discloses an optical multiplexer and an optical emitting device, and relates to the field of optical communication. At least one optical combiner capable of combining two light beams into one light beam is used to form a light combining component, and at least two stages of light combining components are formed. The optical multiplexer enables 2N beams of light to be combined into one beam through N-level light combining components, which reduces the packaging volume and packaging loss, and reduces the complexity of the manufacturing process.

Owner:HUAWEI TECH CO LTD

Electrical connection method capable of reducing module packaging loss

InactiveCN107221576AImprove integrityIncrease the open circuit voltageFinal product manufactureSemiconductor devicesScreen printingSilver electrode

The invention discloses an electrical connection method capable of reducing module packaging loss. Aluminum paste is printed on the back of a screen printing plate, then presintering and sintering are carried out to form an all aluminum back field, and then tin or an alloy of tin is welded as an electrode by adopting an ultrasonic welding technology at the position, corresponding to a positive electrode, on the surface of the back field. Due to the fact that the technology of printing the back silver electrode in a traditional scheme is omitted, the all aluminum back field is formed, and the tin or the alloy of tin is adopted and welded, so that the effects of reducing the cost and enhancing the power can be reached.

Owner:建开阳光新能源科技有限公司

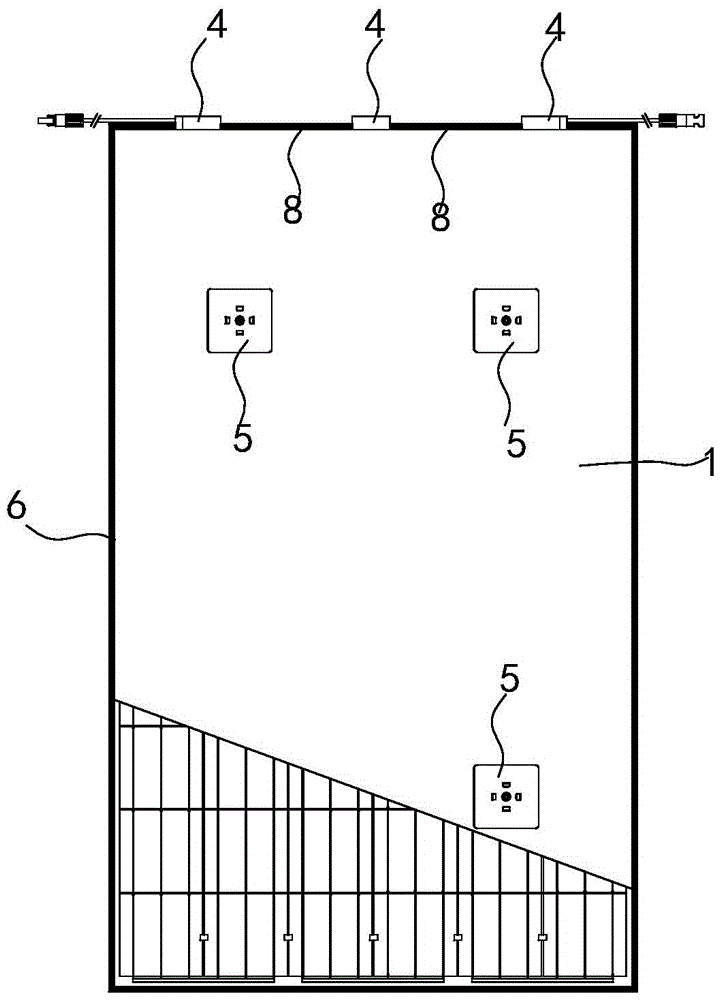

New crystalline silicon double-glass photovoltaic curtain wall light-transmitting components

ActiveCN105870231BChange layoutConform to human body structurePhotovoltaic supportsWallsTransmittanceEngineering

Owner:CHANGZHOU ALMADEN

A kind of solar cell sheet and its diffusion process

ActiveCN104617163BImprove conversion efficiencyImprove conversion rateFinal product manufactureSemiconductor/solid-state device manufacturingDiffusion methodsState of art

The invention provides a solar battery piece and a diffusion process thereof, belongs to the technical field of solar batteries, and aims at solving the technical problem that the conversion efficiency of the solar batteries under the one-step diffusion method in the prior art is generally small. The solar battery piece comprises a plate-shaped solar battery piece body; a positive electrode is arranged at one side of the solar battery piece body, and while a negative electrode is arranged at the other side of the solar battery piece body; 3 main grids and 96 fine grids are uniformly distributed on the positive electrode; the main grids and the fine grids are vertically arranged and electrically connected; the space between every two main grids is 50 to 55mm; the main grids are 1.2 to 1.5mm in width; the space between every two fine grids. The solar battery piece has the advantages of being low in packaging loss and high in conversion rate.

Owner:ZHEJIANG GUANGLONG ENERGY TECH

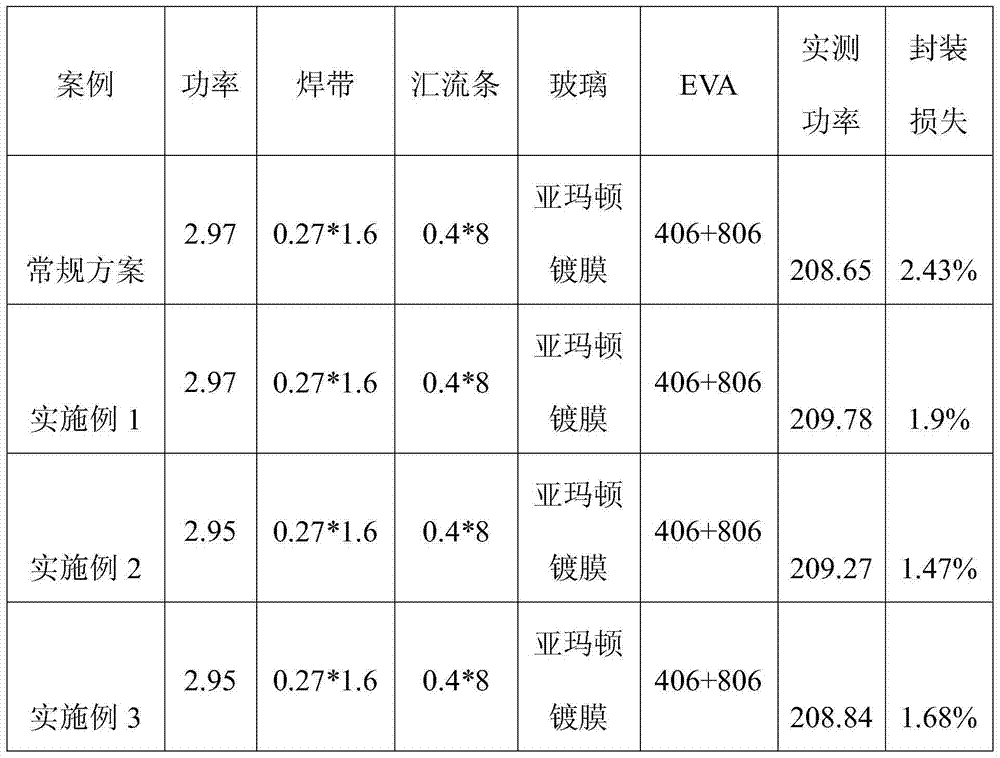

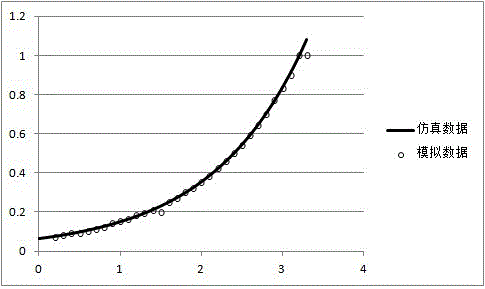

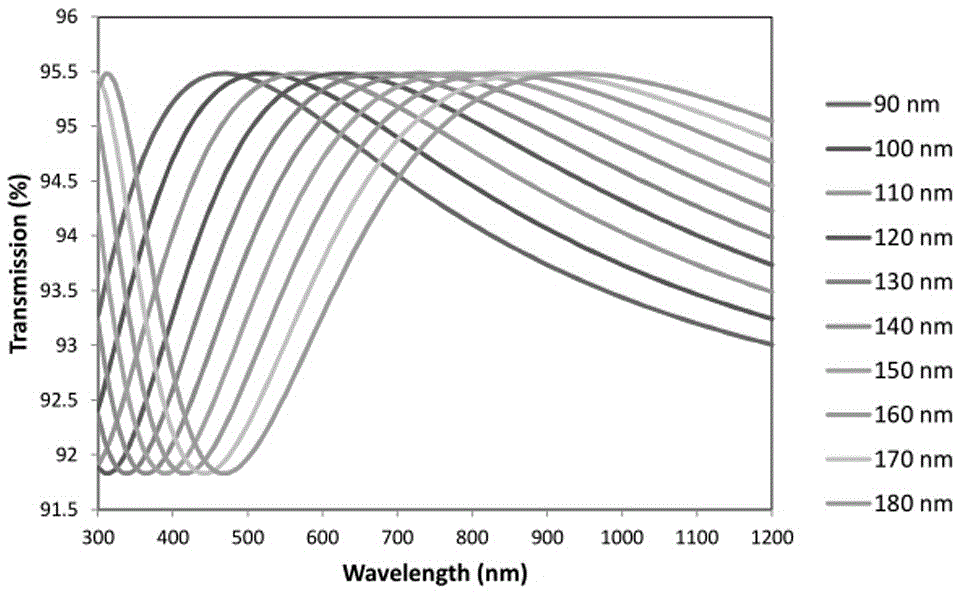

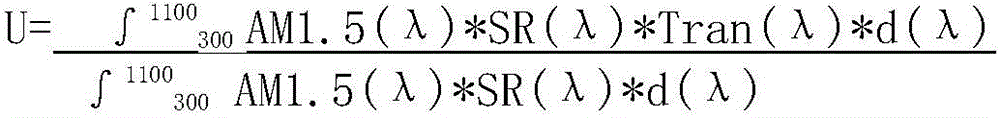

A Method for Optimizing Encapsulation Loss of Photovoltaic Modules

InactiveCN105489678BReduce package lossFinal product manufacturePhotovoltaic energy generationQuantum efficiencySpectral response

The invention discloses a method for minimizing package loss of a photovoltaic module, and discloses a method for minimizing package loss of a solar cell module. The method comprises the following specific steps: (1) fabricating photovoltaic glass with different antireflection film thicknesses, and building a relationship scale of the antireflection film thickness and the transmittance; (2) measuring the quantum efficiency of a tested solar cell through a photocell quantum efficiency testing equipment to obtain spectral response distribution of the tested solar cell; (3) calculating the light utilization rate of the solar cell in the spectral condition in a traversable manner according to the spectral response distribution of the tested solar cell and the transmittances of thick coated glass with various antireflection film thicknesses; and (4) comparing the light utilization rates under the condition of different antireflection film thicknesses to obtain a theoretic optimization value of the package loss caused by an optical loss. According to the method, the light utilization rate difference between the different antireflection film thicknesses is fitted out, so that the antireflection film thickness scheme with the minimum package loss caused by the optical loss is obtained.

Owner:ALTUSVIA ENERGY TAICANG

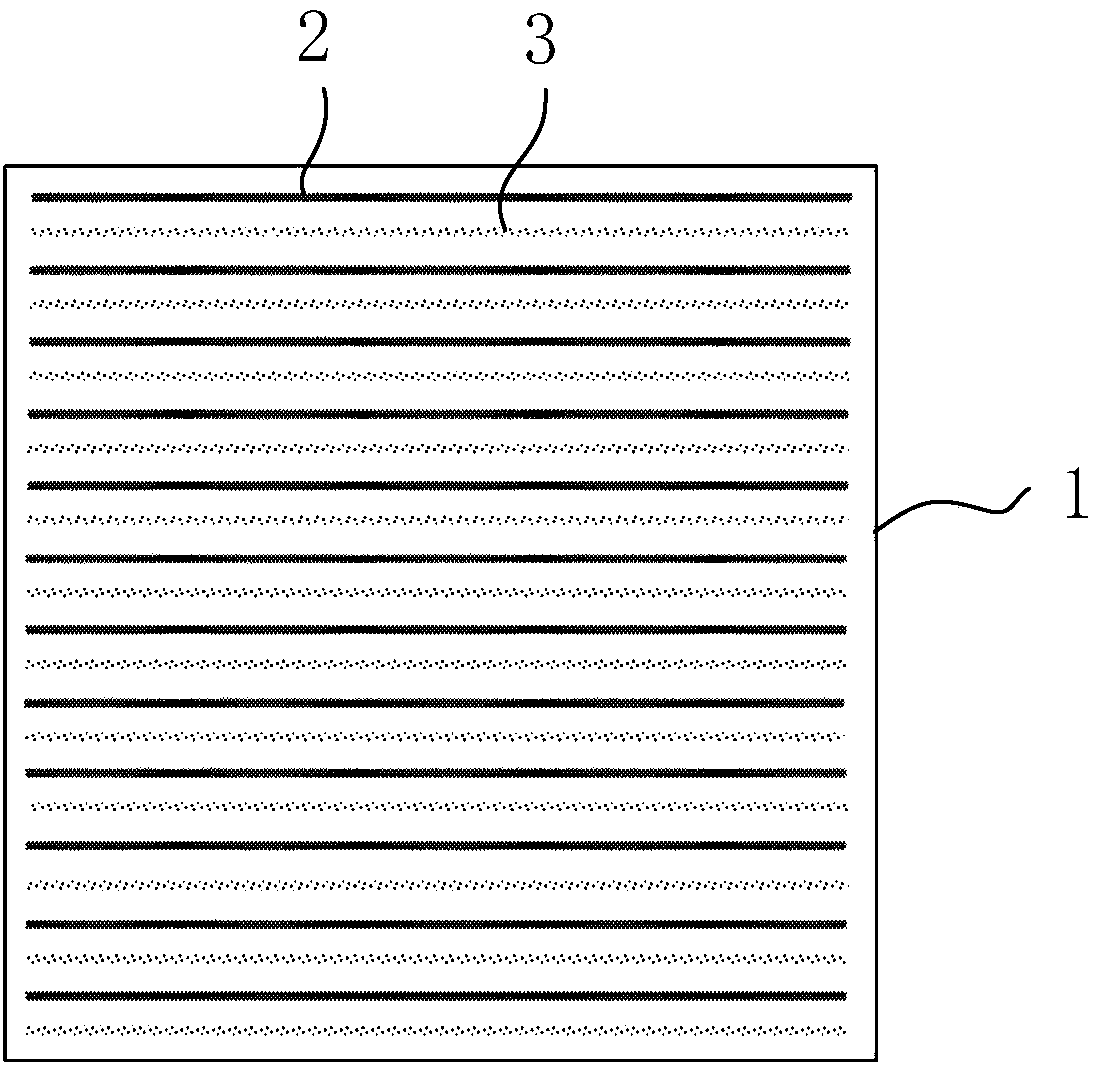

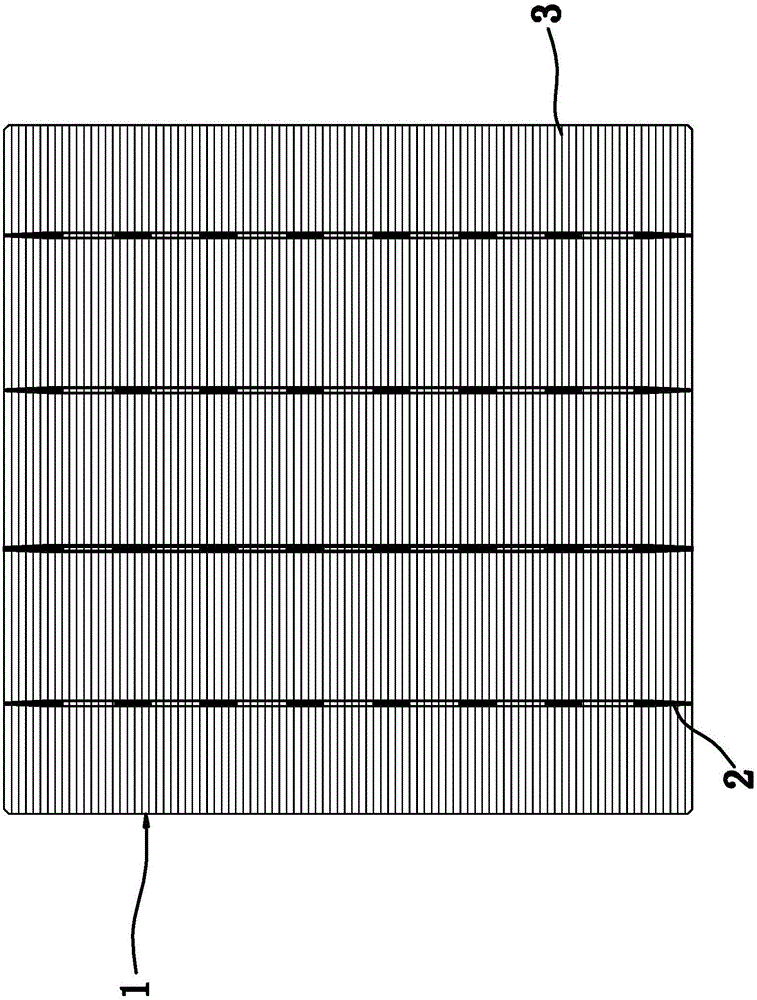

Double glass photovoltaic cell module

ActiveCN104377259BExtend your lifeSolution to short lifePhotovoltaic energy generationSemiconductor devicesCell assemblyEngineering

The invention discloses a photovoltaic cell assembly with two glass layers. The assembly comprises a body, a reflective coating, an end sealing block and a frame, wherein the body comprises the first glass layer, a first encapsulating layer, a cell assembly layer, a second encapsulation layer and the second glass layer, the first glass layer, the first encapsulating layer, the cell assembly layer, the second encapsulation layer and the second glass layer are sequentially stacked, and the outer edge of the first glass layer and the outer edge of the second glass layer are higher than the outer edge of the first encapsulation layer, the outer edge of the cell assembly layer and the outer edge of the second encapsulation layer; the reflective coating is arranged on the second glass layer; the end sealing block is disposed between the first glass layer and the second glass layer and located on the periphery of the first encapsulation layer or the cell assembly layer or the second encapsulation layer; the frame is disposed on the outer periphery of the body. According to the photovoltaic cell assembly, by means of the end sealing block, the defect that a traditional encapsulation material is exposed outside is overcome, moisture and corrosive gas can be prevented from entering the assembly, and the service life of the assembly is prolonged; the reflective coating can reflect light penetrating through a gap of a cell to reduce encapsulation loss, and the frame can effectively protect the cell assembly.

Owner:BYD CO LTD

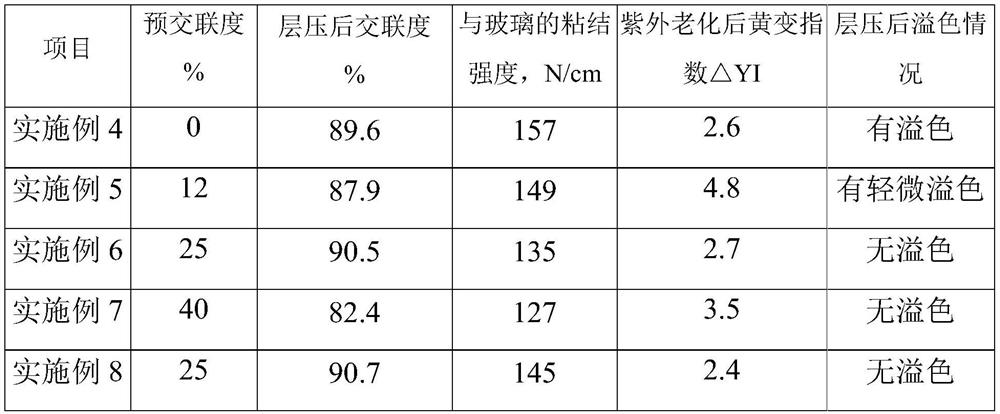

Short-wave ultraviolet pre-crosslinking adhesive film and preparation method thereof

PendingCN114854314AImprove reflectivityReduce package lossNon-macromolecular adhesive additivesFilm/foil adhesives without carriersUv absorbanceComposite material

The invention relates to the technical field of solar cells, in particular to a short-wave ultraviolet pre-crosslinking adhesive film and a preparation method thereof. Comprising the following raw materials in parts by weight: 90-110 parts of polymer resin, 0.2-2 parts of a short-wave ultraviolet light initiator, 0.2-2 parts of a thermal initiator, 0.5-5 parts of a crosslinking aid, 0.1-1 part of a coupling agent, 0.01-0.5 part of a light stabilizer, 0.01-0.5 part of an ultraviolet absorption aid, 0-0.5 part of an antioxidant and 10-20 parts of color master batch. According to the short-wave ultraviolet light pre-crosslinking adhesive film, the short-wave ultraviolet light initiator is added, so that the adhesive film is pre-crosslinked under the short-wave ultraviolet light condition, on one hand, the auxiliary agent fully initiates reaction under the short-wave ultraviolet light to reach a certain pre-crosslinking degree, and on the other hand, the light stabilizing auxiliary agent in the adhesive film cannot be attenuated; when the composite material is used in a solar cell, the photoelectric conversion rate and the packaging formability of a cell module can be improved, and the service life can be prolonged.

Owner:SUZHOU MINGGUAN NEW MATERIAL TECH CO LTD

A kind of ammonium sulfate crystallization method and device thereof

ActiveCN111408157BRaise the ratioImprove economyCrystallization conditions screeningSolution crystallizationChemical industryPhysical chemistry

The invention discloses an ammonium sulfate crystallization method and a device thereof, which belong to the field of chemical industry. The device uses two crystallizers in series and adopts a two-effect vacuum crystallization process, the first effect is neutralization crystallization, and the second effect is evaporation crystallization. The first effect is to neutralize the slurry produced by the crystallization with a large proportion of fine crystal particles, and the second effect is an evaporation crystallization system to obtain ammonium sulfate with a large proportion of large-grained ammonium sulfate. The device makes full use of the heat of gas ammonia dissolution and the neutralization heat of the neutralization reaction between sulfuric acid and ammonia, and uses the secondary steam of the neutralization crystallizer as a heat source to reduce the consumption of circulating water, increase the proportion of large-grained ammonium sulfate, and reduce the production of caprolactam at the same time. Package loss.

Owner:SINOPEC NANJING ENG & CONSTR +1

A kind of preparation method of high open circuit voltage polycrystalline solar cells

ActiveCN103618032BAvoid Series Resistance RisingReduce package lossFinal product manufacturePhotovoltaic energy generationPush technologyEngineering

The invention relates to a preparation method for high open-circuit voltage polycrystalline solar cells. A temperature-variable deposition high-temperature knot pushing technology is adopted in the diffusion process, and the dense grid design of 90 fine grids is adopted by positive pole printing patterns during the positive-pole printing process. The temperature-variable deposition is the process of increasing the temperature to 860 DEG C, temperature-variable deposition for 10 min is conducted on a silicon wafer during the temperature-increasing process, the mixture gas of large N2, O2 and small N2 is led in, and the proportion, by volume, of the small N2 is 7%; the high-temperature knotting pushing process is that the temperature is kept at 860 DEG C stably, the small N2 is stopped being led in, the large N2 and the O2 are led in for impurity re-distribution, the time is controlled to be within 17 min, and the proportion, by volume, of the O2 is 15%. The preparation method enables the square resistance of the silicon wafer to be from 90omega / sq to 95omega / sq, and compared with one-time constant-temperature deposition diffusion, the polycrystalline solar cells produced under the situation that the cost is not increased can obtain the higher open-circuit voltage.

Owner:ZHEJIANG NUOOUBO NEW MATERIAL CO LTD

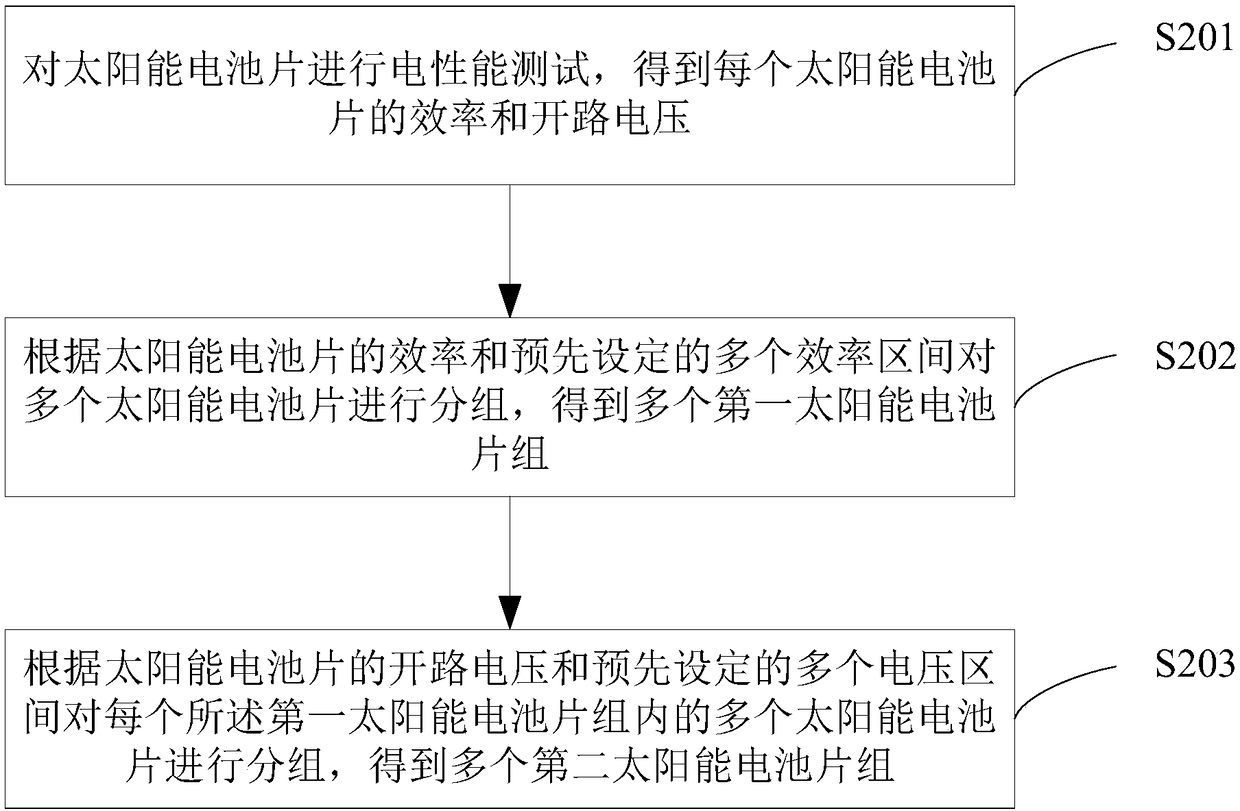

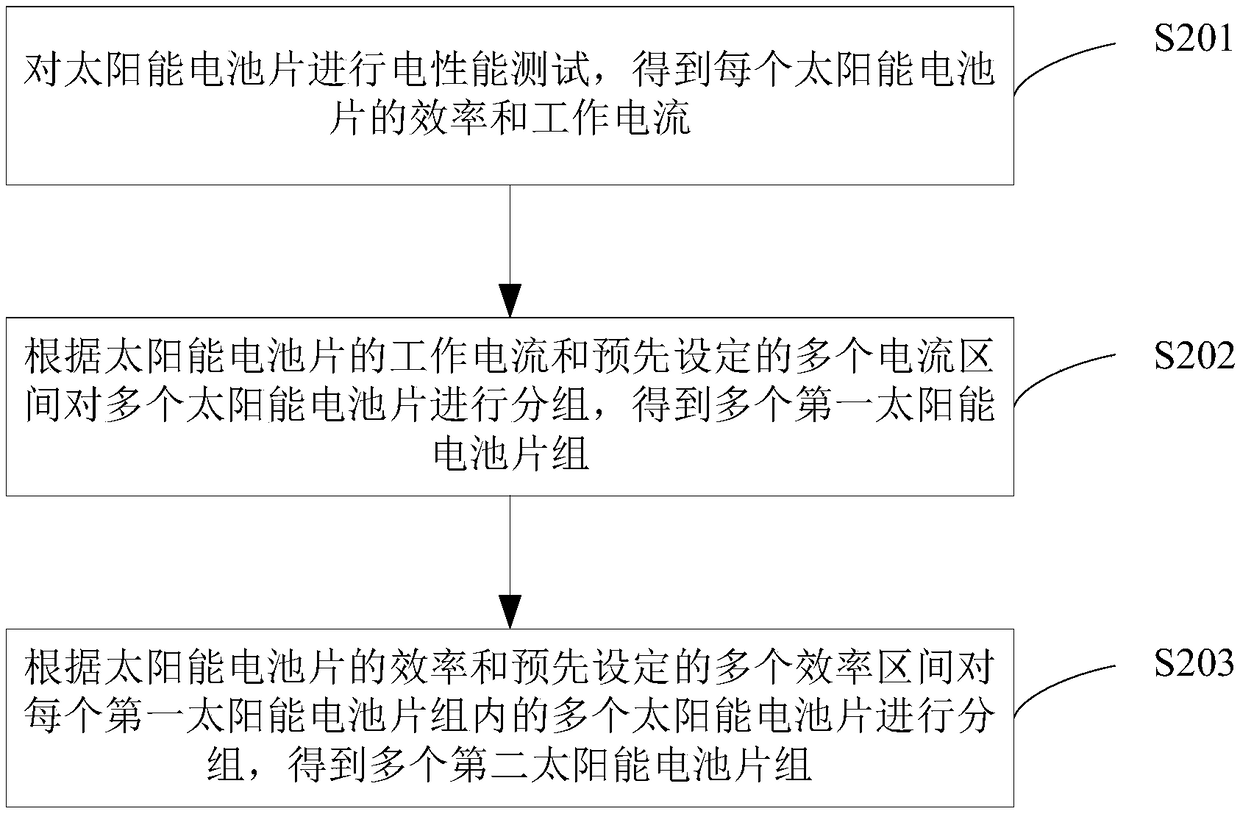

A new type of crystalline silicon solar cell test classification method

InactiveCN105609442BAchieve matchingWork lessSemiconductor/solid-state device testing/measurementPower flowElectrical battery

The invention relates to a novel test and grading method for a crystal silicon solar cell, which is a method for optimally using grades at a working current and grading battery pieces of the same working current grade again through battery efficiency. Flexible grading intervals are set with regard to different situations during grading the battery pieces, different grading intervals are used according to different parameter states of different batches of battery pieces, the difference between the maximum working current and the minimum working current is greatly reduced, the discrete degree is integrated, the matching of the working currents of battery pieces of the whole module unit is achieved, the package loss of the whole module is reduced, meanwhile, the light and shade phenomenon of module E1 test can be also corresponding improved, the yield from batteries to modules is improved, and the primary finished rate of assembly fabrication is improved.

Owner:BAODING GUANGWEI GREEN ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com